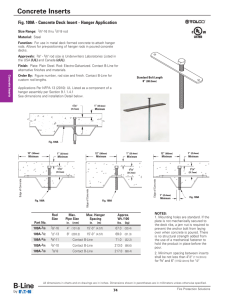

Fig. 109A - Concrete Deck Insert - Hanger Application

advertisement

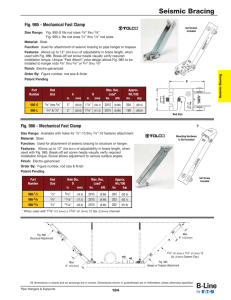

Concrete Inserts Fig. 109A - Concrete Deck Insert - Hanger Application Component of State of California OSHPD Approved Seismic Restraints System Size Range: 3/8"-16 thru 7/8"-9 rod Material: Steel Function: For use in metal deck formed concrete to attach hanger rods. Allows for pre-positioning of hanger rods in poured concrete decks. Approvals: 3/8" - 5/8" rod size is Underwriters Laboratories listed in the USA (UL) and Canada (cUL). Included in our Seismic Restraints Catalog approved by the State of California Office of Statewide Health Planning and Development (OSHPD). For additional load, spacing and placement information relating to OSHPD projects, please refer to the TOLCO Seismic Restraints Systems Guidelines. Standard Bolt Length 8” (203.2mm) Finish: Plate: Plain Steel. Rod: Electro-Galvanized. Contact B-Line for alternative finishes and materials. Concrete Inserts Order By: Part number, rod size and finish. Contact B-Line for custom rod lengths. 12” (305mm) Minimum 12” (305mm) Minimum 1” (25.4mm) Minimum 25/8” (66.7mm) Edge of Concrete Edge of Concrete Edge of Concrete Max. Pipe Size Part No. Max. Hanger Spacing Fig. 109A Max. Recommended Loads 1” (25.4mm) Minimum 25/8” (66.7mm) 25/8” (66.7mm) Fig. 109A Rod Size 12” (305mm) Minimum 1” (25.4mm) Minimum Approx. Wt./100 in. (mm) in. (m) lbs. (kN) lbs. (kg) 109A-3/8 3/8"-16 4" (101.6) 15’-0” (4.57) 572 (2.54) 67.0 (30.4) 109A-1/2 1/2"-13 8" (203.2) 15’-0” (4.57) 579 (2.57) 69.0 (31.3) 109A-5/8 5/8"-11 Contact B-Line 715 (3.18) 71.0 (32.2) 109A-3/4 3/4"-10 Contact B-Line 1000 (4.45) 213.0 (96.6) 109A-7/8 7/8"-9 Contact B-Line 1000 (4.45) 217.0 (98.4) 1” (25.4mm) Minimum Fig. 109A NOTES: 1. Mounting holes are standard. If the plate is not mechanically secured to the deck ribs, a jam nut is required to prevent the anchor bolt from laying over when concrete is poured. 2. Minimum spacing between inserts shall be not less than 41⁄2" (114.3mm) for 3⁄8" and 6" (1152.4mm) for 1⁄2" Max. Recommended Loads shown include safety factor of 5. Weight is based on the standard bolt length. All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified. Pipe Hangers & Supports 192 Revised 11/4/2014 Concrete Inserts Component of State of California OSHPD Approved Seismic Restraints System Fig. 109A - Concrete Deck Insert - Brace Application Size Range: 3/8"-16 thru 7/8"-9 rod Material: Steel Function: For use in metal deck formed concrete to attach hanger rods. Allows for pre-positioning of hanger rods in poured concrete decks. Approvals: Included in our Seismic Restraints Catalog approved by the State of California Office of Statewide Health Planning and Development (OSHPD). For additional load, spacing and placement information relating to OSHPD projects, please refer to the TOLCO Seismic Restraints Systems Guidelines. Hangers certified by a registered professional engineer to conform to Section 6-1.1 of NFPA #13 (1999) and Section 9.1.1.2 of NFPA 13 (2002). Standard Bolt Length 8” (203.2mm) Finish: Plate: Plain Steel. Rod: Electro-Galvanized. Contact B-Line for alternative finishes and materials. Order By: Figure number, rod size and finish. Contact B-Line for custom rod lengths. 12” (305mm) Minimum 12” (305mm) Minimum 1” (25.4mm) Minimum 1” (25.4mm) Minimum ‘D’ Concrete Inserts Qualifies as an acceptable alternate seismic brace fastener per Section 9.3.5.9.6 Certification calculations for this application are available upon request. See dimensions and installation Detail below. 1” (25.4mm) Minimum 12” (305mm) Minimum ‘D’ Edge of Concrete Edge of Concrete Edge of Concrete ‘D’ Fig. 109A 1” (25.4mm) Minimum Fig. 109A Fig. 109A ‘D’ Rod Size Max. Horizontal Load Brace At 45° Part No. 109A-3/8 109A-1/2 109A-5/8 109A-3/4 109A-7/8 3/8"-16 1/2"-13 5/8"-11 3/4"-10 7/8"-9 ‘D’ Min. Anchor Embedment Depth lbs. (kN) in. (mm) lbs. (kg) (2.49) 25/8" 25/8" 25/8" 25/8" 25/8" (66.7) 67.0 69.0 71.0 213.0 217.0 (30.4) (3.02) (3.11) (3.11) (66.7) (66.7) (66.7) (66.7) A (31.3) Max. Horizontal Load Brace At 45° Part No. lbs. 109A-3/8 3/8"-16 109A-1/2 109A-5/8 109A-3/4 109A-7/8 1/2"-13 5/8"-11 3/4"-10 7/8"-9 337 395 395 395 395 ‘D’ Min. Anchor Embedment Depth (96.6) (98.4) Approx. Wt./100 (kN) in. (mm) lbs. (kg) (1.50) 25/8" (66.7) 25/8" 25/8" 25/8" 25/8" (66.7) 67.0 69.0 71.0 213.0 217.0 (30.4) (1.75) (1.75) (1.75) (1.75) (66.7) (66.7) (66.7) Fig. 109A (32.2) Seismic bracing design load calculated in compliance with the requirements of IBC 2009 / CBC 2010. Rod Size (31.3) (32.2) (96.6) NOTES: 1. Mounting holes are standard. If the plate is not mechanically secured to the deck ribs, a jam nut is required to prevent the anchor bolt from laying over when concrete is poured. There is no structural strength added from the use of a mechanical fastener to hold the product in place before the pour. 2. Minimum spacing between inserts shall be not less than 41⁄2" (114.3mm) for 3⁄8" and 6" (1152.4mm) for 1⁄2" (98.4) Seismic bracing design load calculated in compliance with the requirements of IBC 2012 / CBC 2013. All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified. Pipe Hangers & Supports 192a 1î Approx. Wt./100 560 660 680 700 700 (2.93) 1” (25.4mm) Minimum Revised 8/8/2014