Physical, chemical and cooking qualities of eggs as affected by... by Sister Agnes Marie Nash

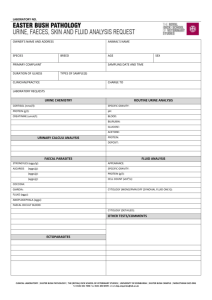

advertisement