(Translation from Proceeding of JSCE, No. 538/V-31, May 1996)

advertisement

CONCRETE LIBRARY OF JSCE NO. 29, JUNE 1997

EFQERIMENTAL STUDY ON REVERSED LOAD-DISPLACEMENT BEHAVIOR OF

RC PIERS USING LARGE-SCALE MODEL

(Translation from Proceeding of JSCE, No. 538/V-31, May 1996)

._.‘.._.\r.

K

1;-_-1-9

V-rev-1-V~V

.;=:=:>.=.$;E‘-:2

.1:-:¥:=;V:=:~V:=;1:I:I-I;-V1-'='V=:Vi?:=:?:i1V:=:Vr='‘=-11-11%

:1:1:=:V:$$=:lr=:-:V:tI;:a11E1

$1113:-:3:1:Xi:i1T:i:1-i-7~;I:fv:¢‘;$;1§;;;1;1;=V<V3<V'5rVI-;"Vl

!;:VVV;:<:<§~'a;V-\;-;1;:;:;:;:,I;.-:;:-:5;

../. .. _. .

.

.....:-5;

.5/:;:V-.‘

\ ;:;;1:-15:,-V

V<

V. .;35V5I'

-V.-:--V::V--' :11" -

I314?21$V§§§1I3;2§=£5{3E5.i£5E1§?££5;V552125???3V§V€?E5E}¢E=E3E=?;-3%

V;-;.V-.V.,V_,V:;<;_;;:;;;;2;::.,._.,en~a:V:g:;¢::g.Vs;.gV;¢;;;V33.1V=VIVVV1-<1:;g@:;;;:gs:r.,,V

.V'IV';>_z.;2:}1f:;rj:_:5§i:1:§r§Vj:§;§:?5:§:§:?:§:1VV*{§:§:V§ :V§i5¥:.-:1:1:l:

V:-V:-:-V-.:-:-:-V~:-:.:-:4-;.-.;V:V ~-f

:-:<:-:V:<:.V:-:~;V:~

.1-1‘-E13-‘E1. .=E1E:E1i1==V'\i1E1¢'1‘V-' VV1‘~'V11'Er‘V-'V€=“‘:=V1V:‘i§l5¥Ii;1E""Z5‘IIE'{V‘1§EI§IE€:IE1iI§IE1E-E’

€z;V£§5§V§=f.Vt'1"'‘1‘ ‘~1t?VV%%VV.

séV"V.‘;.?"'.V''.lV>:¢V1;V.VVVt.V_1:1..V_;V;.;:;z.l

:'.i:?.1‘2E:lslz-ai=l; is1¥.i.%.iEizE§-.;:;1¢:;:;

235;

.V;-:V:V:

. :‘VVi‘;;'i:I.:1.Vl

.

.V~.---3,-1-'t'—,VNV;-1::-:V;-:

={1]V--'-4;-,5-.~_v,q-,1my~"-I . _, >_ < t( \".';

=;-:==;:-;1:‘~.-.:1¢V-:-:V:'»‘-V." ,-V =-$r:'VrV;=r.V'V.V';V(V>V:/V-V:4;-:-:<</as

_.,-.'§§;V:VV.§:1:;;1§-5;~?;,:V

;:;'.11.-;V;=:V§;2g:;;Vj.

-‘V;'<‘<=:1;I;=I-i-5 -‘.VV.V:<V>:~:-:V‘_:;: I .; ‘-.~.‘;:-VVVV1:7:~';:V:‘:'<

"$1.?"-:1

/V;3l3>il$:1E‘V:fE?.V§V‘V‘.'.V~“V

V-V':i'~=:i5??5V$i.

V:‘.::VL-: =:=1:;'_:V;;;;.r 1'>_$:,:::<L:;‘:':\"'-‘

i;-:-:'.;:)‘

2 <'i2,,-i-‘V-V-V

V VV V4V _I_;‘;:V;1:-1‘/.;;~:~ <.-~-.

=i--V=5V1-353 in--' <-1-4-=;-;2V;V:-:-.:V;.V-V

A:I-2*?-§?V.IE1‘:VE1’Z111.”V1"

V4 1' V1; V-- 1- V EV":1';*§1iV‘.'VEI.

VV.V.V:V:.V'.-V-1;13112:;

.‘\

V ~V

- -. -as-&=

, V. 15¢;V; ¢z;; ¢V;1.-V.;j__ _ ':;-1;;;j‘~z.&=5=§§§é<§é2=V'§E=2:2-<-3523?»

V-3 :;:1-=-‘ - -=-V-¢==;.V=;.V;.;<:=;. , ,

V

.

- - : .- . - . ;_ _.

- . ' - -. -'. " _.

-" - - - -

'.

1

. V 5:}?.?:€1:1:V:I:V'?=

' 211:-r‘ ' -' .-j,‘;:§-V:-:;1V.,;.V V

V-i- " ~ V- V-- VV

I. ‘

- '- - -13‘?

V V

V

V‘,.'i=VEi;V:-:;;.V_'

%VZVI _I _" I“:_ __f V: 1' . -:“V" " " ~V

ViiV=:V VVV VVV VVV

-.V;-1-

.

;‘:=:1f;:3:,V;£-VjV;‘_ V1V,:;:;;;s;;.g.;:_:;;;;;;.V;;.1.i,. I:;.§.;§.§:;:§;§:E§;;:§;{;§:

.V

;:jV 1.1 _.=:.-1:1; 5.-.--j5;;;_ .V

.

"-: :- -- --' : ' 1! ::‘1'":-:2:::;:;;:;I.-V'.‘.:

1IV§‘VE=E1%1;:*§:.'V_ .1.-:;:;;V::lV

V:'.V:=;'VV.;:; VV;;

' V,::V-1,::-..;:3;.:r:V;-:1:-:5:-:-:-:<1:-r-.-1:11‘:-:-‘;*

.,;VV__.V:VV;.;;;;;==:;;;§¢;;;;1:15¢;=g1===:===-;VV-;V;=:.=-1

V VV V V VV

VV ‘V.V1.~:1§§'

.>.V'<I:r:;:r-V

V_.VV-:;.‘{¢

-;.V1,V1<=;;/ V. V I . VV V .V V .

: ':~:V:»~V' .1' _. _

- "V“’

- V‘ .;: - . .- - - -V;-;V:-:~>:1:V:~'V*-.~-VV:-:~:V:1

(ii-C‘Z‘;“':v:_:-:.:‘g:"':<.:-El_:.:‘;:‘l'-C‘!:‘>.‘ .: V VV. VV V. V V. ;:V--;-:/~$-V;-;-1-:-:~ .- .-- --V VV V‘V.;¢-/5'-:V

V , . V VV . V

;-. ~:

V

,. V V V V.

>.;.;V;.-.,

. .V:-Y?‘

V .V V.

Y

»<X<

-11' I-IV.r.--.VI7BE-I5;E~:l-VII?Vii ‘I11£3E5§§-3~§Vr1$13&1?i'£VIVE-RifiziaxiSE5Vi15V{$Ei3%i?Z¢5?E€-EIEI§E1ZVE‘§1I¢.1.‘E'I1ii :1-1 I ‘.5

i V ' II 3-'i=§IE5Z52'.-E521‘“°3“““““"$"g'<'

-i ‘

’€;E=:I.V‘

V’ ".7 V.

f;I

-'

-;iFV-‘:':$i2I:i:1:55%IEZ‘E‘;§:':{'E1{1§;E=}:§:i:3;:}:§:5§:;11:1:§:§:§!§fi2:;§!E:?$:§Z:1:Z:§1?§:{:i-j:§":1"1::..-.-‘

VV

i

E

V

V’

-;'.I'I::I

‘

V

;‘

V

:_1:.?E;:F;=r'

:

.:;r;;-.-:

..V.;q_V.V.{:]:I-V.;:-:;:1:V,

_.‘;:_"_.-§_:V.i‘V11j.V:-"%§{:§:§:V:§1{:‘.1:'{3}‘V:Vr,:Vr§‘j:?:'$rIV';I'V:?:V:V:1:é%21:1¥i‘§fi1:1:I:I§V:fs1:I-I1I{I:‘:'E‘§‘§'1'3‘§;i_1'_I. ;

V VV

VV VV V V1VV11V.V1EV;4 1.V1:>;'E-1-=r.V;.§<;==z=>s;-=1;=;=-1111.11"E.;==I;=§V. V V V: VVV VVV VV V

;' 1;"-';V»';'V";1,:_::5;‘_; ::_:V';:V.;VV:-'V:;g¢:;§;;:;1;;.;.;:VV.;V;V_VV_VVV.;;VV.g.§_5;;;;‘;;g;§$;¢tg¢:;:;;:;:;:;:;;;:;:;:;:;:;:V:;:-11-: ;;

VV VV

.V V

;;.;.§.;:;:_gV;:;1gt,:g';r;:;:;E;:;L;.;%V;r:;=¢rV'

V VV VV VV VV .V

;.;.V_.;;.;.V,.;.;.;.-.sV;.;.V.;.;.;.V;V¢a.;;,;.;.V.V.;V;.§~:-.~.V¢.V.-,Q;

V V, V V V V V- V V .VV V V ,;.-:;.;.;

‘;-s.-,

V-V.-;V;-;-.;--_-;

-;- .-/V:;.V.V..: V . VV. V. ;V VV V VV .V V

,:V_._V;_:,V_,._‘___/V,._..C,>_,V:_;..{,;,¢___,V,_._._._._._:Q;.;

.,_-~__ “WV:V.~;:aV:V;i:V:V;V;~:V;.;V;V;V;;;V;;VVV,VV;.

V;.V.;.V,;.,;.;.;.;.;.;.;.;.;.V.V.-.V.;.;.;.,;.V.-;V.-‘

A.;.,;V;;._;.;;._V_VV;,;VV;V-V1M.-~

..

..

my

V

\

_§

..

.

.

...

V..»

.

“MA

/..

.

.

.

):'4*:|:':':/"‘|“»‘;[1‘:‘:§£§:\:.:|l,:':I|:-L|:':>;|:‘:|:‘:b§:%:%%'>€_>:2:::\::€"‘,I-_YKi]:I:I:l(ISA:-i4;4:l‘4:A‘l:l:l‘l‘\‘1‘:::l

.V VV V V V.V VV .V VV _<;.V ~{.;.;.gV

,4.¢,;_;;z;,

.-._;-;V;V;VV VV VV 1 V V V

.'VZV:1EI’V“i‘V1155V.Vf(f?1}I=I1535132I§=3rVr=f<?:¢i3§$==T:V:=1V'V'VV'rV:V"$15E1EflI5IEVi1=r~r1'£V1'S»=1~5'1‘

'

' V VV I I VIV.~>i1ZT' ?V1i=E<E;V‘VV' .VV VV l IV VI

1 V

‘E-E‘VI.55:5:51::E5EV?IE5}3E:¥‘i3E5€5‘§I15‘7";I

V VV 1V.V __.V.,.;;t§:;.;:>;15;:§;:g:;

VV .VV V-¢:€IE1iiE=i=Z

VI VI VV VV VV;V .

127::5:;4IQi§*=12gV2%:12{:é::::2::§:%=::fi:a$:-I.

:_‘.V:-;-.VV‘.V_;V;.,: .1: V; .V VV:';II’.3§1"?3‘3E155EII1E5§V.Ii5.

.;.;.;.;:;.;.;V.;§;.;:;,;s:;;5;tg;;;;4;:3:;<5,.

VVVV

._ -<§;.'4-;¢.V-<q-fl_- _ j"‘jI"'IE.-V

_ .V~,;;¢:;:-z-;5-,~;V.:;VVV

V;>;V;.V;-_V:-',;V;I-;.;V;;;1;';:gn5:;1;1g.;:;!;1g:§:;1 ;;:_:_. V.VV:V>V;_; V:-V.V. V. .V

1r1¢t;i;V;:::1f;.;e;¢§;§:;1$;t;a=;:;<1s;=;$=see»;

-._;-;-:=:§1:1:=:==¢:1a=.-I:V:¥:=:=:

\V

V

VV

;;:;:;:;;;;;:;:;V:;g1;:;:Vg:;¢:¢;;:;;,15_;;§;:5q:;;_V ;;

.V V,__.;:;;;.;:;:1:;1;§:;.¢rV:;:;;V:;._ag:;§:;:;:,:;:;;:g;:g:;§;:p;;;:i

,55$I;25-IQ3!;.,5;l§;£gEZ;?2;I:J;C;!;$5¢

' »';V'V.;V,V;V'~:-fr‘ - -- -fi:!s¢:§!.-fii25:f$:-:2!:e- -VV V.

‘Vs;5;<.55;1;:5;§:;:;I;:;1_5:5&2;g:;;~:;.1:-pg:-1-.-:V:-:_.-'

,§:1§¢>;1,V‘€s;

Vs:3:6-gar?'%:g:;:;g:1:~:;z:;:;;;:;:V‘;3;.

'

;:- _ V _' _- \---VV 3\§|YI"\I

.. . VV. $11113371;I;i1$9211131;QZ5$g2§§;$;3;!;t§;§:;$;:;

. .

¢.......<...

-‘V-‘:1: V_i.&i:=;Iq:1z;.=V;V;1-V‘ 55;:;1:;:;:5»:;:V:;:;::;:-:;:;ee;§-;-z:¥=:-:efisinzi

:V:=:-:»‘;e:'i!»:-:i:<'mi:-1-:-1>:;:¢;:V;;7.¢: .

- »-~ -~V:~ . - . .

‘iii-1:151-‘

,V-rVrV:'V:VV'V'V'5.1:‘ :1zit:;11:Y:1:??E¥i@1:1i1:¥§@:1i~S§$FEa15EE1£:§§$;:E:

-~*§5'¥“

- - . ._ -F41-IEVt-1-;"i*='=-='#i‘=$*%':E:tzinti

-=-V-=-:-:-:

.-.~V:==V:=-V:1:;=: 1: =tr:-;-a=>=VV:=:=:21:=¢=;==z==srs-=-a==-=<r-area-V==-=

‘VV:;=r=-=:a~=:¥====s;=: =-2=¢e=:=:V==$===¢Va‘

as

~~._..<~‘re"

.- . '

EIEII

:V:,.=;;;s;V.V

V .VVV; .V-r;:;V:;:V:;:V:»:;w;:;:;n-§;:q:;:;;:g¢c-z;:e:+:-:-:-:-:e::;'V;:;.;,;.;V;.Mgi;.,._V_.,V,_,,-;..-,rV_z-,--V

~:>.f-:~.k‘V;;>:-g:;:5;:;§t;:-:;:;15:5‘~:;I;lyi,<1

- tr» -.-'‘f<J:."|!f|\AQdlJ!:|"u:<:I4:§l‘v'

-:~';:;:g;:§!;:;._;.;V._=:-15;;§;¢.;;g.;V;.;r<.¢¢;.

i..,.;,_i;.i....,._._.;-,,-;:._a,.;¢¢.;,.gq.;;.g.;¢¢.;,

.. _ -1-;~

4\?\:/5;¢0';\l-'

=V

_1$~'.~IV?\,-In

1:|}4::I:;i

]~:u‘yin:-1{~5‘|';G'~‘<!i‘|kzfd-‘A4=.&4IiL_"."‘..>\li‘l'l.IAl-I-\-1.l5'I‘V5\‘4<.I‘Y-I-A'V‘I‘J.G|>

45¢‘! V -is

-- .- -. - .- fig.;.H.=V;aasg;¢.;.s;;.;¢.;qV;e;V;V-V;

1-;-;-'-‘,-V-:-;-;n-we.-,A-.+:-:-.V.<~.+.-_-:-!<V:-*

-.~.-:V.-:V:-:-:-:-.~.-.-ea-:<use-:a-:<---si-:<,-V:-::-V

:».:~:-s:-:»:;§-axes»:;a~:»:V;~:-:=:aV:V1-:35

V

-. \

,

\

\

I

v

vs

v

t

s

/~

~

Z -*

\

~ \

‘

‘ .»*

ta ‘)1.

9\‘

1 ~

>

. .

2- .'V~;i=‘;E;§V>"=‘<=zV§5sV:V:2 V1.V12-:¢§;2=E?5i5;1EVE1VX2155.-:I<I-_-_..I

>5--‘$l.~.l‘:a¢."V‘E1l3i31"'.

.. "VV~=~:=::;*

1-:Viz.V~;

,

*2;

- :1-.>"r?'T;¢“£1/313-IV-4VII.V..V;-._§ ‘i:1V1‘$?;1i:'1.v$V%}‘3=;'‘lfii’

.- §‘.1:V:‘V"1 ¢‘*'Ii-‘- -. .1 V’-V-I-¢ :‘-;!:f:1;1:‘-:-:V:V: VV:V1'VV

~V:1»V:I:I:V:-V-1VV:V:~V'.V.:-'-::=:- .

13%";5%;V151%E1E1E1E‘l=iV.13V'l§I‘ <‘.V"”‘=?<V:=VVV:1:E:1ZVE'V.'fV"‘.IV-1‘21?<~:---1i:- -1

*i'+;V~*V' :1=1E.:. I I-:~< _.;:,1,1;1

I=*VzI:Vi:€§:Fi=.‘:i‘¥'V;'

: =--I

"

»I.V;‘».I11;r;'<I;V:1:‘.V;VV.;;:1;;:;:;1:;'V,;V'V.-11;‘

V

4‘4\

.

'Jv‘VVV‘.m‘. I ‘ A‘V>I’\“‘l"§’J:_/l

i /~_|'>.*JV.-1~, c‘ \z"{I'r:V'\‘|V!:."iII*‘1V V

V1:-V.1:¢;:-W31:219:1<11:I<~1*:V:-:~:1s-:-:V:V;V’V‘;:==??¢J ~\‘r:§!-.r-V:-:s:vr.:;: V§;;;:;,-:,<;>'-1;;1,V;:_:=.5.V=";:;;V5:-;1;fi;:V;;;;g§.

_.

7:155 /5 :1:V:¢:V>V;-,:-:~-1'V 1.: :1. :';-‘VVVJ_VVI:-‘:1:?>'V=I"V‘- :4

<1->453:?;I:1:IV11=VV".VV1.»-'V.F;lEI;1?¥$f>’§§§?

. VV

4"' mu %:$">.’Z>'~'¢:-‘.'?:1:l1313.;V:-IiI-:;I;r-1;5:%<:;Z\?:V:§.~»V~V-- -VV/ V- - ~

»--~

-- V V

'<.V-:-:-;V:V;:‘ l@4:1E?5'515V“.‘ii‘?-V”-‘--"1

.... "/‘:-:V--I-IVV-‘-Pei’

""1rI=1!1‘:=V: V V V V '

VV V

V" V

V V. 1 I . V =?'- +'.VV ' YV

V 1 . V

. VV isk-:=;>.11;<1;:5‘§i:$11-IV*I1:7$:l.-;I$Er<¢.;.-:-?yqfiiii‘ :‘:V‘: V '

.. V VV V .V V V VV -~r XVI‘:,<4:1:~"VV~VV-1-:1‘VV?‘TV--‘V--1V*V'l¢<fVV-f-1?E<'V’I5'!5-2V:V‘/R‘? 1"?“ V‘ '

V V ' " V

'.

1-V*5‘3V'V‘?3>V'I51:'V'5=?V5?ii3151§V¥Y¢5‘f§iV'

V

VV

-'

.

. VV V .V V

-1->F'3?§;§;jVi1I-I?!VF‘?.-:1:I:E?5"I¥;V‘E1:5I§=I727?:€:iVf:I1?'?5. ;'11VV.V V V‘ 1' V V V V‘ '

1‘.¢Vf§>I=E:;>kE1,*V3=:Ii1'¢VVVE5§?V><;;;j._._;: -'-;V:1V;>V VV.VV 5:-.{._.5.:ji:§:j1?1§1‘V-,:*V--‘.11

V ' "

V V. V ‘V " .Vilfifiléfi¢§Iu§:1i€Ef‘§f$ii:I§,:7Fi'I VV V‘ ,

.

~ V --.15-Y§;<§:5:;2:ii5:;V£;V;w,?».$s:;1:;;?fi:§:=1Vi=jV;:

.V:-,V;-;.Vr;-1;1.r2i1V‘.j'"V-I-:1:_- ~; -I1V

VV 'V' V , V VVV‘ '. I VV -'J1V\zag:V;gV55;Vie-;V.aE§:>a%.;=;:;5§;:;:;=1:;>V;i£:g:;:§V

T'§'-5§-I~1~?:1:IV.?-1-.-11:1:-1-:01. 1' '-IV-/:-:I.V1:1€V:I;»:1:!:V:V:-V:‘

.1-VV;-V”'VV:l’I:I*I-115:1:215+?1-51$:$4-I<iV;1:V:-:3VV:'l<P:Vr¥:V'1VY ' V . ‘V V ' " V VV V ' -V.V 2:-'

V V. ,

, ... V ;;;.V ‘,‘A165'11‘-:>'_"{"l(;:€'-V7A‘I‘:‘:':‘§'f~('{|{‘:':':/>’|¢’r‘}

-;:5~14=:-:V'-lV1<<‘I<:V:-"VVZ-Pie;-1&5;VI-IV:4~;-:V%;fl'

V V .V V

. 1{K-5:1?-1-1-V-:*-:4.V:=V:-:V:V:‘-.

<-.<-.‘.;.r--.-,.5V. ,-VV-VVV:;,:V 1.;_VV;.;V:-;-;V:-;V;-:4-:1-V.-; 3, -;... V. . V - VV, V

-.;

V . -4 . . VV V. V.

V

ff,

“MM

5, -*.<

Q:.§>a‘-‘ $‘‘V’Vkiv/as

- .' ‘IVVV 3131125331;-1V.<!:I$:l::<I;=:I:-1VFifiV?§ii3¢i§:%:§:§E3f€E=}"=1 E1‘ 2': - ' . .V IVV I V"VV'-VV'.-VV'.‘-?E;'1V" §

V I VV

~&~$/M~1IES1;§r7*4‘<:

/R,

'-.= 1‘-- ", .' V7.2

:51;=;1;1;1:;$%$5:i:{:;:{:§:;r;:‘VE!51§;£i;Z2iiI-I‘2f:E.V'

1

:-i‘;..;‘:;.

.

1

.

.

VV

V.

V

V.

V"

*"5'

f

5g7IZI}¢§1_§’;%“f"}F"'

-- ‘ <11‘-:i=§'VVi£1T.I€‘V‘\IV=:';r-‘.V:-V:-:¢¢;11V:33:§;2g{§{:=;~21:1_.-... 1.

V- 4

V V V V .V VV':VII.-V1

‘J:;:f¢:2'<>.<’i:?:3:%¢:if:rk£2=:‘¢<

V V VV

-VV;V.-.1

'.

:V

é-2 'V:»*;;';*’V:-‘:I;1:l:I~V;V:5.}:V:{V§»:;:5;ZV1;r;1;';‘.I;-I:

.

V

VVV

.

,<>2=:>'iae:&;a:r;a2:;;V¥ . . V . V :. . VV VV :~:VVVi;2;i~:¢21‘z1s¢V;-2?:-:aV:V;5

-:4-V

V. V . .V .V V VV V . V .V V VV - ,V.-:V:VVV.;-..-1 “I=~'~:i. ;~‘<{9;-_-f-V~:—;/<-<<--:~:-:<

- -- . .- - .-- -; .. . .. ,.

V _ -re-.<‘_.;._,,V.""‘I<)Vj1f.‘V‘{1'-3.

:1/V-./f-- .=*<.1=<:4--:.<c~‘\°

V.V V V . V V V V V V . V VV VVV. V . .

;&

_

..

.~

.

.V~<§_

.

,,

.

.

..V

.<

V_.

..

V

V....

V- 1 .- V.

,-;

.;:_.;;»:V;-V-.;V--.4,,-;

VV

V .

V.V;:;:+;fi;1.--We-'-1;;Va V:-,--.

-’¢VV<;V:V:V.VVVV

V V

. . V

1 -' 5- -- .. ‘. '1»-::'2.1-1.1?»I:1;1.% ~"’5;1:5"-*- .1-i-:=.VV';VV‘V:‘.V--V " ‘I111?-:11 -E

V .V V; VV V. 1 VVV ‘:1::;:E.:¥-:;\ll::€:;:£:\ ':F.V'i‘fi'*<<.»<»,/'§§I313:V'VV117 V V VV VV

-- .. _'1'3.;:V.§;EIE§3EV?1:§?lfj;;5'

-“lj.1','_'1‘

=',J’V:".‘-2'31;

TVV. VV.V V IV V. .,V;V1V:=;;V¢:r;i

’V

='V‘V

I V V iVi

--2' -- .-.;;.;.

*i;I}{;§;-:-;¥;.<j-Z»;1I;_f~2;lVJ;‘j_iV‘:ii:2Tj;1;1:;1;:;;;Q.V.¢_>

.V!:-"{';¢.1:‘:;';-._I-1,;'<:=-.;-;;;._

¢:;>:I:'?:‘_:=V.}E:;e:*:t 5 fVl;1.-t»=f,’<.’4-:%{;4f1V<’V4%I,-I:TV'-' .-'\:;‘V;:;‘:.VV';V

V-=11;-:1;=:V:V:V-:V..; :V:

yd;->3;-1-1V

4 .-,;V;¢r%V:%15:eVs’:VMI;-V-<V.V:I:V;1;. ~ .

' '. -'

-‘ ~ . ‘I 1-1 ..I:"‘:i:i:5:<.l:=“ :V:V:V VV VVI-1;‘-;l_=.1i.1.?.VV1V'V

;¢;.-:-‘_-tang‘/,1: <‘* V_: VV§t_,_:

:1:§\‘::¢:_\l:[V\'.;4:;';:,'.f_;§':il>::':§E‘If'l5.;:lXi::E:§Q '- - -i-r;1;:,<A:1r»;:41;r;Sr»: ; -:1:1:1~.iV§=;=EV~“l‘.-‘~';IJT1751312112;!-(Viis¥:1;i:i7E;<V

:f:3<\駑¢3¢>$

VV . .4V~:¢;V,:;V:; V:-V’ V V

#1‘<-V-V~A’1m/».<.<E:=‘<¢;»1*1;-. .'I . - if./‘9.*f;1;>;;.

1- " - 1- V<'~-Va

1fi1>‘VV€éI;I:-'

~.»=v.-=3}.

1 \ 5'-:§§i‘§;;;:»:,-:;:$:§

-We-i\3V V-4 <

V

V1-- - /' -- -- '= - -V-V- - <

;~.;:;§$3§;>,E-$4.;-:#:}%-.=.;:{.»:V:'.?$;._¢V-:

}:<_:~?,'V:;;V:_',;'r;g1:;;._~32 ,-43f-4;

‘;z5V:;;.;=;.t;5;;:g:;a§;;V:{;:V:;'-;-¢:]:‘:?:A‘:};d1F :1 “ - _

, V .; -- '; gfi-1-‘:'5':I;i_€I-;?s‘¢!V‘;1155.31.21.-:15-Tgkii34:1!

.1->¢"i»<vj$.§;;.;:1:¢2‘ :‘v;4.‘~'*/:§a,:,$;t¢5'V;;;<;;:_~_._; '.

:?iVi‘IV.E=:i.E1V‘:V1;V~1:1;'?;1.T=VV.§:;:V:V.5?.i$$V=:I:V'$:i1F:;2~ I-1 »:V -;:.;-:;_.~-.,‘+;

Vere ex-' ‘ ‘-" .=i;r.:5VVI1iE‘».'5'V1E=-.VV.§§VVI@:“/5,1-:V:-z==V-1V

4 VJ

»:‘-'-=1-‘==%r<: $.=:=:;V'¢:~§-5 ’$"‘}V; ‘Xe;

<31.

‘.V"VV:V'.V:V:¢~VV-Vs:VV";.VV:V-Va_V¢<;.¢-:r.V:<, :;- .--= -- 1.1 --. '=..1V::a;V:-V:a:$;V;1V‘.:=: V.=-'.'~-V:V;V.V:==r.-VVVVVVV.

rVV VVVV’V‘V2VI—

V"-;:1V::V;‘=VV;:&V.;=.=;V1.~-V;VV.;V:IV:'-ismV*;:2=11.iVt=$.

_,~,_.;:;.;.;<,._'.~. -.-.. 1':-..:1:;s:I:V: :-14: -- -;V;,;;V:V‘

3 ,

V.'VV:V.=V;;V:; =:=-.;:I V-V;V.V ‘V--:1-'

.1V‘:1L<f~;ar;._¢~V:>.=;;

.'.:V:VV‘V

: ' gf.'v-'.~‘='-1-'$5V?<~2d-\}"cuv¢-1-‘

(V.<-.1.

V11 ,:<:,;>_._;\,-.;.¢.;-,=-;z»-v-:4‘:-'\:~:V-,

-<‘;1‘-V--VV:~-V:-\-V=--~1+»:VV_. .-.-_.,.\.fi V .-V ' - ' _ .- --.

3":-:<:>~!» - --1’-r ¢.".'~‘»’-'11-z/--;-1

-- V..VV.

4- 'V .;:V:.e=§g.

V~

-3»-:1

1: ~$‘~4"’. --- -- ._.,;:§2\,:,.;;.;;

§'§'1V;;‘r.'V.;>_i'j[;?§-:;‘V;E?;‘—1V§':-Q?7;;.‘$;§§fi5':fi§.;g‘i; _V -_‘ .-is-s1.~:

;:=_=;A :;.5; ; _ :- - _:;:,:=;V's=‘_e:;:;V;5:_V-.13;rm;q;§V§;(.§;;r-;:VrVV;;:1211.;

>¢ ah ,

‘xv ~

,

,5, 4.’ wit; 1 //0)

\{>‘§ ‘ ‘V =<»\

"5

/an

M‘: 93"’ -./>4’ 1

~

~

The sectional area of elevated reinforced concrete (RC) bridge piers is generally made small in

urban areas because of space constraints. The main reinforcement is then usually multi-layered. In

order to evaluate the influence of this multi-layering on the load-displacement behavior of bridge

piers, reversed cyclic loading tests were conducted on a large-scale model (1/3 scale) constructed

with the same reinforcement details with actual piers as well as on a small-scale model (1/l0

scale) for comparison. According to the experimental results, there was no serious decline in

ductility in the large-scale model as compared with the small-scale model. However, pull-out of

reinforcement from the footings of the large model was three times more serious than in the case

of the small model due to the multi-layered arrangement of reinforcement. This suggests that

reinforcement pull-out may have a significant influence on the behavior of actual bridges under

earthquake loading. On the basis of the bending moment-rotation relationship derived from an

analysis of reinforcement pull-out, fiber model based nonlinear RC analysis was conducted on the

large scale model with reinforcement pull-out taken into account as rotational spring. It was found

that the analytical result was in good agreement with the experimental result.

Keywords: ductility, load-deflection hysteresis, nonlinear analysis, pull-out of reinforcement

Kenji Kosa, a member of the JSCE and ASCE, is a senior highway engineer at the Hanshin

Expressway Public Corporation, Osaka, Japan. He obtained his Ph.D. from the University of

Michigan, Ann Arbor in 1988. His main research interests are the analysis and design of concrete

structures.

Kazuo Kobayashi is a professor in the department of Civil Engineering at the Osaka Institute of

Technology. He received his Dr. Eng. from Kyoto University in 1973. He has authored several

books and a number of technical papers in the analysis and design of reinforced and prestressed

concrete structures. He is a member of the JSCE.

Yasuo Murayama is a senior manager at the Technical Research Institute in Kajima Corporation.

He obtained his Dr. Eng. from Kyushu University in 1995. He is a registered engineer and a

member of the JSCE and JCI. His main research interest is the seismic design of concrete

structures.

Yoshio Yoshizawa is a chief at CTI Engineering C0., Ltd. He obtained his BS in civil engineering

from Saitama University in 1986. His research interest is the design of concrete structures. He is a

registered consulting engineer and a member of the JSCE.

—121—

1. INTRODUCTION

In earthquake-prone countries like Japan, the reinforcement details of RC bridge piers are

predominantly determined by the seismic load because seismic resistance is of such importance.

To date, a number of reversed loading tests have been carried out on the behavior of RC piers

under seismic loading by investigators such as Akimotoi), Kawashima «, Ishibashi 3), Osaka4), and

Machidas). These tests have clarified the failure pattern of piers with a conventional reinforcement

arrangement. Flexural cracks start to appear near the column end and they gradually spread over

the entire cross section subject to reversed loadings by the time yielding displacement ( 6 y) is

reached. Thereafter, when the displacement exceeds 2 d y, diagonal cracks begin to occur and

slowly form an x-shaped crack pattern as loading continues. With further advance, the cover

concrete starts to spall off, and the main reinforcement begins to buckle, leading to ultimate

failure. Clearly, the ultimate displacement of a pier is a complex function of such factors as the

strengths of materials, the main reinforcement ratio, and the shear reinforcement ratio.

Despite this complexity, the specimens used in past experiments have been to 1/6 scale at most, as

shown in Table 1, due to various restrictions associated with the experiments, typically cost and

experimental complexity. They are roughly 50 cm in width and simulate the cross section of real

piers only by the reinforcement ratio.

However, given the failure process mentioned above, it is clear that the arrangement of

reinforcement plays a crucial role in the behavior of RC piers in the ultimate state. For example, it

has been pointed out that if a small specimen, 10 x 10 cm, with only one reinforcing bar in each

corner is used in an experiment, a significant decline in load bearing capacity occurs as soon as

core concrete has been damaged, and thus the derived results do in fact differ from the behavior

of an actual bridge in its ultimate state). Also, the degree of influence of reinforcement pull-out

from the footing on the overall horizontal deformation, which is approximately

50% in small

specimens, is generally considered substantially

less in the case of real piers, because the

reinforcement diameter in real piers is typically

small compared with the cross-sectional size of

the column.

However,few studies have attempted to consider this issue on the real bridge level. Further, in the

case of elevated bridge piers in urban areas, it is feared that the ultimate bearing capacity may be

further decreased and reinforcement pull-out further increased under loading because they contain

a large amount of reinforcement to compensate for their slim configuration compared with

ordinary piers. To summarize, the reinforcement details of ordinary small specimens differ from

those in urban elevated bridge piers in the following points:

Table 1 Reverse-loading

inves ti gators

dimensions (cm) and the

number of specimens

K aw ashim a et al. 40 x 80X 240

:25

50 x 50x 240-250 :15

testes in the literature

mam

parameters

m am reinforcem entratio,loading

type,hoop tie ratio,concrete strength,

bending m om ent/shearforce ratio

35 X 150 x 100-200 :12

60 x 60x 130

40 x 60x 95- 155

:5

0 65 x 165-230

:6

bending m om ent/shearforce ratio,

tension reinforcem entratio,

axialstress,shearreinforcem entratio

O saka cta .

40 x 40x 140

: 12

m ain reinforcem entratio,

hoop tie ratio,axialstress

M achida ctal.

20 x 15 x 85

:33

bending m om ent/shearforce ratio,

tension reinforcem entratio,

axialstress,hoop tie r

a tio,concrete

strength

Ishibashietal.

40x 40 x 150

40x 50 x l15

60x 40 x 150

:27

:15

Y am am olo cta .

tension reinforcem entratio.

hoop tie ratio,axialstress,

concrete strength

122

0 The diameter of the reinforcement in small specimens is relatively large compared with the

column dimensions.

(2) The main reinforcement is single-layered

in small specimens, whereas in real piers it is multilayered.

(D The main reinforcement is not cut off at the midheight of the column, whereas in real piers it

is cut off at the midheight.

© Hoop ties are closed in the cross section of small specimens, but they are not closed in real

piers.

These disparities may cause a difference in the ultimate displacement and ductility between small

test specimens and real piers. Hence, in our experiment aimed at reproducing the behavior of real

piers as closely as possible, a large size model (1/3 scale of column-end flexural failure type) was

constructed with reinforcement details identical to those of elevated bridge piers used in urban

areas. Cyclic loading was applied at the column top in the horizontal direction and the test results

were compared with those obtained with a small specimen (1/10 scale). Next, in order to

quantitatively

evaluate the reinforcement pull-out due to the effect of the multi-layered

reinforcement arrangement, reinforcement stress-pull out analysis was conducted using a bond-slip

hysteresis model proposed by Suzuki et al. 6) as well as a stress-strain model. Then, to evaluate

the overall behavior of the specimen subjected to loading, a P- S simulation analysis was carried

out based on the nonlinear RC analysis method using a fiber model and taking into account

reinforcement pull-out from the footing as a nonlinear rotation spring. Through this procedure, a

modeling method for successfully predicting the load-deformation behavior of real bridge piers

under seismic loading is proposed.

2

. EXPERIMENTAL

2

.1

PROCEDURE

Specimen preparation

a) Configuration and reinforcement details

Two specimens were prepared: one small and the other large. The dimensions of the large

specimen and the test set-up are shown in Fig. 1. The cross-sectional reinforcement details of the

unit

iiuu

PP ctool

Kor

y

reaction wall

^

5500

PC steel

bar

hydraulic

jack

loading

block for fixing

loading flame

PC steel bar

jack

specimen

ajack

/

hydraulic

I

I

I

I

I

I

I

I

I

I

I

I

( North)

plan view

side view

Fig. 1 Dimensions

flame

of the specimen and loading method (Large size model)

-123-

two specimens are shown in Fig. 2. The shear span ratio of the column (a/d, a: shear span length,

d: cross sectional size in the direction of applied loading) was 4.3, the main reinforcement ratio

(the ratio of cross sectional areas of main reinforcement and column) was 2.2% and the hoop tie

ratio was 0.3% at the column end in both specimens.

The small specimen (1/10 scale), manufactured with a similar shape and the same reinforcement

ratio as the large specimen, was used for comparisons with the large specimen. Relatively large

diameter reinforcing bars compared with the column cross section were used in the small

specimen: D19 bars as the main reinforcement and D6 as the hoop ties.

The large specimen was a 1/3 scale model manufactured to model the reinforcement details of a

real pier. In a real pier, D35 and D19 bars are commonly used as the main reinforcement and

hoop ties, respectively.

In this large model, D13 and D6 bars were used, respectively, in

accordance with the reduced scale of the specimen as compared with a real pier. The main

reinforcing bars were arranged in three layers in the lower section of the column, and the innermost layer was extended up to a point 2.16 m above the upper face of the footings. This position

was determined by adding the effective depth of the column cross section to the point at which

such cut-off is allowed by calculation according to the Japanese Specifications for Highway

Bridges.

Main reinforcement was extended down to the bottom face of the footing and anchored there. The

spacing of the main reinforcement was 7.6 $ ( <£> : reinforcement

diameter)

in the small

specimen, whereas in the large specimen the spacing between bars was 3.6 $ and the spacing

between layers was 2.6 <£. As to the shape of the hoop ties, a closed type with hooks at both

ends was used in the small specimen, whereas in the large specimen hoop ties bent into a U shape

in compliance with those used in real piers were inserted from both sides and closed with lap

splices. As shown in Fig. 2, intermediate hoops were placed in a proportion of 0.1% in terms of

hoop tie ratio.

b) Materials

The mechanical properties of the reinforcement such as yield point, tensile strength, and strain

hardening point were identical in both specimens, as seen in Table 2. High-early-strength

Portland cement was used for concrete. In the small specimen, ready-mixed concrete with a

maximumaggregate size Gmaxof 20mm was used, whereas in the large specimen, " micro

concrete " with Gmax

=10 mmwasused in consideration of the reduced scale of the specimen

compared with a real pier. The mix proportion of the concrete and its strength at the time of

loading tests are shown in Tables 3 and 4, respectively.

l

small size model

arge size model

1167

37 68

m m

Br サr

ra

VO

4

VD

X

r CO

16 x 5 0 = 8 0 0

ra

350

8 37

ti a m

la

Q

lo i i n s d ir e :tio n

3 0

145

14 5

3 0

H

Q v

u p p e r se c tio n

o f th e c o lu m n

lo w e r s ec tio n

o f th e c o lu m n

D6

Q

o

CN

o

(N

D 6

fl

lo a d i n g d ir e c t io n

Hm n

s p a c i n go f h o o pt i e s

D13IE I

s p a c i n go f h o o pt i e s

u p p e rs e c t i o no f t h e c o l u m n1 0 . 0( c m )

l o w e rs e c t i o no f t h e c o l u m n5 . 0 ( c m )

n

DT N1i9rv

u p p e rs e c t i o no f t h e c o l u m n1 1 . 4 ( c m )

l o w e rs e c t i o no f t h e c o l u m 5n . 7( c m )

Fig. 2 C r o s s s e c t i o n a l size a n d r e i n f o r c e m e ndte t a i l s

124 -

2

.2 Loading and measurements

Loading was applied to the column top in a horizontal direction while the column was subject to

an axial force from the top so that the axial stress acting on a real pier was taken into account.

The loading set-up is shown in Fig. 1. An axial force equivalent to a stress of 15kgf/cm 2 was

applied using a jack fitted to the column top via a prestressing steel bar through the center of the

specimen and anchored at the footings. This steel bar was encased in a sheath of such size that

the bar did not touch it even when the specimen was deformed.

In both specimens, incremental reverse loading was applied by load control method up to the

yield load Py determined by calculation. This Py is the load at which the outer-most main

reinforcement around the column end reaches the yield point. After the yield load was reached, 10

cycles of reversed loading with the same displacement amplitude were applied successively at

multiples of d y. Loading was continued by the displacement control method until the load fell to

the yield value after reaching the maximum load. The yield load Py and the corresponding

displacement

3 y were 8.5 tf and 10.5 mmin the small specimen, and 92 tf and 26 mmin the

large specimen.

Table 2 Properties

main reinforcements

of large specimen

main reinforcements

of small specimen

hoop ties

of reinforcements

diameter

yield point

(kgf/mm2}

tensile strength

(kgf/mm*)

D13

38.3

57.

D19

39.1

32.6

D6

used

strain hardening

(%)

elongation

(%)

contraction

(%)

1 .7

26

48

57.7

1 .5

23

42

44.2

3 .0

16

57

1

T

able 3 Mix proportion of concrete

water/cement

ratio of fine

unit content (kg/m3)

slump air content

fi ne

coarse

water

cement

ratio (w/c)

aggregates S/a

coarse aggregates

aggregates

aggregates

(cm)

(%)

(%)

S

G

(mm)

max.size of

w

admixture

l

arge model

small model

10

18

62.0

46.0

200

3 23

20

15

57.5

44.8

175

305

785

T

able 4 Concrete strength at the time of experiment

compressive strength tensile strength

Y oung's modulus

( kgf/cm2)

l

arge model

small model

(kgf/cm2)

( x l06 kgf/cm2)

283

24

0 .22

278

26

0 .29

-125

951

1015

0

.808

0 .762

Measurements included displacement

at the loading point, the distribution

of horizontal

displacement in the longitudinal

direction, the relative vertical displacement of the footings and

the column, and the strain of main reinforcement in the footings, as shown in Fig. 3.

3. EXPERIMENTALRESULTS AND DISCUSSION

3.1

Results for small specimen

Load-displacement hysteresis loops for the two specimens obtained at multiples of d y are shown

in Fig. 4. The distribution

of horizontal displacement

in the longitudinal

direction

at each

displacement step is given in Fig. 5, and the crack and failure conditions are shown in Fig. 6. As

seen from Fig. 4, the load-displacement

envelope (P - 8 ) indicates that a maximumload of ll.2

tf was reached at a displacement of 4 8 y, and that the capacity did not visibly decrease even

when a displacement of 5 d y was reached. The yield ratio, which is the ratio of yield load to

maximumload, was approximately 0.75.

Regarding the displacement

ductility

factor, several definitions have been proposed: one, for

example, takes the ductility factor at the point when the load falls to the yield load after reaching

the maximumload; another takes the ductility factor at the point when the load falls to 80% of

the maximumload. In our experiment, however, since the yield ratio was 0.75, the ductility

factor was roughly identical

whichever definition

was adopted. The resulting displacement

ductility

factor, slightly smaller than 6, is 1.2 times bigger than the value calculated using the

equation proposed by Machida et al. (based on the latter definition)

5). Nevertheless, given the

20% scatter in their experimental results, it can be considered that our test on the small specimen

basically differs little from past experiments by other investigators.

3.2 Results for large specimen

The shape of the load-displacement

envelope (P - 8 ) for the large specimen is roughly identical

to that of the small specimen, as seen in Fig. 4. The maximumload of the large specimen was

122 tf, whereas that of the small specimen was ll.2 tf. This difference is approximately the

second power of the size difference between the two specimens. The ductility factor was roughly

5.5, slightly smaller than but broadly similar to the ductility factor of the small specimen.

Though diagonal cracks appeared from the early loading stage around the point where the main

reinforcement was cut off, this section did not undergo yielding or indicate damage progress even

when the maximumload was reached. As a result, the distribution of displacement at over 3 8 y

was roughly linear, as seen in Fig. 5, implying that the main cause of deformation is concentrated

in the area around the fixed end of the column. This was also the case with the small specimen.

However, looking at the yielding displacement (1 8 y) , it is somewhat smaller than the value

obtained by scaling up in accordance with the size difference between the two specimens. Also,

several portions of the main reinforcement ruptured while cyclic loading was being applied with a

displacement of 5 8 y , a behavior not observed in the small specimen test.

3.3 Discussion

As described above, the deformation behavior was roughly the same for both specimens, but there

were minor differences. The following discussion focuses on the potentially

influential

factors

mentioned earlier.

a) Effect of main reinforcement cut-off

In the large specimen, the yield ratio was 0.75, whereas the ratio of the distance between loading

point and cut-off point vs. shear span length was about 0.5. Hence, the specimen had been given a

considerably

large safety factor, approximately

1.5 by calculation,

and so no yielding was

observed in the area of the main reinforcement cut-off. Since the displacement observed at the

column top in the large deformation stage was mostly a result of plastic deformation at the

-126-

o

[=>

>o

r-I

<N

surface of

footing

jRj

unit:

mm "tff

A :LVDT

I : concrete strain gauge

à": main reinforcement strain gauge

* : hoop tie strain gauge

Fig. 3 Measuring

2

l

<5y

points

3£y:.4<Sy

arge model

E>

small model

-6Sy

/

B^f^xfX

arge model

-iay

-2Sy

>U-

V

-5*y.AS^-3Sy

l

H

<\

"A

*yg^?

i

aa

(ton)

-3Sy-4Sy-

^d

&

n

,21

£1

Fig. 4 Load-displacement

at loading points

hysteresis

loops

Fig. 6 Crack and failure

-127-

-,(

v

conditions

I

-\

column end as well as by deformation associated with pull-out of the main reinforcement at the

footing, it can be concluded that the effect of main reinforcement cut-off on the overall

deformation of real piers will remain very minor if the cut-off point is determined as in this case.

b) Effect of multi-layered arrangement of reinforcement

The distribution of the main reinforcement strain in the longitudinal

direction in the area below

the cut-off point was roughly similar in both large and small specimens. However, in the large

size specimen, the reinforcement showed a longer yield extension in the footing as illustrated

in

Fig. 7 and the reinforcement stress was transferred deep into the footings. As a result, as shown

in Fig. 8, the amount of main reinforcement pull-out from the footing is consistently

greater in the

large specimen made of D13 bars than in the small specimen containing D19 bars when compared

at the same ductility ratio.

When reinforcement pull-out is compared at 4 8 y, close to the ultimate displacement, in terms of

a non-dimensional reinforcement diameter, it is 0.4 $ in the large specimen, approximately three

times bigger than the 0.13 $ of the small specimen. This is because the spacing of the main

reinforcement in the large specimen (3.8 $ , 2.6 <f> ) is closer than that of the small specimen

(7.8 $ ). The value (0.4 <£ ) is, however, considerably larger than the 0.2 $ derived by Ishibashi

et al. 3). This is probably because the bond strength between each bar and concrete decreases due

to the multi-layered arrangement of the reinforcement.

The ratio of column top displacement caused by column end rotation to overall displacement was

small in the large specimen compared with that of the small specimen, as shown in Fig. 9. The

loops shown in Fig. 9 are similar to the results of existing studies by others. However,given that

our data shows about 25% of the ultimate displacement at the column top being attributed to

rotation at the column end, the effect of reinforcement pull-out in actual piers cannot necessarily

be assumed to remain minor.

c) Effects of reinforcement diameter and the shape of hoop ties

In the small specimen, fracture occurred in the column in the range 0.8d from the column end,

which is roughly similar to the results by other investigators. In contrast, in the large specimen, it

occurred in the range 0.4d from the column end (Fig. 6). According to visual observations, the

length of the fracture region in both specimens' roughly corresponded with the region in which the

main reinforcement buckled. The difference in the fracture range (0.8d vs. 0.4d) is considered

attributable

to differences in main reinforcement diameter and the shape and size of the hoop ties

used. The cause of main reinforcement rupture in the large specimen is possibly that fracturing

was concentrated excessively in a narrow range around the column end. In the large specimen, the

lap-spliced

hoop ties were reinforced by intermediate hoops amounting to 0.1% in terms of hoop

tie ratio in the same way as done in real piers.

small model

(experiment)

l

arge model

(experi ment)

large model (analysis)

HI

(4.3d)

120

80

South direction

40

0

40

80

120

(mm)

< I > North direction

Fig. 5 Distribution

160

120

80

40

South direction

0

40

(mm)

< I >à"North direction

of horizontal displacement

-128-

I

120

80

40

South direction

in the longitudinal

direction

0

40

80

120

(mm)

< I >à"North direction

The strain of the intermediate hoop measured on the plane perpendicular to the loaded plane was

quantitatively

similar to the hoop tie strain. Accordingly, it is concluded that intermediate hoops

performed as expected as shear reinforcement. Also, in the case of the large specimen, it is

inferred that the presence of the intermediate hoops restrains the decrease of confinement due to

the enlargement of hoop ties, and that a deformation capacity no different from that of the small

specimen was achieved as a result.

4. ANALYTICAL

4.1

INVESTIGATION

OF MAIN REINFORCEMENT

PULL-OUT

Outline

Conventionally, it has been accepted that the influence of rotation at the column end due to main

reinforcement pull-out on displacement at the column top, and consequently on the overall

deformation capacity, is large in small specimens, but that it is comparatively small in real piers.

However,our experiment on the large specimen indicates that this influence is not necessarily

small, because the bond strength between concrete and reinforcement degrades in elevated bridge

piers designed for urban use due to the close arrangement of main reinforcement. To evaluate this

effect analytically,

a numerical investigation was carried out on the amount of reinforcement pullout from the footing in the large specimen.

large model

compress!ve strain

tensile

-5,oqp__

o

l

arge model : <£>=13mm

small model : 0=19mm

strain (x 10"6)

10,000

20,000

fl-q

0

.4 <f>

0.3

l

arge

'(rei nforcement strain gauge)

0

l

0.20

0.10

arge (LVDT)

small (LVDT) i

small

strain gauge)

0

( reinforcement

0

Itfy2Sv3£v4Sy

5Sy

displacement at the columntop

Fig. 8 The relationship

between pull-out of main

reinforcement and displacement

small model

compressive strain

-5,000

tensile

0

strain (x 10"6)

10,000

-n-q

I

.J

I

2w~

3Sy,4Sy,

large : l £y =26.0mm

small l(Sy =10.5mm

small (LVDT)

20,000

5<?y

>>

-°

«à"

à"aa

<U Q>

i§

2a

g&

I^

§3

43

small

0 .4

( reinforcement

strain gauge)

0 .3

U2

32

0 .2

à"8§

0 .1

^

l arge

(LVDT)

l arge

-^(reinforcement

strain gauge)

^- --A

l

arge (analysis)

à"2 '|

a 2

t-4

i-C

0

I

ISy2dy3§y4dy5Sy

displacement at the column top

Fig. 9 Ratio of displacement caused by rotation

to total displacement at the column top

Fig. 7 Distribution of main reinforcement

strain in the footing

-129-

4

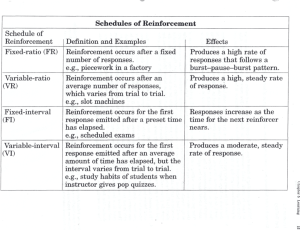

.2 Method of analysis

Analysis associated

with reinforcement pull-out is often conducted using a stress-strain

relationship

for the reinforcement ( a - E model) and a bond-slip relationship

between the

reinforcement and concrete ( T - s model). This procedure was employed in our analysis. The

Menegotto-Pinto model 12) was used as the a - E relationship. This model is characterized by

the explicit derivation of stress level from reinforcement strain. As the T - s model, the model

shown in Fig. 10 as proposed by Suzuki et al. 6) for the analysis of main reinforcement pull-out

wasused.

4.3

Results of analysis

Analysis was conducted on the reinforcement pull-out from the footing. The strain distribution

of

main reinforcement in the footing was calculated

under conditions that the analytical

reinforcement stress was in conformity with the measured stress up to yielding and, after that the

analytical

reinforcement pull-out expressed by an integral of reinforcement strain was in

conformity with the measured stress. The calculated strain distribution

is compared with the

experimental result in Fig. 1 1.

The calculation agrees well with the experimental result in the case of the small specimen. With

regard to development length (the distance from the upper face of the footing to the position

where the reinforcement strain reaches almost zero), the calculation is roughly in agreement with

the experimental result. In particular, the calculation fairly successfully expresses the yielding

range of reinforcement near the face of the footing at a displacement of 2 S y. In contrast, in the

case of the large specimen, the calculation failed to estimate the experimental result as good as in

the case of the small specimen. Although both calculation and experimental results are similar in

terms of the pattern of yielding zone, they deviate quantitatively.

Also, strain of the elastic zone

are in a ' shallow' range in the calculation, a different tendency from the experiment. It can be

said that this is because the bond strength is lower in the large specimen due to the dense

arrangement of bars, whereas the proposed T - s model is intended for columns with relatively

large reinforcement spacing.

4.4 Modification

of analytical

bond-slip

model

The T - s model shown in Fig. 10 was modified so as to reflect the influence

reinforcement spacing in the large specimen. The modifications are outlined below.

of the closer

© Change the amount of yielding slip (Sy) of 0.014 <f> derived from the T - s model by Suzuki

et al. to 0.08 $ based on the experimental result.

(D Reduce the bond strength, or change the scale of the T axis, to take into account the

influence of reinforcement spacing as suggested by Ishibashi et al. 3)

(D As a reduction coefficient for the bond strength influenced by the reinforcement spacing, adopt

the product of the reduction coefficient due to the spacing between layers and the reduction

coefficient

due to the spacing between main reinforcement bars. The reduction coefficient

calculated in this way is approximately 30% for the large specimen.

(D Adjust the residual constant bond strength ( i R ) after yielding to match the calculated pullout after yielding with the experiment.

The modified T- s model thus established

is shown in Fig. 12. Indicated in Fig. 13 are the

calculated strain distribution

corresponding to the measured reinforcement pull-out derived using

the modified x -s model. From this figure, it is clear that the strain distribution

in the large

specimen associated with pull-out of the main reinforcement is well predicted when the modified

T -s model is adopted.

4.5

Analysis

ofM- 6 hysteresis

Using the modified

loop at the column end

T -s model, the bending

moment-pull out hysteresis

130-

loop was calculated.

Next, using this result, the hysteresis loop for the bending moment-rotation angle (M- 9 ) at the

fixed end due to pull-out was calculated. To derive the 9 value, hysteresis

values for

reinforcement stress and position of the neutral axis are needed. For this purpose, the relationships

between bending momentand reinforcement stress, and between bending moment and the neural

axis at the column end were calculated in advance by the fiber model based analysis. The

analytical M-6 hysteresis loop is compared in Fig. 14 with the measured result. The measured

hysteresis loop was obtained from the relative vertical displacement between footings and column

taken on the two opposite sides. As seen from the figure, the measured M-6 hysteresis loop

shows a pattern similar to that of the P- 8 curve, which indicates that analytical result is able to

predict the measured M-6 loop up to roughly a displacement of 3 b y.

M AX

MAXj

s ta n d a r d

/ I

/ I

I

r A f

rAJ

!

§

.£>

-^

S A

A=0.003

<£

Fig.10

s

Fig.

T-s

--e

>

S v

0.014$

Sv=0.0190

slip

-

r c

O

JD

S

c o m p a r e d w i th n o r m a l v a l u e s

i

T3

T3

T is re d u c e d b y 3 0 %

a n d s l ip b y 0 .0 8 <」

12

0.080(about

slips

Modified

T -s

1 mm)

model

model

strain of reinforcement

1.0

o

strain of reinforcement

1.0

2.0

2.0

x

4 .0X

à"3

|4(H

U

C

£ 2

experiment

experiment

experiment

analysis

analysis

analysis

S L'«H

s 20H

*

à"£3

large model

experiment ! Py

experiment : 2d y

-*40\

analysis

analysis

X3

HH

60J

1.0

80 -1

100J

',Py

I23y

Fig. 13

10

! Py

: 2Sy

!3 dy

;Py

;2Sy

.'3$y

Reinforcement strain in the axial

direction (Large model)

600 1

1.5

4CXH

2 .0X10

Oi

-e-

-Q-

à"s

a.

strain of reinforcement

0.5

.0x

20-

10

x

II

4

à"e-

3.0

-e-

CD

3.0

-

^

200-1

x

,s sioi

o H

£2

<u

!!

à"Q-20 -1

à"s

Ou

<u

à"o

small model

experi ment

experi ment

analysis

anal ysi s

£

Py

28y

Py

28y

"S

-200-1

-400^

-600

J

-8.0

30J

-6.0

-4.0

-2.0

0

fixed-end rotation

Fig. 1 1 Distribution

of reinforcement strain

in the axial direction

-131-

Fig. 14

2.0

4.0

: 6 (rad)

M- 6 hysteresisloop

6.0

8.0Xl(T

5

. ANALYTICAL INVESTIGATION OF THE P- 8 CURVE OF THE COLUMN

5.1 Outline

One effective method of estimating the ultimate resistivity

of bridges against strong earthquake

loading is to carry out nonlinear seismic response analysis. In doing so, it is important that the

nonlinear hysteresis characteristics

of the structural members constituting the bridge should be

reflected accurately in the analysis. This is particularly

important in a pier where the design is

governed by seismic loading. Accordingly, in our study, analytical investigation

was conducted on

the large model that simulated the influence of rotation at the column end due to pull out of main

rei nforcem ent.

The fiber model based analysis was employed for the analysis. This method assumes that the

column comprises multiple bar members and that the column cross section is constituted

of

elements of concrete and reinforcement. It also presumes that the cross section remains plane after

deformation and that the material properties are those under the uniaxial stress state. This method

is advantageous in that it is applicable

to a wide range of cross sectional features, material

properties, and loading conditions compared with a method using empirical load-displacement

hysteresis models. Also, the labor and time needed for calculation are significantly

less than for

FEM analysis.

5.2 Modeling

of the column member

a) Material models

As the material models, those used by Yamada et al. 1 0) were employed. Namely, the concrete is

modeled using the ac -E c hysteresis loop based on the rule by Muguruma et al. :n.

As for

the reinforcement, the a s - e s hysteresis loop proposed by Menegotto-Pinto 12) was utilized.

The concrete model and the reinforcement model are shown in Fig. 15 and Fig. 16, respectively.

The physical properties of the materials used are given in Table 5.

b) Modeling of the member and cross section

As shown in Fig. 17, the column member was divided into a total of 19 elements in the

longitudinal

direction. Elements in the possible plastic region in the range up to 1.0 m from the

column end were made small. The cross section was divided into 50 fibers and reinforcement

elements were taken into account according to the arrangement of bars at each position along the

column.

5.3

Model for the rotation spring at the column end

Arotation spring was installed at the column end, in which a series model of the linear spring and

nonlinear hysteresis spring was taken into account. The linear spring and the nonlinear hysteresis

spring take into account elastic deformation of the footing and the pull-out of the main

reinforcement, respectively. By placing these springs in series, the displacement is determined as

the sum of the displacements of each spring when a bending momentacts on the column end.

a) Linear spring

The linear spring was established

by taking into consideration the difference between Young's

modulus of the concrete model and that of the micro concrete, the shear deformation of the

column, and the deformation of the footings.

b) Nonlinear hysteresis spring

The trilinear model shown in Fig. 18, as proposed by Muto, was used as the' nonlinear rotation

spring at the column end. The characteristics of the skeleton curve were determined with reference

to measured and analytical results of the M- 6 hysteresis loop: 4.7 X 10 5 tfm/rad for the first

gradient; 2.1 X 10 5 tfm/rad for the second gradient; and 1.8 X 10 4 tfm/rad for the third

gradient. The rotation angles at the two inflection points were made 6 X 10 ~4 rad and 1.5 X 10

~3rad.

-132-

Table 5 Physical

unloading

A P0"ll

V

/

/ SIVCHUIl

unloading

/ point

properties

(unit : kgf/cm2)

Y o u n g 's m o d u lu s o f c o n c r e t e

2 .2 x I f f

c o m p r e s s iv e s tr e n g th

2 83

2 .1 x lO -

Y o u n g 's m o d u l u s o f r e in f o r c e m e n t

y i e ld s t re n g th

3 83 0

4 .2 x 1 0 "

s e c o n d g r a d ie n t

600

strain

Y ule

Fig. 15

cT" reloadin8

Point

Model for the stress-strain

relationship

of concrete

600

-0. 006

0

.006

fixed end rotation (rad)

E

( eM2)),

(

Fig. 18

(4V ')

i

Relationship

of bending

moment-

rotation at the column end

eW)

Fig. 16 Model for the stress-strain

relationship

of reinforcement

-0. 15

0 .15

displacement

( a)

(b) cross section

of the column

element of the column

axial force

Fig. 19 Relationship

of load-displacement

at loading points

f

1

orced

displacement

li n e a r e l e m e n t

( 9 e le m e n ts )

(m)

1 .1 6 7 m

I B

l l .0 m

4. m

nonlinear rotational spring

+ linear rotational spring

Fig. 17

Analytical

reinforcement

r ^ ^ S ^ rc

element

n l

-150

-0. 15

displacement

(m)

0 .15

model for the column

Fig. 20 Comparison of experimental and analytical

results on load-displacement relationship

-133-

A

nalytical results of the P - 5 hysteresis loop at the column top are shown in Fig. 19. Two cases

are compared: one ignores the rotation spring at the column end and the other takes it into

account. The analytical result for the case where the rotation spring is considered is compared in

Fig. 20 with the experimental result. The analytical M-6 loop at the column end due to pull-out

is compared in Fig. 18 with the experimental result. The proportion of the displacement at the

column top attributed to rotation at the column end induced by the reinforcement pull-out as a

ratio of overall displacement at the column top is given in Fig. 9. The distribution

of horizontal

displacement along the column in the longitudinal

direction is shown in Fig. 5.

From these figures, it is found that a larger load is given by calculations with the same plastic

factor when the rotation spring is ignored (which means that the column end is fixed) compared

with when it is taken into consideration;

this is because the rigidity of the member as a whole is

increased in the former case. This tendency is particularly

conspicuous at the time of 1 8 y (Fig.

19). In contrast, if the rotation spring is taken into account, it is possible to estimate the skeleton

of the P - 8 curve and the hysteresis loop with better accuracy (Fig. 20).

The analytical M-6 loop is in relatively

good agreement with the experimental result, which

suggests that the Muto model is adequate for the analysis of the rotation spring at the column end

in relation to reinforcement pull-out (Fig. 18). In the analytical

result, the proportion of

displacement at the column top attributed to rotation at the column end is approximately 20% at 1

8 y and 30% at 2 8 y. These values are close to those obtained in the experiment (Fig. 9). In the

analysis, the proportion of displacement at the column top attributable to rotation of the column

end decreased near the ultimate state compared with the proportion at 2 d y or 3 8 y. For

example, it was 15% at the displacement of4 8 y (Fig. 9).

The distribution of horizontal displacement in the longitudinal

direction was roughly linear in the

analytical result, except in the area around the column end, and this is in good agreement with the

experimental result, which showed that the bulk of displacement at the column top is governed by

deformation around the column end (Fig. 5).

6. CONCLUSIONS

Experimental and analytical investigations

were conducted using a large model (1/3 scale)

constructed with the reinforcement arrangement of a real pier as well as with a small model (1/10

scale). The type of RC bridge piers used in urban areas was adopted as the prototype. The

following conclusions can be drawn from the results:

© The P- 8 envelope obtained in the experiment on the large model was roughly identical to

that obtained from the small model. The displacement ductility factor of the large model was 5.5,

which was slightly smaller than that of the small model, which was 6.0.

(D The amount of reinforcement pull-out in the large model was greater than that in the small

model. For example, the reinforcement pull-out with a displacement of 4 8 y, which was close to

the ultimate displacement was 0.4 $ in the large model, three times greater than that of the small

model (0.13 $ ) when converted into a non-dimensional reinforcement diameter. This is considered

attributable to a decrease in bond strength between reinforcement and concrete due to the close

spacing of reinforcement and its multi-layered arrangement in the large model.

(3) Analysis was conducted on the large model with multi-layered

reinforcement details to

investigate the main reinforcement pull-out induced by reversed cyclic loading using the T - s

model proposed by Suzuki et al. It was found that the model was not quite satisfactorily

able to

predict the behavior of the large model. Therefore, instead of this model, a modified T - s model

reflecting the influence of the close reinforcement spacing was developed and used for the same

analysis. And then, the result revealed that the modified T - s model is able to simulate relatively

satisfactorily

the measured amount of reinforcement pull-out and distribution

of reinforcement

strain inside the footings.

134-

© As a simulation, nonlinear RC analysis taking into account reinforcement pull-out using a

nonlinear rotation spring was carried out on the experimental results utilizing a fiber model. The

results verify that the load-displacement

relationship

obtained in the experiment was predicted well

by this analytical method.

Acknowl edgements

The authors greatly appreciate the valuable

'Technical Research Group for Investigating

advice from members of the Hanshin Expressway's

the Ductility of RC Piers' in completing this paper.

References

[I] Akimoto and Osaka

"Study on the Deformation

Capacity

of RC Piers under Seismic

Loading,"

Proc. of the Colloquium on the Ductility

of Concrete Structures and its Evaluation,

pp. n-241-252,

1988.3 (in Japanese)

[2] Kawashima, K., Unjoh, S., Sugita, and Nakajima

"Study on Main Reinforcement Cut-Off of

the RC Bridge Piers under Seismic Loading, Evaluation of Seismic Resistivity

and Reinforcing

Methods," Technical Report of PWRI of the Ministry of Construction, Vol. 189, p. 96, 1993.9 (in

Japanese)

[3]

Ishibashi,

T., and Yoshino, S. "Study on Deformation Capacity of Reinforced

Concrete

Bridge Piers Under Earthquake,"

Proc. of JSCE No. 390, V-8, pp. 57-66, 1988.2 (in Japanese)

[4] Ozaka, Y., Suzuki, M., Kuwasawa,S., and Ishibashi,

T. "Load-Deflection

Characteristics

of

Reinforced Concrete Columns Under Static Alternating Cyclic Loads," Proc. of JSCE No. 372, V

-5, pp. 45-54, 1986.8 (in Japanese)

[5]

Machida, A., Mutuyoshi, H., and Toyoda, K. "Evaluation of the Ductility

of Reinforced

Concrete Members," Proc. ofJSCE

No.378, V-6, pp.203-212,

1987. 2 (in Japanese)

[6] Suzuki, M., Jang, I, Watanuki, M., and Ozaka, Y. "Study on the Pullout Property of Axial

Bars from Footings,"

Proc. of Concrete Research and Technology, JCI, Vol.3, No.l, pp. 33-44,

1992 (in Japanese)

[7] Design Procedures for Reinforced Concrete Structures,

Hanshin Expressway Public

Corporation, 1991.4 (in Japanese)

[8] Murayama, Y., Suda, K., and Mimura. "Effect of Column Reinforcement Pull Out on the

Deformation Capacity

of RC Piers,"

Proc. of the Colloquium

on the Ductility

of Concrete

Structures and its Evaluation,

1988.3 (in Japanese)

[9] Yamamoto, T., Ishibashi,

T, Otsubo, M., and Kobayashi,

S. "Experimental

Studies on

Seismic Resistance of a Pier with Reinforcement Terminated in a Tension Zone," Proc. of JSCE,

No. 348, V-l,

[10]

Yamada,

pp. 61-70,

1984.8

(in Japanese)

Y., lemura, H., Matumoto, T., Riestic,

D., and Ukon, H.

"Stress-Strain

Based Inelastic Earthquake Response Analysis of Reinforced Concrete Frame

Structures,"

Proc. of IABSE International Symposium, Delft, 1987

[I I] Muguruma, H., Watanabe, F., Iwashimizu, T., and Mitueda, R. "Ductility Improvement of

High-Strength

Concrete by Lateral Confinement," Transactions of Japan Concrete Institute, Vol.

5, pp.

403-410,

1988

[12]

Menengotto, M., and Pinto, P. "Method of Analysis for Cyclically

Loaded Reinforced

Concrete Plane Frames Including Changes in Geometry and Nonelastic Behavior of Elements

under Combined Normal Force and Bending,"

IABSE Symposium on Resistance and Ultimate

Deformability

of Structures Acted on by Well-Defmed Repeated Loads, Final Report, Lisbon,

1973

-135