p,$e. l s, 6 tie nnli,it ucuri;;; i";:tri,:H;:;;:i:l;'[i:i:i

advertisement

p,$e.

l s,6 tiennli,it

ucuri;;;I i:,:,::::;i

i";:tri,:H;:;;:i:l;'[i:i:i

(CG'fase)from Bacillassp' TS1-1:

Productionof CyclodextrinGlucanotransfcrase

Process0Ptimisation

Azmil

Haizam Ahmad Tarmizir Rosli Md. Illias2 Madihah Md' Salleh3 OsmanHassana

- -r.-"rrir"ti"t

ramaruddinj RoshanidaAbdulRahnran6 Suraini Abdul AzizT

EkgineennS'

FatuLt! afChenicoLE^gittt.riry and NaItuol Resoutces

Ur^,!rtiti TeknabBiMatutskt,8ll lA Ska.ldi,Johor Maldlsi.t.

TeL 6A-7-5535172. Fa\: 6'07'558I 463

Enn iL: hdizan1,79@la hoa. ofi

'Enoil: ftasli@ktnhtY

6Ehail: ranida@ 4.n!

rD.P|nnent oJBiata$

Facrlt! o[Scienc.,

Ltn^e rsiti TeknolagiMak 'rid,3l3IA Skdai, Johat,Mtktltid

TeI : 60-7-553$2A. Entti I : tnatli hah@kinia li. tu n ta'l

aSchaotaJCheDtit:dL

and FoodSciences,

Facult! af Scienceatld Techtnlog',

Urive$i t i KebdnllsaanMaLorsia,430U Bangi, SekutSoLMalavtia

5Bioprccess

an.I CherticaLTechMloS!Centre

SIRIMRerhad,Malalsi(t

l Facultyof Food 7'cc1"1o1os!

anl FoodScience,

Unire,si ti Putn Malaysia, 43100 Setuans, SelanSol Malavsia

Tel: 60-3-89468367.Far: 6'03'89423552

Abstract

Ihe effect d pH a^LI rcnperatutu flere iirestis.lvdfor on

optnrked condition oJ cycLodextth Slucanota tJeruse

GATdse) pra.lu.tion fron BdcilLus sp. TSI t Thc

aptimisation process |9as anaLlsed using Centtul

Canpasite ExperinlnnL Deiisn h ResPo$e Su'face

Llethodoloty (RSM) by Desi|, Eqert V.Nian 60.4

(StatEase,USA). This .Iesip was enpLoled to d.nre a

statistical tnodel for the eJIec^ of pH an.l tetnPerctrre an

the pto.luctian oJ Ccrase fron BaciLlussp. TSI'1. The

Rz was found to be 97 851o.

coe:licient o.f .letenintion,

n1e rcnlpentureof29.5q'C and te PH oJ 10.32had been

lau4d Io be ttp aptidtunt.onJ'lioht lbr th. ncLtihun

production of CGTaseaJter 21 hours of iac\bation tn these

conditiohs, the CGTase activitf wat diaine.l to be 75 46

Luhll. which \|6 clop ta tlz h1odelPrc.lictions

Keywords:

OptimisalionCondition.

CyclodextrinGlucanotmnsferase,

COTrse Acdvity, Prcduction. Response surface

Methodology

Introduction

CGTase(EC 2.4 t 19)has

CyclodextringlucanotransfeLase,

in both

beenfound in severalbacterinlspeciesand catalyses

236

of o'

iniermolecula.and int.amolecula.transglycosylation

1,,1glucan. The reaction between CGTase wilh starch

produced cyclodextrins (CDs) with variety of

malooligosaccharides

tll. CGTase is a mulliiunctional

enzyme,whercasbes;descyclization (!he conversionol

slarch and relared o-1, 4-glucansinto cDs thrcugh an

inlmmoleculartransglycosylatiotreaction) this enzyme

mana8esto catalysea coupling rcaction(openingof CD

to

rings and lmnsfering of linear mallooligosacchandes

acceptos) ihrough intermol@ular rransglycosylalron

reactions-Nevedheless,CGT$e had a week contribulion

towardshydrclysingactivitywilh watermol€culest2l.

Cyclodextr;ns(CDg have a structureof oligosaccharide

rings comprjs;ns '1-1. 4linked slucopymnosere$d!es.

Cyclodextrins are also known as cycloamylosesor

Schardinger

Dext.ins. The are mainly thr@ commontypes

of CDs. which a'€ made up of 6, 7 or 8 molecules,

identifiedas !-, ll- and u-cyclodextrinsresp4tively CD

molecules have a torueshaped structures,wherc the

hydrophiliehydroxyl groups at the exterior site and the

hydrophobicC-H sroups and glycosidic oxygen d the

ofCDs

interiorcavity.lD the recentyears.the requhements

have received grear attentions, especially in food,

pha.maceutical,chemical. cosmetic as well as the

asriculturalinduslriesi3l. The reasonbeing is dre capable

ofCDs moleculesto fomr incllsion complexeswith a wide

variety of guest molecules(organicor inorganic)withou!

changingthe propertiesof fie guesl molecule ir selves.

CDs are atsocapableto slabilizelabile materials,maskoff

ISBN:983-2643-15-5

Pr.ct.tlhSs

odous, emulsity oils and chdge

into powde..

comPounds

viscous or oily

Among the th.ee main types of CDs produced,D-CD is

rnorewidely used and developedtbr variousapplications.

Owing !o ils low solubility in water, -l-CD is readily

from lhe rcactionmixture withoul any lreatment

separated

wirh orSanicsolveDtsand ils inclusioncomplexescan be

easily prcpared. The capability of predominantly!-CD

produciDgcan reducesubseqtrerlpurificationcosts,leading

to commerc;allydesirabilily.Therefore.effofts arelbcused

on finding the suitableCGTaseproduce$for an efficientof

'CD production.

Approach arld methods

Culture ConditioN for CGTaseProduction

Ao.ill!.r sp. TSI I was grown in optimisedmediunrwith

rhe compositionof 2% ($lv) s.so starch.19. (w/v) yeast

extract. 0.1% (w/v) K,HPOa atd 0.02Eo {w/v) Mg

SOr.?HlOand addedwith l0% (w/v) ofNa,COr separately.

dependingon the pH ol fte medium. The cells were

c ltLrredin 250 ml conicrl flasks and incubaledat |he

Empe.arureof 37oC wilb the agitationof 200 rym ior 18

hours.The cellswerc thencentnf!8edat 501ruem ibr 4 to

5 minutes,walhedoncewith no.mal salinesolution(0.85'.4

Nacl), giving a lu.bidi!y (oplicaldensity)of0.5 41600nm.

About l07o of bacterialinmulum was inoculatedinlo the

medjum.giv;ng rhe total volume of 100 ml (includingthe

medium)in each500 ml conical flasks-The cultureswere

then incubated al the rotation speed of 100 rpn wilb

lemperaturc shown in Table I fo. 48 houn in an orbild

shaker.Sampleswere hanesledevery 2 houn for the fi61

24 hoursard every4 hoursfor the next 24 bou.s.ln every

samplirg, rhe sample was centrifugedat 5000 rpm for 2

minutes to separatelhe bacterial cell and the clear

CGTase Assay

The CGTas€ aclivity was measuredusing ihe method

by t4l. The .qtction nixlures containing40 mg

esrablished

of soluble starch in 1.0 ml of 0.1 M sodium phospha€

al

buffer (pH 6.0) and 0.5 ml supernatantwas ancubated

60"C fbr l0 minutes.The reactionwas stoppedby adding

3.5 ml of 30 mM NaOH, followed 0.5 ml of 0.0?% (wv)

phenolphthaleinin J mM Narcq solution-rhe colour

inFnsity of the samples was measurcd al 550 nm afler

The blank

slandingup for 15 minutesat room temperature.

solution, which lack of enzyme (m€dium) was prepared lor

eachbatchof assays.Standardcurve using0.1% v of ll-

Results

From the experimentaldesign,experimentswith different

combinationof temperaturcand pH were performed.The

CGTase activities of each s€ts of experiment were

d€termined after he cul$re was cultivat€d for 24 hours.

The equationobtainedafleranalysisof variance(ANOVA)

ISBN:981-2643-15-5

af Inxmotiona! Ca'!f.En.e Ar Ch.mi.al and BiL?taces Et$nt1titl!

27r' 2qt Aut:d?003, U,tnPt\itiilolnrsia Sabrh.Kttt Kt)atalr

CD (Fluka) to repLacesoluble strrch and c.ude enzyme

re$ecdvely was plotted. A unit of erzylre acllvrry wrs

definedas the amounlof enzymethal forms I $nol of F

Drt Cell Weight D€terminalion

The.e werc rwo approaches

in lhe cell mrss dererminltion,

dependingto lhe starch presencein the culture- li the

(Novo

culture containssta.ch.0.L ml enzynre

--anylase

Nordisk) was added1o I ml of culturc to hydrolysethe

residuestarch to soluble sugars [5]. Tfie mixlure was

incubatedat 100'C fof 20 nrinutesand centrifugedat 3000

efl for 30 minures. The supenritanlwas thcn decanled

_im

and the cel l s sere fi hered oni o prc$ei ghted0 . 2

cellulose nifiaG fiher (Wh.tmrn). $ashed twice with

distilied watef lnd dried in rn oven aI 95!C ibr 24 hours.

Freshmediumsas trextedsimilady and usedas blaik for

reductionofstarch impudticsin lhe sanrple.

Il srarchwas depletedfrorn the samplc,rhe cell masswas

nreasured

by taking I ml ofcuhure and cenr.ilugedar 5000

The cell pellel was

rpm for 3 minutesin a microcentrifuge.

washedtwice with saline solution aDd died in vacuun

drier, lollowed by drying in the oven at E0 "c to constart

the cell weight-The presence

of slarchin the cuhtrrecan bc

deleminedby usingiodinesolution.

Starch Concentration

Starch concentmtion in lhe sample was canied out

acco.dingto lbe methodof t6l. 1.0 ml of srpernatantwas

mi xedsi rh 4 ml ol 001 M i odi l e | l 025 M po r ds. iur ,

iodide (KI) and diluted wirh 15 ml of distilled waler.The

colonr intensitywas measuredal 465 nm againstblank of

distilledwatertreatedin lhe samenanner above.The starch

in culturefiltrate was quantifiedaccordinSto the slandard

curveof sttuchbelween0 to 3.5 mg/nrl.

Protein Content

Protein conrent was determ;nedaccording to Modified

LwD' PrcreinA,sa) I7l.

Exp€rimental Derign

Experimenlal design was determjned based on lhe

establisbedmethodt8lt9l. Tbe effect of temperalureand

pH were studied using Central Composite Des;en in

ResponseSurfaceMethodology(RSM). The optimisation

was performed to the total sets of l7 experiments,

consistin8four factorialpoinls,eight axial (star)pointsand

Iive cente points. Tbe ranges chosen for botr process

variableswere 9 to ll for pH and 25oC to 35'C for

remperature, The CCTase aclivily was chosen a1 the

du.ation of 24 hour in every run of experimenls.

givesthe CGTaseproduciionfrom Ba.ir6 sp. TSI-1 as a

function of lemperatu.e and pH. The final equaiion (actual

value)w6 exprcssedin secondorder polynomialequarion

0).

X= 2252.35464+51.59356A+301.62010B-0.90418A?15.05414B1

+ 0.27550A8

(l) where X=CGTde activiry, U/ml, A=Tempera re, "C

andB=pH.

237

Pnaalklt

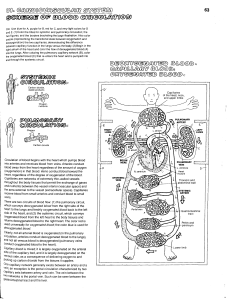

The rhree dinreisional presentation(co.relxtionberween

reDpemrure

rnd pll on rhe ccTase production)lvasshown

in Figure l. The optimnm temperatureand pH lbr lhe

maximun CGT.se production werc 29.59'C and 10.32

respecrively,giving ! prcdicted CGTrse productionof

7 6 .17U/ m l.

The op{inru|rconditionsfor both rempenturernd pH were

applied in the sh.ke ilasks to conrpare lhe CGTase

p,!duction with the predictedor€s. BeskLes,lhe grcwth

kinctics of the nicrobc was also studied.The CCTase

prcducrionat 24 houlSincubationwas oblainedIo be 75.48

Ll/,nt. whi.h $rs closedto the nrodelhad p'tdicted. The

CGTaseproducrioniourrl ro be consrantatter l8 bou6 of

Discussion

The CGT.se production.s a functionof lemperalureand

pH is $rosn in equntion(l). The fitnessof the nrodelrvas

expessedby rhe coefilcienrof determination,Rr. The R2

value, 0.9785 oL 97.85'Z indicate the !a.iability in the

.l httltti.krl

27' 2q

Ca'*ratu

On ChentetL tnd Biopn..s

Erlittitt

Arfui 2AA3. Urliftrxiti M.la,"sh Sahah Kotu Ktnnnh

rcsponseof the model, whe.e 2-15610

of lhe total varirtion

was not explainedby tlre model(equation-l).The valueof

adiusleddeteflninationcoefticient(Adi R' = 0.9687)was

found to be hish lnd .dvocatedfor a hish sisnificanceof

1bemodel.The coirelationcoefficient.R lvas mai.ly used

to show the corelation measu.ement

of estimationin lhe

regression

model.The closerthe R !.lue to the unity, the

beuerco.Lelationbetweenthe obseNedand the predicted

valueswas gain. From ANOVA, the R valuewas found !o

be0.98,12.

As mentjonedpfeviously, the oplimum conditions ibr

mllximum CCTrse prcduction lvere pH 10.12 and

lempemtureof 29.6"C,giving n predicrodvalue ot 76.17

U/ml. From lhe rwo-dimensionalpr€seirarion of dre

rcsponse

sudace,it was observeddratthe optlnum CGTase

productionresponsewas more sensitiveto chrngesin one

pH unit rathertban one temperaturennit (t). Thereib.e.

lhe responsesu.frce analysisof Lheexperimentrlrcsulrs

cleirly revealsrhe intenelationshipbelveen reinperarure

andpH asafecting theCGTaseprodlction.

764m7

642494

CGTase

Act. 52.oso1

399303

277715

Figure I : The lhrce-dnnensio'1alpresentatian of the rcspansesurfacefor th. CGTdseauiyirJ of Bacillus sp. TSI 1. Tenperdture

units are in.legrees Celcirswhile the CGTaseactivit! unns werc i1tU/nl.

The lemp€ratureaboveo. below lhe oplimum temperature

(29 6 C) was observedro give low CGTaseproduclion.A1

lower temperatufelimil, it seemthal insufficientaclivation

enerSy was prcduced that allow the critical process

(d€crcase

the effectiveness

ofCGTaseproductioD)to mcur

while,

at

the

upper

limit. the increment of the

ll0l

prodDction rate as proporl;onal Io the lemperature

increnrentwas oUset by the changesin prctein structures

238

resulting inactivation or denaturalion of critical cell

proleinsiwilh an accompmyingcessation

ofgrowth.

Tbe alkalinityof the growth environmentof the microbes

ds response!o the spec;ficchangesin proteinstructures.

ln one study,the rcsponseof an alkali-lolerant,a.ill!r sp.

!o growlh at pH 7.5 and 10.2,it was shown rhartherewere

quantitativediffercnces in the cell membmne protein

conpositionsIlll Studieson an alkalopb;lic,a.ir6 sp.

ISBN:983-2643l5-5

Pneedi^ss

fiat grow at pll 10.0 and 8.2 also show ihal there were

speclflcdifferencein rhe prcteincompolitions.which were

reflectedin the greaterlegativecbargeof the proteinsrl pH

10.0

tl2ltl3t.

Similarly,analysisof the cell envelopeof a largenumberol

alkalophilicBacill,rr sp. show ftat in some shins there

were largeamountsof negativelycharsedcompounds{141.

This may be one of the redons the cell membranercquired

sh;le

alkaline pH for the aansport charged substances.

pH

at

neulral

funclion

optimally

I15l

intracellularenzymes

Conclusion

The optimisationof CGTase p.oductionb.!-'Ba.illlr sp.

TSI-I was conductedi| batchcullure.From the Response

SurfaceMethodolosy(RSM), the optimum condirionsfor

and pH obsered to be 29.59'Cand 10.32,

boih temperature

where tfie expecrationof CGTasepoduction was 76.17

U/ml. Wbile from the experimenlapplied, the CGTase

p.oductionobtainedto be 75.48 U/ml, which was closeto

the modelpredictior.

Acknowledgement

Tbefullysuppo by Assoc.Dr. RosliMd. IuiasandDr'

Mdihah Md. Sallehwas gmlefully acknowledged.

References

tll S@rli J. 1998. lntroductionand generaloverview of

cyclodextrinchemisrry Chem.Ret'.98:1743't'153

1998. Bacterial Cyclodextnn

[2] Tonkova A.

and

Microbial

Erctme

Glucanotransferase.

TechnoIoI r. 22t6'78 -686.

[3] A. Biwe., G. Antranikian.E. Heinzle2002.Bnzymatic

Microbiol

production of

cyclodextrins. Appl

Bi otechnol. 59.609-6 17.

t4l Kaneko T., Kato T., NakamuraN. and Horikoshi K.

1987. Spectrophotometric Determiration of

Cyclization Activity of il'Cyclodextrin-Fo.mit8

ISBN:983-2643-15-5

En,ilt. tki

anrl Biort.Qs

ol IntznntionaL canI..ohe on chatud

2/ -2q' AuEti2AA3. Unive^iti tlok]-:id Sabah.Kala KinLb.tr

J. Jpn.,to.S/dr.,tJ.t.

CyclodexrinGlucanotransfe.ase.

29:4548.

t5l Anff A.8., Kadm M.1.. Madihah M.S., SahaidK.M

and Suriani A. 2001. Direct Fermentatron ol

GelatinizedSago Starch 1a Acercne-Butanol_Ethanol

by Clostridium acertobutylicun Wotkl JourMl of

Micnbioloey otld BiarcchnoLoqyl7.l-lo

[6] Kitahah S., Tsuyuma N. and Okada S 1973

Purificadon and some properties of cyclodextnn

glycosyltnnsfemsefrom the $ain of Ba.llrlr sP.

Oumal of Agricultuml Biological Chemistry.

38(2):387-393.

[?] PierceChemicalCompany.(1996). Modified Lolvry

P ro.ei nA \-) . R o.kford.U .S .A .In' rru' .on

l8l Haalaid P.D. (1989). Expenmental Design in

Biolechnology. New York. MarcelDekker.

tgl MontgomeryD.C. SecondEdition. t992. D.sitln and

AnallsisE peinents. Ne|t York. John wiley & Sons

lnc. 540.

li0lCaldwell D.R. 1995. Mictobiat Phlsiotas! and

Inc.

Merarolk,n.lA Wm C BrorvnCommunications.

IlllKoyama N., Takinishi H. and Nosoh Y. 1981. A

possible relation of membrane proteins of the

aLkalostabililyof

a facullatively alkalophilic Bd.illur.

FEMS MictobioloSy Lette rs. 16:213-216.

ll2lKoyana N. and Nosoh Y. 1976.The effect of the pH

of culturemediumon lhe alkalopbilicityofa speciesof

Bacillus.Achieresof Micrcbtolos). 109:105'108.

tl3lKoyama N, Kiyomiya A. snd Nosoh Y. 19?6. Na1

dependantuplake of amino acids by an alkalophilic

Bacillus.FEBSLztIe$. 72:77-l L

It4lHorikoshi K. and Akiba T. 1982. Alkalophitic

Micrco.ganisns- Spnnger. Berlin. Heidelb€.g and

ll5lOhlaK., KiyomiyaA., Koyma N. andNoschY. 1975.

The basis of the alkalophilic property of a species of

Bacillus. Joumal of Genetut Microbiolosy. 86.259

266.

239