FOR

advertisement

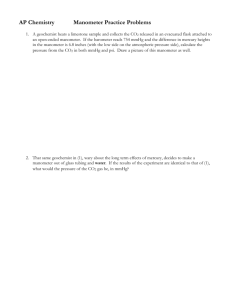

A MICROPROCESSOR BASED SYSTEM FOR W I N D TUNNEL MEASUREMENTS C. Ravikumar, lbl. B a l a k r i s h n a n and V.S. Holla D e p a r t m e n t of Aeroepaco E n g i n e e r i n g Indian I n s t i t u t e of Science, Bangalare, India. bbatract : A 1 6 - b i t micoprocessor based system has been d e s i g n e d a n d d e v e l o p e d for a u t o m a t i c flow f i e l d p r e s s u r e survey and f o r c e m e a s u r e m e n t s i n t h e l o w s p e e d wind t u n n e l a t t h e I n d i a n I s t i t u t e of S c i e n c e . The i n s t r u m e n t a t i o n s u b s y s t e m s t h a t a r e r e q u i r e d f o r t h e above m e a s u r e m e n t s u n d e r the processor control, the system processor unit, interfaces t o standard p e r i p h e r a l s , f u t u r e expansion p r o v i s i o n s to other and communication channel c o m p u t e r s y s t e m s h a v e a l l been d e v e l o p e d in- house. Software h a s been designed t o provide a powerful friendly and reconfigurable integrated instrumentation. The s o f t w a r e a l s o e n s u r e s q e a l time data acquision, on- line 'preprocestling and s t o r a g e o f t h e d a t a on a floppy. S o f t w a r e h a s a l s o been d e v e l o p e d the data on a n i n e x p e n s i v e PC f o r presentation i n color graphics. The design, development and i m p l e m e n t a t i o n d e t a i l s , o f t h e s y a t e m have been p r e s e n t e d l a thie p a p e r . i s a blunted c o n i c a l nose 5 h o l e probe. Both U- tube manometer banks and r e s e r v o i r t y p e manometer b a n k s a r e a v a i l a b l e f o r pressure data collection. For a c c u r a t e p r e s s u r e m e a s u r e m e n t s a s e t of p r o j e c t i o n manometers i n d i g e n e o u s l y d e v e l o p e d a t t h e These department a r e also available. m a n u a l l y r e a d manometers have a r e s o l u t i o n the of 0 . 2 ~ ~ . I n a t y p i c a l t u n n e l r u n , t e s t model i s mounted on t h e m e c h a n i c a l b a l a n c e ' s t r u t s and t h e aerodynamic f o r c e s a n d moments a r e measured m a n u a l l y by c o u n t e r b a l a n c i n g t h e unknown l o a d s w i t h dead weights. Flow f i e l d d a t a is collected through the pressure probe, f i t t e d t o t h e manually operated t r a v e r s e meachanism a n d a manometer bank o r t h r o u g h a s e t o f 6 p r o j e c t i o n manometers. The p r e s s u r e s u r v e y f r o m t h e body t a p p i n g s is made w i t h a manometer bank. For t h e d a t a reduction, t h e gathered data i s f i r s t punched on c o m p u t e r c a r d s and t h e n f e d t o t h e main frame c o m p u t e r DEC s y s t e m 1090 a t t h e c e n t r a l computing f a c i l i t y of t h e institute .. System O v e r v i e w Xntroduction : The c l o s e d c i r c u i t wind t u n n e l (CCWT) at the department of Aerospace Engineering, Indian I n s t i t u t e o f Science, h a s been e s t a b l i s h e d i n 1947. The t e s t s e c t i o n of t h e t u n n e l has an e l l i p t i c a l c r o s s - s e c t i o n o f d i m e n s i o n s 7 ' x 5' a n d i s being used f o r f l o w field surveys, force/moment and pressure survey measurements. Recent i n s t r u m e n t a t i o n s e t u p i n c l u d e d a 3-D t r a v e r s e mechanism p o w e r e d by i n d u c t i o n m o t o r s , pressure probes, manometer banks t o r e a d t h e p r e s s u r e s and a mechanical balance f o r f o r c e measurements. The p r o b e t r a v e r s i n g i s done t h r o u g h a s e t o f ON/OFF s w i t c h e s o o n t r o l l e d m a n u a l l y t o move t h e p r o b e i n t h e r e q u i r e d d i r e c t i o n over a t e s t sect'ion o f 96" x 48" x 3 6 " . A set of mechanical c o u n t e r s a r e used t o i n d i c a t e t h e t r a v e r s e position. This arrangement provided a r e s o l u t i o n o f 0.0025t1 a n d 0.1l' overall positionin The accuracy i n probe pre8sure p r o b e u s e d f o r f l o w f i b f d s u r v e y . I n o r d e r t o meet t h e increasing demand f o r t h e t u n n e l a v a i l a b i l i t y , t h e i n s t r u m e n t a t i o n Rystem i n t h e t u n n e l h a v e b e e n u p g r a d e d t o a u t o m a t e moat o f t h e e x p e r i m s n t a l p r o c e d u r e s [ I 1. The i m m i n e n t a d v a n t a g e s due' t o t h i e a r e f a t i t e r a n d accurate data acquisition that is free from human e r r o r s , a n d r e d u c t i o n i n t o t h e a e r o d y n a m i c q u a n t i t i e s , which make t h e s y s t e m s e l f c o n t a i n e d a n d improve t h e t u r n a r o u n d time. The modern t e c h n o l o g y i n t h e f i e l d s of wind tunnel instrumentation and computer based systems, o f f e r a wide c h o i c e o f i n s t r u m e n a t i o n and p r o g r a m m a b l e c o n t r o l l e r s t o automate a t e s t f a c i l i t y . On t h e i n s t r u m e n a t a t i o n f r o n t , h o w e v e r , f o r most o f t h e small- and medium- range t e s t f a c i l i t i e s , t h e c h o i c e i s l i m i t e d by several factors like the present c i r c u m s t a n c e s of t h e t u n n e l o p e r a t i o n , , t h e e x h o r b i t a n t c o s t f a c t o r s involved i n t h e the required inatrumentation and 1 54-IClASF '87 RECORD CX2449-7/87/0000-004 1 $1.00 @ 1987 UJB m o d i f i c a t i o n s t o t h e t u n n e l t o accomodat e new i n s t r u m e n a t i o n . Due t o s u c h r e a s o n s , t h e i n s t r u m e n t a t i o n i n t h e above t u n n e l h a s been upgraded t o f a c i l i t a t e automation i n s t e a d o f a c q u i r i n g modern e q u i p m e n t l i k e [Z-81. l a s e r doppler velocimeters, e t c . T h i s u p g r a d a t i o n work i n c l u d e d t h e d e s i g n and i n t e r f a c e s t o c o n t r o l t h e mechanical i n s t r u m e n t s , t h e d e v e l o p m e n t o f a new p r e s s u r e m e a s u r i n g d e v i c e and tin a n t i l o g DAS. A d i g i t a l i n t e r f a c e has been d e s i g n e d and d e v e l o p e d t o a u t o m a t e t h e 3 - D p r o b e t r a v e r s e o p e r a t i o n . A new 6 - c h a n n e l d i g i t a l manometer h a s b e e n d e s i g n e d a n d developed t o a c q u i r e t h e p r e s s u r e d a t a from t h e 5- hole probe and t h e t u n n e l f r e e stream. This sensor is based on automating the prassure measurement p r o c e s s o f a c o n v e n t i o n a l U- tube manometer under t h e c o n t r o l of a microprocessor. I n s t r u m e n t s l i k e s c a n i v a l v e o r a n ESOP [ 7 1 would a l s o c l a i m a p l a c e i n s u c h a n a p p l i c a t i o n . However, t h e a b i l i t y t o r e a d all the 6 channels accurately s i m u l t a n e o u s l y o v e r a wide dynamic r a n g e , a n d t h e r e l a t i v e l y low c o s t makes i t a more suitable one f o r t h e present 8ppliCatiOn. To f a c i l i t a t e t h e a u t o m a t i c c o n t r o l t h e model a t t i t u d e , a new model m o u n t i n g r i g h a s been i n s t a l l e d . The model m o u n t i n g r i g d e s i g n e d a n d d e v a l o p e d by a n o t h e r group i n the departbent provides the model c o n t r o l in the d i r e c t i o n s o f p i t c h a n d yaw. For accurate force m e a s u r e m e n t s , a s a n o b v i o u s c h o i c e , a 6- component s t r a i n gauge b a l a n c e h a s been a c q u i r e d . The p r e s e n t and t h e f u t u r e e x p e r i m e n t a l n e e d s a t t h e CCWT d i c t a t e t h a t t h e d a t a from t h e s t r a i n g a u g e b a l a n c e be a c q u i r e d a t a 1 KHz s a m p l i n g r a t e a n d a r e s o l u t i o n of a t l e a s t 12-blttl. In view of this and the possible future expansions, a 32-channe1, 12- bit d a t a acquisition system (DAS) h a s i b e e n included. of I n o r d e r t o c a t e r t o t h e needs of p r e s s u r e p l o t t i n g e x p e r i m e n t s and wake p r e s s u r e s u r v e y s , a 48 p o r t s c a n i v a l v e v i t h a n LVDT t y p e p r e s s u r e s e n s o r h a s a l s o been included i n t h e system. The LVDT o u t p u t i a a c q u i r e d by t h e DAS. The task of automating the e x p e r i m e n t a l p r o c e d u r e s c o u l d be e f f e c t e d by integrating the above individual subaystems with an a p p r o p r i a t e l y s e l e c t e d programmable c o n t r o l l e r a n d DAS f r o v t h e commerbially s e v e r a l high performance, a v a i l a b l e , o f f - t h e s h e l f computer based systems. For example, systems like MACSYM, m a n u f a c t u r e d by Analog D e v i c e s , U.S.A. o r DATA TRANSLATE ( D a t a T r a n s l a t e [91 e t c . , o f f e r h i g h Corporation, U.S.A.) performance s p e c i f i c a t i o n s and a t t r a c t i v e capabiliti6s. However, m o s t o f t h e s e modules are o f g e n e r a l p u r p o s e n a t u r e . B e s i d e s , t h e r e q u i r e m e n t s i n a wind t u n n e l c a l l f o r several specialised acquisition a n d c o n t r o l f u n c t i o n s t h a t c o u l d n o t be met e a s i l y by t h e c o m m e r c i a l l y a v a i l a b l e systems. F o r example, t h e i n t e r f a c e s t o t h e 3-D t r a v e r s e mechanism and t h e d i g i t a l manometer a r e t o o s p e c i f i c t o wind t u n n e l a p p l i c a t i o n s . Commercial s y s t e m s g e n e r a l l y do n o t meet t h e s e r e q u i r e m e n t s a n d o f t e n r e q u i r e e x t e n s i v e t c t i l u r i n g , i f chosen. I A l t e r n a t i v e l y , t h e above t a s k can be i m p l e m e n t e d by d e s i g n i n g a d e d i c a t e d c o s t effective system p r o c e s s o r u s i n g the e a s i l y a v a i l a b l e advanced microproceusors. A 1 6 - b i t m i c r o p r o c e s s o r system has been designed a n d developed t o meet t h e s e requirements. The p r e s e n t c o n f i g u r a t i o n of t h e system i n c l u d e s a CRT terminal f o r u s o r i n t e r a c t i o n , an i n t e r f a c e t o s t a n d a r d p r i n t e r s f o r h a r d copy o u t p u t s , a MULTIBUS i n t e r f a c e f o r any f u t u r e w p u n s i o n s a n d t\ floppy disc controller f o r data atorage. The block diagram of the system c o n f i g u r a t i o n i s given i n Figure 1. P o w e r f u l h a r d w a r e w i l l be o f l i t t l e use without appropriate software. I n many applications the software development bears a d i r e c t relationship with the a v a i l a b l e hardware. T h i s often leads t o a s i t u a t , i o n wherein an i n t e g r a t e d a p p r o a c h t h a t caters, with equal emphasis t o b o t h h a r d w a r e a n d s o f t w a r e a s p e c t s would be needed f o r a s u c c e s s f u l design e x e r c i s e . The s o f t w a r e duvtiloped i n a s s e m b l y l a n g u a g e i n i t i a l i z e s t h o p e r i p h e r a l I/O chips and the interfaces to the instruments. The software f o r user a friendly interaction, provides e n v i r o n m e n t f o r t h e user. In t h e s e t - u p mode, a s e t of prompt and h e l p m e s s a g e s a l l o w s t h e user t o e a s i l y c o n f i g u r e t h e i n s t r u m e n t s t o t h e s pe c i f ic e x p e r i m en tal. needs. The s o f t w a r e t o c o n t r o l the e x p e r i m e n t h a s been d e s i g n e d t s s e q u e n c e t h e c o n t r o l o p e r a t i o n s through t h e d r i v e r r o u t i n e s f o r , each of t h e interfaces, a c q u i r e t h e dn'ta i n r e a l t i m e and p r o c e a s i t on- line. The p r o c e s s e d d a t a i 6 e i t h e r p r i n t e d o r s t o r e d on a f l o p p y i n t h e IBM format. The d a t a on t h e f l o p p y c a n a l s o b e t r a n s f e r r e d t o t h e mainframe c o m p u t e r DEC 1090 f o r d e t a i l e d a n a l y s i s , i f n e e d e d . The data p r e s e n t a t i o n i n a n e a s y t o i n t e r p r e t form, i s also a n i m p o r t a n t a s p e c t o f an i n t e g r a t e d s y s t e m . The c o l o r coded g r p h i c s t e c h n i u8 d e v e l o p e d by Winkleman e t . a l . I l O C f , i s a v e r y u q e f u l t o o l f o r f l o w f i e l d v i s u a l i s a t i o n and as i t requirss interpretation, But s o p h i s t i c a t e d c o m p u t e r systems a n d image p r o c e s s i n g s y s t e m s i t becomes u n a f f o r d a b l e f o r s m a l l s c a l e s y s t e m s . However f o r t h u p r e s e n t s y a t e n , g r a p h i c 8 s o f t w a r e has b e e s d e v e l o p e d on a n IBM PC c o m p a t i b l e m a c h i n e , t o p r e s e n t t h e p r o c e s s e d d a t a in c o l d r ICIASF '17 HL;COHL)-SS g r a p h i c s contour p l o t s and v e l o c i t y v e c t o r plots. The package exploits the c a p a b i l i t i e s of t h e PC a n d s i m p l i f i e s t h e flow f i e l d a n a l y s i s . A detailed description of the hardware and software f o r the user i n t e r a c t i o n , o v e r a l l experiment automation and d a t a p r e s e n t a t i o n i s g i v u n below. t i m i n g a n d power s u p p l y l i n e s . Modules t h a t U Y t~ h e MULTIBUS h a v e a m a s t e r - s l a v e relationship. The s y s t e m p r o c e s s o r , w h i c h i s t h e bus m a s t e r , d r i v e s t h e command a n d a d d r e s s l i n e s and c o n t r o l s t h e b u s . The p r c o a n t d e s i g n p r o v i d e s s i x a l o t , a for t h o slave units, o u t o f which t h e f i r s t s l o t h a s been u s e d f o r t h e 32 c h a n n e l a n a l o g d a t a a c q u i s i t i o n system. A floppy d i s c c o n t r o l l e r has buun u u u d i n t h e s u a o n d slot. System P r o c e s s o r U n i t : The b l o c k d i a g r a m o f t h e system p r o c e s s o r u n i t h a s been shown i n F i g u r e 2 . The h e a r t %f t h i s u n i t i s a 1 6 - b i t microprocessor and numeric d a t a p r o c e s s o r 8086-8087. The 8086, a t h i r d pair, g e n e r a t i o n m i c r o p r o c e s s o r , is c a p a b l e o f a d d r e s s i n g u p t o I M b 1113. I t o p e r a t e s on and t r a n s f e r s 1 6 b i t d a t a a t a t i m e . The i n c l u s i o n of 8087 i n t h e d e s i g n * i m p r o v e s the processing speed phenomenally. B e s i d e s , t h e 8087's i n h e r e n t c a p a b i l i t i e s t o o p e r a t e with 8 0 b i t words, p r o v i d e higher accuracy. The u n i t has been deeigned t o accommodtite t h e n e c e s s a r y memory a n d o t h e r programmable p e r i p h e r a l chips to interface the subsystems. N o t a b l e amongest them a r e a 0 0 Programmable p o r i p h o r a l t i m o r s ( I n t e l 825.3) t o lt,.t.mv utuinp' ~ t i c i I t o q u i k i J d d a t a titid t o g e n e r a t e t l n i r i r I n t e r r u p t s f o r t h e data sampling p u r p a s a s , - Programmable interrupt controller ( I n t e l 8259) to rocess multiple i n t e r r u p t 6 ( u p t o 8 7 from t h e s u b syiit'Fm niodulev a n d t i n i e r i n t . e r r u p t 3 a n d draw t o t h e a t t e n t i o n o f t h e p r o c e s s o r when r e q u i r e d (121. - Universal synchron ous and a 3y n c h r on o u s t r a n s m i t t e r / re c e iv e r Y (Intel 8251) t o support a CRT t e r m i n a l f o r u s e r i n t e r f a c e , and t o p r o v i d e a programmable a u x i l i a r y RS232C c o m m u n i c a t i o n c h a n n e l [I31 f o r l i n k i n g t h e system t o o t h e r computers ( a PC h a s b e e n c o n n e c t e d t o t h i s channel). - MULTIBUS i n t e r f a c e - t o f a c i l i t a t e any f u t u r e e x p a n s i o n s ( u p t o 6 ) . 3- D T r a v e r s e A u t o m a t i o n : T r a v e r s e m e c h a n i s m s may employ e i t h e r stepper m o t o r s o r i n d u c t i o u n i o t a r s . One of t h e i m p o r t a n t f a c t o r s t h a t i n f l u e n c e t h e c h o i c e o f motors i s t h e c a r r i a g e l o a d . Stepper motors a r e s u i t a b l e f o r d r i v i n g light carriages. But uost often the c a r r i a g e w e i g h t e n c o u n t e r e d i n ti t y p i c a l medium and l a r g e s i z e wind t u n n e l s e t u p i s c o n s i d e r a b l y more. I n such s i t u a t i o n s i n d u c t i o n motors a r e p r e f e r r e d t o s t e p p e r motors. Several i n t e r e s t i n g p o s s i b i l i t i e s d o e x i s t for a u t o m a t i n g t h e p r o b e t r a v e r s e mechanism e m p l o y i n g i n d u c t i o n m o t o r s . The technique employed t o i n t e r f a c e the t r a v e r s e mechanism t o t h o 1 6 - b i t p r o c e s s o r makes i t s i m p l e r t o p o s i t i o n t h e p r o b e precisely. '1'11e t 3 ~ ~ ~ v ~ ? tmechanism rstj dtnployrtd i n C C l i T h a s t h r e e n o t o r s t o move the p r o b e 9ott a l o n g t h e f l o w d i r e c t i o n (Xdirection), 48" along the lateral direction (Y- direction) and 12" in tha vertical direction (2- direction). In order t o k e e p t h e t r a v e r s e mechanism upstream effects to a minimum, the movement of t h e c a r r i a g e i n t h e Zd i r e c t i o n i s l i m i t e d t o 1 ' . To c o v e r t h e complete 2 - d i r e c t i o n t h e probe h o l d e r r o d can be c h a n g e d t o e x t e n d t h e probe movement downwards. Automating the above traverse mechanism usipg the microprocessor involves : (i) A F u t u r e expansion p r o v i s i o n s have been by designing a MULTIBUS simplified interface t o t h e p r e s e n t system [14,151. The bus s t r u c t u r e p r o v i d e s a common e l e m e n t f o r communication between a wide v a r i e t y o f s y s t e m m o d u l e s which i n c l u d e memory, d i g i t a l and a n a l o g I/O e x p a n s i o n It b o a r d s and p e r i p h e r a l c o n t r o l l e r s . c o m p r i s e s o f 20 d a t a l i n e s ( e q u i v a l e n t t o a n a d d r e s s s p a c e o f 1 Mb,), 16 b i directional data lines, 8 multilevel i n t e r r u p t l i n e s and s e v e r a l bus c o n t r o l , a Probe d i s p l a c e m e n t s e n s i n g o v e r maximum d i s t a n c e o f 96 i n c h e s . ( i i ) C o n t r o l l i n g t h e t h r e e m o t o r s t o move the probe t o t h e r e q u i r e d position In a l l t h e t h r e e d i r e c t i o n s ( i i i )C a r r i a g e l i m i t s e n s i n g a t ends of each of the d i r e c t i o n s , and (iv) either three S o f t w a r e f a r e a s y programming o f t h e module One o f t h e w e l l known and a c c u r a t e methods f o r p o s i t i o n s e n s i n g i s by u s i n g t h e Gray c o d e s c a l e . But c o n s i d e r i n g t h e . . I + % I 56-ICIASF '87 RECORD span of t h e p r e s e n t system, a 0.01" r e s o l u t i o n w i l l n e e d a 1 4 - b i t Grey c o d e scale. Due t o t h e o b v i o u s d i f f i c u l t i e s i n v o l v e d i n f a b r i c a t i n g a 1 4 - b i t Gray code scale with O.O1ll lines, often a p o t e n t i o m e t r i c method i s u s e d f o r p o s i t i o n However, i n t h e p r e s e n t sensing [16]. system, in order t o adhere t o the simplistic design goal, an alternate method h a s been d e v e l o p e d . In this m e t h o d , p r o v i s i o n s h a v e b e e n made t o counL t h e number o f r e v o l u t i o n s o f t h e l e a d s c r e w of each motor with the required r e s o l u t i o n , u s i n g I R o p t i c a l s e n s o r s , MCT8 [17]. The number o f r e v o l u t i o n s a r e counted u s i n g a s o f t w a r e programmable i n t e r v a l t i m e r (8253) i n t e r f a c e d t o t h e This avoids t h e problems processor. a s s o c l a t t r d w i t h t h o t i n u l o g t o o h n i q u a s . To c o n t r o l t h e 3 motors, a b i d i r e c t i o n a l motor c o n t r o l c i r c u i t r y i s d e s i g n e d u s i n g a simple l o g i c c i r c u i t and r e l a y s . In order t o safeguard t h e motors a g a i n s t t h e p r o g r a m a n d human q r r o r s , f e a t u r e s l i k e , c a r r i a g e l i m i t s e n s i n g , a u t o - m o t o r OFF a n d interrupt to the processor are incorporated in the design. The e l e c t r o n i c i n t e r f a c e i s shown i n the Figure 3 . The software f o r t h i s interface f a c i l i t a t e s c a l i b r a r t i o n of the traverse and forms a look- up t a b l e for4 the calibration constants. This calibrbtion compensates f o r t h e e r r o r s duo t o t h e inertia of the inducLion motors, mechanical g e a r s and a l s o t h e misalignment e r r o r s i n each a x i s . For probe position control the software allows the user t o define the s c a n volume i n t h e t e s t s e c t i o n a n d o t h e r parameters. The f e a t u r e s o f f e r e d by t h i s aoftwgre include - P r o b e movement selections. e I, S c a n limits directions. MANUAL on each o f / AUTOMATIC the Number o f s e g m e n t s w i t h i n t h e three limits i n each d i r e c t i o n . Different grid sizes f o r different segments w i t h i n t h e s c a n limits. Other options i n c l u d e I, Default grid s e l e c t i o n . Grid size dynamically altekable without discontinuing t h e experiment. a C a l i b r a t i o n a n d f o r m i n g a new l o o k - u p t a b l e f o r t h e correction terms t o 6 - C h a n n e l D i g i t a l Manometer : The i n s t r u m e n t is b a s e d o n d i g i t a l r e n d i n g o f t h e d i s t a n c e between t h e l i q u i d levels in a U- tube manometer by mechanically traversing a c a r r i a g e to which a r e f i x e d a p a i r of l i q u i d l e v e l sensors. The c a r r i a g e t r a v e r s e i s s e n s e d b y a d i s t a n c e s e n s o r which p r o d u c e s a p u l s e p e r O . l m m movement o f t h e c a r r i a g e . T h e s e p u l s e s a r e c o u n t e d by a f r e e r u n n i n g counter. The m i c r o p r o c e s s o r r e a d s t h e l e v e l s e n s o r s ' s t a t u s and a t t h e i n s t a n t s of the carriage crossing the liquid level meniscus, samples the free running counter. The r e a d i n g s a r e s t o r e d i n t h e s y s t e m memory. Once t h e s e r e a d i n g s a r e taken f o r a l l t h e channels, t h e d i f f e r e n c e in r u a d i n g u fLJr each o f t h u nilrnornetora i e c o m p u t e d by t h e m i c r o p r o c e s s o r a n d t h e d a t a i s a v a i l a b l e f o r p r i n t i n g o r any further processing. A semi autoniatic version o f t h i s i n s t r u m e n t , i n which TTL hardware h a s been u s e d t o r e a d t h e l i q u i d column h e i g h t in a U- tube has been developed in the d e p a r t m e n t of Aerospace Engineering, IISc [ I 81. However, in this prototype i n s t r u m e n t , t h e motor c o n t o l i s manual and a cam m e c h a n i s m i s u s e d f o r t h e c a r r i a g e movement. I n view o f t h e r e l a t i v e l y l a r g e r a n g e o f movement r e q u i r e d f o r t h e p r e s e n t instrument, t h e mechanical d e s i g n o f t h i s p r o t o t y p e h a s been changed c o n s i d e r a b l y i n t h e new I n s t r u m e n t t o f a c i l i t a t e r e l i a b l e operation under the control of the micrprocessor. The machanical construction and t h e electronics interface t o the processor h a v e b e e n shown i n t h e F i g u r e s 4 1791. The l e n s e e f f e c t of a glasii t u b e f i l l e d w i t h a l c o h o l i s c o n v e n i e n t l y made u s e o f , t o sense t h e l i q u i d l e v e l using I R o p t i c a l s e n s o r s (MCT-8). The d i s t a n c e t r a v e r s e by t h e c a r r i a g e i s sensed as a f u n c t i o n o f the motor d r i v e s o t h e r e a d i n g s a r e i n d e p e n d e n t 04 t h e m o t o r s p e e d v a r i a t i o n s . Although t h e p r e s e n t d e s i g n i n c l u d e s o n l y 6-channels, w i t h minor e x t e n s i o n s , the i n t e r f a c e c a n be i m p l e m e n t e d f o r a s many channels as required with a s u i t a b l e mechanical set- up. The r e s o l u t i o n o f t h e s y s t e m i s O . l m m of l i q u i d column. With t h e p r e s e n t mechanism, i t may b e n o t e d t h a t t h e accuracy of t h e readings i s independent of t h e speed v a r i a t i o n s of t h e motor. T h i s e l i m i n a t e s t h a need f o r a p r e c i s i o n motor and speed c o n t r o l c i r c u i t r y . The a c c u r a c y o f t h e u n i t i s f o u n d t o be b e t t e r The r a n g e o f t h e i n s t r u m e n t t h a n 0.2mm. i s +1000mm. T h e p r e s e n t d e s i ne r e q u i r e s 2 . 5 s e c t o a c q u i r e one s e t o f samples. .. .. .,.? ICLASF '87 HECOKD-57 thut I n e t r u m u n t a t i o n f o r Force Moasurumente a n d Preasure 3urvey0 F o r c e meaaurement i n s t r u m e n t a t i o n ut acquisition has implemuntud t h r o u g h CI u t r i i i ng:’*ugu A b a l a n c e and a 32-channel a n a l o g UAS. p o s i t i o n e n c o d e r and a m o t o r control i n t e r f a c e h a s been d e s i g n e d t o c o n t r o l t h e m o d e l on t h e new m o u n t i n g r i g d e s i g n e d by a s e p a r a t e group [ r C O l . provides an overall t h e system. The analog data acquisition software r r l l a w 3 tdhu iIBoc t o o o n f i p u r o t h e module t o the specific requiremarit of the experiment. The c h a n n e l numbers t o be s a m p l e d , b o u n d s on i n p u t l e v e l s , s c a n r a t e a n d number o f s a m p l e s f o r a v e r a g i n g a r e programmable. The a c c u r a c y o f t h e a c q u i r e d d a t a i s f u r t h e r improved by a u t o m a t i c d r i f t and g a i n e r r o r c a n c e l l a t i o n s . Once t h e module i s d e f i n e d f o r a n e x p e r i m e n t , i n o r d e r t o a c q u i r e t h e d a t a , the system processor i s s u e s a command t o i n i t i a t e the d a t a conversion. Once t h e d a t a conversion is complete, the data System w i l l i n t e r r u p t t h e acquisition p r o c e s s o r s o t h a t t h e p r o c e s s o r may r e a d the converted data. During the conversion time, t h e p r o c e s s o r can e i t h e r proceed w i t h o t h e r t u s k s a s s i g n e d , o r wait f o r t h e c o n v e r s i o n t o cornplete. Thia feature contributes t o f u r t h e r processor t i m e s a v i n g s when t h e module i s used i n t h e t i m e r i n t e r r u p t mode. When t h e d a t a a c q u i s i t i o n i s completct, t h e i n p u t l e v e l s on t h e s e l e c t e d c h a n n e l s a r e compared against the set limits. A 48- port scanivalve has been i n t e r f a c e d t o t h e system processor a s a part of the pressure survey instrumentation. 6-Component S t r a i n Gauge B a l a n c e : For a c c u r a t e f o r c e m e a s u r e m e n t s , 6 component s t r a i n g a u g e b a l a n c e h a s b e e n acquired. I t h a s e i g h t s t r a i n gauge b r i d g e s t o i n d i c a t e a l l t h e s i x components of f o r c e / m o m e n t s . These e i g h t s t r a i n gauges provide e l e c t r i c a l s i g n a l s i n t h e r a n g e o f 22 rnv f u l l s c a l e w i t h e x c i t r r t i o n voltage of 4 V dc. The straingauge b a l a n c e h a s been c a l i b r a t e d f o r u s e i n t h e p r e s e n t s y s t e m [213. 32- Channel Data A c q u i s i t i o n System : ri The 32- channel data ncquisitfon s y s tern ( e x p a n d a b l e t o 256 c h a n n e l s ) has It c o n s i s t s o f 8 been shown i n F i g . . c h a n n e l p r e a m p l i f i e r s which a r e t a i l o r e d t o r e a d t h e s i g n a l s from t h e s t r a i n g a u g e b a l a n c e , a 32 c h a n n e l m u l t i p l e x e r , a g a i n selectable instrumentation amplifier, a s a m p l e and h o l d c i r c u i t and a b u f f e r e d 12b i t succesvive approximation analog t o d i g i t a l “converter. The t i m i n g s i g n a l s t o sequence t h e o p e r a t i o n o f t h e s e blocks controller have been p r o v i d e d by a circuitry. T h i s module i s c o n f i g u r e d f o r memory mapped I / O a n d t h e a d d r e s s i s jumper s e l e c t a b l e . The module h a s b e a n i n t e r f a c e d t o t h e system processor through i t s MULTIBUS. The b l o c k d i a g r a m o f t h e DAS i s g i v e n i n F i g u r e 5. .. Expansiori u p t o 2 5 6 c h a n n e l s may be effected by u t i l i z i n g the expander c i r c u i t r y w i t h minimum a d d i t i o n a l h a r d w a r e Other of p r e a m p l i f i e r s and m u l t i p l e x e r s . harduare features include signal c o n d i t i o n i n g a t t h e i n p u t end i n t h e s h a p e o f h a r d w a r e l o w p a s s f i l t t i r s , nnd i n p u t over voltage protection. In its cpnfiguration, the 8 l o w input chaneels a c c e p t i n p u t s i n t h e r a n g e o f 2 2mv w h i l e t h e h i g h l e v e l i n p u t s ~ ~ l l oi nw p u t s o f + 5 v f u l l scale. The s e t t l i n g t i m e s o f e z c h component p u t t o g e t h e r w i l l amount t o 38 u a e c when t h e o v e r a l l a m p l i f i e r g a i n i s 1 , b u t w i l l i n c r e a s e u p t o 100 u D ~ J C f o r a maximum gtiin o f 1000. These f i g u r e s i m p l y system u o c u r t i c y at. 0 . 1 % . T h i i 3 w o d u l u hus b e o n wired f o r i n t a r r u p t modu 01’ o p u r u t l O r i iir buan #--ICIASF ‘117 HECOHD :;uolpLiirlC: r*tltuu u p t u 10 K J I Z Ul‘d w ti i 1 u o p u i - .1. ~ i r i g th v ti III 1) 1i i’1 u r u iiiuximiirr guJ.11. ‘The 12 bit dtitu c ti i e v Z I b 1o ; S c a n i v a l v s Pressure Measurement System : ’ P r e s s u r e survey expurlments a t t h e CCWT r e q u i r e m u l t i p l e p r e s s u r e measurement from a r a k e o f p i t o t t u b e s t r a v e r s e d i n a v e r t i c a l p l a n e , i n t h e wake o f t h e m o d e l , o r from t h e t a p p i n g s drawn from t h e m o d o l surface. I n t h e system, a 48- port s c a n i v a l v e ( m o d e l 4Sd3) e n a b l e s these m e a s u r e m e n t s t o be made u s i n g a s i n g l e pressure transducer. F i g u r e 6 shows t h e b l o c k diagram o f t h e e l e c t r o n i c i n t e r f a c e t o t h e system processor. In order t o o b t a i n t h e p o r t ‘ . n u m b e r s p r e c i s e l y , a 6-bit o p t i c a l s h a f t p o s i t i o n Gray e n c o d e r h a s b e e n u s e d on t h e s c a n i v a l v e motor s h a f t . O p t i c a l Gray e n c o d e r h a s been d e s i g n e d u s i n g s i x s e t s of I R e m i t t e r a n d s e n s o r mounted a c r o s s a n o p t i c a l p a i r s (MCT-8) c i r c u l a r Gray code d i s c . The Gray c o d e p a t t e r n on t h e d i s c w i t h 48 l e v e l s , h a s b e e n made u s i n g ‘a c o o r d i n a t o - g r a p h t o A bi- directional ensure high precision, m o t o r d r i v e c i r c u i t r y htls been d e s i g n e d and developed ( u s i n g t r a n s i s t o r s ) to c o n t r o l t h e s c a n i v a l v e motor o p e r a t i o n . Based on t h e d i r e c t i o n arid ON/OFF i n p u c s t o t h i s block, t h e c i r c u i t d r i v e s the m o t o r i n t h e u p p r o p r i a t e d i r e c t i o n , and thus p r o v i d e s a random a c c e s s o f 8 particular port. Th B p r i u u in u L I (I 111 u J, L 1 p 1w x IJ J o u L p u L i d f e d t o a LVDT t y p e p r e s s u r e t r a n s d u c e r which p r o v i d e s a +5v o u t p u t f u l l s c a l e w i t h an accuracy o f 0.1% o v e r a range of 0 t o 0.1 p s i . C h a n n e l 10 o f t h e oarliur d e s c r i b e d d a t a a c q u i u i t i o n s y Y tem h a s be en used t o r e a d t h e a n a l o g o u t p u t o f t h i s transducer. As a r e s u l t , although the s a m p l i n g r a t e on e a c h c h a n n e l o f t h e d a t a a c q u i s i t i o n a y s t e m is u p t o 10 KHz, t h e s a m p l i n g r a t e of t h e p o r t s is l i m i t e d t o 0.4Hz. T h i s l i m i t a t i o n i s p r i m a r i l y due to t h e maxiarum m o t o r s p e e d of the e c a n i v a l v e u s e d , which i s 3 rpm. The s o f t w a r e t o c o n t r o l t h e p r e s s u r e s u r v e y d a t a a c q u i s i t i o n o f f e r s two modes of scanivalve operation. In the f i r s t mode, s c a n i v a l v e is o p e r a t e d i n s e q u e n t i a l port selection. I n t h i s mode t h e p o r t numbera t o be s a m p l e d a n d t h e s a m p l i n g r a t e o n e a c h p o r t a r e s e l e c t a b l e by t h e user b e f o r e s t a r t i n g t h e e x p e r i m e n t . When t h i s mode o f o p e r a t i o n i s s e l e c t e d , t h e s y s t e m homes t h e s c a n i v a l v e t o i t s p o r t 0. Then t h e s c a n i v a l v e motor i s a c t i v a t e 6 f o r B c o n t i n u o u s o p e r a t i o n and t h e port numbers a r e a o n t i n u o u a l y snmpled. The d a t a is a c q u i r e d w i t h i n t h e d w e l l t i m e , when t h e p o r t number c o r r e s p o n d s t o t h e p o r t s t o be s a m p l e d . The s e c o n d mode p r o v i d e s a random a c c e s s o f a p a r t i c u l a r F o r t h i s mode a l s o , s e l e c t c b b l p port. p a r a m e t e r s a r e t h e same. However, i n t h i s mode, t h e s c a n i v a l v e c u r r e n t p o r t number i s r e a d a n d compared a g a i n s t t h e p o r t t o be s a m p l e d . The processor determines t h e d i r e c t i o n i n which t h e m o t o r h a s t o be r o t a t e d t o r e a c h t h e n e x t p o r t from which t h e d a t a h a s t o be r e a d . Based on t h i s , the proceesor controls the motor appropriately through t h e i n t e r f a c e . On accessing the required port, the data is a c q u i r e d a8 p e r t h e s e l e c t e d mode. Lu progr.trei t h 3 riyi t a m f o r h i s axprimant. During t h i s e x e r c i s e , t h e software ensures e r r o r - f r e e parameter s e l e c t i o n through a s e t o f h e l p m e s s a g e s and s o l f e x p l a n a t o r y quuriiiu. Onto l h o tlyutum i u l l ~ e t "f o r t h e experiment, the configuration of the experiment i s s t o r e d on t h e f l o p p y and t h e experiment d r i v e r takes- over t h e c o n t r o l t o initiate t h o actucil conduct o f t h e experiment. T h i s p a r t i n i t i a l i z e s and c o n f i g u r e s t h e subsystems i n s t r u m e n t a t i o n , and performs r e a l - t i m e d a t a a c q u i s i t i o n and c o n t r o l . The d a t a i s s t o r e d i n t h e The s o f t w a r e p r o c e s s e s t h e floppy disc. data on- line and also responds a p p r o p r i a t e l y t o t h e i n t e r r u p t s from t h e subsystems instrumentation. The s o f t w a r e a l s o c o n t i n u o u s l y u p d a t e s t h o d i s p l a y of the status i n f o r m a t i o n on the CRT terminal. The u s e r may i n t e r r u p t t h e process, through the terminal keyboard, e i t h e r t o hold/terminate t h e experiment o r t o modify t h e set- up information. On s u c c e s s f u l completion of t h e experiment, the control i s transfered t o t h s data presentation eoftware. The d a t a p r e s e n t a t i o n m e t h o d o l o g i e s h a v e b e e n f r a m e d b a s e d o n t h e common e x p e r i m e n t s c o n d u c t e d i n t h e CCWT. These into three have been sub- divided catogories i.e., flow field data presentation, f orce/rnoment data p r e s e n t a t i o n and p r e s s u r e survey data presentation. The experiment driver s o f t w a r e s t o r e s t h e d a t a on a f l o p p y , which c a n be r e a d i l y p r e s e n t e d i n t h e f o r m of t a b l e s . The d a t a p r e s e n t a t i o n i n t h e form o f p l o t s can be obtained e i t h e r t h r o u g h t h e main- frame computer DEC s y s t e m 1090 o r t h r o u g h an IBM PC c o m p a t i b l e machine. The i n t e r a c t i v e n a t u r e o f t h e p a c k a g e s developed improves t h e u s e r ' s c o m p r e h e n s i o n o f a l a r g e volume of d a t a by a choice of c o l o r s / p a t t e r n s , Software D e s i g n : i) The s o f t w a r e d e s i g n e d f o r o v e r a l l s y s t e m o p e r a t i o n may be g r o u p e d i n t o t h r e e p a r t s , i.e., ( i )systems s o f t w a r e , (ii) user interaction software, (iii) experiment d r i v e r s o f t w a r e and ( i v ) d a t a presentation software. The s o f t w a r e , e x c l u d i n g f o r t h e d a t a p r e s e n t -a t i o n h a s been d e v e l o p e d i n 8086 a s s e m b l y l a n g a u a g o . The s o f t w a r e f o r t h e d a t a p r e s e n t a t i o n has been d e v e l o p e d on a n I B M PC c o m p a t i b l e machine so that the color graphics c a p a b i l i t i e s o f t h e PC c o u l d be e x p l o i t e d . Besides i t would ease t h e necessary modifications t o t h e application software, which a r e o f t e n r e q u i r e d f r o m time t o time. The u s e r i n t e r a c t i o n s o f t w a r e f o r setting- up t h e experimentation provides a f r i e n d l y i n t e r f a c e , which e n a b l e s t h e u s e r S y a t e m s software : The s y s t e m s o f t w a r e i n i t i a l i z e 8 t h e p e r i p h e r a l i n t e r f a c e s and submodules f o r I t also a p p r o p r i a t e mode o f o p e r a t i o n . i n i t i a l i z e s the i n t e r r u p t vector t a b l e for i n t e r r u p t s e r v i c e handler. The s o f t w a r e also ensures appropriate proceesor r e s p o n s e f o r i n t e r f a c e s o f t w a r e and t h e application software. i i ) User interaction software : The h a r d w a r e h a s been d e s i g n e d , as d e s c r i b e d e a r l i e r , t o c a t e r t o a wide spectrum of experiments l i k e i ) f l o w f i e l d s u r v e y , i i ) f o r c e / m o m e n t measurements a n d iii) p r e s s u r e s u r v e y s , w h e r e i n the r a n g e o f s e v e r a l p a r a m e t e r s , l i k e t h e mode o f operation o f t h e sub modules, data ' - ICliASF '87 HKCOHD 59 ncqui i i t i o n spocificationu utc., would vary. Hence, for any t;paciFic e x p e r i m e n t a t i o n n e e d e d by t h e u s e r , t h e r e i s a need t o r e - c o n f i g u r e , by s o f t w a r e , the individual sub- systems and the software- generated time- markers. The precise role of the user- interface software i s t o acquire t h e set- up data f r o m t h e u s e r t h r o u g h a s e t o f q u e r i e s and use i t t o configure the sub- systems accordingly. The q u e r i e s a r e s e l f - e x p l a n a t o r y and e a s i l y understandable. The p e r m i s s i b l e answers, parameter range etc. are d i s p l a y e d along with each query. I n o r d e r t o ensure e r r o r - f r e e s e t - u p e n t r i e s , t h e software accepts t h e parameters t h a t a r e a l l o w a b l e and i n t h e c a s e o f i n c o r r e c t e n t r i e s , an e r r o r message i s f l a s h e d on t h e CRT t o warn t h e u s e r a n d r e q u e s t s f o r a p e r m i s s i b l e answer. Figures 7 depicts t h e s e l e c t i o n o f t h e measurement o p t i o n s . For t h i s s e l e c t i o n , t h e u s e r is a l s o Once prompted w i t h t h e expected answers. t h e r e q u i r e d experiment i s s e l e c t e d , t h e system draws t h e u s e r ' s attention t o v e r i f y the e n t r i e s (Figure 7 ) . The u s e r 1s a l l o w e d t o make a n y a l t e r a t i o n s t o h i s sslaction. On c o n f i r m i n g t h e o u l u c t i o n , d e p e n d i n g on t h e e x p e r l m e n t e s u l a c t u d , queries f o r configuring tho individutii experiments a r e i n i t i a t e d . F o r example,t o e n t e r the set- up parameters f o r t h e DAS, t h e ayst4em d i s p l a y s t h o d t t f a u l t parameters required for the data a c q u i o i t i o n and t h e mode o f r t i w d a t a output. F o r t h u c o n v a n i u n c u of' L h u u t l u r , t h e c u r s o r , l s p l a c e d a g a i n t i t e a c h of t h o p a r a m e t e r s 'on t h e s c r e e n , i n t h e o r d e r shown, a n d waits f o r t h e u s e r r e s p o n s e . The eelection of the respective p a r a m e t e r ' s v a l u e i s f u r t h e r s i m p l i f i e d by showing t h e a d m i s s i b l e r e s p o n s e / range a t t h e bottom of t h e s c r e e n . S i m i l a r p r o c e d u r e h a s been adopted t o configure experiments f o r flow field survey a n d t h e p r e s s u r e s u r v e y s . F o r f l o w f i e l d survey, t h e u s e r h a s t o s e l e c t t h e mode of t h e p r o b e t r a v e r s e c o n t r o l , e i t h e r T h i s i s f o l l o w e d by Manual o r A u t o m a t i c . d e f i n i n g t h e probe t r a v e r s e range a n d t h e size i n the three directions. grid Besides, the pressure data acquisition t h r o u g h t h e 6 - c h a n n e l d i g i t a l manomster has t o be c o n f i g u r e d . I n t h e c a s e of t h e pressure survey experimentation, the u s e r i s r e q u e s t e d t o s e l e c t t h e p o r t numbers (of t h e 48 a v a i l a b l e p o r t s on the s c a n i v a l v e ) t o be s a m p l e d , t h e s a m p l i n g p e r i o d , a n d t h e number o f s a m p l e s f o r averaging. In t h i s f a s h i o n , the user interaction for configuring the e x p e r l m a n t a hcls b e s n made s e l f - e x p l a n a t o r y and simple. The above u s e r i n t e r a c t i o n 60-ICIASF '87 RECORD software f o r . t t r t t y u t - u p has been d e v e l o p e d i n t h e usuufllI,Ly LUIl~ULLgU 01' ti08L. I I l > W U V l ~ I . , CiJ I I U W t h e b a s i c c e n t r a l p r o c e s s o r board and t h e a s s o c i a t e d h a r d w a r e h a v e been i n t e r f a c e d t o a n 1BbI PC c o m p c l t i b l c ii~ichinu, n supartltc uzer i n t e r a c t i o n routine which usus IBM PC a s a s t a n d - a l o n e color t e r m i n a l ha5 a l s o been developed. The photograph presented i n Figure 7 i s f r o m t h e I B M PC t e r m i n a l , which hau an i n i p r o v e d a p p e a r a n c e a s compared t o t h e b l a c k a n d w h i t e t e r m i n a l d e v e l o p e d as p a r t o f t h e systems hardware. iii) E x p e r i m e n t D r i v e r : 'I'he e x p e r i m e n t d r i v e r p a r t o f t h e software c o n f i g u r e s and c o n t r o l s the parameter8 subsystems, based on t h e p r o v i d e d by t h e u s e r , a n d a c q u i r e s d a t a i n r e a l t i m e , The s o f t w a r e a l s o m o n i t o r s t h e h e a l t h of t h e i n s t r u m e n t s and c o n t i n u o u s l y u p d a t e s t h e s t a t u s o f t h e e x p e r i m e n t s on the CRT s c r e e n . The u s e r may a l s o i n t e r r u p t t h e p r o c e s s o r a t any s t a g e o f t h e experiment, view t h e sot- up p a r a m e t e r s t h r o u g h s i m p l e commands and a l t e r them f o r the rest of the experiment. The e x p e r i m e n t d r i v e r s o f t w a r e f o r each o f t h e a x p e r l m e n t v i s d i s c u s s e d balow. For f o r c e m e a s u r e m u n t a , d e p e n d i n g o n t h e user s e t p a r a m e t e r s , t h e i n t h e m a n u a l mode, system prompts t h e u s e r t o s e t t h e model p o s i t i o n i n t h e r e q u i r e d p i t c h a n d yaw. The u s e r i s t h e n r e q u i r e d t Q s e t t h e modul p o s i t i o n a n d p r e s s ' r e t u r n ' on t h e kuy b o u r d ( I n t h u u u t , o n i t i L i o m o d u t h u etiiiie w i l l btt d o n e by t h e tlyutum). Whuri t h e ktly i s pressed, t h e system i n i t i a t e s A / D c o n v e r s i o n on each of t h e a n a l o g c h a n n e l s first i n i t i a l i z i n g the timer for by s a m p l i n g p e r i o d a n d t h e n by issuing a start c o n v e r s i o n command t o t h e d a t a a c q u i s i t i o n system. When t h e a n a l o g t o d i g i t a l c o n v e r s i o n i s c o m p l e t e , t h e DAS i n t e r r u p t s t h e processor SO t h a t the c o n v e r t e d d a t a i s r e a d by t h e p r o c a s s o r . The p r o c e s s o r t h a n l o o k s f o r t h e a c q u i r e d d a t a , and i f t h e d a t a is a v n i l a b l e i n t h e memory, i t w i l l b e p r o c e s s e d . A t the the i n t e r v a l s o f t h e sampling p e r i o d , timer interrupts the processor t o acquire sampling the data precisely a t the intervals. The p r o c e s s o r k e e p s t r a c k o f t h e number o f s a m p l e s a c q u i r e d a n d when t h i s number r e a c h e s t h e s a t v a l u e , t h e timer i n t e r r u p t i s d i s a b l e d and t h e above process continues until the data c o l l e c t i o n a t a l l t h e r e q u i r e d angles i s complete. When f l o w f i e l d s u r v e y i s s e l e c t e d , t h e d r i v e r software i n i t i a l i z e s t h e 3- D t r a v e r s e i n t e r f a c e module f o r a u t o m a t i c probe positioning. Thu probo i u positioned using the user set-up information a t the t o p l e f t corner of t h e f i r s t cross- sectional plane i n the test s e c t i o n . D e p e n d i n g on t h e s t e p s i z e ( g r i d s i z e ) , i n each of t h e t h r e e directions, the probe i s moved i n t h e lateral d i r c e t i o n (Y- direction) i n t h e cross- flow plane. A t each s t e p , a flow s e t t l i n g time o f a b o u t 1 second i s a l l o w e d and t h e n t h e d a t a a c q u i s i t i o n i s e f f e c t e d through the manometer. When t h e p r o b e 6- channel rurraohuu thrr l u r i t gr*Itl pui.rit r i l o n y l,tIiAt, l i n e , t h e p r o b e i s raoved t o t h e n e x t s t e p i n t h e v e r t i c a l d i r e c t i o n (downwards) and the pressure data i s collected. The d i r e c t i o n o f t h e p r o b e movement a l o n g t h e l a t e r a l p l a n e is t h e n r a v u r s u d . Thi~i process is continued t o complete the After scanning of each cross- flow plane. c o l l e c t i n g t h e f l o w f i e l d d a t a from t h e f i r s t p l a n e , t h e p r o b e t r a v e r s e i s moved in t h e a x i a l d i r e c t i o n t o p l a c e t h e p r o b e i n s u c c e s s i v e c r o s s - f l o w p l a n e s and t h e data coll.ection is completed. The pressure d a t a from t h e 5- hole probe throught t h e manometer s u b s y s t e m i s a c q u i r e d i n i n t e r r u p t mode. This approach makes t h e b e s t u s e o f p r o c e s s o r t i m e a n d facilitates on- line data reduction while t h e d a t a i s acquired'. In the case of pressure survey experiments, t h e s c a n i v a l v e motor is controlled t o access the required ports, i n s u c c e s s i o n , as p e r user r e q u i r e w n t s . A t each o f the required ports, the pressure d a t a f r o m t h e LVDT p r e s s u r e s e n s o r i s a c q u i r e d t h r o u g h t h e a n a l o g DAS a a described above. Once t h o d a t a a c q u i s i t i o n f o r t h e selectGd experimenta i s completed, the d a t a p r o c e s s i n g and p r e s e n t a t i o n s o f t w a r e receives the control. T h i s p a r t h a s been described i n t h e next section. The a c q u i r e d d a t a , d e p e n d i n g on u s e r requests, has t o be bound checked, averaged and norrnalised. This procesving i s c a r r i e d o u t by t h e c e n t r a l p r o c e s s o r . I f t h e d a t a a c q u i s i t i o n r a t e s a r e low, t h e p r o c e e s o r w o u l d h a v e s u f f i c i e n t time t o c o m p l e t e this p r o c e s s i n g w h i l e t h e d a t a i s being acquired. However, i f t h e i n t e r v a l b e t w e e n t h e a c q u i r e d d a t a i s small, t h e p r o c e s s o r would c o n t i n u e t o c o m p l e t e ' t h e processing a f t e r completion of t h e d a t a acquisition. The acquired and the processed data a r e then written i n t h e auxillary storage i n a format acceptable t o IBM PC c o m p a t i b l e m a c h i n e s f o r f u r t h e r p r o c e s s i n g and p r e s e n t a t i o n . iv) Data P r e s e n t a t i o n : T h i s p a r t of t h e s o f t w a r e t h a t r u n s o n t h e PC h a s t h e f o l l o w i n g f u n c t i o n s t o p e r f o r m on t h e a c q u i r e d d a t a . (i) Reduction of aerodynamic q u a n t i t i e s from t h e a c q u i r e d d a t a , (ii) Graphical- - Velocity colour contour measured d a t a , and (iii)Force plots. and vector maps of pressure and the distribution Uuta p r o c e s v i t i g soPtwtlre f o r f o r c e measurements i n c l u d e s computation o f t h e aerodynamic c o e f f i c i e n t s . The l o c a l f l o w a n g l e a n d t h e v e l o c i t#y m a g n i t u d e h a v e b e e n o b t a i n e d from t h e Plow f l u l d d a t a , s u n s e d by t h e f i v e h o l e probe and t h e probe From t h i s d a t a c a l i b r a t i o n d a t a [221. o t h e r parameters of i n t e r e s t are a l s o computed. P r e s s u r e survey d a t a from t h e m o d e l o r f r o m t h e model wake i s p r o c e s s e d t o y i e l d t h e load d i s t r i b u t i o n over t h e b o d y o r t h e p r e s s u r e l o s s i n t h e wake. T h e s e r e s u l t s a r e used t o c a l c u l a t e t h e n e c e s s a r y aerodynamic q u a n t i t i e s . The d a t a p r e s e n t a t i o n s o f t w a r e f o r the force and p r e s s u r e results is i m p l e m e n t e d i n t h e u s u a l manner t h r o u g h which multiple c o l o r p l o t 8 of compurable p a r a m e t e r s c o u l d be o b t a i n e d . I n t h e cc18e o f flow f i e l d data presentation, the s o f t w a r e developed provides t h e u s e r w i t h t h e v e l o c i t y v e c t o r p l o t s o n a HP7470 color graphics plotter. For a quick v i s u a l i s a t i o n o f t h e flow f i e l d a r o u n d t h e model, a s o f t w a r e package h a s been developed t o present t h e velocity d a t a ( o r l o c a l head l o s s ) i n t h e form of c o l o u r g r a p h i c c o n t o u r p l o t s on t h e PC. Uaing t h i s pcickage~, t h e c o n t o u r s o f s e l e c t i v e magnitudes o f t h e f l o w f i e l d may b e plotted. Corresponding t o t h e u s e r ' s choice, t h e software first searches f o r and s e p a r a t e s o u t t h e iso- magnitude d a t a from the velocity data. Then the equivelocity contours a r e displayed i n colour graphics. The r a n g e b e t w e e n t h e a d j a c e n t c o n t o u r s i s shaded w i t h d i f f e r e n t colour patteqns. This provides a q u i c k , v i s u a l a p p r e c L a t i o n of t h e f l o w f i e l d a r o u n d t h e t e s t model i n a n e a s y a n d if some inexpensive way. However, contours are c l o s e l y spaced, depending on the actual layout of the contours, the p a t t e r n s u s e d t o s h a d e t h e r e g i o n s may l e a d t o c o n f u s i o n . T h i s h a s been overcome by p r o v i d i n g t h e u s e r w i t h an o p t i o n t o change t h e c o l o u r p a t t e r n s a f t e r examining t h e c o n t o u r p l o t s p r e s e n t e d on t h e s c r e e n . T h e a v a i l a b l e c o l o u r p a t t e r n s a r e shown a d j a c e n t t o t h e p l o t with an i n d i c a t i o n o f the d e f a u l t colours a s s i g n e d t o the s e l e c t e d magnitude r a n g e s . Through t h e k e y b o a r d , t h e u s e r can s e l e c t a p a t t e r n a n d g i v e a command t o f i l l u p t h e s e l e c t e d contour region. Representative photographs of t h e c o l o r graphics displays (CIASF '87 RECORD-41 o f t h e f l o w f i e l d d a t a have b e e n g i v e n i n The f i n a l formu o f Lha F i g u r e s 8 and 9. d i s p l a y s o o u l d a l s o be s a v e d f o r f u L u r e reference. [ 8 1 C.F. [9] Conclusions : [lo] The h a r d w a r e and t h e s o f t w a r e o f t h e i n t e g r a t e d i n 8 t rumen t a t i o n s y s tem t h a t i s suitable t o small s c a l e wind tunnel applications has been successfully d e s i g n e d and r e a l i s e d . The s y s t e m has been i n s t a l l e d i n t h e CCWT a t 1 . 1 . S ~ . a n d tested, Representative color graphics p l o t s h a v e been p r e s e n t e d . Since t h e i m p o r t a n t f e a t u r e , i n t h e s e p l o t s is t h e d i f f e r e n t c o l o r s , t h e same may n o t be e f f e c t i v e l y seen i n t h e f i n a l form of t h e paper. However, we expect a distinguishable gradation i n t h e contour levels i n t h e f i n a l p i c t u r e s . [113 [ 121 [131 [14] Acknowledgements : [151 The a u t h o r s g r e a t f u l l y acknowledge t h e A e r o n a u t i c a l R e s e a r c h and Development Board f o r f u n d i n g tiis p r o j e c t . The authors wi8h to acknowledge Prof. Ramssuamy, Prof. S.P. C o v l n d a r a j u arid Prof, P.R. Mahapatra f o r t h e i r u s e f u l suggestions. The a u t h o r 8 w i s h t o t h a n k Mi-. B . A . Mtldankumclr f o r h i 8 a c t i v u o u p p o r t i n t h e p r e p e r a t i o n of t h e manuscript. 4 [I61 [171 [I81 References : [1 ] C. [2] [3] [4] [5] [6] [7] Ravikumar, " A M i c r o p r o c e s s o r b a a e d I n t e g r , a t e d S y s t e m f o r Wind T u n n e l A p p l i c a t i o n s t ! , M. Sc. (Engg. ) T h e s i s , 1986. M. Konig a n d H . J . P f e i f e r , "LDA d a t a acquisition systems with high a c c u r a c y and h i g h d a t a r a t e " , ICIASF '77 R e c o r d , pp. 13- 21, 197'7. A . B o u t i e r , C. F e r t i n and J . L e f e v r e , " L a s e r v e l o c i r n u t e r f o r wind tunnel. m e a s u r e m e n t s f t , ICAISF ' 7 7 R e c o r d , p p . 1- 12; 1977. W.J. Yanta, "A t h r e e dimensional l a s e r dopplar velocimeter f o r use i n wind t u n n e l s b 1 ICIASF ' 7 9 , R e c o r d , pp. 294- 301, 1 4 7 9 . D.W. Schmidt, " A c c o u s t i c a l methods f o r f a s t d e t e c t i o n a n d measurement o f v o r t i c e s i n wind t u n n e l s " , ICIASF ' 7 5 R e c o r d , pp. 216- 228, 1975. R.H. E n g l e r , H . H o l s t , D.W. S c h m i d t a n d R I Wulf, "Measurement o f v o r t i c e s i n wind t u n n e l e x p e r i m e n t s by U B ~o f ultrasonic pulseall, ICIASF '79 R e c o r d , pp. 163- 170, 1 9 7 9 . C. Meyer, "Wind t u n n e l m e a s u r e m e n t s with an electronically scanned m u l t i p o r t p r e s s u r e s e n s o r l l , ICIASFI81 R e c o r d , 1981. 62-ICIASF '87 RECORD Coe, P a r r a and R . C . naw e l u c t r o n i c t i c u n n u r of pressure designed for i n s t a l l l a t i o n i n wind t u n n e l modelstl, ICIASF ' 8 1 R e c o r d , 1981. IIMACSYM 2 0 Users Manualft, Analog D e v i c e s , I n c o r p o r a t e d , USA. A.E. Winkelmann, and C . P . TSAO, " A c o l o r v i d e o d i s p l a y technique f o r f l o w f i e l d s u r v u y e t f A I A A Journal, v o l . 2 3 ( 9 ) , p . 1 3 8 1 , September 1 9 8 5 . t r i A P X 8 6 , 8 8 U s e r ' s Manual", I n t e l C o r p o r a t i o n , A u g u s t 1981. Robin Jigaur, "Using t h e 8259A p r o g r am ma b 1e i n t e r r u p t c on t r o 11a r I t , Application Note AP- 59, Intel Corporation, 1979. "Using the 8251 Universal S y n c h r o n o u s / Asynchronous R e c e i v e r / T r a n s m i 1t e rll Peripheral design handbook, h t e l Corporation, pp. 2.241-2.270, August 1981. David B . G u s t a v s o n , tfComputer Buses-A T u t o r i a l t 1 , I E E E M i c r o , August 1984. Joe Barthmaier, tfXntel multibus i n t e r f a c i n g f t , A p p l i c a t i o n N o t e , AP 2 8 4 , I n t e l C o r p o r a t i o n , 1979. Z.M. Rtimly, E I and W.J. Ranbird, ItGomputer controlled system f o r t h e i n v a u t i g a t i o n of t h e flow behind wingsll, J o u r n a l of A i r c r a f t , v o l . 1 4 ( 7 ) , pp. 668-674, J ~ l y . 1 9 7 7 . llOpto-ulectronics cornporittnt Hund Booktf, General Instruments, USA, 1979. S.P. G o v i n d a r a j u , N. B a l a k r i s h n a n a n d C. Ravikumar, "Development o f a pressure aensor with d i g i t a l output b a s e d on a l i q u i d manometer" , P r o c . o f 1 1 t h N a t i o n a l symposium on f l u i d m e c h a n i c s a n d f l u i d power, pp. A P l 4 1 9 , December 1 9 8 2 . C. Ravikumar a n d N . B a l a k r i s h n a n , " A low c o st m i c r o p r oc e s s o r based m u l t i p l e p r e s s u r e m e a s u r i n g system!', t o a p p e a r i n J o u r n a l of Microcomputer A p p l i c a t i o n s , Academic P r e s s , v o l . 1 0 , 1987. S.P. G o v i n d a r a j u , and V.S. Iiolla, " D e s i g n o f k h e p i t c h and t h e yaw mechanism for a wind tunnelw', T e c h n i c a l R e p o r t No; AE-380/A, 1984. C . R a v i k u m a r , M.A. Ramaswaruy and V.S. Holla, "Calibration of the six component s t r a i n g a u g e b a l a n c e for t h e CCWTII T e c h n i c a l R e p o r t No .AE397/A, 1 9 8 b . R . W i c k e n s , P. S o u t h , R.S. Rangi a n d D . Henshaw, " E x p e r i m e n t a l d e v e l o p m e n t i n V/STOL wind t u n n e l t e s t i n g a t t h e national aeronautical establishmenttt, Canadian aeronautics and space j o u r n a l , v o l . 1 9 , pp. 145- 154, A p r i l 1973. Kuuf'firiun, [19] / [20] L21.1 [22] C.T. "A - Model c o n t r o l notors S h a f t Encoders .3-D T r a v e r s e Mechanism Motors, sensors ode1 c o n t r o l -r r Interface for 3- D Probe Traverse 9 System .F P r e s sur e Tappings From -6-channel Pressure Ports @-port P=ocesa*r r Interface f o r ~6-channel D i g . nanometer Scanivalve I Interface FIG. 1 . E Unit Computer I L-----i CONFIGURATION OF TEE SYSTEM Merory (ROM * & RAM) ' /' Programable I/O 8255 ( 3 ) Memory Decoder I/O r BUS Contr, I r r CPU Decoder Data Buffer Addres 8 - 8086 ,' L a t c h I ? System Proceseor BUS (Multiplexed) I 4 MULTIBUS Interface Logic II n t e r r u p t s V f MULTI BUS FIG. 2. FIG. 3 . 64-ICIASF '87 RECORD SYSTEM PROCESSOR U N I T 3-D PROBE POSITION CONTROL INTlEHPAClG I I motor PUllY disc vith holes optical s0nsor Lase U - t u b e s 76 sete) -\ a). Motor Control I Circuitry Optical l i m i t A 1 Motor ON/OFF * I I senaore Lower Sensor Circuitry Upper \ I )I n System 8- bit latch +Port Optical clock Lower M e c h a n i c a l Set-up . A* data P r o ce B sor b PPI 8255 Distance 8 Level Sensor J ort 8- bit latch I l i I / b). - ALE J E l e c t r o n i c s Interface FIG. 4. 6 - CHANNEL DIGITAL MANOMETER ICIASF '87 RECORD -65 Decoder addrees FIG. 5 . 32 - CHANNEL ANALOG DATA ACQUISITIQN SYSTEM 6 bit a p t i c a l gray sensor motor control c i r c u i t r y IC I ai 24v D C FIG. 6. SCANIVALVE INTERFACE 66-ICIASF '87 RECORD Syste. FIG. 7. USER INTERFACE Set-'UP Mode FIG. 8. COLOR G R A P H I C S ISOMACNITUDE P L O T S -a l Equivelocity Contours at x / d = 2.4 p h a = 18, V i n f = 30 D/S (body : ogive nose-cylinder body of l/d=10) Color pattern selection -- FIG. 9. COLOR G R A P H I C S P L O T S - continued -a f t e r completing t h e color pattern selection and before saving the picture. BRIEF BIOGRAPHIES OF AUTHORS C. Ravikumar graduated in 1979 from Nagarjuna University, Guntur, India and received M.Sc. degree in engineering physics and instrumentation in 1981 from Osmania University, Hyderabad, India. In 1981 he joined the department of Aerospace Engineering, Indian Institute of Science, Bangalore, India where he was employed as a Scientific Assistant. At the Indian Institute of Science he had also completed a research oriented M.Sc. (Engg) degree. His fields of interest include microprocessor based instrumentation, microcomputer systems and computur orig inuering . N. Balakrishnan received the BE degree in electronics and communications from the University of Madras, India in 1972 and the Ph.D. degree from the department of Aerospace Engineering, Indian Institute of Science, Bangalore, India in 1979. In 1973 he joined the Department of Aerospace Engineering where he is currently employed as Associate Professor. His fields of research interest include numerical electromagnetics, space craft antennas, computer science and microprocessor systems. ' Prof. Balakrishnan is a life member of the Instrument Society of India and is on the editorial board of the Current Science Journal. He is the recipient of the UNESCO/ROSTCA award for outstanding contributions in the area of computers and informatics for the year 1985. He is the Convener of the Centre for Microprocessor Applications and also the Centre for Science He is also a Information at' the Indian Institute of Science. consultant to lhading Government and Private industries .. V.S. Holla received the B.Sc. (1956) and B.Ed. (1960) degrees from Mysore University, India, the M.Sc. (Mathematics) degree from Karnataka University in 1961 and the Ph.D. degree from Indian Institute of Science, Bangalore, India, in 1969. He joined the department o f Aerospace Engineering, Indian Institute of Science in 1965 as a Technical Assistant and is currently an Associate Professor in Aerodynamics. His interests are in Theoretical and Experimental Aerodynamics and has been working in this area for the last 2 2 years. Prof. Holla l a a member of the'Aeronautica1 Society of India. He is also on the Editorial Boar4 of the Journal of Aeronautical Society of India, as an Associate Editor since 1980. 68-ICIASF '87 RECORD