MATHEMATICAL MODELLING and RESEARCH for DIFFUSION

advertisement

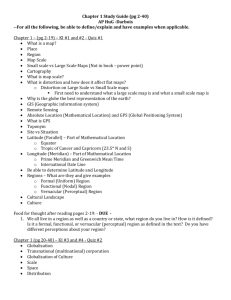

MATHEMATICAL MODELLING and RESEARCH for DIFFUSION PROCESSES in MULTILAYER and NANOPOROUS MEDIA M. PETRYK, O. SHABLIY, M. LENIUK, P. VASYLUK Ivan Puluy Technical State University Laboratory of Mathematical Modelling of Technological Processes Rue Ruska, 56, 46001 Ternopil, Ukraine Abstract The problem of mass transfer for diffusion and adsorption in non-regular disperse and porous multilayer media with no stationary regimes of mass exchange processes on the mass exchanged surfaces, which is described by systems of differential equations with boundary conditions and contact conditions, is introduced. The exact analytical solution of the problem by the application of Laplace, Fourier and Bessel integral transforms and the fundamental function method of Cauchy is established. Models were selected in accordance with component distribution in the multilayer media Me-MeO area. The solution of equation systems for different models as well as the investigation of the functions made it possible to find the effective meaning of the diffusion coefficient. The investigations will allow to correct multilayer chemical composition, to understand better the high-temperature oxidation mechanism and adsorption mechanism in nanoporous n-component structures. 1. Introduction The development of modern technologies in chemical technology, engineering ecology and biotechnology raises new problems in the kinetics, mechanism and acceleration of mass transfer processes for diffusion and adsorption in multilayer media, which one considers as well as technological materials. To study such processes it is necessary to develop new simulation methods and mathematical models to describe the internal kinetics considering different regimes and no stationary modes of change of mass on the surfaces of mass for homogeneous media. Multilayer oxide media (Fe-Cr, Fe-Tb, Fe-Dy, etc.) are used in the fields of semi-conductor engineering, nuclear energy, building technology, thin films and covering, mineral filament production. 1 2. Analysis of scientific content of modelling methodology The mathematical modeling of mass transfer processes for different homogeneous media and the creation of analytical solutions are described in the work of Lykov and Mykhaylov [1], Ufiland [2], Sergienko et a.l [3], Kärger and Ruthven [9], Fraissard, et al. [6,7,10,11], Mathieu-Balster and Sicard [12], Zapolsky et al. [13], de Boor [14], Mongiovi [15]. These methods use integral transformations for the simulation of these processes. The methods of Fourier, Laplace, Fourier-Bessel, Weber, Hankel and Hilbert integral transformations will be used intensively for the solution of mass transfer problems, especially for diffusion and adsorption processes in regular media. The theory of integral hybrid transformations and application for simulation of mass transfer problems has been developed in the work of Leniuk and Petryk [4]. Considering that the framework of Fourier, Bessel, Weber and Hankel differential operators, boundary conditions and contact conditions offer a more general view, we have created unified Fourier, Fourier-Bessel, Weber and Hankel transformations for unlimited, half-limited and limited non-regular media. This work is devoted to the simulation of mass transfer for diffusion and adsorption processes. 3. The Mathematical Model of Diffusion Process in Multilayer Media The definition of the diffusion kinetics characteristics enables one to update an elemental multilayer chemical composition. By selecting a model one considers the construction of media, modes of mass transfer and experimental concentration profiles on each unit in multilayer media. For example, experimental concentration distributions of Al, Cr and Si in oxide media - fig. 1. The Fe-Cr multilayer systems are applied as a structural material in nuclear engineering and in mineral fiber production. Oxides, including multilayered ones, find wide application in semi-conductor engineering. The creation of multilayered oxides on a surface provides high heat resistance in the interval of 1273-1623 K. The oxide is based on components such as: Cr, Al, Si. Amongst others, alloys (mass %) such as Fe-35Cr-(0.5, 3)Al are of great interest. When the content of Al is 0.5% oxides on the alloy surface are formed according to the scheme - Me-Al2O3-FeCr2O4. If the Al content is raised to 3%, then the scheme changes to Me-FeCr2O4-Al2O3. This is accompanied by a sharp rise in the heat resistance, because external Al oxide formation prevents oxygen penetration into the internal layers. 3.1. DETERMINATION of KINETIC PROCESS PARAMETER Determination of kinetic diffusion characteristics allows to correct the chemical composition of the alloy as well as to predict its service life. The alloys 1020 2 mm specimens were held at 1200С for 20 h and weighed every 5 h [21, 22]. When choosing a mode, the working conditions as well as the element distribution pattern in the Me–MeO zone were taken into account. The Al, Cr, and Si distribution curves include peaks at the places where the corresponding oxides are formed (fig. 1). 80 C,% 70 60 S1 50 40 30 20 10 0 0 50 100 Al x 10 Cr 150 200 Si x 10 z ,мкм Figure 1. Experimental concentration distributions of Al, Cr and Si expérimentales d s concentrations des Al, Cr, Si en multicouche d’oxyde ~ The effective diffusion coefficients D for the elements Al, Cr and Si were determined by means of inverse problem solution using mathematical modelling methods, and the parameters obtained were used to determine new concentration profiles for the diffusion media investigated. 3.2. METHODOLOGY of ANALYTICAL SOLUTION CONSTRUCTION of MODEL Based on the results of experimental work as well as numerical investigations on kinetic coefficient determination (effective diffusion coefficients Dk, k=1,n) a mathematical model of the mass transfer diffusion process for a multilayer oxide medium was built according (fig. 2) to the scheme Me-Al2O3-FeCr2O4 in the form of an equation system of second-order partial derivatives: Ck (t , z ) 2 Ck k2Ck Dk t z 2 (1) According to the initial conditions: 3 Ck ( t ,z )t 0 k ( z ), k 1,n (2) y C1 C3 C2 D1 D2 Z l0 l1 l2 lnl Figure 2. Schematic representation of the multilayer structure of an oxide medium the boundary conditions: 0 0 d 0 0 ( ) 11 11 11 11 C1 (t , z )z l 0 g10 (t ) t dz Cn 1 z 0 z (3) and contact conditions: k k k k ( j1 j1 t ) z j1 j1 t Ck ( kj2 kj2 ) kj2 kj1 Ck 1 0 (4) t z t z lk j 12,k 1,n The exact analytical solution of the problem (1)-(4) can be constructed using Fourier integral transformations, determined by the following integral operators [4, 21]: - the integral operator of direct action: lk ~ F, n Ck (t , z ) Ck (t , z )Vk ( z, ) k C (t ) (5) l k 1 4 - the integral operator of inverse action: ~ 2 ~ F,1n C (t , ) C (t , )Vk ( z )2 ( )d Ck (t ) k 1, n 0 - the identity principal of integral Fourier transformation of Laplace differential operator: (6) n 2 1 ~ F, n 2 Ck (t , z )( z lk 1 )(lk z ) 2C (t , ) 1D1 110 V1 (l0 ) g10 (t ) k 1 z (7) n 1 li i 1 l i 1 ki Ci (t , z )Vi ( z ) i dz. The following designations will be used: Vk ( z, ) of the Fourier integral transformation: k 1,2,3 - the components n Vk ( z , ) C 21, k 1bk1 1 ( k 1, 2 ( ) cosbk z k 1,1 ( ) sin bk z ); k1 1 Vn 1 ( z , ) n 2 ( ) cosbn 1 z n1 sin bn 1 z; n k j k n ( ) 1 C11, j 1 C11,n 1 1 ; n ; n1 ; Dk C 21, j Dn C 21,n Dn Dn1 bn1 n 2 ( ) 2 n1 ( ) 2 1 ; bk2 2 k k Dk ; k k2 12 k2 , k 1, n; k c j1,k ; m, j 1,2; k 1,2,3 ; mj , mjk , - the experimental k 2j k 1j k 1j k 2j constants, which determine conditions of mass transfer on the mass exchanging surfaces lk, k=0,n (boundary conditions and contact conditions); 01 ( ) v11011 (b, l 0 ); 02 ( ) v1102 (b, l 0 ) ; jm ( ) j 1, 2 ( )1mj (bi l j ; bi 1l j ) j 1,1 ( )2jm (b j l j ; bi 1l j ); km k jm (bk , l k , bk 1l k ) v11j (bk l k )v 22 (bk 1l k ) v 21j (bk l k )v12km (bk 1l k ); k k vk1jm ( bs lk ) kjm qs sh qs lk jmk ch qs lk ; v kjm2 ( bs lk ) kjm qs ch qs lk jmk shqs lk s k,k 1 j,m 1,2 k 1,n As a result of the integral operators (5)-(7), applied to the equations (1)-(4), the Cauchy problem can be obtained: 5 ~(t , ) dC ~(t , ) F (t ) (k1 2 )C dt ~ C (t , )t 0 ~( ) (8) (9) The solution to the Cauchy problem (8)-(9) is the function [5]: t ~(t , ) e ( k1 )t ~( ) e ( k1 2 )(t ) F ( )d C (10) 0 The determination of the main solutions of the boundary problem (1)-(4): - Grin function [4]: Wk ,1 ( z, l 0 , t ) 2 e ( k1 2 ) t Vk ( z, )V1 (l0 , ) 2 ( )d (11) 0 - fundamental function (Cauchy function ) [4]: k ,k1 ( z, , t , ) 2 e ( k1 2 )( t ) Vk ( z, )Vk1 ( , ) 2 ( )d (12) 0 As a result the exact analytical solution of the boundary problem (1)-(4), which describes diffusion process in the multilayered medium, has the following form: 1D1 3 k C (t , z ) Wk ,1 ( z, l0 , t )k (t ) 11 k , k ( z, , t , ) g10 (t )dd (13) 0 0 k 1 l 1 1 k 3.3. MODEL TESTING, SIMULATION and ANALYSES of the DIFFUSIVE MULTILAYERS. The experimental concentration curves, which were used in the model as boundary conditions r and initial conditions, are presented in fig. 3 [21].Using the obtained analytical model solution (13) as well as the first experimental Al concentration profiles (fig. 3.), the inverse problem of the effective diffusion ~ coefficient D determination for Al as a function of a specimen thickness can be solved. The results of computer simulation – numerical values of the effective ~ diffusion coefficient D by the experimental Al concentration distribution data are presented in fig. 4. This is the first stage of model testing. As it can be seen, the diffusion coefficient dependence on specimen thickness coordinates is determined by the experimental concentration profile. 6 0.8 0.6 C Al_exp. k C Cr_exp.k 0.4 C Si_exp. k 0.2 0.0031 0 0 0.2 0.4 0.6 0.8 1 0 1.2 1.4 1.6 1.8 2 2.0 lk Figure 3. Experimental concentration curves of Al, Cr and Si 5.0 10 54 10 5 D Al 10 5 0 0 0.4 0.6 0.8 1 0 1.2 1.4 1.6 1.8 2 2.0 lk Figure 4. The results of numeric modeling on the effective diffusion coefficient ~ D for Al determination, [mkm2/s] 0.4 0.3 C Al_model ( 1000 z) 0.2 C Al_experm k 0.1 0 0 0 0 0.2 0.4 0.6 0.8 1 z lk 1.2 1.4 1.6 1.8 2 2.0 Figure 5. Model and experimental concentration distributions of Al vs. specimen thickness 7 The following stage of the investigation implies that the diffusion coefficient constituent values obtained are placed into the analytical solution (13) – model distribution. With the resulting, more precise, model distribution, numerical modelling of the Al concentration profiles is performed. The results of the modelling are presented in fig. 4. Along with the numerical model concentration distribution obtained, the experimental distribution is placed in the graph. This constitutes the second stage in testing the proposed model. As it can be seen in fig. 5, the mathematical modelling results, possessing sufficient accuracy, are close to their corresponding experimental parameters. The maximum error value does not exceed 2-3%. By the same scheme (using model (13) and experimental concentration profiles) the investigations on effective Cr and Si diffusion coefficient determination as well as their simulation profiles were carried out. Fig. 6-9 present the results of simulation on effective Cr and Si diffusion coefficient calculation, as well as simulation results given together with experimental data for Cr and Si concentration distribution. The Cr distribution curve has three ~ peaks. The effective diffusion coefficient D was determined for each of them. ~ For D calculation the Cr concentration distribution curve was divided into three areas (first area – from 88 to 116 mkm, second area – from 116 to 138 mkm, third area – from 138 to 166 mkm). The experimental data and the simulation data correspond quite well. ~ ~ ~ The obtained values of DCr , D Al , DSi confirm the fact that the component mobility decreases at transition from internal to external oxides, which in the best way secures their protective properties. The layered phase oxide content was determined using methods. 1. 10 D Crk1. -4 5 10 5 0 0 0 0.2 0.4 0.6 0.8 1 lk 1.2 1.4 1.6 1.8 2 2.0 ~ Figure 6. Numerical modelling results on the effective diffusion coefficient D determination for Cr, [mkm2/s] 8 0.8 0.8 0.6 C Cr_model ( 1000 z) 0.4 C Cr_experm k 0.2 0 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 z lk 0 2 2.0 Figure 7. Model and experimental concentration distributions of Cr vs. multilayer structure thickness D Si 2 10 5 k i 0 0 0.2 0.4 0.6 0.8 1 0 1.2 1.4 1.6 1.8 2 2.0 lk ~ Figure 8. Numerical modelling results on the effective diffusion coefficient D determination for Si, [mkm2/s] 0.5 0.4 C Si_model ( 1000 z) 0.3 C Si_experm k 0.2 0.1 0 0 0 0 0.2 0.4 0.6 0.8 1 z lk 1.2 1.4 1.6 1.8 2 2.0 Figure 9. Model and experimental concentration distributions of Si vs. specimen thickness 9 4. Mathematical Modelling of Mass Transfers in Multilayer Porous Media. Definition of the process. The processes of mass transfer by adsorption in multilayered porous media are introduced (fig. 10). The liquid phase with an adsorption substance concentration C (t , r , z ) supplies the porous media of the "solid-liquid" system in a working chamber in directions z and r. As a result of this process, a substance in a liquid phase is transformed into a solid phase of adsorption media with concentration a (t , r , z ) [16]. z ln l1 l0 r Figure 10. The working chamber of process The mathematical model, which describes the kinetics of this process, is considered as the boundary problem by system: to create in the area D1 t 0,r ( 0, ),z : z ( l0 ,l1 ) ( l1 , );l0 0 the limited solution of the system of partial differential equations: 10 2 1 Ck ak 2 Ck k2 Ck Drk 2 C D f k ( t,r,z ) (14) zk k t t r r z 2 r a k k C k k a k t (15) with initial conditions: Ck t , r , z t 0 C0 k r , z , ak t , r , z t 0 a0 k r , z (16) the boundary condition for variable z: 0 0 0 0 ( 11 11 11 11 )C1 t,r,z t z t z 0 w1 t,r ; C 2 z 0 (17) z the contact conditions for variable z: 1 1 1 1 1 1 1 1 j1 j1 j1 j1 C1 (t,r,z ) j 2 j 2 j 2 j 2 C2 (t,r,z ) t z t t z t j1(t,r ) (18) z l1 the boundary condition for variable r: Ck t,r,z r r 0 0; Ck z (19) 0 r Here: Dz , Dr the components of effective diffusion coefficients for k k coordinate z and r, k - the adsorption constants, k - the mass transfer coefficients, k - section number of porous media. Using in a problem (14)-(19) the Laplace integral transformations for variable t and the Bessel integral transformation for variable r [4, 16], we obtain the following boundary problem: to create in the area I1* z : z (l0 , l1 ) (l1 , ); l0 0 the limited solution of the equation system: ~ d 2Ck* ~ ~ qk2Ck2 ( p, , z ) Dzk1 Fk* ( p, , z ) g~k* ( p, , z ) 2 dz (20) 11 with boundary conditions: 0 d 0 * 1* ( p, ), 11 11 C1 ( p, ,z ) dz z l0 dC*2 ( p, ,z ) dz 0 (21) z and contact conditions: 1 d 1 d 1 * 1 * j1 dz j1 C1 ( p, ,z ) j 2 dz j 2 C2 ( p, ,z ) j1 , j 1,2 (22) z l1 Isi Fk* fk* ( p,r,z ) Cok ( r,z ) k k a ok ( r,z );1* ( p,z ) *0 ( p,r ) 110 110 Co1 ( r,z ) p k k z z l 0 *o ( p,r ) o1 ( r ) ; j1 (r ) 1j1 qk2 1j1 C01 (r , z ) 1j 2 1j 2 Co1 (r , z ) z z z l1 1 p 2 p k (1 k ) k2 k kk2 1 D rk 2 Dzk p k k Dzk ( p k k ) p 2 p k (1 k ) k2 Dzk 2 k k (k* Drk 2 ) Fixing a direction, where Re qk 0 , creates a solution of a problem (20)-(22) using the fundamental function method of Cauchy [4]. As a result, we obtain a unique exact solution of a problem (20)-(22): 2 ~ ~ ~ ~ * ( p, ) C k* ( p, , z ) W1*k ( p, 2 , z ) R *j1,k ( p, 2 , z )~ j1 ( ) 1 j 1 l1 ~ ~* 2 * ~ * ( p , , ) d H H k*1 ( p, 2 , z , ) g 1 k 2 ( p, , z, )g~2 ( p, , )d (23) l1 l0 The Cauchy functions of system (20) are: 12 ~ H11* ( p, 2 , z , ) 0 2 1 11 (q1l0 , q1 z ) S1 ( p, , ), l0 z l1 ; 0 q1( p) 11 (q1l0 , q1 ) S1 ( p, 2 , z ), l0 z l1 C ~ H12* ( p, 2 , z, ) 21 110 (q1l0 , q1 z )eq2 ( l1 ) , ( p ) C ~ H 21* ( p, 2 , z, ) 11 110 (q1l0 , q1 )e q2 ( zl1 ) , ( p) ~* H 22 ( p, 2 , z , ) q ( l ) 2 1 e 2 1 S 2 ( p, , z ), l1 z ; q2 ( p) e q2 ( z l1 ) S 2 ( p, 2 , ), l1 z The Grin functions of boundary conditions are (21): S ( p, 2 , z ) C q ~ ~ W11* ( p, 2 , z ) 1 , W12* ( p, 2 , z ) 11 1 e q2 ( z l1 ) , ( p ) ( p ) The Grin function contact conditions (22) are: 1 1 22 q2 22 1 q 1 0 0 11 ( q,l0 ,q1z ), R*211, ( p, 2 ,z ) 12 2 12 11 ( q1l0 ,q1z; ) ( p ) ( p ) ( q l ,q z ) 21( p, 2 ,z ) q2 ( z l1 ) * * 2 R11 ( p, ,z ) e ,R21,2 ( p, 2 ,z ) 11 1 0 1 eq2 ( z l1 ) ,2 ( p ) ( p ) * 2 R111 , ( p, ,z ) Here : m2 m1 mjk ( qi lm, qi z ) V jk ( qi lm )chqi z V jk ( qi lm )shqi z, 01 02 11 j1( q1l0 ,q1l1 ) V11 ( q1l0 )V 12 j 2 ( q1l1 ) V11 ( q1l0 )V j 2 ( q1l1 ), 1 1 1 1 1 S1 ( p, 2 , z ) ( 12 q2 12 ) 121 ( q1l1 ,q1 z ) ( 22 q2 22 )11 ( q1l1 ,q, z ) 1 S2 ( p, 2 ,z ) 11( q1l0 ,q1l1 )122 ( q2l1 ,q2 z ) 21( q1l0 ,q1l1 )12 ( q2l1 ,q2 z ) Special points of the problem (19)-(21) solution are: p1, 2 1 S1 ( 2 ) S 2 ( 2 ) 0 and p . 2 Here: S1 k (1 k ) k2 Drk 2 ; S 2 ( k k k2 Drk 2 ) 2 k k 1 2 k 2 k2 Drk 2 0. 13 Thus, in the area Re p 0 we can determine the following original analytical functions [4]: 1 i * 1 * 2 pt 2 ist W ( p, ,z )e dp 1k Re W ( is, ,z )e ds; 2 i i 0 1k W1k ( t, 2 ,z ) 1 ~ ~ R j1,k (t , 2 , z ) Re R *j1,k (is , 2 , z )eist ds; 0 1 ~ ~ H kj (t , 2 , z ) Re H kj (is , 2 , z, )eist ds; Z kj ( t, 2 ,z, ) 0 1 j j t 2 ist Re H kj ( is, ,z, ) e e 0 j j is j j Dzj1 2 12 12 ds, Returning to the original solutions of the problem (20)-(22) and after mathematical transformations, we obtain the exact solution of the problem (14)(19): t 0 0 0 Ck (t , r , z ) W1k (t , r , , z ) 0 ( , ) dd W1k (t , r , , z ) 01 ( ) d 2 t l1 R j1,k (t , r , , z ) j1 ( ) d (t , r , , z, ) Dz11[ f1 ( , , ) j 1 0 0 0 l0 t C01 ( , ) t ( )] ddd H k 2 (t , r , , z, ) Dz21[ f 2 ( , , ) 0 0 l1 l1 C02 ( , ) t ( ) ddd Z k1 (t , r , , z, )a01 ( , )dd 0 l0 Z k 2 (t , r , , z, )a02 ( , ) dd ; k 1,2 (24) 0 l1 ak (t , r , z ) e k k t t a0k (r , z ) k Ck (t , r , z )e k k d (25) 0 Here, the main solutions of the boundary problem (14)-(19) are: W1k ( t ,r, ,z, ) W1k ( t , 2 ,z )J 0 ( ) d , k 1, 2 ; (26) 0 14 R j1,k ( t,r, , ) R j1,k ( t, 2 ,z )J 0 ( r )J 0 ( ) d ; j,k 1, 2 (27) 0 H kj ( t,r, ,z, ) H kj ( t, 2 ,z, )J 0 ( r )J 0 ( ) d ; k , j 1, 2 (28) 0 Z kj ( t,r, ,z, ) Z kj ( t, 2 ,z, )J 0 ( r )J 0 ( ) d ; k , j 1, 2 (29) 0 5. Conclusions The models developed and exact solutions obtained allow a more general view, which enables one to analyze and investigate different variants of the schemes and regimes of diffusion and adsorption process. Using the obtained analytical solutions of the proposed models as well as experimental concentration profiles and solving the inverse problems, the kinetic parameters of internal processes (the effective diffusion coefficients, the adsorption constants, and the mass transfer coefficients as functions of geometrical coordinates of layer media) are defined. The methodology of the process model solution can be further developed and applied to: - Simulation of diffusion processes in multilayered media and adsorption processes in n-component media ( n 2 ) and media of complicated structure; - Models which consider mass transfer by diffusion and convection/adsorption processes as well as non-linear models. 15 References 1. Lykov A.V., Mykhaylov Y.A. (1963) The theory of mass transport, (State Energy Publishing, Moscow) 535. 2. Ufliand Y. (1967) Integral transformations in problems of theory of elasticity, (Nauka, Saint Petersburg) 3. Sergienko I., Skopetsky, Deineka B. (1991) The mathematical modelling and research of process in no regular medias, Kyiv, Naukova Dumka (Academic Publishers) 432 4. Lenyuk М.P., Petryk M. (2000) Fourier, Bessel integral transformations with spectral parameter in mathematical modelling problems of mass transfer in non regular media, Kyiv, Naukova Dumka (Academic Publishers) 372 5. Stepanov V.V. (1959) Course of differential equations, (Physical and Mathematical Publ., Moscow), 468 6. N’Gokoli-Kekele P., Springuel-Huet M.-A., Fraissard J. (2002) An Analytical Study of Molecular Transport in Zeolite Bed. Adsorption, (Kluwer Academic Publishers, Dordrecht) 8, 35-44 7. Bonardet J.-L., Fraissard J., Gédéon A., Springuel-Huet M.-A. (1999) Catal. Rev.-Sci. Eng., 41, 115-225 8. Chen, N.Y., T.F. Degnan, M.C. Smith (1994) Molecular Transport and Reaction in Zeolites: Design and Application of Shape Selective Catalysis, (V.C.H. Weinheim, New York). 9. Kärger, J., Ruthven D. (1992) Diffusion in Zeolites and Other Microporous Solids (John Wiley & Sons, New York). 10. Magalhães, F.D., Laurence R.L., Conner W.C., Springuel-Huet M.-A., Nosov A., Fraissard J. (1997) Study of molecular transport in beds of zeolite crystallites: semi-quantitative modelling of 129Xe NMR experiments, J. Phys. Chem. B, 101, 2277-2284 11. Springuel-Huet, M.-A., Nosov A., Kärger J., Fraissard J., 129Xe NMR study of bed resitance to molecular transport in assemblages of zeolite crystallites (1996) J. Phys. Chem., 100, 7200-7203 12. Mathiu-Blaster, Sicard J. (1999) Thermodynamics of irreversible processes applied to solute transport in nonsaturated porous media, J. Non Equilibrium Thermodyn., 24, 107-122 13. Zapolsky H., Pareige C., Marteau L., Blavette D., Chen L.Q. (2001) Atom probe analyses and numerical calculation of ternary phase diagram in NiAl-V, Calphad, 25, 125-134 14. de Boor R. (2000) Contemporary progress in porous theory, Appl. Mech. Rev., 53 (12), 323-369 15. Mongiovi M.S. (2002) Thermo mechanical Effects in the Flow of Fluid in Porous Media. Math. And Comp. Modelling, 35, 111-117 16. Petryk M., Babiyk M. (2000) Mathematical Modelling, Saint Petersburg, 1, 133-137 16 17. Krimitsas N., Vorobiev E., Petryk M.,(2000) Continuous solid/liquid expression in screw press: process analysis and modelling, Proceedings of 8th World Filtration Congress FC-8, Brighton (UK), Vol. 2, 763-766 18. Petryk M. (2002) Modelling and investigation of mass exchange of biological materials processes, Thermoynamics, Microstructures and Plasticity. NATO Advanced Study Institute, Frejus (France), 74 19. Petryk M., Petryk N., Matiega V. (2002) The Intensification of Process of Vibrofiltration in non Regular Cylinder Media, Proceedings ICEST-2002, Compiegne (France) 1, 143-149 20. Petryk M., (1998) Mathematical model of the filtration process half-limited mediums in conical canals. Ternopil State Technical University Bulletin, 3, 20-29 21. Shabliy O., Petryk M., Vasylyuk P., Katerynyuk І., (1999) Diffusion processes in oxide layer of Fe-Cr alloys, Ternopil State Technical University Bulletin, 1, 5-13 22. Vasylyuk P.M., Butenko L.I., (1989) Increase of the Fe-Cr alloys resistance, Metals. АS USSR, 1, 154-156 17