Research on Coal Enterprises Activity-Based Costing Accounting Model Based on ERP

advertisement

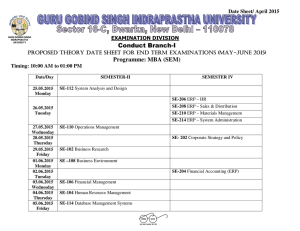

Research on Coal Enterprises Activity-Based Costing Accounting Model Based on ERP Yan-hui Hou 1, Min Hao1, Wei Wang2, Hong-tao Yue3, Yong-jun Ding4 1 Department of Economic and Management, ShanDong University of Science and Technology, Qingdao, China 2 The principal's office, ShanDong University of Science and Technology, Qingdao, China 3 Mechanical and electrical team, Xinglongzhuang Coal Mine, Jining, China 4 Electrical and Mechanical Division, Wanfu Coal Mine, Heze, China (Coolhyh@126.com, candyca4145@sina.com, W1969@sdust.edu.cn, hongtaoyue@sina.com, dyjjdd@126.com) Abstract - ERP (Enterprise Resource Planning) and ABC (Activity-Based Costing) have the different management fields, but they still have the basis for integration, such as the same costing objects, ideas for cost management and management purposes. In this study, based on the system integration thinking and basic concepts of ERP and ABC, the theoretical and practical integration model and framework (based on J2EE platform and web service) of them was constructed. Furthermore, the ABC accounting model of coal enterprises was discussed. This study worked out a new feasible method for ABC accounting in coal enterprises. predetermined range and controls it more effectively. III. INTEGRATION BETWEEN ABC AND ERP A. The Integration Framework from Perspective of New Coal Enterprise ERP 1) Theory Integration between ABC and ERP For coal enterprises, ABC and ERP can be integrated in the following aspects: (1) Analyzing every activity in activity chain using the method of ABC to identify value added and no value added activities, restructuring and optimizing the business process of supply chain[1]. (2) According to resource driver and cost driver, calculating activity costs with the method of ABC is more scientific and reasonable. So it provides the foundation for the quotas in EPR and the BOM’s making. The model was showed in Figure 1. Keywords - activity-based costing management, ERP, integration, accounting model, web service I. INTRODUCTION II. Although there are different standpoints and functions between ERP and ABC, it is feasible to integrate the ideas of activity based costing management into the use of ERP systems, using ERP’s advantages of strong computing power and detailed data. Thus, we can collect, calculate and analyze the activities which consume the resource in supply chain from the design stage, in order to distinguish the value-added and non value-added activities, and take measures to minimize non value-added (or value-added is not strong) activities to optimize resource allocation. Meanwhile, we can implement different activity management in the field of cost accounting, which brings the cost within a 2) Implementation Integration between ABC and ERP We can integrate ABC and ERP, with integrating the concept of ABC into ERP, to build an activity-based ERP system, which can deepen the level of enterprise management to operational level. In the traditional ERP, main production schedule which guides the entire process of production and operation management drives the capacity requirement planning and material requirements planning [2]. The traditional functional departments and the basic production units are in the layer of planning and ABC system ERP system Resource Consumption Activity-based Activities Main production schedule cost accounting and analysis Value-added activities and non value-added activities Material requirement planning BPR Supply Production Sale Foundations Cost objects Standards (quotas, BOM, etc.) Fig. 1. Theory integration model between ABC and ERP production management. Yet, in activity-based ERP, it starts from the main activity-based production planning, which on one hand drives the capacity requirement planning and material requirements planning, and on the other hand guides the activities of production and operation in activity chain management. And the B. The Integration Framework from Perspective of Existing Coal Enterprise ERP Based on J2EE Platform and Web Service On J2EE Platform, implementation framework of EAI based on web services (shown in Figure 3) includes Production schedule, cost target, profit target Activity Optimization Optimization Main activity production schedule (coal mining, tunneling) planning layer Material requirement planning, capacity requirement planning, aided activity production schedule Activity Optimi implement -zation layer Purchase Operation Activity1 Activity2 Sale Activity3 Logistics ··· Activity4 Activity N Supply chain Activity chain Optimization Optimization Activity Activity-based cost accounting management Activity control Activity analysis layer Activity evaluation Fig. 2. Implementation integration model between ABC and ERP activities are in the layer of planning and production management [3][4][5]. As to the coal enterprises, the material consumption doesn’t constitute the product as an entity. So there are some kinds of specialties in the relationship between production schedule and material requirement, between activity and activity division. The activity-based ERP model is shown in Figure 2 [6][7][8]. three parts those are client, middle layer and background system [9]. Client allows customers to find and call web services in different ways (web browser or enterprise application programs), so as to achieve the client's connection. The middle layer is responsible for developing, deploying and publishing web services, and connects client with background system. It also can be divided into presentation layer, business layer and the Enterprise Application Program Client MT WEB Browser UDDI Server HTTP/XML HTTP/SSL Presentation Layer Web Container JSP Servlets EJB Container Middle Layer JAX-RPC JAXP/JAXB SOAP Request Business Layer JAXR EJB session Bean JAXM Integration Layer J2EE AS JCA EJB Entity Bean Proprietary/Protocol JDBC Background System ERP ABC Enterprise Database Fig. 3. Implementation framework of ERP and ABC based on J2EE platform and web service integration layer [10][11]. Presentation layer is comprised of the web components (JSP, Servlets etc.) and responsible for handling request / response of HTTP, XML and other, session management and calling of the business layer components, etc. Business layer uses EJB Session Bean to achieve the logic functions of company's core business, meanwhile transforms the related business logic into web services, and published it to the UDDI server; integration layer is responsible for disposing communication and connections between business logic and background systems, such as using EJB Entity Bean to access ERP financial Uncontrollable subsystem cost Calculating Activity pool Can be directly allocated Material costs Wage costs Electricity value of various resources, such as: human resource, material resource, financial resource, information resource, technology resource, etc. The resource consumption is divided into the controllable cost and the uncontrollable costs. For coal enterprises, controllable costs generally include material costs, wage costs, electricity fees, repairs fees, rental fees, etc. And other costs occurring in the chains underground and over ground are classified as uncontrollable costs. Step two: Determining the activity driver and resource driver. Cost allocation fees Repairs fees Controllable Activity center 1 … Calculating controllable cost of activity centers coal product cost cost Can not be directly allocated Rental fees Manual entering Determining resource driver Calculating driver rate Production driver, machine-time driver, quantity driver, footage driver… ERP production planning and controlling subsystem Fig. 4. Business process of coal enterprises activity-based cost accounting under ERP corporate databases and using J2EE Connector Architecture (J2EE Connector Architecture, JCA) to reach integrations between business logic and enterprise information systems, etc. Background systems afford supporting environment for enterprise application integration, including corporate databases and enterprise information systems [12][13][14]. IV. ACCOUTING MODEL OF ACTIVITY-BASED COST BASED ON ERP FOR COAL ENTERPRISES A. Basic Procedures of Activity-based Cost Accounting Based on ERP for Coal Enterprises The core idea of activity-based cost accounting is “activities consume resources and products consume activities”. According to the basic accounting principle above, the procedures of activity-based cost accounting based on ERP for coal enterprises consist of the following three steps: Step one: Identifying and calculating resource consumption, allocating the resource consumption value into various resource pools. This step is only a process of value classification. It is neither necessary nor possible to directly credit the consumption value into activities, so the value of resource consumption is always classified by resource types in a larger range than activities’. Its basic work is to establish calculating standards of resource value and calculate the Determine the activities according to the principle of activity division, and make every activity to be ensured. Once it is decided, no change shall be made arbitrarily. The basic rules of activity costing should be carried out through this entire process. The amount of the activity determines that of resource consumption, and it has noting to do with the level of final product output. The relationship of the amount between resource consumption and activity is often described as resource driver. Resource driver reflects the patterns, causes and conditions when activities consume resources. For coal enterprises, we should choose the right resource consumption driver for the consumption of controllable cost, in terms of resource character, and then calculate the amount of resource driver, which is the basis to allocate the resource consumption to every activity. The accurately-measured cost should be counted to the corresponding activity. Meanwhile, the cost which can’t be accurately measured or is co-consumed by several resources can not be imputed to a special activity, and it should be allocated by resource driver. Of the controllable costs for the underground part, material costs and wage costs can be directly counted, but electricity, repairs and rental fees, for their specialty in operation and management, may need to be allocated by resource driver. Generally, the electricity fee chooses the actual start time and power as resource driver. The large amount of repairs fee can choose the actual load as resource driver. And rental fees can choose actual occupancy time as resource driver. Step three: Allocating the resource value pool to the activity value pool, and determining every activity cost. Coal enterprises just have a single product. So there is no need to allocate the activity cost to various products. Finally, we can get the cost of coal products by summarizing the controllable cost and the uncontrollable cost of every activity which have been calculated in step two. During the implementation of the three steps above, the data about resource costs can be obtained from the EPR financial modules, and the data that can’t get directly need to be entered manually. B. Business Process of Activity-based Cost Accounting under ERP for Coal Enterprises Considering the activity-based cost accounting, management theory and the character of the coal production process, we can use the ideas of activity-based cost accounting to calculate every activity’s activity cost by the feature of production organization in cost accounting. Ultimately, we can calculate the cost of coal products [15]. Figure 4 shows the business process. V. SUMMARY In conclusion, ERP and ABC have the different management fields, but they have the basis for integration: the same costing objects, the same ideas for cost management and the same management purposes. So it is necessary and feasible for the integration between the two. We can integrate the enterprise resource management into activity-based costing management (This article mainly refers to the activity-based cost accounting), which will provide the activity-based costing management with timely and reliable raw data. Instead of manual operation, computer and network will speed up the cost accounting. So it is more effective to carry out the activity-based costing management among coal enterprises. Meanwhile, the feedback of original information can show us the formation process and resource consumption of every activity timely. Tracing the origin through the activity analysis, we can continuously improve operation processes and production methods by the principal of uniting function and economy to rationally allocate the limited resources. Finally we can achieve the goal of sustainable cost reduction. REFERENCES [1] ZHUANG Xinzhi, “Research on the activity-based cost accounting system under ERP” (in Chinese), master thesis, Harbin University of Technology, 2006, pp.19. [2] XIA Xin, “ERP theory and method of coal enterprises” (in Chinese), Lixin Accounting Press. Shanghai, 2006,pp.105-110. [3] XU Xue-jun,HUA Xue-lan, “On cost management research in ERP operation costing”(in Chinese), Commercial Research, 2003(21), pp.3-4. [4] Baxendale, Sidney J,Jama, Farah, “What ERP can offer ABC”, Strategic Finance, 2003, Vol.85, pp.54-57. [5] Shaw, Russell. “ABC and ERP: partners at last”, Management Accounting, 1998, Vol. 80, pp.56. [6] Khozein, Ali; Dankoob, Morteza; Barani, Ghasem, “Major factors affecting launching and implementing activity based costing system”, International Research Journal of Finance & Economics, 2011, Issue 71, pp.112-117. [7] Schulze, Manuel; Seuring, Stefan; Ewering, Christian, “Applying activity-based costing in a supply chain environment”, International Journal of Production Economics, Feb2012, Vol. 135, pp.716-725. [8] Bushong, J. Gregory; Talbott, John C.; Cornell, David W. “Instructional case—activity-based costing incorporating both activity and product costing”, Accounting Education, Dec2008, Vol. 17 Issue 4, pp.385-403. [9] Yuan Zhanting, Zhang Qiuyu, Yang Jie. “Research on EAI solutions based on web services”, CIMS, 2004(10), pp. 394-414. [10] Marks, Eric A, “Web services and ERP”, Managing Automation, Dec2004, Vol. 19 Issue 11, pp.53-53. [11] La Monica, Martin, “Web services will move slowly to ERP”, Info World, 2001, Vol. 23 Issue 50, pp.18. [12] Meehan, Michael, “EAI vendors embrace web services”, Computer world, 2001, Vol. 35 Issue 50, pp.18. [13] Ferguson, Renee Boucher, “EAI vendors vie on web services”, eWeek, 2001, Vol. 18 Issue 47, pp.14. [14] Houlding, David; Govindasamy, Sekar. Dr. Dobb's, “Integrating .NET & J2EE with web services”, Software Tools for the Professional Programmer, Sep2003, Vol. 28 Issue 9, pp.24-29. [15] JIANG Haihong, “Coal enterprises activity-based costing management system design and implementation,” master thesis, Dalian University of Science & Technology, 2005, pp.32–34.