Chabot College February, 1993 Removed Fall 2010

advertisement

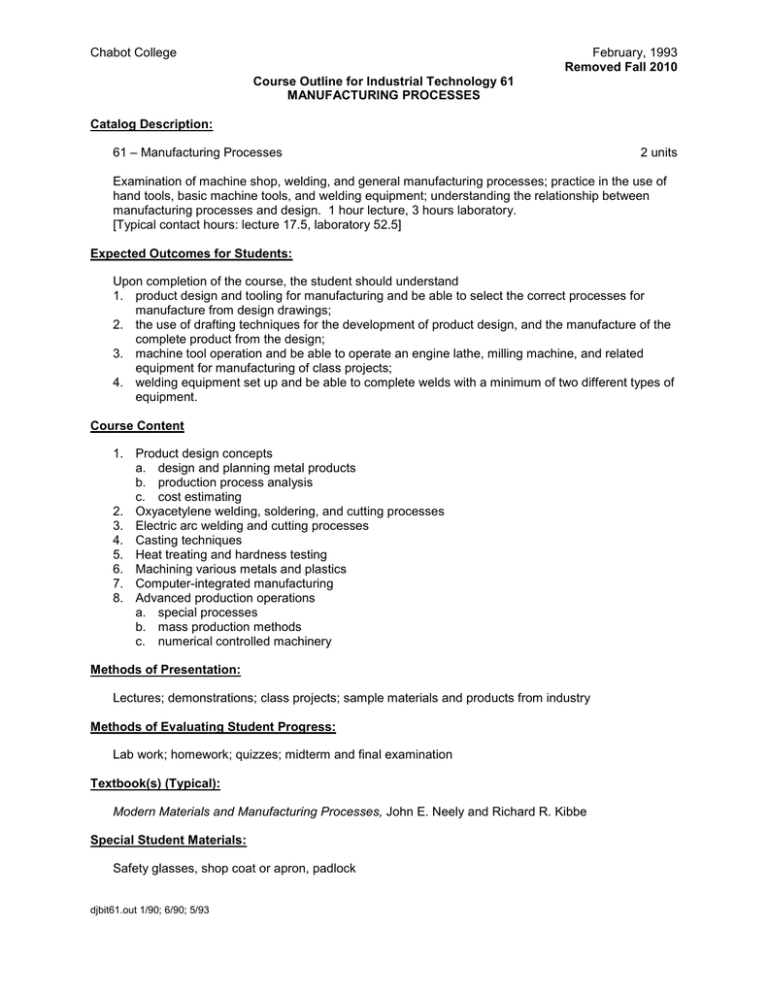

Chabot College February, 1993 Removed Fall 2010 Course Outline for Industrial Technology 61 MANUFACTURING PROCESSES Catalog Description: 61 – Manufacturing Processes 2 units Examination of machine shop, welding, and general manufacturing processes; practice in the use of hand tools, basic machine tools, and welding equipment; understanding the relationship between manufacturing processes and design. 1 hour lecture, 3 hours laboratory. [Typical contact hours: lecture 17.5, laboratory 52.5] Expected Outcomes for Students: Upon completion of the course, the student should understand 1. product design and tooling for manufacturing and be able to select the correct processes for manufacture from design drawings; 2. the use of drafting techniques for the development of product design, and the manufacture of the complete product from the design; 3. machine tool operation and be able to operate an engine lathe, milling machine, and related equipment for manufacturing of class projects; 4. welding equipment set up and be able to complete welds with a minimum of two different types of equipment. Course Content 1. Product design concepts a. design and planning metal products b. production process analysis c. cost estimating 2. Oxyacetylene welding, soldering, and cutting processes 3. Electric arc welding and cutting processes 4. Casting techniques 5. Heat treating and hardness testing 6. Machining various metals and plastics 7. Computer-integrated manufacturing 8. Advanced production operations a. special processes b. mass production methods c. numerical controlled machinery Methods of Presentation: Lectures; demonstrations; class projects; sample materials and products from industry Methods of Evaluating Student Progress: Lab work; homework; quizzes; midterm and final examination Textbook(s) (Typical): Modern Materials and Manufacturing Processes, John E. Neely and Richard R. Kibbe Special Student Materials: Safety glasses, shop coat or apron, padlock djbit61.out 1/90; 6/90; 5/93