- development of ERP system based ...

advertisement

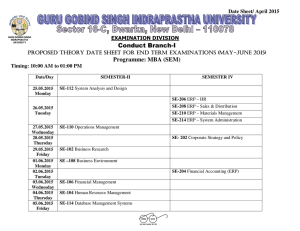

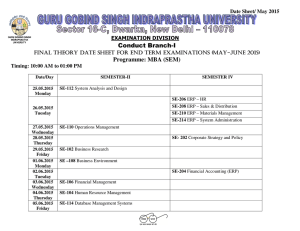

Research on Operation Mode of Green ERP Based on Multilife Cycle Yong Ren1, Min Zhou1, Yan-xia Chen1, Hua Zhang2 1 College of Machinery and Automation, Wuhan University of Science and Technology, Wuhan, China Green Manufacturing and Energy Conservation & Emission Reduction Technology Research Center Wuhan University of Science and Technology, Wuhan, China (michelle_zhoum@163.com) 2 Abstract - By analyzing the background and research fields of green manufacturing, the authors propose the concept of green ERP (enterprise resource planning) based on multilife cycle, elaborates its essence and characteristics. On the basis of that, an operation mode of green ERP is built and each operation stage of it is expatiated in detail. During multilife cycle of green ERP, the factors of cost and resource efficiency are focused on. The proposed operation mode is a comprehensive qualitative answer to the question of what is green ERP as well as a roadmap for future quantitative research to better understanding. development of ERP system based on virtual team. Generally speaking, green ERP is in a fuzzy concept and growth period. Based on the analysis above, the authors propose a concept of green ERP based on multilife cycle and analyze its essence and characteristics by referencing philosophy of green manufacturing. Keywords - Green, multilife cycle, operation mode, ERP system A. Concept and essence of green ERP based on multilife cycle I. INTRODUCTION The way of society development is challenged by environment, resource and population problems, and the mode of sustainable development is expected to be a selection for human being. Achieving green sustainable development mode of high efficiency, low cost & energy consumption and less environment pollution becomes goal of human society development. The "Twelfth Five Year Special Program" led alone by Minister of Science & Technology, presents two special programs: great task of manufacturing informationization and green manufacturing. The Ministry of Industry & Information also argues that green growth in industrial development and information is a new growing point [1]. At present, green subject is widely researched, such as green manufacturing [2-3], green design [4], green supply management [5], green project management and so on. Green IT/IS[6-11] subject is also involved, but it mainly focuses on energy consumption and enterprise implementation strategy from perspective of enterprise. Among them, green ERP is rarely involved. In process of informationization, ERP system is also required to be more and more scientific with the development of industry management .It is required to be innovation and green feature etc. Indeed, virtualization of hardware and embedding accounting of environment cost [12] into ERP system to save electric energy and reduce environmental impact are concerned by some scholars, but greening ERP system itself is ignored, such as adopting green design of ERP system based on multilife cycle and green ____________________ This paper is supported by the project Green Optimization Method & Support Technology of Steel Manufacturing System, Innovation Team of Hubei Province (T201102) II. CONCEPT AND CHARACTERISTICS OF GREEN ERP BASED ON MULTILIFE CYCLE According to value theory, green technology is a combination of multivalue. It takes green ecotype society and environment value as its core beyond traditional enterprise boundary. Green technology integrates the benefits of customers, society and environment with process of company value’s increment. From perspective of cost (including primary development cost and secondary upgrade cost) of ERP development taken by customers (enterprises that implement ERP system), an efficient and low cost green ERP based on multilife cycle aims to achieve unification of economic, environmental and social benefits. In this paper, green ERP is defined as following: green ERP based on multilife cycle is a green philosophy of management, method and tool which integrates with traditional ERP system such as purchasing management, design and production management, sales and distribution management, and embeds environment cost management module into financial management subsystem and so on, is oriented for customers demand and market, associates with advanced technology superiority and supports rapid reconfiguration technology, emphasizes on high efficiency, low cost during multilife cycle stage to optimize resource allocation of inter and extern of enterprises for unification of economic, environmental and social benefits. Green ERP based on multilife cycle extends traditional space & time boundary of ERP system, its essence integrates with system theory during multilife cycle to achieve green goal of high efficiency and low cost. Its essence can be understood from the following aspects: 1) From perspective of ERP system itself, green ERP system requires a green design in system architecture and a guarantee of perfect performance quality such as a good system expansibility ,reconfiguration and portability and other advanced technology merits to own the ability of upgrading or "remanufacturing" that oriented for multilife cycle. This perspective presents the green merit of reuse, remanufacturing and other green requirements. 2) From perspective of development process of ERP system, green ERP requires a green operation model of development team to reduce cost, especially the human resource cost, to promote resource efficiency of development process. So a collaborative method & platform, such as virtual team, information network technology and so on, should be taken to guarantee a green ERP development process. 3) From perspective of customers, green ERP is required to own the ability of promoting enterprises’ green management level based on GSCM(green supply chain management) and cultivating green culture for enterprises. B. Characteristics of green ERP based on multilife cycle On the basis of a thorough understanding of essence about green ERP based on multilife cycle, a three dimensional characteristics model is built by referring to philosophy of green manufacturing. In this three dimensions model, green evaluation on ERP will be made in different project stages according to resource consumed by each stage. The green degree is evaluated by time, quality, cost, resource, environment five dimensions. Then an accumulated green degree curve will be made after evaluations. In fact, the accumulated green degree curve oriented for multilife cycle varies from different ERP projects and different stages. It is shown as figure 1. Evaluation Indexes time accumulated green degree of ERP quality cost resource environmrnt hum te c h n c a p i ta in equ forma ology l lysis ysis sign ent ing ing vice rade ation n r g l ti o n r i pm ana ana m de elopmebug run se upg ene m an ent res ateri a n d e m s te e v d te m te m te m x t g al our em syst sy tem dystem sys sys sys ne d ce sys s Process Resource Fig.1 Characteristics of green ERP based on multilife cycle 1) Process dimension Process dimension extends life cycle of green ERP system. It includes demand analysis, system analysis, system design, system development, system debugging, system running, system service, system upgrade, and developing next generation system and so on. For example, in process of design & plan for green ERP system, not only a thorough consideration on factors those affect this generation ERP system should be predicted, but also a further research on next generation ERP system such as upgrading cost, technology feasibility and other factors, should be considered. So that an overall consideration on cost (consists of development cost, running and maintenance cost, upgrade cost), technology portability and reconfiguration, effectiveness and implementation achievement and so on, is required to be scheduled systematically oriented for multilife cycle. 2) Resource dimension Under green background, resource includes capital, technology, information, equipment , material, energy, human resources etc. During multilife cycle of green ERP, how to make use of resource more efficiently, especially human resource, is a core factor for green ERP. Integrating different types of resources effectively and optimizing resources allocation in every key process node group are very important reflections of green ERP. In fact, different types of resources consumed by different processes will affect the evaluation indexes in certain degree and these green indexes of ERP will totally produce effect in green degree of ERP. 3) Evaluation indexes dimension Green ERP is a kind of product and service in deed. According to green manufacturing theory, green product can be evaluated by TQCRE(time, quality, cost, resource, environment).As to green ERP, it involves a series of green manufacturing processes and activities during multilife cycle with information exchange, resource consumption, and environmental impact etc. In evaluation indexes dimension, time refers development period, service respond time. Quality represents system functional quality, technical performance quality, service quality etc. Cost consists of primary development cost, maintenance & service cost and upgrade cost etc. Resource refers the efficiency of different kinds of resources consumed by each operation stage. Environment reflects the environment impact during multilife cycle of green ERP. Generally speaking, evaluation indexes dimension should be extended to cover a more wide green conceptual scope and activities with a broad understanding about green ERP. Ⅲ. OPERATION MODE OF GREEN ERP BASED ON MULTILIFE CYCLE Operation mode of green ERP based on multilife cycle consists of four stages: green philosophy and design process, green development process of ERP R&D team, green implementation & running process, Plan "remanufacturing" process. Its operation mode is shown as figure 2. Do Check Project planning Green philosophy & design process Time Green development process of R&D team Quality Action P D A C System analysis Market/ Customers R&D team deveopment Demand Analysis Green ERP Design/ Management ERP system debug/implementation Green implementation & running process Green running in enterprises Cost Platform of Performance /Control/ Feedback ERP Suppliers/ Servicers Resource Next generation Maintenance service System upgrading/remanufacturing Remanufacturing process Environm -ent Fig.2 Operation mode of green ERP based on multilife cycle A. Green philosophy and design process Green philosophy and design are the basis of obtaining green product. Green philosophy does not simply refer to ecological economy,it makes more sense to save energy and resource consumption, to promote operation efficiency, to realize benign circulation and great vitality. Green design[13](also called ecological design or design for environment)means to make use of related product data during multilife cycle of product, including technology information, environment information, economy information, resource information etc, to take advanced design theory & method such as CE(current engineering) for product design process which does not only meet the common requirement of function, quality, cost and so on, but also meets requirement of good coordination with environmental characteristic. So the whole goal of green design is to optimize design factors that consist of static design data and dynamic design data for minimizing negative environmental effect, and promoting resource efficiency. As to green ERP, designers should consider technology factors, economy factors and environment factors etc. in each stage and process of ERP during multilife cycle. In process of design, technology information includes technology feasibility, technology reconfigurability and flexibility, technology maintainability, technology advancement. For example, technology of supporting virtualized hardware and software should be taken to reduce energy consumption and promote operation efficiency of ERP system. For economy factors, economic feasibility, primary development cost, maintenance cost, secondary development & upgrade cost should be paid more attention to systemically. For environment factors, design of green ERP requires an accounting module of environment cost embedded into financial management in ERP’s running process and an effective development process design. In fact, a conceptual model and whole project plan oriented for ERP multilife cycle that meet green requirement of function, quality, cost and other factors should be built to make reasonable decision during green philosophy and design process. B. Green development process of ERP R&D team In this stage, the concept of green ERP refers to high efficiency and low cost. In the traditional development team, the team members complete their task personally according to their own experience or knowledge. But in the era of knowledge economy and information, product development method of traditional team is confined to low efficiency and high cost. So collaborative work mode under network platform, effective virtual team[14] should be applied to green ERP development process associated with KM (knowledge management), CE and significant incentive & coordination mechanism and so on. The development mode of ERP R&D team is shown as figure 3. The cultural platform of trust and cooperation 1th stage plan of milestone plan Overall plan of ERP R&D 2th stage plan of milestone plan M th stage plan of milestone plan The platform of information & knowledge & skills Deviation analysis The platform of incentive contract and performance evaluation The platform of task allocating & coordinating The platform of task monitoring Fig.3 Team operation mode of green ERP Team members Member 1 Member 2 Member N As figure 3 shows, in order to have a significant efficiency and controlled cost of ERP R&D project, it is necessary to make overall schedule and milestone plan for each stage ahead. And quality, cost and time plans for each task also should be scheduled. During implementation of ERP project, the progress must be tracked dynamically. When the deviation rate exceeds the allowable range, remedy measures should be taken timely. ERP R&D team will locate every role of team member taken in ERP development project according to their individual skills & expertise and adhere to principle of ability priority. Each member’s task taken in ERP R&D team will be controlled in a certain scope and equipment and fund and so other resource also do not exceed a set limit. As shown in equation (1). N Sj Snmxt | x j , t t1 t2 S ' (1) n 1 Where Sj is the total amount of resource j in a certain period of time t1 to t2, Snmxt is the consumption of resource j by member n and stage m in a certain period of time t1 to t2, S ' is the limit consumption of resource j in a certain period of time t1 to t2.Suppose that C C (m, n, s j , t ) (2) Where C is the cost of ERP project, m is project stage, t is the time of cost occur, Sj is resource j. J N C P m C P (m, n, s j , t ) (3) Similarly, other green indexes of ERP such as time, quality, resource and environment can also be controlled or evaluated by experts marking or other methods. By this operation mode of ERP R&D team, high efficiency and low cost of ERP development process can be realized in a more green method to prompt green degree of green ERP. C. ERP implementation & green running process Green running process of ERP means that ERP system helps to promote green operation ability and cultivate green management philosophy for enterprises. It bases on standard management and efficient operation mode of enterprise by controlling every "business node" of management mechanism to realize green philosophy that rapid response to market, efficient and agile operation, lean management and low cost running process, friendly environmental production. Based on environment cost management module of enterprise ERP system, and associated with financial management, production management, material management, sales and distribution management and other modules, green ERP makes use of ERP system’s powerful prediction, planning, accounting, control, analysis, and other functions during production activities to improve economy benefit of enterprise. For example, controlling the environment cost of enterprise is an effective approach of implementing green management philosophy. D. "Remanufacturing" process j 1 n 1 Cm C d m C P m C d (m, n, s j , t ) C P (m, n, s j , t ) For green ERP based on multilife cycle, upgrade of technology and "remanufacturing" merits are very important reflections of green ERP system. It means "reuse", "recycle", "reconfiguration" and low cost. Green ERP requires advanced, reliable, reconfigurable system technique architecture to manifest its green philosophy such as taking agent technology with rational, aptitude, autonomy, ego drive merits ,adopting object oriented for design based on components development ,dispensing exorbitant dependence on hardware or database, supporting virtualized hardware to save energy consumption and modularized function design programming and so on. Indeed, next generation and "remanufacturing" of ERP system make a multilife cycle, green, efficient and low cost ERP system. (5) E. Platform of performance evaluation & control p Where C m is the plan cost of ERP project in stage m of the total consumption resource J by all members N. J N C d m C d (m, n, s j , t ) (4) j 1 n 1 d Where C m is the actual cost of ERP project in stage m of the total consumption resource J by all members N. Because of a lot outside factors, there is always much difference existed between actual and planed cost. The cost discrepancy of ERP project is to subtract the actual cost from the planed cost. As shown in equation (5): J N j 1 n 1 Where J N j 1 n 1 Cm is the cost discrepancy between actual cost and plan cost of ERP project. When Cm exceeds a set limit or allowable range, remedy measures should be taken timely and then improve. As the same, Cn that in a certain period time t by all members N, Cmnj that total project cost of in all stage M by all member N can also be controlled and evaluated. In order to guarantee the total green degree of green ERP based on multilife cycle, a platform of performance evaluation & control should be built. The platform of performance evaluation & control consists of process layer, indexes layer, control & feedback layer. In process layer, process is oriented for multilife cycle and it consists of four operation stages during each life cycle. In indexes layer, green indexes include TQCRE five dimensional indexes from perspectives of ERP supplier and customers. And each 1th level index can be divided into more 2th level indexes and even 3th level indexes. In control & feedback layer, planned indexes and actual indexes will be evaluated according to experts, ERP project plan, knowledge database etc. Then deviation analysis and Process Layer Indexes layer solution will be feedback to control and improve process layer continuously in real time. The whole control platform mechanism is shown as the figure 4. next generation green philosophy and design process green development process of R&D team Quality Time Control/ Feedback Layer Planned inedxes green implementation & running process Cost "remanufacturing" process Resource Environment Actual inedxes Deviation Analysis/Solution/Control/Improvement Fig.4 Performance evaluation & control mode Ⅳ. SUMMARY AND FUTURE WORK With the development of informatization construction, energy, resource, cost, effectiveness become key influencing factors for enterprise’s initiatives to informatization implementation, especially the cost factor. From the two perspectives of life cycle and green concept, the paper has put forward the concept of green ERP based on multilife cycle, analyzed its operation processes ,especially ERP R&D team green development process. Greening ERP design and adopting highly efficiency development process such as virtual development team are effective approaches to reduce cost of ERP system. On the other hand, research on green ERP stays preliminary stage. How to achieve green operation goal and reach enterprises’ green philosophy for enterprises with the help of green ERP system ,how to build a standard criterion for green ERP ,are all needed to be further research. REFERENCES [1] “Suggestion for accelerating integration informatization with industrialization” (in Chinese), The Ministry of Industry and Information, 2011. [2] Fei Liu, Hua-jun Cao,“Theory framework of green manufacturing (Periodical style),” (in Chinese), China Mechanical Engineering, vol. 11, no.9, pp.961-964, 2000. [3] Ahmed M. Deif., “A system model for green manufacturing (Periodical style),”Journal of Cleaner Production, vol.19, pp.1553-1559,2011. [4] J.Y. Zhu, A. Deshmukh, “Application of Bayesian decision networks to life cycle engineering in Green design and manufacturing (Periodical style),”Engineering Applications of Artificial Intelligence, vol.16, pp.91-103,2003. [5] Iuri Gavronski,Iuri Gavronski,Robert D.Klassen,Stephan Vachon,Luis Felipe Machado do Nascimento, “A resourcebased view of green supply management (Periodical style),” Transportation Research Part E, vol.47,pp.872-885,2011. [6] Dedrick,J,“Green IS: concepts and issues for information systems research(Periodical style),” Communications of the AIS ,vol.11,pp.173-183,2010. [7] David C. Chou,Amy Y. Chou, “Awareness of Green IT and its value model (Periodical style),”Computer Standards & Interfaces,2012. [8] Chibli Joumaa, Seifedine Kadry, “Green IT: Case Studies (Published Conference Paper style),”International Conference on Future Energy, Environment and Materials, vol.16, pp.1052-1058, 2012. [9] Tracy A. Jenkin,Jane Webster, “An agenda for Green information technology and systems research (Periodical style),”Information and Organization, vol.21,pp.1740,2011. [10] He Zhang, Lin Liu,“Designing IT systems according to environmental settings: A strategic analysis framework (Periodical style),”Journal of Strategic Information Systems,vol.20, pp.80-95,2011. [11] Ranjit Bose.Xin Luo,“Integrative framework for assessing firms’ potential to undertake Green IT initiatives via virtualization-A theoretical perspective (Periodical style),”Journal of Strategic Information Systems,vol.20, pp.38-54,2011. [12] Hua-jun Li, “Research in the Environmental Cost Management of Manufacturing Corporations under the Framework of ERP System (Dissertation style),” (in Chinese), Sichuan university,pp.70-83,2005. [13] Fang-yi Li, Jian-feng Li, Jin-song Wang, Guang-hong Duan, “Present Status and Prospects of Green Product DesignGeneral Theory and Methodology (Periodical style),” (in Chinese), Aeronautical manufacturing technology, vol.10, pp.73-78, 2004. [14] Min Zhou, Yan-xia Chen, “Research on cooperation model of virtual team based on multi-project under the network environment (Published Conference Paper style),”presented at the 3rd International Conf. on Information Science and Engineering, Yangzhou, pp.1164-167, 2011.