. wcu -

advertisement

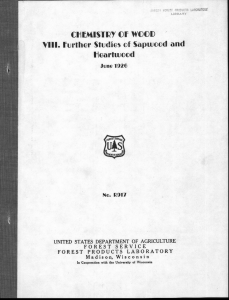

OREGON FOREST PRODUCTS LiBRARY LAIIr4 LALiIJS CF USCCLCIfL i AII2CIAFi VFFLI2S wcu Novcmbcr 1944 )Qt41fl ThIS L?FIDOF?T IS ONE 0E A SUiES ISSIJEt WAL? I)L?OGL?AM TO AIE ¡I-lE ForQst IDithoIoy SpQdaI LcIeusc No. 22 NATION'S . UNITED STATES DEPARTMENT OF AGRICULTURE AGRICULTURAL RESEARCH ADMINISTRATION BUREAU OF PLANT INDUSTRY. SOILS, AND AGRICULTURAL ENGINEERING DIVISION OF FOREST PAThOLOGY MADLSON, WISCONSIN IN COOPERATION WITH THE FOREST PRODUCTS LABORATORY FOREST SERVICE . LAR ,-._ -- B:EAIcnTa PAD lUS OF DISCOLOPD Py THEODORE C. WOOD flT SCH'FER, ans. CATHERINE G. DUNCAN, AIRCRAFT VEIEERS Patho1ogit Patho1oist Division of Forest Patho1oy1 Bureau of Plant Industry, Soils, and. Agricultural Engineering Agricultural Research Administrat ion United. States Department of Agriculture Sutnmary :e IDreaking radii of hardwood. cate that . s:ecìes riously discolored veneers of six different were small enough, for most of the discolorations, to indimich veneers can be used- successfully on members having curved sur- faces. rnen expressed in terms of the radius of curvature attained without fracturing, the ìreaking radius minimum in nearly cases was small enough to be aomly covered by a ninimum factor of safety all of 3, as suggested in ARC-19, Wood. Aircroît Inspection and. Fabrication. The only definite exception was veneer discolored by decay fungi. Some uncertainty as to sharply curved surfaces was indicated, however, for mineralsuitaMlity for in yellow birch, for the dark reddish-purele variety of mineral stain streaks in yellow-poplar, and. for gum streaks in mahogany and. khaya. Introduction ?he principal discolorations of yellow-poplar, sweetgui4, yellow biroh, lIn cooperation with the Forest Products Laboratory, Service, United maintained. by the States Department of Agriculture, at Madison, Wis., Forest in cooperation with the University of Wicconsin. -?Credit is due Francos N. Lombard. for oubstantial assistance in preparing a portion of the test material. Tue veneer was collected. and the toughness tests were made by the authors of articles cited in footnotes 3-7. Hepting, George H., Roth, Elmer R., and Luxford., R. F. The significance of the discolorations in aircraft veneers: yellow-poplar. Forest Prod. Lab. i4imeo. 1375. 8 pp., il1s. Nov. 1942. .Scheffer, Theodore O., arid Hansbrough, John R. The significance of the discolorations in aircraft veneers: sweetgurn. Forest Prod. Lab. Mimea. 1376. B pp., illus. Oct. 1942. j. R., Waterman, A. II., andLuxford., R. F. The significance of the discolorations in aircraft veneers: iirnoo. 1377. 7 pp., illus. Jan. 1943, yellow birch. Forest Prod. Lab. Hansbrough, Por. Path, Spec. Release No. 22. -1- OREGON FOREST PRODUCTS LIBRARY mahoany.9-, khaya, and. American beech2. have reont1y been claBsifle6- and- dOescribed. The utility of the discolored veneer for aircraft as evaluated from tougbness tests, was discussed in the same reports. With the exception of the gum streaks and the brown streaks in mahogany zd khaya, all of the discolora tion not associated with decay listed in this report were previously determined to be accetab1e from the standpoint of tougbnoss. The present report gives the results of bending tests made to ascertain which of the discolorations may cause veneer to have such a large breaking radius as to present objectionable dif ficulty in the inanufact-ure of curved parts of aircraft. ,' Test Methods The breaking radius of the veieer was deternined on a step-type series of constructed of wood and designed at the Forest Products Laboratory for determining the relationship of radii of curvature at breakage to elope of grain through sheets of veneer. The radii of curvature of the mandrols ranged from 3.50 to 0,125 inches, in steps of 0.25 inch between 0.75 and 3.50 inches, and of 0,125 inch between 0.125 and 0,75 inch. rnandrels, In testing, specimens of veneer, 2-1/2 to E inches long in the direction of the grain and 1/2 to i inch wide, were bent around mandrels of decreasing radius until definite evidence of fracture was obtained. The radius of curvature last preceding the one causing fracture was recorded as the breaking radius. This radius was determined usually for 2 portions of each specimen and the results were avoraged. The bending was done with the fiber direction at an angle of 90° to the axis of curvature, and with.the "tightt side of the veneer toward th mandrel. To insure a reasonably accurate evaluation of the breaking radius, the veneer was pressed as firmly againt the mandrel as possible over the entire length of the bend, which usually was not greater than about l-1/2 inches, Each test, moreover, was started. on a radius of curvature several steps larger than the breaking radius, This was done in order that all of the specimens might be subjected tri about the carne amount of flexing preceding fracturing, Specimens for the tests were taken from etraight-grained areas on the veneer sheets and as nearly parallel with the grain as cöuld 'ne determined by eye. In t1e majority of determinations each individual test was represented by at least two specimens, one being taken foni the discolored area and the other, serving as a control, being taken from an adjacent area of clear, sound wood. To get both specimens as nearly as possible from the saine growth rings of the wood, the control was taken from wood extending frrim the end of the discolored specimen in quarter-sliced veneer or from wood. either at the end or side of the discolored specimen in rotary-cut veneer. Tacts of this sort are Hansbrough, J. R. and Krause,R.L. The significance of the discolorations in aircraft, voneers: mahogany and. khaya. Forest Prod, Lab. Mirneo, 1379. 7 i?P. , illus, Nov, 1943. .ZHansbrough, J, R, Waterman, A. M,,, and Krause, R. L. discolorations in aircraft veneers: American beech, Release o, 16, 6 pp. illue, April 1944. For. Path. Spec, Release No, 22 -2- The significance of the Forest Path, Spec. commonly known as matched tests, and are particularly useful in that differences obtained between the sound and discolored wood. ascribable to factors other than those related to the discoloration itself are reduced to a minimum. With rotarycut veneer, the discolored and control specimens could not be SO 9ömetimes closely matched, because of the way in which the discoloration was distributed. Clear veneer anywhere in the same sheet then had. to be used for the controls. Supplementary tests showed that the reliability of tests was riot consequentially reduced by matching of this kind. In fact, it is necessary to have some such matching in order to sample centers as well as the margins of discoloration zones. With sorne of the material, discolored, and adjacent clear wood was included in the same test specimen. This was done to find whether any consequential weakness existed along the line of juncture. Prior to and during the testing, the specimens were held at a relative humidity of 30 percent and. a temperature of 800 P. This resulted in an equilibrium moisture content of the wood of approximately 6 percent. Results and. Conclusions The mandrel-bending results shown in tables 1 through 6 are summarized. in tbree ways: (1) as the actual 'breaking radii of both normal and discolored veneer of irarious thicknesses, (2) as ratios of the breaking radius to veneer thickness, and (3) as ratios of the breakiig radius of the discolored veneer to that of the matched normal on any of these difComparisons can ferent bases, as desired. However, the results expressed in terms of the ratio: discolored veneer 9 may be evalulated. without regard to veneer thickness-, and normal Veneer it is from this ratio that the conclusions were largely derived. In interpreting such a ratio it should be kept in mind that since increase in the breaking radius meant decreased bending capacity, lowered bending capacity is indicated 'by ratios greater than 1. . . Measured by these ratios, the 'breaking radius of veneer containing most of the different types of discolorations was somewhat larger in general than that of veneer of normal color, but because of the comparatively large factor of The breaking-radius ratioswere averaged geometrically. The geometric average th root of the product of is the n values. With the present data the geometric averages are, for the most part, not much different from those obtamed 'by ordinary arithmetic averaging. They were used because they give discolored normal normal is the reciprocal of the geometric average o± the values which discolored is not true for the arithmetic average. Althcugh the minimum breaking radius increases markedly with increases in thickconsistent relative values, ness of veneer, the ratio The geometric average of the values radius item breaking radius control if at all, related to veneer thickness, Por, Path. Spec, Release No. 22 -3- apparently was 'but slightly, safety generally used in bending, the increase was not enough to be of concern in the fabrication of curved aircraft surfaces. For a few of the discolorations, however, the averare breaking radius was enough larger than that of the normal veneer to suggest an objectionably low bending capacity. Discolored veneer with a breaking radius represented by a ratio greater than 3.00 would fracture if bent to the degree permitted by a factor of safety of 3 for the associated normal veneer. If the normal veneer itself were in the low range of bending capacities for material meeting Specification AN-NN-P-511b, a ratio presumably could be substantìally less than 3.00 and the veneer still fracture on the radii of curvature prescribed by a factor of safety of 3 applied to the breaking radii indicated by figure 5-90 of ANC-19. Since the normal veneer used in the present tests was of about average aircraft quality, it is not possible to define precisely what ratios would be indicative of excessively reduced bending capacity if the discoloration were in veneer cf otherwise low capacity. It is regarded as conservative, however, to assume that with discolorations that in these tests gave ratios of 2.00 or higher, there is likely to be an objectionable proportion of material of inadequate bending capacity. Although none of the ratios exceeded. 2.00 on the average, they d-id in many individual tests, With the decayed birch and. beech veneer, 58 and 45 percent, resuectively, of the ratios were greater than 2.00, and 15 and 11 percent of the respective ratios were as great as 3.00. Slight decay may not increase the breaking radius to this extent; it did not in the sweetgum and yellow-poplar samples. Nevertheless, veneer with incipient decay should not be used since there is always the possibility that the bending capacity may be severely reduced. Of much greater importance is the critical weakening caused by decay. Of the discolorations not associated with decay, only the dark reddishpurple mineral stains in yellow-poplar, mineral streaks in yellow birch, and gum streaks in mahogany and khaya had a bending capacity seemingly inadequate for the more severe aircraft curvatures. Aproximately 1 percent of the ratios for each of these discolorations except for the gum streaks in khaya.21, exceeded 2.00. Gum streaks, because of their general lack of strength, might well be restricted on a basis such as is applied to splits and open joints. The other two cliscolorations might be restricted to flat-panel construction or moderate curvatures insofar as is practicable. There wa no marked tendency for the veneer to split along the margin of normal and discolored wood. as a result of bending. It is suggested in ATC-l9, Wood .ircraft Fabrication and Inspection, that a minimum factor of safety of 3 be used, in which case the bending radius used would be at least 3 times as large as the average breaking radius for veneer of the same kind and condition. For example, if the average breaking radius of the specified veneer is 2 inches, a minimum working radius of 3 times 2, or G IflCilGS, is suggested. iGum streaks were found in supplementary observations to be quite brittle for the most part, and it is probable that their true bending deficiency was not developed in the lthaya tests because of the large proportion of streaks that were so narrow as to involve only part of the width of the test specimen. For. Path4 Spec. Release ITo, 22 -4- Table 1. ---Breaking radiue of normal end diecoored 8weetUm1 - -- Average ratio: :Veneer:Number :Medlan breek1ng:Rtio of medien breakNormal to :ing radius radius of thiCese:Bre :thickradius,'Çreakin radi wood of control neas :watched: of item -' used as Control Item Item :Control: testg control : : Item tested : : : : : : : : :Inee: : : Decay (varioe ehados of doll brown). :Heartwood:O.023 :eartwood: .035 .066 :Sapwooi .086 :Sapwood :1.11 testa: : : : 10 g : 16 : : ; Mineral streak .022 Broad; rt-bron color ............ $apood .066 Do .............................. Sap,od Do ............................. :Eeartwood: .066 : : POOd Ìarrov; reddie'-bon color ....... Do ............................ :Sapwocd Do, ............................ :Sapwood Heartwood streak ..................... ;Se.pwood : : 21 : 0.38 : .60 : .87 2.56 : 1.93 2.20 : : : 37 12 : .031: : 9 : : : : ; .3g : l.21. : 1.52 : .2Z . : .5 .61 .7'4.: .51. 13 : 1.0 i.g : : .39 : 121 : 16 : .714 : .72 16.5 17.1 29.2 25.6 : : : 25.6 29)4 : 1,314 ¡ 1.32 : 1.65 1.91 1.11 : : : l.25* : 21.5 2g.O ; 1.20 : : 1.15e' : : : ig.a 19.7 25.k 12.7 22.9 23.9 11.7 23.9 17.3 : : 1$. : ¡ 23.0 : 1.13 1.07 1.10 12.1 : i.o6 25. : : 16.14 : : i6.g 23.2 ; 20.3 : 20.0 .93 1,25 1.12 : : Highly significant. Lese than i cnance in 100 of accidental occurrence. Vlue not footnoted are no statisttca.ly significant. F : : : .1O Gecmetric average of ratios for the individual matched tests. Z?6 : 2$.7 33.k 32.1 32.3 : ; : : 2.kk : Ahout 75 percent was rotary-cut material; remainder was quarter sliced. Z M : .75 ; : : : 29 : ; .066 0.66 1.17 2,12 2.7e : 7 .024 : Inches: : J : .022 or gra'-brown color....:Sapwood Gt'eonish .031 Do ............................. Sapwood :A11 tests: : lachee: io ; O3 .037 :Sapwood A11 teets: ; : : : :fl,tod; Sap (blue) etain ...................... : : : : : 1,08e. 1.01 Tablí - .-rakin radtu of noraal and d1co1ored oraa1 : Ttan testad used au : control no : to dar-bro,n color breaking: Ratio of median breakAyera «e ratio radine :in radtn to .._.Break1ng radtue,éBreang radlu matched: --- te8tu ttin :Control: Ttaa of of control Control : : 12 : b : SapwOOd ande heartwood :!eartwood color over1rtnr black adneral itMn .0I4 ?A11 "!naral stain (inc1udtn bine bott) an minra1 tra 'ark r,iih-nnrc1e color ......... .050 tet : : : 1.79 2.99 : : J 116 : 1.70 : 0.93 : : 24.l 1.59 2.70 22.7 : : : : : : 35. : 35.6 reanth-brown color ..... : 1.52 : .052 : 1.1S 103 .95 .05 Taartwood : : t*t : : rethHah-ourole color ......... ;SOod and; !A11 : : tst .6 : ig. 2.0e : : i.o6 1 : 27.9 32.0 1.09 1.09 : 1.13** : : 24.6 34)4 23.7 30.2 : i.06 ; 1.13** : tests : : : : : : : : Sapwood : :Allteste : : : : : ; : : : : : : : : : : 23 31 19 : : : : : 1.21 1.20 2.62 : : 1.08 1.06 1.5k 2.k9 : : : : : : 1.12 1.56 2.29 : : : ; : 23.7 22.5 : sapwood :Sapwood : :Sawood : 043 : : .04$ .056 .062 27.9 : 27.7 11 ; : 12 : : $2 : : 1.05 : : 25.3 23.3 : : 19.0 30.1 : 25.1 : 2.k : 28.6 : : 21.k 23.5 25.7 26.3 : : : 1.05 1.13 : 2Q.4 1.03 : 19.3 22.0 23.6 28.3 1.1 1.10 1.0$ ¡ : : : 1.09** : 10 : 1.09 : TI stain ...................... : : : .3 : : 26.k : : : .92 1.20 1.70 2.29 214.5 : : 1.09 19.1 : : 1.4+ : : : : : : .051 .066 .081 : : 1.145 28 30 21 10 22.5 : 1.40 .97 : : : : 1.02 6 : .th3 1.30 : j : : : : : orma1 heartwood ..................... :Sapwood :Sapwood :Sapwood j 39 : : .82 .97 : : Lavender color .................... :Sapwood. and: heartwood .043 :Heartwood : .052 :Eaartwood : .063 :Heartwood. .087 All teste : : : : tests ; 22 : Black ............................. Sawood and: eartwood .O43 :Sapwood and: lieartwood .052 .99 .95 1.29 : : 1.3 : : .99 1.06 1.23 1.50 23.0 : : : 19$ 23.0 23.1 : : 23.0 22.1 22.0 2k.2 : .95 .92 1.02 : : : cut. Geometrtc average of ratios for the individual matched teste. e Reasonably significant. Less then 5 chences to 100 of as lar,e a deviation from 1.00 occurrin$ High17 sinhutcant. Less than 1 chance in 100 of accidental occurrence. Values not footnoted are not statistically significant. E 1.1 : 24.5 29.7 ; 1.02 1.51 1.72 19.5 ; : : 57956 1.22 : : ; ; 23.2 : 1.30 1.93 : J, keartwood .043 :Sapwood and: eartwood .053 :Sapwood :A].l teSt, 1)4e 6 Sapwood and; AU 1.02 36 11 0 ; .0l .050 22.7 : 33 : 1.15 : : 21 : :A11 : 17.4 : : : .01;4 fl 1.11e : : : heartanod 30.4 : 20.0 : fl : heartwood eartwood 74.0 : 75 Sanwood and: A11 Purp1h-brown oobor .............. 0 : : tet heartwood Sawood and : M 1.06 1.1v 32.1 : : .&43 h,artwood ?A11 t 1.07 : 31. : : : apwood and i11 rotar7 : anwood and heartwood Blue (sap) 0.99 ie / : ieartvood . p*1 : 3 rown green to : : .0 : : , : : : beartwood :O.Ol tbcea: : : apwood and : -- Nber :ledian of : ecay Lit : :thick- wood : yelloN-poplar1 Veneer pre1y by accident. Pable 3.-Brean rMiu. bircb of normal and diecolored ye110 Normai. : WOOd used as contrai Iten teeted : test8 : Decay (cream colored to broan diacolorations) ............... Heartwoo& :Eeartwood :Heeztwood A3.1 tests streak Yellow to yellowish-white color. . . Sapwood Do ............................. Heartwood ; :O.Okk .052 ; .060 : : : .032 ; : .05 ; .052 .07ê : Striped zone ......................... ;HeartOOd :end sapwood: .062 .072 :Heartwood : .108 :Heartwood : :Allteets Normal h.artwood ..................... $apwood :Sapwood :$epwood :fll testa Eeartwood streak ..................... ;$ep,od :Sapwood ¡Sapwood ¡Ail tests Light streak. ........................ ;Eeartwood :Heartwood ¡Ail tests 1.21 61 : : 13.2 13.1 13.5 : : : li 6 : 3 ; lê2 ; : ; .87 : 13 : 1.08 1.35 : j :158 : 2 16 .76 .9 : .91 : 1.l : : : : .071& . 62 1.01 1.12 17.« 19.3 28.6 : ; 2.00CC : : : 15.8 ¡ 1.10 1.23CC : : 1.25 1.21 1.51 : 1.19 ; ; 16.9 18.1 : : : l7. : : 18.2 : lk.7 15.k : : : : : 1.19CC : : ; ; 1.10 1.20 2.12 17.2 : : ; : : : ; 1.19 1.16 2.3? 19.5 : ; . : : : 20 : : : : : ; ; .98 : . 1.k9 : : ..3 .0k9 .060 : ; : : 2.13 2.00 : : : 17.2 : : : : 19.2 16.1 21.9 : : : 17.7 16.7 19.6 1.09 .93 : : 1.070* . 62 .99 .99 : : 12. 6 12. 6 16.8 15.1 16.5 l3.k 00 1.06 i. : 1.03* 23 ¡ .0143 l .052 .062 8 ¡ : .062 .110 181 89 : .71 .87 1.03 91 ¡ .69 .68 .98 16.5 16.0 1.03 16.7 16.6 13.1 15.3 1.08 ¡ : 1.05* : ¡ ...a 1.05 2.37 1.10 2.37 ¡ ¡ ¡ 17.7 21.5 : 16.9 21.5 1.05 : : AI1 rotary cut. of ratios for the indivithial matched tests. a deviation from 1.00 occurring purely by accident. Reasonably significant. Less than 5 chances in 100 of as large occurrence. of accidental SCHigh]. in 100 Lese thar 1 chance significant. not tatisticaily significant, Talues not footnoted 0eometrtc average * ar, Z M 5795? F , radine Z Breaking of control : 29.1 31.1 25.7 : : .55 : : : :l9b :Allte.ts .55 : : :and sapwood: .062 Sapwood : : : ; : : .63 .81 : : : 3 : : :and sapwood: .062 :111 tests Do ............................. : : : : : : : 0.58 : 35 : Broen to greenish-brown color ..... Do ............................. :Sapwood Do .............................. Sapwood Do ............................. Reartwood : 1.2$ 1.62 1.5k : Control : ration e radius Ofit6 ,,' ; : : : 60 9 : Item ¡Control: Inch.,: luche.: : : : It :Br8n - : : : Ave : :ing radius to thickese: radius : of :thick-: nose ;matched - :Incbes: z Mineral :Veneer:Nber :Mediau breakinRatio of median break- 1.050 Table 1--Break1n raì1us of nornal an1 diecolored merican beech : Item tooted :Verieer:Nimiber :Hediaxz Normal usedas : : : : Do .............................. Sapwoo& :A11 : tests Sap (blue) stain ...................... Sapwood Pink heart ........................... :Heartwood :1.11 Tau heart ................ :Heertwood Brownish-yellow :B.artwood :A11 tests Mineral strasic (gray-brown color).... :Sapwood 1A11 50 : .0k : : : : : : : ¡ : : : : _.3ì 13k 28 29 : : : : .$3 .96 1.3 57 32 .25 .73 .60 1.29 ¡ ¡ .67 1.62 : : : : .81 : : : : : : 15.9 3$.7 32.0 3k.5 : : : : : : : : 1.62 : : 19.3 1.3 .6 : : : 1.59 : : : 16.8 : 10.0 16.2 1I.5 15.2 : : : : : 12.2 19.0 11.2 ¡ : 10.8 ¡ 16.14 2J5 : : 1,91** 17.0 : 1.12** 1.8 : 1.03 16.6 13.3 19.0 .92 : 1.27 : : 1.01 : 1.02 10.0 17.8 12.2 18.7 .90 1.25 : : : 1.01 : 10.9 ik.o : .2k 1.07 2.10 : : u.k : : 17.8 : : .27 : : : .2k .59 ; 17.14 : .80 15.0 : 19.5 : .73 .25 : .25 : 108 : .73 ¡ ¡ .0142 : .$0 : .k .025 : .&4 : 3k : : 2.93 : .0k2 ¡ 1.76 .63 kl 13b .022 : 0.63 : ¡ : : : : : .025 ,0k5 .055 .085 : : 1.03 ¡ : 93* : 9.6 1.09 : : .69 : .70 : ¡ ¡ 16.7 ¡ : ____ : .99 rotary cut. Geometrtc average of ratios for the individal isatched tests. Reasonably significant. Less than 5 chances in 100 of as large a deviation **Hjghl significant. Less than 1 chance in 100 of accidentai occurrence. Values not footnoted are not statistically significant. * Z M 57958 F o1:___ ; : : 0.67 1.7k 200 : .055 .og5 : : 17 :Sapwoodand: heartwood: ¡Ail tests : : .013 :Heartvoo. ¡Ail tests 36 : heart ............................ ;Heartwood :Heartwood :Heartwood : 36 : tests 21 ratio radis,"Breaking radius - Ip.he,: Inches; : : .043 ; :Hsartwood. :Heartwood .085 : Pith flecks .......................... : : :O.O2 .045 .055 Sapwood :Sapwood Do .............................. Sapwood Average - :Incbas: With blue stain Without b1ie stain : - ------ : Decay :atched :--------- : __!:__ - breakin;Ratio of median break:_r1 eto thiebiase froa 1.00 occurring purely by accident. ab1' 5.-:rea3c1ng radi of nornaJ. aiid discolored mahoan.y Normal : wood : I tern tested : : used as control ; Gwn :Veueer:Number :Mediai breakiug:Ratio of median brea]o- :thjc-; : ;Ins; ........................... :Heartwood: Brown streak .......................... Heartwood End stain ............................. Reartwoo&: rox streak ......................... :Reartwood.s Water stain .......................... ;Reartwood; :Haertwood: tests: ............................'Eeartwood: Brown spot ............................ Reartwoo&: Red streak .......................... :Heartwood: White ensthge .......................... Hsartwoods spots tests : : Iron stain Mold of ness :matched streak........................... ;Heartwood:O.035 :A11 (Swietenia)1 .O3 .035 : : 27 : 51 : s .0314 35 143 : 0.90 s : .89 s s .70 s : 1.06 s .75 .80 .99 . 314 s s 38 : .71 148 : .80 : s z M 57959 F : 25.7 : 30.6 : 22.6 214.7 : s 22.6 28.2 ; s 20.0 21.9 25.2 : 21.k of item : 20.9 s 1.175* : 1.11 : 1.07 : 23.0 s ì.o6 19.1 s 1.03 1.01 21.6 23.6 s 1.02 22.0 s .99 23.1 s .98 : : .75 s s .81 : 22.8 : 23.5 : 214.1 s .96 26.6 s 27.3 s .96 .0314 s 27 s .80 : .82 .0141 s 16 s 1.09 : 1.12 quarter and flat sliced. Geowetric average of ratios for the individual matched tests. 55Highly significant. Less than 1 chance in 100 of accidental occurrence. Valuas not footnoted are not statistically significant. Mixed 2 : .83 .67 Control : ; .96 .79 : .035 0.79 : 1.014 29 .037 .0142 Inches; Inches: i .035 .036 : Itesi :Control: ratio , radiis of control ,// 3reaking radis - : Item 37 Aver e --------------- --------------------- : : : :lng radius to thickness: radius : ¡ Table 6. -- --Breaking radius of normal and discolored kbaya (African _____------ Item tested : Normal : wood : used a : . Red nd etreak . control :Veneer:Ninber :M.&ian breakin:Ratio of median break- Ave ratio :ing radiusto thickness: Breakin radiuB/ Breaking radius ness :matcbM: of item ,,,' of control : te8te Item :Control: Item : Control : :thick-: of : : stain ............................ :Heartwood: .053 :Heartwood: tests: .ø6ê streak .......................... :Beartwood: .036 Worm :Heartwood: .055 :Heartwood: .065 :A1l tests: streak ......................... :Heartwood: .053 Brown : : : : : : : 30 33 J. I9 Gum streak spot Brown tests: ........................... :Heartwoodr : r 29 : rl.].ltests: : r : 31 8 16 : 16 r 22 : 1.03. l.74 : : .92 1.19 1.5k : : 1.05 : : 1.68 : 21.9 19.0 27.2 : : : : : : i.ik 2.37 : r .97 1.29 1.62 .95 : : r 1.16 2.62 r : : : 25.5 27.1 23.7 19.8 26.2 r : .93 2.05 2.87 : r : 21.5 27.5 18.3 3k.0 29.5 : : 26.9 : : 23.1 : : 2k.9 : r r 21.9 30.5 r : r 17.9 3k.2 33.)4 r : Z M 96O F .95 j3 1.01 .98 1.17 1.00 : .98 : r r 97 1.02 1,01 : r 28.9 20.0 i.06 : : : 26.2 21.k : : : : 1.07 1.12 : : : : r r .97 1.20 : : : 2.0k 2.5k 2O.4 ; : : : 1.06 : r quarter and flat sliced. Geometric average of ratios for the individual matched tests. Reasonably significant. Less than 5 chances in 100 of as large a deviation from 1.00 occurring purely by accident. Values not footnoted are not statistically significant. Mixed j : : r : 31 l.l4 : r r Inches: Inches: : : 1$ r .037 :Heartwood: .056 : : : :A1l ........................... :Heartwood: : 3 : .052 :Heartwood: .060 :Heartwood: .086 tests: : 9 :Heartwood: .0g6 :A3.1 : radius ; :Keartwood:O.052 :1.11 : :Inhe: ; maìiogany)1 .98 .88 kQI 93