COURSE OUTLINE Transportation Technology – TTJ3C1 Philip Pocock Secondary School

advertisement

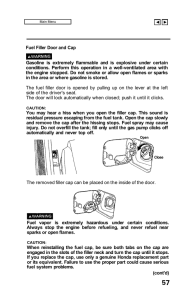

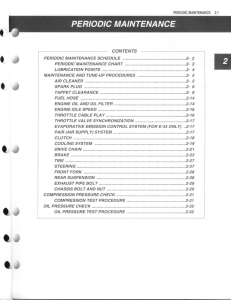

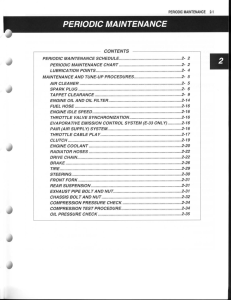

COURSE OUTLINE Transportation Technology – TTJ3C1 Philip Pocock Secondary School Room – 101 Instructor: Mr. Lijiam http://teacherweb.com/ON/PhilipPocock/MrLijiam/ The following page outlines your course of study in grade 11 transportation technology. Units/lessons are listed in order in which they will be presented. Each unit/lesson outline tells you the topic of the lesson, the theory content and the support activity. The activities in which you are required to complete worksheets, you are expected to fill out all the necessary fields neatly and submit the worksheets for marking in due time. Lessons will be given daily with practical work following each lesson. Upon completion of each unit a review and a test will be given. Attached with your course outline are 2 copies of the general safety rules. These rules must be followed whenever you are in the shop area. After the rules have been read and explained to you, you and your parents/guardians must sign on the designated spots and submit one copy. SAFETY IS OF PARAMOUNT IMPORTANCE IN THE SHOP. ANY INFRACTION OF THE SAFETY RULES MAY RESULT IN THE STUDENT BEING DENIED THE PRIVILEGE OF USING THE SHOP. Course Evaluation Breakdown: Term – 70% Practical work evaluation: 30% assessment will be made based on technical aptitude, safe work practice, time management, work procedures and maintenance of work area. There will be a daily mark input for this assessment. Welding projects and brake line manufacturing: 5% Unit Culminating/Worksheets: 15% based on completion and accuracy of data. Theory: 15% unit tests, quizzes and class works Organizational skills: 5% assessment will be made based on performance during foreperson duties, reporting, neatness & organization of worksheets and notebooks Final/culminating – 30% Project: 15% build a snowmobile trailer & wiring. Follow rubric for evaluation Final Exam: 15% Evaluation Structure: Knowledge/Understanding Thinking/Inquiry Communication Application Course textbook Automotive excellence – Volume 1 and 20% 25% 20% 35%. Volume 2 Theory Content Unit 1 – Introduction & Applied Work Practice 1.1 1.2 1.3 1.4 1.5 Introduction to TTJ3C1 Careers in Transportation Technology Safety – ongoing throughout the course Tools Welding Practical Activities/Projects Most of the practical activities are accompanied with printed instructions and worksheets that need to be filled up and handed for marking Unit 1 - Identify, sort out and familiarise with all the tools available in the shop - Practice welding with oxy-acetylene, MIG and stick welding equipments - Welding projects to be handed in for marking Unit 2 – Engines 2.1 2.2 2.3 2.4 Sources of Power & Applied Science Engine Construction Engine Operation Engine Classification Unit 3 – Engine Systems 3.1 3.2 3.3 3.4 3.5 3.6 3.7 Lubrication System Fuel System Air Induction System Ignition System Exhaust System Cooling System Electronic Controls Unit 4 – Electrical Systems 4.1 4.2 4.3 4.3 4.4 Basic Electricity Automotive Batteries Starting System Charging System Lighting System & Wiring Diagrams Unit 5 – Running Gear 5.1 5.2 5.3 5.4 Automobile Construction and Chassis Measurements Wheels and Tires Brake Systems Suspension and Steering Systems Unit 6 – Drive Line 6.1 6.2 Introduction to Transmissions Clutch Operation 6.3 Differentials and Drive Shafts Units 2 & 3 - - Perform basic engine services including minor tune-ups and fuel system services Disassemble automobile engine, identify all the engine components and reassemble to industry standards following procedures and torque specifications provided in service manuals Identify and locate electronic system components Unit 4 - Replace starting system components – battery, starter motor replace and adjust alternator belts replace alternators Design and build a snowmobile trailer lighting system Unit 5 - Remove and reinstall brake pads and brake shoes - Machine brake rotors, measure their thickness using micrometers and compare with specs. - Identify suspension and steering system components - Perform brake line flaring and use couplings to join brake lines for repair Unit 6 - Remove and reinstall clutch disc and plate - Identify drive line components - check and top-up/replace fluids