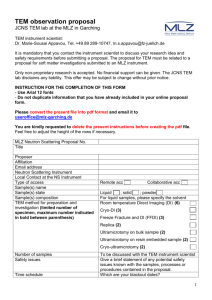

Instructions GA--AS 001 TEM Combination System with TEM Instrument Set

advertisement