COMPARISON OF BRIDGE DESIGN IN MALAYSIA BETWEEN AMERICAN

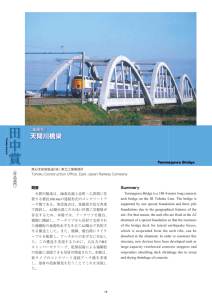

advertisement