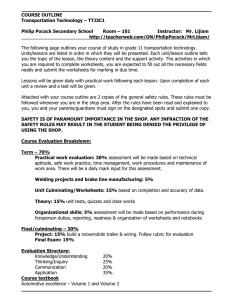

Manual for Jawa 350

advertisement