EXPERIMENTAL INVESTIGATION OF INTERACTIONS BETWEEN EXPLOSIVE DETONATIONS AND THE RESULTING SNOWPACK RESPONSE

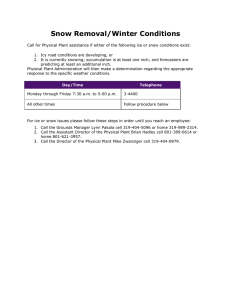

advertisement