CONCRETE LIBRARY OF JSCE NO. 34, DECEMBER 1999

advertisement

CONCRETE LIBRARY OF JSCE NO. 34, DECEMBER 1999

AN EXPERIMENTAL STUDY ON PENETRATION OF CHLORIDE IONS INTO CONCRETE

AND CORROSION OF REINFORCING BARS IN VARIOUS MARINE ENVIRONMENTS

(Translation from Proceedings of JSCE,

No.599/V -40, August 1998)

4

<

.1-.:s=£;s:;:&;2 ;r..

i-.~.<:<1>:>:-:l:1$;1;¢E5' 5:1’:51¢:1:1:i:i:i:?:1:1:3:1:i:1:i$:?:1:i:1:i:3:';?;I:1:EIE=515r5rEIErE1E1E1E1E;EiE:E1E13;--;;;;;I;':.,

1;£1&;€‘£'E"51*i"EE;§.5=;_

.;.;.;.;.;;;tg:;:_; .1:;;;:;:;:;I;:;I;1;:;1;Z;.;.1!.~I~.~.~I,I

"S~.“ ’:-:-:-:-:-:

-:-:-1,;-:v:»:-::‘ -E=£=5=E¢€1€:E1E:%1£1£1i

:-:-:~:~:~:':-:~:-:~;~::-=:~.~;-.-:-:-1sE:."E~;";151i

- "11 . ".1#I13=

‘i:5:1:1:¥:'-.:'$ti<Z:=: 911:‘

-._ .;..¢.;.;.;.g.;.;.;.;.;.;.;.; ;._ -;

'*eéi;1s:1=’1iI""""'.f§rE:%j*=1111:.

31 F 1"

:E:£:%:E:?é;E:E:5:5:§E=§%$5§$*¥I‘. i"2Ef53‘1%1?15I??‘1‘=‘

-:~:-.-.’~.~i-;'*

P4,-1-.;~

4,,’.;.;.;.;.;.;.;i;.;2;.;.;.;.;.;.5;

,;q.1i;.;.;,_.,._-5.);.;.;.1.;.1v ;--

:==¢;1;:;s:;s;;r;;=;¢r=;:;=;;;;;:;s;&;:g¢, .1 ~r=:;:; =;=;=;=; ; .;¢3.:'

E151il:=.:1:ifl:1:¢;I:!:23$:%i:1:;:¢:=;¢:- 9. -==.=.--

g.1.;¢~}Z;5;!:-pp:-gt;-_-,_

z352:3$23:§:§§:§:§:§E§:§:§§:{:§:§:§:§:§:§:§:§:§:

i-:-:_~:-:-:-:<:+:;:'

=?5?5%5i=%=5=5*¥3=?=i-=:-qz:;:;:-g:;:;;-.:i;a

?=5ii5?55=5*?=?5?55=‘1 it ,;.;:;:-'

»=‘P5=5="'<:;'=i=5=i.;.;:;:;

*l§*- _.;:;:;:;:;:;:;g:;.;:g.;:;:;.;$¢:;.;.>;:;.;:;.;,1.;!;!;

Is1:I5:1:E1:¥:=:=$:1:.~:-:-;-:1:-:-rel:-:15 r:~:-:-:*é~:-: ~:-:~:-'-:- .-:a4-:-:+:’:-:-:e:~:~:-:i1-:a~:a-:':~:~:':»:-:-:4-v

1-;;:;:;~.1=3=1=1:5=§:3:3gr$;:;:=; g; ; ;:; V

;§.':I:2

Nobufumi TAKEDA

'3':1?=!.1:='1~'- '

Q5$3fit-:;¢;.;Z$§;1;2g27ig2g?;. 1». .v?'I<I<Z.'I'I 1»

5

.1.;.;.-.;..~.».;.-.-.;‘;r_r';";:<:-:Y:;

'

?;§\W~*;'\'5;s‘¢*.‘£;;¢‘5‘§,\V

i~:-:~r-:-:-2611:!:-;rI:¥;.=:1:=:-:-:=;=:1:=;l:¢:4.

‘:f:‘:':’i'PE‘:‘:1I‘f‘:‘;';":i*:‘:‘§":':‘:'l*§§'l‘.

!;a:‘15;7;?;I;!‘f;§;l;l53:32:33‘!-2'2-ii-.2-2-2-2*:

===i='==r=:=*=1==5%:=====:@%=%=efi=3=E=i131E1i=3=i=¥=§5~

"-l:¢:~:~.'-;-:-:-;+ - , 5 .¢

t

3=2€=E=3=i=5=%=?=E=%=EI£1511;E=%?E=E==$====r°$:*i=:=:

:1:I:I:=:¢:=:&=$&1;I:&?‘

1'YE!:1~=*1*I==1i511ii iri fii12-231-2-2%t'-!¢‘~24E-J'-351%:?;5:3:3:§:3$:?:52-§§:-

=<::;=z:;=s:2:z.~

-. I ¢=~.~:~%€';'-r,'-¥.»-*,f§¥’i_'i*‘

' - . 4-_-,3 . *>,§es.fz%z%;i:¥:%s"*?=i.=,

it‘.

,< .\ -:-:-:A:<:'-: '-:-:1"-.~". '. “ ‘I '2'

avg: ‘

3

~I-I-1-‘-‘.~ :-.;:~ .<- ~ ~'~ ‘ ="?- ."-’ P 3';

Ifiitgt>83_ 3.1’;

<.-‘er?

.é'.:E=?1?-;*.

35>-?~i‘-“3-I‘-’";“3§§5 ti»

'~:-:»‘- ’ y"

3*‘

_

1351=~IEF=‘=iEl=1F$1?a==¥i=$r1;1r*t*¥??

z-~ =:¢==:=:=:' ===;=r2=s:==i=2=s=is=ee&::;s=¢=;=2={:s:

Shigemi SAKODA

-

'-i=

-

I

'1‘ " ~

; 1

.

. 1:’

.515 ' ' .

~

e » . » . ‘ . - _ » - . - . ' ' . ..- <-

‘

-

":1.

" -'=1:-‘;~.,

-:-:=!-r-1-.:-:=:=:h~

__ =z-1-are:=:;:»;;i

211;?-.~:':-7:.-1-;:;;+;-IA?‘:~!>:-1*:

-111-13;§;$;i;!1I:Z}I;,;I=:l:Z1IgI;;;i-I-1'

E:~:-:@:~:~'

3:£=§;i;,s-:-:-:»:»_:»:-.:-:+r-:-;-:-;-:~;=:~:#:l

;z;2;z1;z;z;§;a“;z;s;5z;;g; ; ; ; ; 2=-:1:v:!:=;¥:1;¢

; =; ; ;=;=;

,; =;=;: ;;:>;_

;=;-11"

I, ‘ ,,.;f;:-1;;;;;:;:;>:¢t-:-;;:~1-:-:-:;:1:':~:~:-:1

-;.:~;:;.;-;1;-;.;:;.;2=¢-;!:¢;=:!;t;=;:;r~2<~r

=3i:-:$;:;:;;;:;:-:;:;:;:;;;:;:-:~>:~:z:-:-:»:+:-:-:-:~;'

s;1§1=11:15aa1:i=:=:¢=i=i:Er5:E=3¢i颧:E:§:;:5::-2‘§:5::-zv.

5:;5: 5,-;-:4-'

15.-=" ~ :-.1‘_ 515;

;:3:35=3=3;=3$5:;:; ;&; gs;i31;=:=E1:=5=

Shigeyuki SOGO

‘ V

‘A " _

.1:;E¢5=r€;EuE:i:i1&;i i¢5:§1i1§:E=E1515?

\:l:§:=:=:=1=:-. %:~.:45:%;1:1:t?:=;1;f;1;1;Y;r;¢;¢~l:1;:;i;:¢:;

->=:~§¢;=;I;!;:;:~ ' i ;1;:~:»:Y;;:<-r-:-:-t:;;-:-.:-;-rim:»;»:»

=:;:§:3:5:£:§:§

"====='%'

'

‘""¢;‘;1;§;

.

‘

>

I

.-iIE1i=§‘-3Y:‘;=§E=1=' 'E¢§iE1‘lE‘-i i:11125119:'-=,

..

‘=i=?:~:;i=.=:f&_:%

:‘15‘3:~‘.-11-? '=£~§-I=2v:'1'$.

’-:;1;;;:~t;‘i;Z;

‘

‘~1e1£=Eé>i<€ei?€1S1§=2=?=E:E1E1E1E1E15rErE=5=i=i=Zr;

..~$:!:&1:?:%2:=:?:="¥:“=.."'=s."1*:15:l:1;l-1;I;I-I"~'-'-‘ .1:-t~' 2114*‘

_.;.;;=;;5:1:=:;:3:;:=:;;=:;==;=:1E;§i

:,=;:»=Z5=;Yin?I*:‘

; :=:;i:>r¢!?=-:§1?5r¥$:-:-.

=:;:;r:;=¢:;:;==:2

<-:7I-;~1~;-:-‘

-‘l‘1;.;.e--§.>i~.;l;1-Ia-iris}-.

12%--:-§:~:-:-2-=:<~

-.:: -:4»;I;-rei;-:!;:;.;.;:;;;1;.»-:~:=‘

f;‘/=:e".<¥-'.€=§'1.=.~.1E=E=;:=:=:¢==-'=:=:1:5:l:lrl:l-'"

-A-<‘»""'-'11!-e,-‘~£.\'=§,»’~;;~;-‘r,’-'~"

:;:;:;:;r1."~

‘"11~;1:1" ' . ‘ ,

'

. »- I ~».-:-"1:-:-1-;-:-:1: “ ;-:

_

iv, ;- I , ‘

’

"=

.~.-.1.-.-:-.;.;.g:¢:¢:;.§:;;

'»:;;§;i:11§;;:§:§;§§.*;.;:{.{;§;§:§:§@g§;ESE!§1§}:§§?:!:i:7:1:§*3'- ‘

"-:§:1:l':j:§:§:§:3L§t;;f:l'l'?"?~'t7:'f7::

.-.;... ‘

EIEIEIEIZIEII‘:

.:1§i7;:i:-1-'-;-,._

.

‘$151513E1;.fF;§§=E1E1E131EiE¢I»£'I4-"

. 3»-%~."~‘.¢.r»=~;4.*-¥.~.’.¢§3*.<‘¢-

-

.=

-:-===-==

j~.-;-Ii~.:\

‘§1-i i%;t:'§ 1}I»‘~}:~;-§?§§i.»;».-;-.-...‘;-;‘,~;'y»'

’-. ~51»'I3i§3Y????E§E§5§3§‘§?§'§1.‘.-»~'--.

E55§55§555§E§E5i

5*

_.;1;.;;~.;:;.;.-:;'

~:»

.,.;.¢:f @531»:'=‘=i=i1iIEIEIiIi1}f;IZ¢i=i=E1‘1E1'

.‘-:1:-:-:1.‘-:1:1:' ==1-2'.~;;==i=;:;=‘:-“'¢-:>,:¢,I

~ .. . ¢

_.;,g:;:g;:;:;:;:;:;:;:;:;:;.-:;.;*;:;:\ .\~

~"-.':':-:-;i:~:~»+: ,__-,'-:,<-:-:1‘;-;.

:~

Q9521-..-:-:-1-:-:-:2»:-;<:-:~:-:X-:-. ~>.‘'*~*'>,;§§5;;:-,~:~:~:-:-:=

.~> "°~“é;=:?:>.1:1-'-‘

:l-‘:1.1:‘.‘;f:‘ >“‘{$,‘,‘,‘;‘.;‘~"~;-,‘§§’§_

-~%'~*‘¢>‘-<1:<->- ~ e : ,

nu‘!as-I§£'14;1~1-;-I-Z-21>:-Ia-I-1~i~_

.3$55:51;:$5:;=;:;=;:;:;r=;=;:;=,=,.,

;==nu=========er;====:==sa=====¢==s=-;-.-.

»:1:§:1:¢:¥:1:I:1:15:1:hi:i:$:?:¢:1:¢:?:=:%1:1:1:

;:;:;.;:;:;:¢:5:;:gt;\3:;:;:;:;:;:;:;:;:;:;:;:;:;:;

.

I;:11:-;1;=;1¢=;=:=:1:=:1:

"1=IE1E=E=E3%1§1?

:z?¢? IY=*1E1**" 4 *

-1327;»

:‘:::- ‘

,-.<,t_»

'§:7‘7:1!-res:

.1:_~;_¥:-*,4:~:»:'~'

_,;;;._.:._-;.;_.;

'_ ._

--.-I.t,E"51313:;rE:E:>:%1¥1i

1E:E=Er£r=1.

+'.';:=:=1=;=1=.1:=.~-‘:15.-;..-Y-'

1:¢;I;*:':1:=:1:‘:1~‘:1:f-:'.1-11.‘.--I:+;1;1;1:r:1~'

."-‘1;=::;r:r;=;=;r3i;r.

";

;-1‘;-:-:-:~:i.1:-:-:5’:

-. .;.;.

__

. .-:1;1:I:-;§:§:§:f:,.§:j:§‘§:§:§15.13:1

2§Z;..,._$§;2§§§;-;,--i»‘-‘:51i'7‘1‘7‘1i3i11‘i35"

~.*§.-.> '.- . ':-':Z'C'*I'IiI‘I'Z‘I‘2-16'

.

3E5§*§§5E=E=ErErE=E1E=E1€1§?{?%?=115111IREElililififi-if

"-"1-I-P1-P1~?'¢;i:'Ig-I~I~Y‘

:51;:; ;11~!4*“'

; ; :5-;;1:¢‘

,;,1;=l:,I:¢:I:'

¢,=,:

,.;.;.;. .;.;.;.;. r5s==:r¢;~-.».;.;.;.;.;.;.;.;-;-1.¢.;.;-<

»~:1:§:=:1'i'?

*"'.=:=:=-111%!" l-;.;=:.:»---;-;-__

:¢:=:1:=:-:-..

_,__‘,Eg;:-;.;.¢.;.;:;;v:;.;:,,'».;,;‘..gt_

,,,.:q.;.;1;,;T;‘-'

,~.-.-.-.~.

'

1£;=2l£%zi=iai;%:%zis%s:2¢;i;. '

1;~:5‘=‘;<iz?;‘ -1 -""."-=*+1*"=21*.

. . _ .a‘s%zi:%2i=.i:r= 11>:_ sia_..,._.;.;.;.;.;.;.;.;

:aiz:11si: z=z:z--.:2

.

‘-I.-=:z:2%§’;-in ' .»;'~’;f.=Ii,»;lji;3535§E:§§$§;:;. :j;E}£;£;E=E§i;E=§;E$

~=:ztisfigi:»::-»z:s:s=1a§z=s:.A-.=~==z> 1;» ;=‘:r.=

‘"=2:§5:512:22:s: :5:z?§§§::s=§iziai .5‘ 1’;-?1*"'*.:.'-. ;:;3;1-I~-'

-—~,1»;-;-;-1-;-:-;-:-;»;-;>:-:-;-;-:<;<;i:~,,' >

.___._._-,»,;.;.;.;.;.;.;.;,;.;.;.;.7.;.;,-.-;-- :-.1

TEEEEE}51513:}:§:§:§:§:§:i:1:1:1:§1§:1;;:; ;:i:;;;a_;§.; 51.5; I ,:‘

':I:5:!:$:3:I:1:5 #%5:7:1:?:l:1:3::~‘

='~'-'v'-:-:-:~:v:-:-:-;-:-:-‘-'-'-;-.<:\:\:\:\:-:-:A

it?22:;=2:=213:===Er§=:21=1:=:2=;:=;= "~'-r:=:r:1~.:-‘

5:1:fi¢:!:1:1:1:1$:1¢=r!:=:i

:i:=:=:?:1:1$ . V .

1t-:11;:;:1I;:$;:;:;:;:;:;§:;i;:;:;:;:55; ,. \_ .;'¢'/_t;";¢_

=-

:§5Z=I ‘E1315151515?§1§i?I§1§1EIE:§:E:;‘ :15.‘-::\ :'f:§§1Ir§Z,:E 1?" i:f:;:T‘~j'

.;.;.-.;.; -;.;;.;~___;_;,i_i,- -5,‘

- ,

_.

‘s5§i§.~$525552?:iz1zi2Ez%zi;5$‘g§?zE1ii"2:.==’=i;T;=1 5. =1,

-.-',I:~$?5¥:€Y'=:=:=:1$:=§¢$:=:='53I: . .. .~:-:-.-:~.-:-:-:~'¢‘=:-:¢»--=:~:-+-.—.- --Q.-.-\:v.=1‘-.¢;1a,,-;-3-;-g34,),-.

». -,<x;>a;:;:;:§*.¢:;>i.;. EYE???5E1E:§¥?5§?§5§5§§§§:;:¢.;.

. =§.i-T~'35i=35;'i.»51‘~

- ‘£3

I ,'31:‘:"if-5‘:15T5I§'§23i3:3:5t7!EI~

,, 5‘.-f?:?;3i-11:13:‘

. ..

,-_._

._,,._.s

.

'~:-:1 :~:1:1:': :I:?.1‘l" .. '

‘P-‘IiiI'2\I<I<i~=I~I~T-I-t-3‘ §-:-;r‘3‘'1: -131-I-L-I-23?}Z‘./Z" ‘

?:i.1;I.l:I:I:i1I:1:!;I;I:I:I¢1; i_¢;1;I?1?§1£1-:ErE1E1E:ErEIEIE=€=i=' ._=‘_,

..»%:i:5;342;E5:;.=‘51j'

_5:;:<:;1;ifr;r~'~‘»~~='1'-“Ij'i f -‘ 1" :-' .“'-‘::1,I;I;Z;2;2;i;£;I;L;I;;;I;1;!_.

'=:=:=:=:'>_

'_: 1£‘=3=5=E=‘

=i:1:=‘ -:1:=;=;=-'-1-1-1;

- :;.- .»:-:-zlikwna-:\:~_~.

.“1I'i‘5i"

_ ; 1

11E:E=E=E=E¢ErE$%$iE2£E2=%%:=?:=E=Z~. . '

.

.-:1

. I

-7

. " ,._.,.,_._.,., -13:5:1t1:5:?:1:3"'.

_.

_

, .;~;.;1;<;‘;-:q -;-:-;‘;':-;1.-:n-:-~.

;:;:;:~:»:~:~:»:':':

'

‘

1:1:1:i;i;

, :;:;:g:;:;:;:,:;>;~‘-ti"-::'

===;;;:;:;:;:;~j-.f:j~;~-g‘

1 __-._1*}

.

:-g-15$;-'

"

, '.

.-

1:1 .11'

.

.

‘

1

7;

)9

-

. =11"

--~=‘<:\:::-~11‘

=:=:r.-1-:

i

,..~.».-:~:=:=:§i=:=:=:§:§:I:=:=$re.

-.-,i;1;¢§§;§:1:f:¢:!;§$1:§h»:l:¥:1:!:1;%:¢:

2;2;1;1;i;!;;;I;Z;Z;ij!;2;-§I;i;i;l3I;t;§;l1l:2;!§1_

-;" " .

3

:i;1i‘:;:;:i:;:;:§:_»:':;:;:;.;._.__

===:====;=*=1:======::=:==ru:¢=a=§=z:s=2isszsizi

:ItI:I*i

5-.Ei5::f:l3:‘:3l:='i:§=i=5=ii I:=:I:1:1:¢:!:Y:i

:i:§2r3i1Z=:E:E:i:£::1:=:1:?:1r-:15:1.

3=§=5=E=3;E;£=i=i

::-:-111+:-;-:v:»:+~-:-:~:=;-2:":-:@:~i

3:5:5:;:§:i:5; :3:£=i3i :i:§:§E1E=&;5:;:£:-2-1-:-1+:-*-.

:£:_E=%£ii§:=

=i=

.I:-:i.=;:¢I:=z~:"-:»:1:»:\:-:-'

'*=i=E=E=E

sei~;~:':1t1:~:1:);+:¥:?:-;-:-ti:-:-:I:~:».

as=z=::2=&=2:e=-a=sa2=2s=::2:z:2

1;£§;:E~:~:»:-:-:-:»1-:-:-:<-:-:-:>;~:~:A

3E33;S;23E5E5£;3;?;i;55E§E;E3E;EgS;

;-:-:i

:;:-2;:-:;:;:;:-:-:;:;:;:-2;:-as-:;;;:;:;:

;rs=’=;=Z‘=.: ;=:;E_=5§=:; ;E;‘:;E§1E=;;=;=;s

Takashi IDEMITSU

Exposure tests on concrete in marine environments were conducted over a period of 10 years to

establish a rational design method for concrete structures that takes account of the durability. In these

tests, the penetration of chloride ions, the corrosion of reinforcing bars, and changes in concrete quality

were investigated. The following findings were obtained: (1) Chloride ion distribution can be predicted

using the chloride ion diffusion coefficient (Dc) and the surface chloride ion concentration (Co)

obtained from exposure tests; (2) The rate of chloride ion penetration in marine environments is fastest

in the splash zone, followed by the underwater and atmospheric zones; (3) In marine environments,

properly treated construction joints and cracks under 0.1mm in width do not significantly advance

reinforcement corrosion for an exposure period of up to 10 years.

Key words: diffusion coefiicient, exposure test, marine environment, penetration of chloride ions,

reinforcing bar corrosion

Nobufumi Takeda is a deputy chief research engineer at the Technical Research Institute of Obayashi

Corporation, Tokyo, JAPAN. He obtained his D.Eng. from Kyushu Institute of Technology in 1999.

His research interests include the durability design and durability improvements of concrete structures.

He_i_s a member of the JSCE and J CI.

,,__

Shigeyuki Sogo is a General manager at the Technical Research Institute of Obayashi Corporation,

Tokyo, JAPAN. He obtained his D.Eng. from Kyushu Institute of Technology in 1991. His research

activities relate to the development of special concreting methods such as underwater concrete, mass

concrete, and self-compacting concrete, and the durability design of concrete structures. He is a

member ef the J$CE.e11dlCI@.

"

.

1

Shigemi Sakoda is a professor in the School of Marine Science and Technology of Tokai University,

Tokyo, JAPAN. He obtained his D.Eng. from Tokai University in 1992. He has been involved in

research on the properties of concrete with inferior quality aggregates and the durability of concrete in

marine environments. He is a member of the ACI JSCE and JCI.

Takashi Idemitsu is a professor at Kyushu Institute of Technology, Fukuoka, JAPAN. He obtained his

_

_. ,_.___,_R

,

V

—

’

_

C ___

if

_i_ Rf if __ _

*__*i___*___

___

C

_

__

_._i R KWKRY

_

if

D.Eng. from Kyushu Institute of Technology in 1992. His research interests include prestressed

concrete using reinforcing bars, self—compacting concrete, and the quality assurance of concrete

structures. He is a member oft_he,JSCE and JCI.

__ p

_

__ ____W_p_ _

_

1

. INTRODUCTION

In order to design concrete structures for a marine environment with a proper consideration

of durability,

it is vital to clarify the rate of chloride penetration into concrete and the rate of reinforcement corrosion.

There have been numerous reports on both these topics, mainly based on investigations

of structures

constructed in marine environments and exposure tests in such environments [1]. According to these

reports, chloride ion concentration, moisture content, and oxygen supply in the concrete all affect the

corrosion of reinforcing

steel, and the splash zone is generally

considered

to be the severest

environments with regard to concrete structure durability,

followed by the underwater and atmospheric

zones. It has also been reported that the chloride ion limit, at which reinforcement corrosion begins to

occur, lies between 1.2 and 2.5 kg/m3[2],[3].

Further, estimation of long-term chloride ion penetration

has been attempted by measuring chloride ion concentrations near surfaces and using the diffusion

coefficient

of chloride ions in Pick's diffusion equation [4],[5],[6].

However, in a report in which a number of investigations

of chloride penetration

into concrete in

various marine environments were analyzed, it is pointed out that chloride ion concentrations in marine

structures vary widely even in environments that may be classified into the same category [7],[8].

In

addition to these wide variations, the marine environment varies according to geographical

location,

position of the structure, and the arrangement of structure members, making it difficult to correlate their

influence on the rate of chloride penetration

and progress of reinforcement corrosion. This has

hampered the elucidation

of the effects of different marine environments and construction parameters,

such as cracks and construction joints, on chloride ion penetration in concrete and reinforcement

corrosion.

In this study, exposure tests on concrete specimens in different marine environments, i.e., the splash

zone, underwater, and the atmospheric zone, were conducted over a period of 10 years with the aim of

establishing

a rational design method for concrete structures in marine environments taking into account

durability.

This paper reports on the estimation of chloride penetration and rate of reinforcement

corrosion based on the results of these exposure tests, and the following issues are discussed:

(1) Influence of different environmental conditions on the quality of concrete, chloride ion penetration,

and reinforcement corrosion

(2) Influence of types of cement on concrete quality, chloride ion penetration,

and reinforcement

corrosion

(3) Influence of cracks and construction joints on the rate of reinforcement corrosion

2

. METHODSOF EXPERIMENT ANDANALYSIS

2.1 Outline of experiment

Three experiments were implemented with the following aims:

Experiment I: Experiment to elucidate the effects of different environmental conditions

Experiment II: Experiment to elucidate the effects of cement types

Experiment III: Experiment to elucidate the effects of cracks and construction joints

For each experiment, concrete specimens encasing reinforcing

steel were exposed to different marine

environments for 10 years. Changes in the quality

of concrete, chloride

ion penetration,

and

reinforcement corrosion over time were investigated

periodically.

Table 1 gives the combinations of

experimental conditions, such as exposure, type of cement, and presence of cracks and construction

joints. Four exposure conditions were selected: splash zone, atmospheric zone, underwater, and inland.

Three cements were used: ordinary portland cement, Type B blast-furnace slag cement, and sulfateresistant portland cement. Specimens with cracks or construction joints were also prepared using

ordinary portland cement and were exposed to the same four environmental conditions.

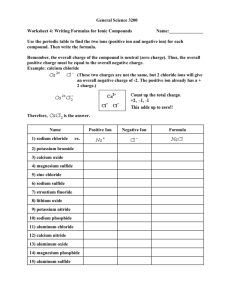

90-

Table 1 Combinations of Experimental

E xposure env ironm ents

Sp lash A tm ospheric underw ater Inland

zone zone

o

o

o

o

O rdinary Portlan d cem ent (O P)

S tand ard T ype B blast-furnace slag cem en t (B B )

o

o

b eam

o

S ulfate-resistantPo rtland cem ent (SR )

o

C rack ed O rdinary portland cem ent (O P)

o

o

o

o

b eam

Jointed O rdinary portland cem ent (O P)

o

o

o

o

b eam

T y pes o f

sp ecim en

nnnDeformed bar

900

/

j

Ba 3

(a ) S ta n d a rd b e a m

(b ) J o in te d b e a m

c

rn

fro

m

0,

W

[ ]

- - M

m

*

T y pes of cem ents

Table 2 Physical Properties and Chemical

Composition of Cements

P ro p e rtie s

T yp es o f

^

S p ec ific

-

g rav ity

O rd in a ry

,

(c) Crackedbeam

.

.

mm)

Us

v Jt-f

l .4 . u

Ur

1 4n1a

Uc

W e

bIoiSll aasi-iurnace

of chloride

S O 2 A 12O 3 F e2 O 3

C aO

M gO

SO 3

3 .1 5

3 ,3 0 0

0 .5

0 .3

2 1 .7

5 .3

3 .0

6 4 .7

1 .3

2 .2

3 .0 4

3 ,4 4 0

0 .9

0 .5

2 5 .2

7 .3

2 .2

5 7 .5

2 .8

1 .7

3 .1 8

3 ,3 7 0

0 .8

0 .1

2 2 .1

4 .1

4 .5

6 4 .3

1 .0

1 .9

slagcement

ion penetration)

P o rtla n d c e m e n t

Portland

cement

Fig.l Type, Shape and Size of Beam Specimens

Table 3 Properties

M a te ria ls

F in e a g g r e g ate

C o a rs e a g g re g a te

2

In so l.

s la g c e m e n t

S u lfa te -re sis ta n t

( 4" Direction

(c m /g ) Ig .lo ss

T yp e B

10 0

(unit.

C h e m ic a l c o m p o s itio n s ( % )

B la m e

tm e n es

c e m e n ts

P o rt la n d c e m e n t

IO C

Conditions

of Aggregates

P ro p e rtie s

L a nd sa n d , S p e cific g ra v ity : 2 .5 8

A b so rp tio n : 1 .6 4 % , F in en e ss m o du lu s : 2 .6 7

C ru sh e d ston e , G m ax : 15 m m

S p ec ific g rav ity : 2 .6 6 , A b so rp tio n : 1 .0 9 %

.2 Specimens

a) Composition, shape, and size

Three types of specimen were prepared for exposure: reinforced concrete beams for investigation

of

reinforcement corrosion (RC specimen), plain concrete cylinders

for compression tests, and plain

concrete cylinders for chloride penetration analysis. The reinforced concrete beams were 9 by 18 cm in

cross-sectional

size and 90 cm in length, as shown in Fig. 1. These beams had deformed reinforcing

bars embedded with a cover depth of 2 cm. These were SD 295/D19 bars with transverse ribs

conforming to JIS G 3112. Both sides and ends of the beams were coated with a thick-film epoxy resin

to allow chloride ion penetration

only from both edges. Whereas cylinders for the compression tests

were 10 cm in diameter and 20 cm in height, those for chloride penetration

analysis were 15 cm in

diameter and 15 cm in height. The curved surface and one end of each cylinder for chloride penetration

were coated with a thick-film epoxy resin to allow chloride ion penetration only from one end.

The reinforced specimens included some with a construction joint (jointed

beams) and some with

bending cracks (cracked beams) prepared for exposure in experiment III. Jointed beams had a

construction joint at mid-length.

At 7 days after placement of the first half, the joint surface was

wirebrushed to a depth of 0.5 mmor deeper to remove the laitance layer, and the second half with

identical mixture proportions was placed. Cracked beams, with four to five pre-formed cracks per beam,

were fastened into jigs to maintain the crack width at 0.05 to 0.1 mmat the surface.

-91~

Table 4 Mix Proportions

O P

B B

SR

G m ax w /c

(m m ) %

T yp es o f

ce m e nt

Sym b ol

O rd inary

p o rtlan d ce m e nt

T yp e B

b last-furnac e

slag cem en t

S u lfate-resistan t

P o rtlan d ce m e nt

Ad : air-entraining

and Properties

15

s/a

%

of Fresh Concrete

U nit w e igh t (k g/m )

w

c

s

G

1 6 6 3 3 2 8 4 7 9 3 5 1.0 4 1 2 .0

5 .0

5 0 .0 4 8 .0 1 6 2 3 2 4 8 5 1 9 3 5 1 .0 1 1 0 .5

4 .4

1 6 6 3 3 2 8 4 9 9 3 7 1.0 4 1 3 .0

4 .1

and water-redueing-agent

A g e (d a y ) 7

14

35

D

HD

(a ) S ta n d a rd b e a m ,

P la c in g C on structio n

jo in t

D

DD

(b ) J o in te d b e a m . A

D1 M ak in g crac ks

(c)

C

uring

method!

p

F resh c on crete

S lu m p A ir co% ntent

A d*

cm

50

E x p o su re

start

Cracked beam

*+à"*

M-*

M

Moist

I

Coating

| Dryingin

|

curin§

atmosphere

Fig.2 Flow of Specimen Preparation

b) Materials and mixture proportions

The following three types of cements were used: ordinary portland cement, Type B blast-furnace slag

cement, and sulfate-resistant

portland cement. Table 2 gives the physical properties

and chemical

compositions

of these cements. Land sand and crushed stone were used as the fine and coarse

aggregates, respectively,

in every experiment. Table 3 gives the properties

of the aggregates. An airentraining and water-reducing agent containing modified lignosulfonate

as the main component was

used as a chemical admixture.

Table 4 gives the concrete mixture proportions and the properties of the fresh concrete. Concretes made

using ordinary portland cement, Type B blast-furnace slag cement, and sulfate-resistant

portland cement

are hereafter referred to as "OP," "BB", and "SR," respectively.

Whereas OP, BB, and SR were used in experiments I and II, only OP was used in experiment III. All

concretes were proportioned to have a water cement ratio of 50%, a cement content of around 332 kg/m3,

a slump of 12.0+1.5 cm, and an air content of 4.5± 1.5% in consideration

of the maritime conditions.

c) Preparation of specimens

Figure 2 shows the flow of specimen preparation from concrete placing to the beginning of exposure, as

well as the curing methods. The specimens were wet-cloth-cured up to an age of 14 days. They were

then dried in preparation

for epoxy coating on the specified

surfaces, air-dried, and exposed to the

marine environment at an age of 50 days. Beams to be precracked were loaded at an age of 14 days such

that one of the permeable edges formed the tension edge, thus inducing bending cracks. After unloading,

pairs of cracked beams were fastened together with jigs as shown in Fig.l before being coated on both

sides.

2

.3 Exposure conditions

The exposure site was a breakwater in Shimizu Harbor, Shizuoka Prefecture.

location of the exposure site. Figure 4 and Table 5 indicate the exposure positions

-92-

Figure 3 shows the

of the specimens on

the breakwater and the conditions

to which each position was exposed, respectively.

The marine

environments were three: the splash zone between high and low tide (splash),

in the atmosphere and

subjected to salt spray only during the strong winds (atmospheric),

and in the sea at a depth of ll m

(underwater). An inland site was also selected at a point 30 km from the coastline with little influence

from air-borne chloride ions (inland).

Whereas specimens were exposed to all four environments

(splash-zone,

atmospheric, underwater, and inland) in experiments I and III, the environments for

experiment II were only atmospheric and underwater.

E138

Gauze-covered wood frames

30'

tiu-Mucm;\

/Specimens

Measurementpoint ol

Air-borne chloride

ions

Atmospheric zone

+5.0

0.5'

m

Splash zone

Breakwater

H.W.L

+1.7"

L.W.L

0.0

1"

Underwater

l

Direction

Fig.4 Exposure Positions

Fig.3 Location of Exposure Site

Table 5 Environmental Conditions

E n v iro n m e n t

E n v iro n m e n ta l c o n d itio n s

A tm o sp h e ric Z o n e 5 m h ig h e r th an L .W .L

B

A ffec ted b y s p in d ri ft a n d sea b re ez e

zo ne

D ep th o f s eaw ate r

:llm

S e aw ate r p rop erties :

A v e ra g e te m p e ra tu re

: 1 8 .4 C

c U n d e rw a te r

pH

: 8 .2 9

C h lo rid e io n c on c en tra tio n

: 1 8 .4 % o

Ins olub le o x yg en

: 7 .98 p p m

In la n d

of Specimens on Breakwater

of Exposure Positions

A S p la s h z o n e B e tw e en H .W .L (+ 1.7 m ) an d L .W .L (0 .O m )

D

-l.0m

of chloride ion penetration

L ev el 5 0 0 m o ff

S h im iz u p o rt

A v e rag e

tem p e ra tu re : 1 6 .0 C

P rec ip ita tio n

:2 3 60 m m /y ea r

3 0 km fro m c o astlin e (K iyo se , T o ky o )

A v e rag e te m p e ra tu re

: 1 5 .3 C

P rec ip itatio n

: 1 4 6 0 m m /y ea r

Also set up on the breakwater were a capture

vessel for air-borne chloride ions as proposed by

the Public

Works Research Institute

of the

Ministry

of Construction

[9], and four gauzecovered wooden frames. These were positioned

0.5 m above the top of the breakwater, so were in

the atmospheric zone. The amounts of air-borne

chlorides

(NaCl equivalent)

from four directions

were measured using these devices every month

from July

through

December

1995.

The

measurements are shown in Fig.5. The values

varied widely depending on direction,

with the

maximumand minimum of the averaged catch

over the period in one direction being 1.5 and 0.32

mg/dm2/day, respectively.

The average of airborne chloride ions from all directions

over the

period was 0.77 mg/dm2/day. The average of air-

-93

^ >

s

'3

10

ll

12

Month of measurement (1995)

Fig.5 Result of Measurements of Amount of

Air-borne Chloride Ions

borne chloride

2

ions from all directions

measured using the capture vessel was 0.22 mg/dm2/day.

.4 Measurements and methods

The measurements made and methods used are given in Table 6, and the times of each measurement are

given in Table 7. Compressive strength and progress of reinforcement corrosion were measured by

recovering specimens from the sites at 1, 3, 6, and 10 years of exposure. The chloride ion concentration

was quantitatively

analyzed in terms of total salts by potentiometric

titration with chloride ion-selective

electrodes, using concrete drill dust samples from each 2 cm in depth at 1 and 6 months and 1, 2, 3, 4, 6,

and 10 years of exposure. The chloride ion concentration was expressed as a percentage by weight of

concrete. Corrosion of reinforcing steel was evaluated by cleaving the beams and measuring the ratio of

corroded area to total reinforcement surface area.

Table 6 Measurement Items and Methods

Ite m s

M eth o d s

C o m p ressive

streng th

C o m p ressive stren gth test (JIS A 11 08 )

. S p ec im en s : diam eter lOc m , len g th 2 0c m

N eu traliz atio n

M easu re th e d ep th o f z on es un co lo red b y

p h eno lp hthalein so lu tion sp ray

C h lo rid e io n

c on ten t

Q u an titativ e d ete rm ina tio n of tota l salts b y p o te ntiom etn c titra tio n

w ith ch lo rid e io n-selec tiv e electro d es

S am p ling o f co n cre te d rill du st from each 2 cm in de pth

R e in forcin g

b ar co rrosio n

Sk e tc h co rro de d p arts a nd ev alu ate p erc en tage c orro d ed are a

to to tal reinforcem en t surface are a

C h em ical

c om p ositio n

P ow d er X -ray diffractio n an aly sis

P orosity

/v dp istrib

o re size

u tio n '¥

M ercury m strusio n m etho d b y p orosim eter

2

M ea su re m e nt ra ng e o f p ore d iam eter :3 .O X lO"

3.O X lO " m

Table 7 Measurement Period

Exposureterm

Measurement

item

1M 6M 1Y 2Y 3Y 4Y 6Y 10Y

Compressive

o

o o

o

strength

o

o

o o

Neutralization

Chlorideion o o o o o o o o

content

Reinforcing

o

o

o o

barcorrosion

Chemical

o

composition

o

Porosity

.5 Method of estimating chloride ion penetration

Movementof chloride ions into concrete dose not simply depend on diffusion of chloride ions, but is

knownto be macroscopically describable as diffusion. Many models have been proposed for chloride

ion movementinto concrete [5],[10],[11],[12],[13].

When the boundary condition is the chloride ion

concentration at the surface (Co) and is constant, the solution of Pick's diffusion equation can be

expressed as Eq. (1). When expressing the movemento f chloride ions into concrete in a marine

environmentusing this equation, the diffusion coefficient (Dc) in Eq. (1) takes account of such

phenomenaas concentration and fixation of chloride ions and suction of water, as these are included in

the diffusion phenomenonand are dealt with as macroscopic diffusion. For this reason, this diffusion

coefficient is referred to here as the "apparent diffusion coefficient."

In this paper, the movementof chloride ions by meansother than diffusion is included in the diffusion

phenomenonto simplify the movementof chloride ions as muchas possible, thereby grasping the trend

in long-term indices of chloride ion movement.T he changes in the chloride ion concentration at the

surface (Co) and apparent diffusion coefficient (Dc) in Eq. (1) were investigated for up to 10 years of

exposure under these assumptions. Co and Dc in Eq. (1) were calculated by the least squares method

from the chloride content distribution measured for each exposure period. However,if the penetrability

of chloride ions is assumed to change over time, then Dc changes accordingly, and the value of Dc

determined in this mannerwill indicate an average of changing diffusion coefficients over the period

from the beginning of exposure to the time of measurement.In other words, the value may reflect the

influence of penetrability of chloride ions prior to the time of measurement.

-94-

C

(1)

=Co \ 1-erf

where x =depth from the surface (cm)

t = elapsed time (s)

C =chloride ion concentration at depth x from the surface (%)

Co =chloride ion concentration at the surface (x = 0) (%)

DC=apparent diffusion coefficient of chloride ions (cm2/s )

2

erf:

error

function,

erf(Z)

z

2

= -j= -f e"r-dt

VrcJo

3

. INFLUENCE

OF ENVIRONMENTAL CONDITIONS

PROPERTIES OF CONCRETE IN MARINE ENVIRONMENTS

3.1 Influence

AND CEMENT

TYPE

ON

of exposure conditions

a) Appearance of specimens

Photograph

1 shows the appearance of

cylinder specimens exposed to the splashzone environment for 10 years. Organisms

such as shellfish

became attached to the

splash

and submerged specimens, and

particularly

on splash specimens. Cracks and

rust exudations

due to reinforcement

corrosion were observed on the splash and

submerged reinforced specimens, both those

with precracks and joints and others. No

cracks or rust exudations were observed on

atmospheric and inland reinforced specimens.

No sign of deterioration was observed in the

appearance of any plain concrete specimen in

any of the environments.

Photo. 1 Appearance of Cylinder Specimens at

10 Years of Exposure (Splash Zone)

b) Changes in compressive strength

The changes in compressive strength of concrete made using ordinary portland cement (OP) are shown

in Fig. 6. The compressive strength before exposure (at 50 days) was approximately 45 N/mm2.The

compressive strength of atmospheric cylinders took nearly the same course over time as standard-cured

cylinders,

increasing by about 10% after 10 years of exposure. The compressive strength of splash

cylinders increased in the first year by about 20% compared with the pre-exposure strength and leveled

off thereafter up to 10 years. The compressive strength of submerged cylinders was 10% higher at 3

years of exposure, but was 4% lower at 6 years, and eventually 8% lower at the end of the 10-year test

period. Inland cylinders showed few changes in their compressive strength over 10 years.

The compressive strengths of the cylinders in all marine environments except the inland environment

were higher than those of standard-cured specimens for up to 3 years. At 10 years of exposure, however,

the ratio of compressive strength to that of standard-cured specimens was 1.12, 1.02, 0.83, and 0.89 in

the splash, atmospheric,

underwater, and inland zones, respectively.

This suggests wide-ranging

compressive strength changes over time depending on the environment. In addition to the wetness of the

site, various other factors are thought to synergistically

influence the compressive strength of concrete

exposed to a marine environment, including the amount of ettringite

formed through reaction with

sulfates in the seawater and the amount of calcium leaching into the seawater.

-95-

40

S ym bol E nvironm ent

S plash zone

Sym bol E nvironm ent

Azone

tm ospheric - o

A

Inland

D

Standard curing

U nderw ater

0

u

I

2

£

S ym bolC em en t E nvironm ent

Inland

OP

o

A

B B A tm ospheric

zo ne

n

SR

3

10

6

1

3

Exposure term (years)

6

Exposure term (years)

Fig.6 Changes in Compressive Strength over Time

c) Progress of carbonation

Figure 7 gives the measurements of carbonation

depth. At 10 years of exposure, no carbonation

was observed in splash and submerged beams,

while the carbonation

depths of atmospheric

beams and inland beams were 1.2 mmand 2.0 mm,

respectively.

Progress

of carbonation

may

therefore be affected

by its wetness. In all

environments, alkalinity

was maintained at the

reinforcement depth (2 to 4 cm in depth).

d) Powder X-ray diffraction analysis

Figure 8 shows the results of powder X-ray

diffraction

analysis of OP specimens after 10

years of exposure in the four environments. A

comparison of the X-ray diffraction

intensities

of

calcium hydroxide (Ca(OH)2)

in the surface range

(0 to 2 cm in depth) shows that intensities

for

splash and underwater specimens are lower than

those for atmospheric and inland specimens. This

suggests leaching

of Ca(OH)2 from near the

surface of splash and underwater specimens into

the sea. When exposed to the underwater

environment, leaching

of Ca(OH)2

can be

expected to cause losses in compressive strength.

The tendencies

exhibited

by underwater

specimens were also observed in splash specimens,

but Friedel's

salt was detected near the surface

(within 2 cm of the exposed surface). Ettringite

was not clearly

detected

in any of the

environments.

Fig.7 Changes in Carbonation Depth over Time

Depth below surface :8~10cm Ca(OH)2

Splash zone -^^^^^^t

4

~6cm

Ca(OH) 2[

if

: fn

A|-M>v'w^Jl^Y^Jj|~-

5

/\iraospnenc

-^

- *- _ , à"

j-Lj-L-ii^.

10

20

_.

_Depth below surface:8~10cm

Ca(OH)2

zone

0

~2cm

|

Ca(OH)

^W^<lNvA>AA\K^-/l>li^ALjA^

j^^-

10

Underwater

Jl

15

Depth below surface:

A|'^s^rv~^/^v^?^--^-^^

4 ~,6cm

*X**UWw*A,~iJlA^L

20

8~10cm Ca(OH)2

2

J^,l^ Ca(OH)

^ l^ _ii>,..

\J<

10

D

Inland

1

15

epth below surface:

'^^^m^v^vX

20

8~10cm CapH)2

,~; 6cm

r^^v<>^v^Awaw^^^A.

_yx-

4

0-

-2cm

>*''o>HW-*N-Va-u.

'*HW"-wV\i-u-J-Js-i.j/'^->.

IA

10

28

Ca(OH)J

.

A

15

20

(deg)

Fig.8 Result of Powder X-ray Diffraction

(OP, after 10 Years of Exposure)

-96-

-k-.-.-r'A

15

Analysis

0 .8

1 .3

S .3

^t

CS (D

<u 43

>~*

i/i

<LJ

5 a

sH ァS 0.4

1 .2

o <u

T-H

>

O u_,

o

o. 5"

C

S plash zo n e

U

nderwater

ea

* 0 .6

0.2

^ ,

¥ *m

*A ,>

,

ー ^

_

V

* x 5.

1 .1

X O

<D O

0 -I f o .4

1 .0

'C

o<o

1-4

p V

0 .2

PS &

Inl and

A tm o sph eric z o ne

^

J ^

'fr

1

3

5

^ m ^

0 .9

0.95

1.00

1.05

1.10

1.15

n

Ratio of surface (0 to 2 cm in depth) to

middle (8 to 10 cm in depth) total pore volume

7

9

1

3

5

7

9

Depth below surface (cm) Depth below surface (cm)

Fig.10 Changes in Chloride Ion Content

Distribution

Over 10 Years (OP)

Fig.9. Relationship

between Ratio of Surface to Middle

Total Pore Volume and Ratio of Post-exposure

to Pre-exposure Compressive Strength

e) Pore volume

Figure 9 shows the relationship

between surface (0 to 2 cm in depth) to middle (8 to 10 cm in depth)

total pore volume and the ratio of post-exposure (10 years) to pre-exposure compressive strength. The

total pore volume refers to the total volume of pores 30A to 30Mm in equivalent diameter. The total

pore volume near the surface tended to be larger than that in the middle for all cement types. This

tendency was more evident in underwater specimens than in atmospheric specimens. Submerged OP

specimens exhibited a total pore volume 13% larger near the surface than in the middle. In the case of

OP specimens in the splash and atmospheric zones, the differences were 3% and 5%, respectively.

This

may be because Ca(OH)2 in the concrete exposed to seawater leached into the seawater, increasing the

total pore volume near the surface. According to this X-ray diffraction

analysis, leaching of Ca(OH)2

from concrete also takes place in specimens in the splash zone, but the difference between the total pore

volume near the surface and that at 8-10 cmin depth is inappreciable.

This may be affected by the fact

that shellfish

and other organisms cling to concrete surfaces in the splash zone, filling relatively

large

pores of specimens.

The compressive strength ratio after 10 years of exposure decreased more significantly

as the surfaceto-middle total pore volume ratio increased. The pore volume measurements also suggest that Ca(OH)2

loss has an effect on the compressive strength loss of submerged specimens.

Cement : OP

f) Changes in chloride ion content over time

Environment

Underwater

The changes in the distribution

of chloride ion

R^

content (as a percentage of mass of concrete)

.3

over 10 years are compared among the four

\ Exposure terra

environments in Fig. 10. At any time during the

s1 ~3 years

period, the chloride ion content was the highest

bO

in the splash zone, followed by the underwater

3

and atmospheric

environments.

Figure

ll à"sg

0~1 year

~6 years

.1

ctf <u

x

shows the distribution

of increments in chloride

-y

-/

av&

L6 à"10 yea'rsion content with depth from the exposed surface

during four time spans: from the beginning to 1

3

5

7

year, from 1 to 3 years, from 3 to 6 years and

Depth below surface (cm)

from 6 to 10 years. Up to 3 year, the increments

near the surface (0-3cm) are relatively

high, but

Fig.ll Distribution

of Increase in Chloride Ion

the increments in the deeper range became

Content (OP)

relatively

large there after.

\

0 .4

0

_«>.G

\

3

o

0 .2

<D

Cfl

-97-

O

V-c

0

Figure 12 shows the surface chloride ion concentration (Co) calculated from the measurements using

Eq. (1) as well as approximation curves. In all environments, the surface chloride ion concentration

increases with time up to an exposure period of 3 years and levels off thereafter. When exposed to the

splash zone, the surface chloride ion concentration at 10 years was 0.70% by mass of concrete (around

16 kg/m3), whereas for underwater and atmospheric specimens the figures were 0.57% (around 14

kg/m3) and 0.22% (around 5 kg/m3), respectively.

The time-related changes in surface chloride ion concentration were approximated using Eq. (2). In this

approximation equation, the ultimate surface chloride ion concentration (Co*) and coefficient

a for

each environment are the values indicated in Fig. 12. The ultimate surface chloride ion concentration

(Co*) was highest in the splash zone, followed by the underwater and atmospheric zones. These results

are similar to those reported by Sugiyama et al [14]. The differences in coefficient

a with environment

were relatively

small. As in past reports [8],[15],[16],

these experiments also confirmed the strong

correlation between environment and surface chloride ion concentration.

exp

(2)

:)

Co(t)=

Co* (1-

where

Co(t) = surface chloride ion concentration after an exposure period of t years (%)

Co* =ultimate surface chloride ion concentration (%)

a =coefficient

t = exposure period (years)

Figure 13 shows the changes in apparent diffusion coefficient

(Dc) over time, as determined similarly

to the case of Co and the approximation

curves. The apparent diffusion coefficient

of chloride ions

diminishes

with time in all environments. The fall in the first 3 years tends to be large, but becomes

movemoderate thereafter. The apparent diffusion coefficients

after a 10-year exposure period were

7xlO~8 cm2/s, 4.3xlO"8 cm2/s, and 2.4xlO~8 cm2/s in the splash, underwater, and atmospheric zones,

respectively,

so the fastest rate of penetration of chloride ions is in the splash zone, followed by the

underwater and atmospheric zones.

X-ray diffraction

analysis and pore volume measurements revealed the leaching of Ca(OH)2 and a large

increase in total pore volume near the surface of underwater specimens, suggesting that the concrete

surface has a porous microstructure. However, the chloride ion penetration was found to be lower than

in the splash zone. This may be because more chloride ions penetrate into concrete in the splash zone

than in the seawater under the influence of effects other than diffusion,

such as cyclic drying and

wetting due tidal wetting and the impact of chloride ions against the concrete surface caused by waves.

This leads to a higher apparent diffusion coefficient in the splash zone.

E n v iro n m e n t

fe~(U

.-

£3

1.0

0 .8

II

C a lcu la te d

v a lu e

A p p ro x im a tio n c u rv e

S p la s h z o n e

C o (t) = 0 .7 0 ( l -e 'a t>11 )

A tm o s p h e ric

zone

U n d er w a te r

C o ( t) = 0 .2 2 ( 1 -e "" " ' )

A

100

"

J i

o

I

_

-

-

ォ

A pp ro x im atio n cu rv e

D eft) = 18 .9 x lO

t

D c(t) = 9 .7 x lO'8 -t

D c(t) = 2 1 .3 x lO--- t

U nd erw a ter

C o (t) = 0 .6 3 ( l -e " * " )

0 .6

E nviro nm en C alculate

v alue

Sp lash zo ne

A tmneo spheric

zo

A

«

ォ

S

x 10

BQ

m

OH

t

3

4

5

6

7

8

3

10

Changes in Surface Chloride Ion Concentration

over Time and Approximation Curves (OP)

5

6

7

-

10

Exposure term t (years)

Exposure term t (years)

Fig.12

4

Fig.13 Changes in Apparent Diffusion Coefficient

over Time and the Approximation Curves (OP)

98-

The changes in apparent diffusion coefficient

over time were approximated using Eq. (3). In this

approximation expressing time-related changes in apparent diffusion coefficient, coefficients

DC* and (3

for each environment are the values shown in Fig. 13. Over a long period, the apparent diffusion

coefficient approaches a limit value, and this is highest in the splash zone, followed by the underwater

and atmospheric zones. This suggests that the environment also affects apparent diffusion in concrete.

The tendency of the apparent diffusion coefficient to fall over time has been reported in past studies

[8],[14],[17],[18].

This may be attributed to the high penetration of chloride ions at an early stage in

marine environments and the increase in the denseness of the concrete microstructure over time.

(3)

Dc(t)=

DC* à" t

where

Dc(t) = apparent diffusion coefficient

DC*=coefficient

(3 = coefficient

t = exposure period (years)

after an exposure period of t years (cm2/s)

Accordingly,

the surface chloride ion concentration

and apparent diffusion coefficient

are strongly

affected by environmental conditions. Also, these values can be approximated by Equations (2) and (3),

and can be estimated to a certain extent if the exposure periods and environmental conditions are known.

For a more accurate estimation, the water-cement ratio and curing temperature should also be taken into

account.

g) Progress of reinforcement corrosion

Figure 14 shows the state of corrosion of the reinforcing steel in RC specimens without precracks or

construction joints after an exposure period of 10 years. The ratio of corroded area at 10 years was

highest in splash zone specimens, followed by underwater and atmospheric specimens. Corrosion was

limited to the surface of the reinforcement in all environments, and no pitting corrosion was observed.

The changes in reinforcement corrosion ratio over an exposure period of 10 years are shown in Fig. 15.

In the splash zone, corrosion was first observed after an exposure period of 1 year and it increased over

time until the corrosion ratio reached more than 25% after 10 years. In submerged specimens, corrosion

first appeared at 3 years but scarcely increased up to 10 years. In the atmospheric specimens, corrosion

was observed for the first time after a period of 10 years.

Underwater

Splash zone

Corroded

area ratio

: 27.5%

Atmospheric zone

Corroded

area ratio

Corroded

area ratio

: 5.1%

Corroded

area ratio : 0.4%

Inland

: 2.3%

Fig.14 State of Corrosion of Reinforcing

Steel after 10 Years of Exposure

Figure 16 shows changes in the chloride ion content at the depth

the surface). In all environments, the chloride ion content at this

3 years of exposure. Chloride contents at the reinforcement after

0.34% (around 8 kg/m3), and 0.46% (around 10 kg/m3) by

underwater, and splash zones, respectively.

of the reinforcement

(2 to 4 cm below

depth scarcely increased after the first

10 years were 0.06% (around 1 kg/m3),

mass of concrete in the atmospheric,

The chloride ion penetration rate and oxygen supply are said to affect the onset and progress of

corrosion. As shown in Fig.15, it was confirmed in this experiment that corrosion progresses more

rapidly in the splash zone, where both are high, than in the air and underwater. The corrosion ratio in

-99-

u

1

2

3

4

5

6

7

8

9

3

10

6

Exposure term (years)

Exposure term (years)

Fig.15 Changes in Corroded Area Ratio of

Reinforcement over Time

Fig.16 Changes in Chloride Ion Content at

Reinforcement Depth over Time

atmospheric specimens was as low as 2% after an exposure period of 10 years, though more than 1.2

kg/m3 of chloride ions had been present near the reinforcement after the first 3 years.

In the marine environments studied in these experiments, reinforcement corrosion was most intense in

the splash-zone specimens up to an exposure period of 10 years, followed by underwater and

atmospheric specimens. Reinforcement corrosion in submerged specimens started early due to the high

chloride ion content, but the low oxygen supply inhibited

its propagation.

The time to onset of

reinforcement corrosion in atmospheric specimens was long, but the high oxygen supply may lead to a

higher rate of corrosion than in submerged specimens for exposure periods over 10 years.

3

.2 Effects of cement type

a) Compressive strength

Figure 17 shows the time-related changes in compressive strength of concretes made using OP, SR, and

BB cements. When submerged, SR and BB specimens began to lose compressive strength after the first

3 years as in the case of OP specimens, but at 10 years, they were both 5% higher than the values before

exposure. The loss in compressive strength of submerged SR and BB specimens was less than that of

OP specimens.

(b) Underwater

3

o s p h e ric U n d e rw a te r

e

o

A

A

n

6

Exposure term (years)

Exposure term (years)

Fig.17 Time-related

C e m e n t A tm

zon

O P

BB

SR

Changes in Compressive Strength

-100-

of Concrete Made with Different

Cements

b) Pore volume measurement and powder X-ray diffraction

As shown in Fig. 9, the total pore volume of SR and BB specimens submerged for 10 years was higher

near the surface (2 cm from the surface) than in the middle (8 to 10 cm below the surface) by

approximately

10% and 5% in SR and BB specimens, respectively.

Whereas the total pore volume of

SR specimens showed a similar tendency to that of OP specimens, BB specimens exhibited small losses

in total pore volume, as their low initial Ca(OH)2 content limits the leaching of Ca(OH)2. This

presumably explains the smaller fall in compressive strength than with OP and SR specimens.

Powder X-diffraction

revealed that the diffraction

intensities

of Ca(OH)2 near the surface (0 to 2 cm in

depth) of SR and BB specimens submerged for 10 years were low, as with OP specimens, suggesting

that it leached into the sea.

^ -v U . O

^

<u

ァg

o

o

o

<^

T <o3

ITg

n

」 >

to o

o .6

\

\

ァa

E n v ir o n m e n t

C e m e n t A tm o s p h e n U n d e

rw a te

zo n e

o

O P

B B

A

A

SR

D

0 .4

o .2

(D

o

a

c) Chloride ion penetration

Figure 18 shows the state of chloride

ion penetration in specimens made with

different cements and exposed to the

marine atmosphere

or seawater.

Similarly to OP specimens, the chloride

ion contents in SR and BB specimens

were higher in submerged specimens

than in specimens exposed to marine

air. In the sea, the chloride ion content

in BB specimens was higher than that

in OP specimens near the surface, but

lower beyond 3 cm below the surface.

The chloride ion distribution

in SR

specimens was similar to that in OP

specimens in all environments.

1

3

5

7

Depth below surface (cm)

Fig.18 Chloride Ion Penetration of Concretes

Made with Different Cements

Figures 19 and 20 show the time-related

surface chloride ion concentration

and apparent diffusion

coefficient

with approximation

curves, respectively,

determined from the distribution

of chloride ion

content using Eq. (1). All cements exhibited small changes in surface chloride ion concentration after

the first 3 years of exposure. When exposed to marine air, no marked differences

were observed

between cement types with regard to surface chloride ion concentration at 10 years. When submerged,

however, the surface chloride ion concentration

in BB specimens was 0.95% (around 21 kg/m3),

whereas that of OP and SR was 0.60% (around 14 kg/m3). The apparent diffusion coefficient

of all

cement types diminished over time. SR specimens exhibited apparent diffusion coefficients

similar to

OP specimens up to 10 years both in marine air and underwater. The apparent diffusion coefficients

of

BB specimens were similar to OP specimens in the air, but these were lower when submerged,

illustrating

BB's effect of inhibiting

chloride ion penetration throughout the exposure period.

d) Reinforcement corrosion

Figure 21 shows the time-related

changes

specimens containing different cements. The

content in atmospheric specimens. In the sea,

OP and SR specimens leveled off after the first

increase thereafter.

in chloride

cement type

the chloride

3 years, but

ion content at the reinforcement

depth in

had no appreciable

effect on chloride ion

ion concentration near the reinforcement in

that of BB specimens continued to gradually

Figure 22 shows the changes in ratio of corroded area over time in concretes made of different cements.

Corrosion in submerged BB specimens commencedlater than in OP specimens, and its area was found

to be smaller than in OP specimens after 10 years. The corrosion ratio of submerged SR specimens was

smaller than that of OP specimens up to 6 years, but converged at 10 years. In the atmospheric

environment, no appreciable

differences

in corrosion ratios by cement type were observed after

-101-

exposure for 10 years. In other words, within the range of experimental exposure, BB had a certain

inhibiting

effect on reinforcement corrosion in submerged specimens when compared with OP, whereas

SR was similar to OP in terms of corrosion-inhibiting

effect.

1 .2

( a ) A tm o s p h e ric z o n e

*」

o

C e m e n t C a lc u la ted

v a lu e

o

OP

A

BB

1 .0

*

8

8 0 .8

'S >+-<

B =CTJK O I

5e SE O .6

o

ァ

"

sw

h

a

c3

se

(

A p p ro x im a tio n c u rv e

C o (t) = 0 .2 2 (l-e -- -55 t)

C em ent C alculated

value

o

OP

100

IS

» I-I

C o (t) = 0 .2 2 ( l-e -1 -17 ')

n

SR

a ) Atmospheric zone

£j

x

S

Q

O -4

A

D c(t) = 9 .7x lO

A

BB

SR

C o (t) = 0 .1 7 (l -e -- -'70 t)

A pproxim atio n curv e

f

D c(t) = 6 .7x lO -I '

D c(t) = 12 .9 X lO f

n

I

0 .2

A

u

uo

o

1 .2

( b ) U n d e rw a te r

oocd ^" **

( b ) Underwater

1 .0

ォー>

CO

ァ

rca;

oc

S o .8

uo-c

8

d

1

- -6

&

0 .4

^

C e m e n tI B C S a ulcS u la t e d

O P

100

A

X

BA ,

A

A p p ro x im a tio n c u rv e

D c ( t ) = 2 1 .3 x l O

A

B B

D c ( t) = 8 .2 X l O

S R

/

t

-I"

D c (t) = 2 4 .8 X l O " - t "

*

/

D

//

0 .2

'

X

, i / l

'

A p p ro x im a tio n c u r v e

C o (t) = 0 .6 3 ( l-e " * " )

1

2

3

4

5

6

*-»

o

§

£

Q

C o (t) = 0 .9 6 ( l-e " " ')

C o (t) = 0 .5 9 ( l-e "* " )

SR

r "i

0

15

x

à"a ^

x ' -'

'

C e m en t C alc u la te d

v a lu e

OP

A

BB

7

8

9

0

10

1

2

Exposure term t (years)

Fig.19 Time-related Surface Chloride Ion Concentration

with Approximation Curves for Concretes

Made with Different Cements

0

3

4

5

6

7

8

9

10

Exposure term t (years)

Fig.20 Time-related Apparent Diffusion Coefficient

with Approximation Curves for Concretes

Made with Different Cements

.4 r

S«

8*

w

c

0 .3

°

5

813

I1

<DE

3^

cd

CD

S

'O

CD

TD

0.2

21-

g

n

0.1

6

0

a

lh

3

6

10

0

Exposure term (years)

2

4

6

8

Exposure term (years)

Fig.21 Time-related Changes in Chloride Ion

Content at Reinforcement Depth in

Specimens Containing Different Cements

10

0

2

4

6

8

Exposure term (years)

Fig.22 Changes in Corroded Area Ratio Over Time

in Concretes Made with Different Cements

102

10

4

. INVESTIGATION INTO METHODS OF ESTIMATING CHLORIDE TON CONTENT AND

REINFORCEMENT CORROSION

4.1 Estimation

of chloride

ion content

If the apparent diffusion coefficient

in Pick's diffusion equation were constant and independent of time,

then concrete's resistance to chloride penetration

would not change over time. However, the apparent

diffusion

coefficient

evidently

changes with time, as described

in the previous chapter. Concrete's

chloride penetration properties

are therefore variable with time. The apparent diffusion coefficient

calculated from the accumulation amount of chloride ions in the concrete after, say, exposure for 10

years does not represent a property of the concrete at the 10 year point, but is rather an averaged

property for the period. As noted in Chapter 2, the apparent diffusion coefficient

thus determined will

include the effect of chloride ion penetrability

prior to measuring the chloride ion content, including the

early stage during which chloride ions penetrate rapidly into the concrete.

Figure 23 shows the chloride ion content distribution

in OP specimens exposed to the underwater

environment for 10 years as estimated from the surface chloride ion concentration (Co) and the apparent

diffusion coefficient

(Dc) obtained at 1, 3, 6, and 10 years using Eq. (2) and (3), respectively.

Whereas

the estimated chloride ion distribution

differs widely from the measured values when using Co and DC

data obtained at 1 or 3 years, it agrees better with the measured values when using the data obtained at 6

years. This is because, when calculated using Eq. (2) and (3), Co is lower and DC is higher before 6

years than the values at 10 years, as shown in Figs. 12 and 13, but these values converge at around 6

years and thereafter.

Figure 24 shows the chloride ion distribution

at 1, 3, 6, and 10 years as estimated from Co and DCdata

obtained at 10 years. The small Co value at 1 year led to a large error between the estimated and

measured values. At 3 to 6 years, the estimated chloride ion content was lower than the measured values,

due to the DCvalues being smaller than the actual values.

These results indicate that the accuracy of estimation

can be improved by using Co and DC values

obtained after exposure for the longest possible time span. Conversely, DC obtained from a long-term

experiment may lead to underestimation

of the earlier chloride penetration.

0 .8

C o e ffic ie n t

E t e x r mp o s u r e C o

D c

C

0.7

ement : OP

Envi ron ment

: Underwater

(y ea rs)

D

0.6

E s t i m a te d

§£

O

o

v a lu e

0.5

6

1 0

M

0.4

B

3

e a su r e d v a lu e

(%

(X l O

c m

0 .2 2

2 1 .3

0 .4 6

9 .6 6

0 .5 8

5 .8 6

0 .8

C h lo r i d e

io n

/s) c o n te n t

4 .0 6

0.6 2

(a fte r 1 0 y e a rs )

0.7

ti

H

0.5

0.4

0.3

0.2

0.2

0.1

0.1

3

5

7

Depth below surface (cm)

Fig.23

Chloride Ion Distribution

at 10 Years

Estimated from the Co and DCData

Obtained at 1,2,3,6, and 10 Years

E x p o s u r e M e as u re d

te rm

v a lu e

(y e a rs)

D

n

A

3

6

n

n

0.6

0.3

1

Cement : OP

_

Environment : Underwater

1

3

5

E stim a te d

v a lu e

7

Depth below surface (cm)

Fig.24 Chloride Ion Distribution

at 1,3,6, and 10

Years Estimated from Co and DCData

Obtained at 10 Years

103

In actual practice, a surface chloride ion concentration and apparent diffusion coefficient obtained from

an experiment over 5 to 6 years appears to be adequate for estimating chloride ion penetration after a

relatively long exposure period of more than 10 years, as the values have nearly converged by this time

and the resulting estimate falls on the safe side.

Figure 25 shows the chloride ion distribution

in concrete made using OP and BB after exposure periods

of 50 and 100 years as estimated using the above-mentioned equations for estimating Co and DC. When

BB is used for a typical underwater marine structure in which the reinforcement cover is 75 to 100 mm,

it is estimated that the chloride ion content is held to a low level at near the reinforcement even after

100 years, and that the chloride content is lower,than with OP.

i

.o r

E nv iro nm en C em ent Y ears L ine

^

0 .8

|-

O P

U nd erw ater

BB

I80*8

50

Co

(% )

1 .2

D c

(X lO

0 .63

cm

/s)

TCL=

8*

1.2 7

«

:

100

0 .63

0.77 3

50

0 .9 6

0.5 73

'-^

ID

100

0 .9 6

0.35 8

1-1

-i->

u

n

cd

« o

o f

o 3

Ss

C S

c

Q

.2

0 .4

J2

0.8

0.6

>.

<D

3&

° 2

At:)

i.o

H

g8

0 .6

V/Ch+Clm

l(i=iv

2

"°

0.4

C

u 8

0 .2

0

5

10

15

Fig.25 Estimated Chloride Ion Distribution

after Exposure for 50 and 100 Years

.2 Estimation

1

Exposure term (years)

Depth below surface (cm)

4

0

Fig.26 Calculation Method for Total Chloride

Factor (TCL)

Ion

of corroded area of reinforcement

The ratio of reinforcement corroded area in concrete exposed to the splash-zone environment for 10

years was around 25%, and there was no marked profile loss. Nevertheless,

corrosion-induced

cracks

were observed. It follows that even a relatively small corroded area ratio can threaten the durability

of

reinforced concrete. The authors therefore attempted to estimate the reinforcement corrosion ratio as an

index of the durability

of reinforced concrete.

As shown in the previous chapter, reinforcement corrosion can propagate even while the chloride ion

content at reinforcement depth scarcely increases. This suggests that the degree of corrosion cannot

simply be estimated from the chloride ion content at a certain time. Though oxygen supply should be

taken into consideration,

the environmental conditions selected for this study were limited, and the

water-cement ratio was equalized to estimate the corroded area. As shown in Fig. 26, the sum of the

products of the mean chloride ion content near the reinforcement multiplied

by the exposure period

calculated at yearly measurements is defined as the total chloride ion factor (TCL), and is calculated

using

Eq. (4).

-104-

n-i/ri

TCL=?!

where

61

+n

'

2

\

i+1"AtJ

(4)

V

TCL = total chloride ion factor (%à"year)

Clj = measured chloride ion content at z'-th time increment (%)

At; = time interval between measurements at z-th and (z+l)th time increment (years)

n =numberof measurements of chloride ion content

Figure 27 shows the relationship

between total chloride ion factor and corroded area ratio for concretes

made with different cements. In the case of OP, the total chloride ion factor at the reinforcement depth

in the splash and underwater zones is 7 times and 5 times that in the atmospheric zone, respectively,

after an exposure period of 10 years. A linear relationship

is observed between total chloride ion factor

and corroded area ratio for each environment. As the total chloride ion factor increases, the corroded

area ratio exhibits an increasing tendency. Corroded area ratios of up to 30% can be estimated to a

degree from the total chloride ion factor, if the environmental conditions are known.

In the splash zone, the same total chloride ion factor leads to a higher corroded area ratio than

underwater. This suggests a strong effect of oxygen supply on corrosion propagation. Despite the high

oxygen supply, corrosion is retarded in the marine atmosphere due to the low total chloride ion factor.

30

U

nderwater

30 }-

a

E nv iron m ent O P B B S R

S p lash zon e

A tm ospheric A A A

zone

o c

U nde rw ater

C0

-g*------:o

\3ndetwatet

_.

--^r%SS)

1

Total chloride

ion factor TCL (% à"years)

Fig.27 Relationship between Total Chloride

Factor and Corroded Area Ratio

5

. EFFECTS

CORROSION

OF

3

6

10

1

Exposure term (years)

3

6

10

Exposure term (years)

Fig.28 Time-related Changes in Corroded Area Ratio

in Specimens with Cracks or Construction Joints

Ion

CRACKS AND CONSTRUCTION

JOINTS

ON REINFORCEMENT

Figure 28 shows the time-related

changes in corroded area ratio for specimens with induced cracks and

construction joints. The state of reinforcement corrosion in cracked specimens after exposure for 10

years is shown in Fig. 29. Corrosion in cracked beams in the splash and underwater zones began earlier

than in uncracked beams, but eventually led to corrosion ratios similar to those of cracked beams at 10

-105-

years. When the initial crack width was 0.05 to 0.1 mm,the cracks did not significantly

corrosion up to 10 years in any of the environments in this experiment.

accelerate

Figure 30 shows the state of reinforcement corrosion at 10 years in beams having a construction joint.

Corrosion tended to start at the joint in all environments and was concentrated near the joint up to 6

years. By 10 years, however, corrosion had propagated to other parts of the reinforcement. Nevertheless,

the corroded area ratio of beams with a construction joint was similar to that of monolithic beams at 10

years in all environments. Accordingly,

properly treated construction joints may not significantly

accelerate corrosion in marine environments.

Over a 10-year exposure period, the splash zone is the harshest environment for concrete with minute

cracks 0.05 to 0.1 mmin width or properly treated construction joints, followed by the underwater and

atmospheric environments. In this respect, cracked and jointed concrete is similar to plain reinforced

concrete.

Splash zone

Corroded

area ratio

[Lc<|

Underwater

: 20.9%

|u=a|

Corroded

poi]

area ratio

^ "

: 5.2%

pan

isr

TRT

4 .2%

Atmospheric zone

Corroded

area ratio

: 2.6%

[fag

Corroded

peg

area ratio

: 0.3%

!"="!

1

s

M

Inland

/

^

y

1

2 3

r>

o

l >

/

s

w** . . - t

be d

Fig.29

( )

¥

*l '

t*. f

ォJ

- .,

0l n .= 3n l%

State of Reinforcement Corrosion in Cracked Beams at 10 Years

Splash

zone

Corroded

Constructionjoint

area ratio

Underwater

: 28.0%

Atmospheric zone

Corroded

area ratio : 5.1%

Inland

in

El

Corroded

Corroded

area ratio : 1.9%

area ratio

: 0.5%

Fig.30 State of Reinforcement Corrosion in Beams with Construction Joint at 10 Years

6

.CONCLUSION

Concretes made using different types of cement and also concrete samples with induced cracks and

construction joints, were exposed to various marine environments for 10 years. An investigation

of

-106-

these concrete revealed the following:

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Whereas the compressive strength of concrete scarcely changed in the marine atmosphere over an

exposure period of 10 years, that of submerged concretes tended to decrease after the first 3 years.

In the marine environments selected for these experiments, the rate of chloride ion penetration was

highest in the splash zone, followed by the underwater and atmospheric zones.

In the marine environments selected for these experiments, the rate of reinforcement corrosion

propagation was highest in the splash zone, followed by the underwater and atmospheric zones.

Type B blast-furnace slag cement was found to inhibit chloride ion penetration when compared with

ordinary portland cement. When the same concentration of chloride ions was present in submerged

specimens, the propagation of reinforcement corrosion was slower in specimens made with Type B

blast-furnace slag cement than in specimens made with ordinary portland cement.

The surface chloride ion concentration in the diffusion equation tends to increase over time, while

the apparent diffusion coefficient

of chloride ions tends to decrease. However, these changes

become less significant

after the first 3 years. Both surface chloride ion concentration and apparent

diffusion coefficient

are strongly affected by environmental conditions.

Changes in the surface chloride ion concentration and apparent diffusion coefficient of chloride ions

can be predicted

using approximation

equations. Long-term chloride ion content is roughly

predictable

from the surface chloride ion concentration and the apparent diffusion coefficient

if the

type of marine environment and cement type are taken into account.

The ratio of reinforcement corrosion was found to correlate with the product of chloride ion content

and time in each environment. Corroded area ratios of up to 30% may be estimated to a certain

degree using this index.

It is considered that properly treated construction joints and cracks of up to 0.1 mmin width do not

significantly

accelerate corrosion of reinforcement in any marine environment.

Reference

[1]

Ohtsuki,

N., Mori, Y., and Seki, H., "Some Consideration

for the Chloride

Content of the Concrete

in Marine Environment", Proceedings

of JSCE, No.332, pp.107-118,

1983 (in Japanese).

[2] Miyagawa,T.,

"Early Chloride

Corrosion of Reinforcing

Steel in Concrete, Doctoral thesis

in

Kyoto-University,

1985.

[3] Ohtsuki,

N., Yokoi, T., and Shimozawa, O., "The Influence of Chloride

on the Passivation

Film

Surface of Steel Bars in Mortal", Proceedings

of JSCE, No.360, pp.111-118,

1985 (in Japanese).

[4] R.D.Browne: Mechanism of Corrosion of Steel in Concrete in Relation to Design, Inspect ion and

Repair of Offshore

and Coastal Structures,

ACI SP-65, 1980.

[5] Maruya, T. and Uji, K., "Prediction

of Diffusive

Salt Penetration

into Concrete", Proceeding

of the

Japan Concrete Institute

Vol.ll,

No.l, pp.597-602,

1989 (in Japanese).

[6] Takeda, N., Sakoda, S., and Sogo, S., "Estimation

of Chloride Penetration

into Concrete Based on

Exposure Test in Sea Environment",

Proceeding

of the Japan Concrete Institute,

Vol.13,

No.l,

pp.595-600,

1991 (in Japanese).

[7] Takewaka, K., "Arrangement and Analysis

of Already Surveyed results of Chloride

Contents in

Concrete Exposed to Marine Environment", Collected

Papers 43th Annual Academic Lecture Meeting,

Part 5, JSCE, pp.36-37,

1988 (in Japanese).

[8] Hamada, H. and R.N.Swamy, "A Discussion

on the Amount of Chloride

Intrusion

into Concrete in

Various Marine Environment", Concrete Research and Technology,

Japan Concrete Institute,

Vol.7,

No.l, Jan. pp.ll-22,

1996 (in Japanese).

[9] Katawaki,

K., Moriya, S., and Minosaka, H., "Character and Method of Measurement of Saline Air

Coming from the Sea", Journal of Prestressed

Concrete, Vol.27, No.l, pp.68-73, 1985 (in Japanese).