Statement of Request

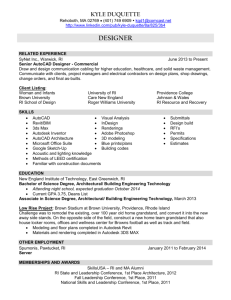

advertisement

Statement of Request I am proposing an upgrade to our design software system in the Albany branch of MTI. Installation, training, data analysis, and full implementation of the upgrade will take 13 months. The ultimate goal of this project will be to increase the efficiency of our manufacturing and design teams, to increase our technological standing, and to relieve stress for the design and manufacturing teams. If the data analysis suggests enough benefits from this project, then it will be suggested that it be carried out through the other branches of MTI as well. The total cost of this project will be $157,334.43. Need Obsolete Technology Our version of AutoCAD is the 2000 package. Just the date alone should suggest that there is a problem. When software is labeled with a year, generally it was made the year before. This would suggest that our design program is approximately six years old now. Not only is the technology obsolete because it is outdated, but the functionality of the program is becoming obsolete as well. According to Steve Jeski1, a mechanical engineering instructor at Stafford Technical Center, “the AutoCAD package was initially geared toward two dimensional architectural designs and then people began using it for mechanical designs.” Although the AutoCAD program is capable of modeling in three dimensions, it is not as effective as some other software that is available. In the AutoCAD program, the model is transparent, with only the object lines that make up each edge and all you see other than that is the dull white background that is provided by the paper. With AutoCAD, it can be quite hard for manufacturing personnel to visualize the part that they are to be making. Other programs save a lot of time, because in AutoCAD, both the three dimensional drawings and the two dimensional projections must be done from scratch. AutoCAD still has some good functionality to it, but the combination of AutoCAD and some other advanced modeling software is a much higher powered approach to design for manufacturing. Manufacturing Efficiency Every engineer knows that the manufacturing process is based on the design process. When a design is made in the AutoCAD program, it can be very hard for the manufacturing engineers to visualize the part that they are trying to make. The three dimensional models that come out of the AutoCAD program are not solids. They are what are often referred to as hollow isometric views of the object. More simply put, you 1 can see right through them. You may be thinking to yourself, “how is this a problem?” One common problem with that is that it’s not hard to mistakenly think that a line in the back of the object is actually a line in the front of the object, especially with more complex parts. According to Mary Waldo2 a Design Communications teacher at Vermont Technical College, “it comes to a point where a three dimensional solid model is necessary to visualize a part for manufacturing purposes.” Frustrated Workers The fact that it can be hard for the manufacturing engineers to interpret some of the AutoCAD drawings (see Figure 1) is an extra stress in the working environment that can take a toll on the workers. It is not uncommon for workers to mess up on a part or a program because he/she misinterprets a part drawing. When this happens, the responsibility falls on his/her shoulders and not only that but he/she must start the part or program over. To have to start something over is time consuming, stressful to the workers, and unbecoming of a successful manufacturing company. According to Lauri Wilson3, a computer aided design teacher at Stafford Technical Center, “many design engineers are frustrated by the small number of businesses that offer high powered, three dimensional modeling software.” She continued on to say that “recently, design engineers have developed a tendency to flock to companies with these types of packages (speaking about the proposal of AutoCAD and another software combined).” This is why I feel that it will be a great stress reliever for both the design and manufacturing engineers. (Figure 1) left: A drawing in AutoCAD 2000 as opposed to right: A 3D rendering done with Autodesk Inventor 8 Professional 2 Background Three Dimensional Mechanical Design Process The process of mechanical design is one of great intricacy and painstaking. The process of mechanical design usually starts with what is known as a concept sketch. According to Encyclopedia.com4, a sketch is “a rapidly executed kind of pictorial note-taking. The sketch is not usually intended as an autonomous work of art, although many have been considered masterpieces in their own right. Used extensively in the planning of large, complex projects, the sketch allows the artist to visualize quickly the bend of a knee or the sweep of an arm without having to experiment directly on the work itself.” That is one of the most complete definitions for the term sketch that can be had. A concept sketch occurs on many media, from white lined or unlined paper, all the way down to a napkin from a local diner. It has occurred more than once in my career that a drawing on a napkin became a working project. The concept sketch outlines the general idea for the design that is to follow, but it usually does not go into deep details as far as dimensions are concerned. After the concept sketch is completed, it is drawn in two dimensions in the design software (Inventor for instance). From this point, the 2D design is modified using specific commands such as revolve and extrude, which sweep the 2D drawing into a three dimensional space. This is done through a process that involves the three dimensional planes, the XY plane, the XZ plane, and the YZ plane. This sweeping of the part into 3D space is known as a rendering or a model of the part. Encyclopedia.com5 defines the term modeling as “in painting, the use of light and shade to simulate volume in the representation of solids… As opposed to carving, modeling permits addition as well as subtraction of material and lends itself to freer handling and change of intention. This definition is true of the three dimensional design software as well. Material can be both added and removed from the solid model. This would seem to make sense, because the technical name for the software is, a three dimensional solid modeling software. Once a model has been rendered, the designer must produce drawings of the part that are fairly easy to interpret. The drawings are usually what are known as orthographic or orthogonal projections. According to Dictionary.com6 orthogonal projection is “the twodimensional graphic representation of an object formed by the perpendicular intersections of lines drawn from points on the object to a plane of projection. (Also called orthographic projection.)” (See Figure 2). These drawings are used to convey the geometries of the part, one side at a time for ease of dimensioning (A.E. front view projects to right side view and top view) 3 (Figure 2) Orthographic projection. Notice that there is a definite relationship from one view to the other in this simple projection. Bottom left: the front view is used as a base to project the right side (right) by way of parallel and perpendicular lines. Top left: parallel and perpendicular lines are projected from the right side, up to a 45 degree angled line and then across to create the top view of the part (in combination with projections from the geometries of the front view). Once the interpretable drawings have been produced, they must be dimensioned. Dimensions simply further the description of the geometries of the part by specifying their given point to point quantities. Some such examples are length, angle, height, or radius. Once the dimensions have been placed, the dimensions must be given tolerances. According to Dictionary.com7 the definition that best fits this type of tolerance is “Leeway for variation from a standard. (Or) The permissible deviation from a specified value of a structural dimension, often expressed as a percent.” Basically, these tolerances tell the manufacturer how much he can miss a desired dimension by. They are often given as rectangular deviation tolerances that appear with a plus and a minus value. This means that the manufacturer can be that specified distance over or under the desired dimension (A.E. 1.000 inches + 0.010 -0.005: this means that the dimension can be missed to 1.010 or 0.995 and still be an acceptable part). Once the part is dimensioned and has been given tolerances, it can be sent to the manufacturing cells to be made. It is not uncommon to see a design guide with a mechanical design that makes it to production. These design guides specify certain restrictions that the design may put on certain manufacturing processes. It also mentions minimum clearances of mating part and talks about the tolerance scheme. 4 Project Description Data Acquisition and Analysis Throughout the course of this project, data will be obtained as it pertains to all of the costs associated with the software upgrade. There will also be data tracked with regards to the training of our design team. An archive of all of the existing products that the company produces will be made in the Inventor program. Data will also be taken with respect to the overall benefits of this upgrade process. This data will include, but not be limited to revenue and profit increases, productivity increases, and any increases in efficiency. Personnel The following list of people and their positions will be required to make this project a success. Personnel Harry Apkarian Position Vice President of Research and Development Department Software/Hardware Installation Supervisor Software/Hardware Installation Technician Software/Hardware Installation Technician Equipment Purchasing Director Financial Advisor Design Software Training Director Design Technician/ Project Director Design Trainees/ Technicians John Langless Eric Plumber Chris Seager Mike Shultz Brian Greenspan Rick Jameson Sean Hesse Design Team of 20 The preceding list of personnel will be actively involved in the project on a day to day basis, from its start to finish. The Financial Advisor and the Equipment Purchasing Director will be actively involved in tracking all data that applies to the cost of the project and its positive or negative impact on the company’s revenue and profit. Equipment and Necessary Tools The first necessary step is to upgrade the video cards that are in our systems. Our current video cards only possess 64 MB of DDR and according to the Autodesk web site, at least 128 MB of DDR are required. It is for this reason that we will have to upgrade to the PNY GeForce 6600 GT video card in each computer8. This video card will meet the guidelines laid forth on the Autodesk web site9. 5 The next piece of equipment necessary is the program itself. The program is a three dimensional modeling program that allows the user to create a real life 3D rendition of the part that is to be manufactured (see figure 2). The program also allows for easy conversion to an automated manufacturing system. The last piece of equipment that is necessary is a training book that can be used to assist the design team in learning the new program. The suggested text for this is entitled “Instant Design: Fundamentals of Autodesk Inventor 810.” (Figure 2) Sample of Inventor Graphics 6 Time Table of Implementation Date December 15th, 2005 Activity Discussion of project budget proposal Result Desired Approve budget for project December 17th, 2005 Place shipment order for new software and hardware Receive shipments of video cards and Inventor software Installation day Order new components (By) December 30th, 2005 January 1st and 2nd,2006 January 2nd- April 2nd,2006 Training sessions with design team March 30th, 2006 Quarterly project evaluation April 3rd- June 29th, 2006 Supervised use of program and translation of existing archive June 30th, 2006 Mid-project evaluation Receive new components Upgrade to Inventor Professional 8 and install new video cards Teach design team how to use the new software Study and analyze data of benefits and downfalls Study proficiency of designers and translate existing archive into Inventor files Study and analyze data of benefits and downfalls Responsibility Apkarian, Hesse, Langless, Shultz, Greenspan, and Jameson Shultz Apkarian, Shultz, and Langless Langless, Plumber, and Seager Jameson, Hesse, and Design Team Apkarian, Langless, Shultz, Greenspan, Jameson, and Hesse Jameson, Hesse, and Design Team Apkarian, Langless, Shultz, Greenspan, Jameson, and Hesse June 30th- September Supervised use of Get back to the Jameson, Hesse, th 30 , 2006 design software in normal flow of and Design development of new business with the new Team products and concepts software in place September 30th, 2006 Quarterly project Study and analyze Apkarian, evaluation data of benefits and Langless, Shultz, downfalls Greenspan, Jameson, and Hesse 7 September 30thDecember 31st, 2006 December 31st, 2006 January 1st, 2007 Supervised use of design software in development of new products and concepts End of project and final evaluation Report of data and analysis Normal flow of Jameson, Hesse, business with the new and Design software in place Team Study and analyze data of benefits and downfalls Apkarian, Langless, Shultz, Greenspan, Jameson, and Hesse Results of project and Apkarian, overall study of Langless, Shultz, benefits of the Greenspan, project, presented in a Jameson, and board meeting Hesse Results and Evaluation This project will be implemented over the course of approximately one year and one month, but the impact of the project will last for the rest of the company’s life. This new software upgrade will finally draw our company away from just the AutoCAD program which was originally intended for use in architectural design only. Our company will become properly geared toward mechanical development and the invention of new products. This new program will also gear the company toward a more automated manufacturing environment, which will allow us to downsize our workforce. This downsizing will raise our company’s revenue and profit. This new technology will also make our mechanical drawings easier to interpret, which will relieve stress on the manufacturers and the designers. With this new software, mechanical drawings are derived directly from the existing 3D model. This will save the designers a lot of time and stress as well. With the Inventor program, animations can also be made of the 3D models, which will make for high class, attractive presentation files for perspective buyers. The drawings produced by the Inventor program will be much easier to interpret and can also lead directly into automated manufacturing. This will most definitely increase the efficiency of the manufacturing phase of product creation. According to Paul Johnson11, a former design engineer at Black and Decker Industries and a Design Communications professor at Vermont Technical College; “(the inventor package) is more adequately geared toward creative design, new products, and automated manufacturing.” 8 Budget Item Quantity Unit Cost 10 $164.99 Total Cost Equipment PNY GeForce 6600 GT / 128MB DDR3 / AGP 8X / Dual DVI / Video Card Autodesk Inventor 8 Professional industry grade design package Inventor Training Manual $1649.90 ** $4,500 10 $45,000.00 20 $36.67 1 N/A $733.40 Personnel Software/Hardware Installation Supervisor Software/Hardware Installation Technician Equipment Purchasing Director Financial Advisor Design Software Training Director $328.00 N/A 2 $320.00 1 N/A $30,000.00 1 N/A $25,000.00 1 N/A $40,000.00 Subtotal 10% Indirect Costs Grand Total $143,031.30 $14,303.13 $157,334.43 ** Inventor 8 price based off of price for Inventor 10 Justification Work hours in a year = 360 days @ 8 hrs. per day = 360 * 8 = 2880 hrs. Software/Hardware Installation Supervisor: Hourly salary of $20.50/hr. works 16 hrs. on the project therefore, 16 * 20.50 = $328.00 Software/Hardware Installation Technicians: Hourly salary of $10.00/hr. works 16 hrs. on the project and there are two of them therefore, (13 * 10.00) * 2 = $320.00 Equipment Purchasing Director: Annual salary of $30,000 for duration of one year = $30,000.00 Financial Advisor: Annual salary of $25,000 for duration of one year = $25,000.00 Design Software Training Director: Annual salary of $40,000 for duration of one year = $40,000.00 9 Conclusion Benefits With the completed implementation of the Autodesk Inventor 8 Professional package, we should see an increase in manufacturing efficiency and design time efficiency, coupled with a decrease in the stress levels of the workplace. This means that more work gets done in a given amount of time and the efficiency and precision of the work should be much greater. The addition of this software will also make us a more competitive firm from a technological standpoint, because we will be on the cutting edge of graphic mechanical design. All of these factors together should lead us to a decrease in wasted time, material, and designs, which will translate into higher profits. 10 End Notes 1 Steve, Jeski. Manufacturing/Engineering Instructor. Personal Interview. 17 February 2005 2 Mary, Waldo. Professional Designer and Design Instructor. Personal Interview. 24 January 2005. 3 Lauri, Wilson. Design/Engineering Instructor. Personal Interview. 17 February 2005 4 Encyclopedia.com, “Sketch,” <http://encyclopedia.com/html/s1/sketch.asp> Encyclopedia.com, “Model and Modeling,” <http://encyclopedia.com/html/m1/modelN1mo.asp> 5 Dictionary.com, “Orthogonal Projection,” <http://dictionary.reference.com/search?q=orthogonal%20projection> 6 7 Dictionary.com, “Tolerance,” <http://dictionary.reference.com/search?q=tolerance> Tiger Direct, “PNY GeForce 6600 GT video card,” <http://www.tigerdirect.com/applications/SearchTools/itemdetails.asp?EdpNo=1184256&Sku=P56-8529> 8 Autodesk, “Autodesk Inventor Professional: System Requirements,” <http://usa.autodesk.com/adsk/servlet/index?siteID=123112&id=5194311> 9 Wal-Mart, “Instant Design: Fundamentals of Autodesk Inventor 8,” <http://www.walmart.com/catalog/product.gsp?dest=9999999997&product_id=3376477 &sourceid=0100000012231186102498> 10 11 Paul, Johnson. Professional Designer and Design Instructor. Personal Interview. 24 January 2005. 11