Lab 1 – Driving LEDs

advertisement

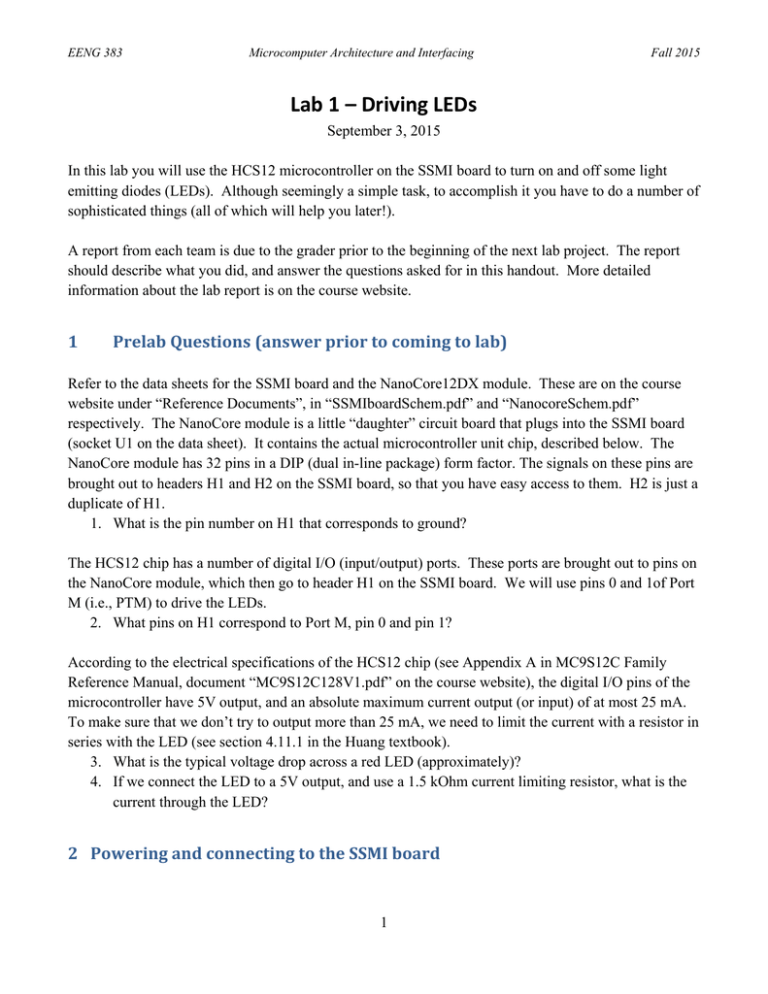

EENG 383 Microcomputer Architecture and Interfacing Fall 2015 Lab 1 – Driving LEDs September 3, 2015 In this lab you will use the HCS12 microcontroller on the SSMI board to turn on and off some light emitting diodes (LEDs). Although seemingly a simple task, to accomplish it you have to do a number of sophisticated things (all of which will help you later!). A report from each team is due to the grader prior to the beginning of the next lab project. The report should describe what you did, and answer the questions asked for in this handout. More detailed information about the lab report is on the course website. 1 Prelab Questions (answer prior to coming to lab) Refer to the data sheets for the SSMI board and the NanoCore12DX module. These are on the course website under “Reference Documents”, in “SSMIboardSchem.pdf” and “NanocoreSchem.pdf” respectively. The NanoCore module is a little “daughter” circuit board that plugs into the SSMI board (socket U1 on the data sheet). It contains the actual microcontroller unit chip, described below. The NanoCore module has 32 pins in a DIP (dual in-line package) form factor. The signals on these pins are brought out to headers H1 and H2 on the SSMI board, so that you have easy access to them. H2 is just a duplicate of H1. 1. What is the pin number on H1 that corresponds to ground? The HCS12 chip has a number of digital I/O (input/output) ports. These ports are brought out to pins on the NanoCore module, which then go to header H1 on the SSMI board. We will use pins 0 and 1of Port M (i.e., PTM) to drive the LEDs. 2. What pins on H1 correspond to Port M, pin 0 and pin 1? According to the electrical specifications of the HCS12 chip (see Appendix A in MC9S12C Family Reference Manual, document “MC9S12C128V1.pdf” on the course website), the digital I/O pins of the microcontroller have 5V output, and an absolute maximum current output (or input) of at most 25 mA. To make sure that we don’t try to output more than 25 mA, we need to limit the current with a resistor in series with the LED (see section 4.11.1 in the Huang textbook). 3. What is the typical voltage drop across a red LED (approximately)? 4. If we connect the LED to a 5V output, and use a 1.5 kOhm current limiting resistor, what is the current through the LED? 2 Powering and connecting to the SSMI board 1 EENG 383 Microcomputer Architecture and Interfacing Fall 2015 We will power the SSMI board with a 9V DC power supply adapter, which is in the lab kit. The +9V and ground of the adapter need to be connected to jack J5 of the SSMI board. • Plug the power adapter into the AC outlet and determine with a digital multimeter (DMM) which leads of the adapter correspond to +9V and ground. Although the nominal voltage is +9V, what is the actual voltage as read by the DMM? • Unplug the adapter from the wall outlet. Connect +9V and ground to the correct inputs on jack J5. Show the instructor your connections before proceeding further. • Once the instructor verifies that your connections are ok, plug the adapter into the wall outlet. Verify that the green LED on the SSMI board comes on, indicating that the board has power. Make sure the little switch on the NanoCore module is set to “Load”, not “Run”. 3 Creating a simple program Create a new CodeWarrior project. • Open CodeWarrior and select File->New Project… • Expand HCS12 and HCS12C and then select MC9S12C32. This is the microcontroller that the Nanocore uses. Note: Make sure to selected HCS12 Serial Monitor for the default connection. Press Next to continue. • Deselect C and select Absolute assembly. Change the project name and location if needed. Press Finish to complete creating the new project. Edit the default template program and change it to the simple Fibonacci program as done in the lecture: • Replace the declarations for “Counter” and “FiboRes” with the declarations for “N1”, “N2”, and “N3”: N1 N2 N3 • DS.B 1 DS.B 1 DS.B 1 Replace the lines between “mainloop” and “RTS” (inclusive) with the instructions for the simple Fibonacci program: movb movb #0,N1 #1,N2 loop ldaa adda staa movb movb bra • N1 N2 N3 N2,N1 N3,N2 loop Compile the program. 2 EENG 383 • • Microcomputer Architecture and Interfacing Fall 2015 Connect the serial cable from the PC to the SSMI board, and start the debugger. This should download the program to the SSMI board. Step through the program. Verify that the Fibonacci numbers are produced in N3. Where does RAM start? It is not $0800, as was the case with the simulator in lecture. The instructions at the beginning re-map the location of RAM. One way to find out where RAM starts is to look at the address of N1, since it is the first storage location in RAM. 4 Driving the LEDs You can write to Port M just like a memory address. The address of Port M is given by the label “PTM”, which is defined in the file “mc9s12c32.inc”, that is automatically included in your CodeWarrior project. To output a logic high (+5V) on Port M, pin 0, you write a “1” to bit 0 of location PTM. To output a logic low (0V) you would write a zero to that location. Change your program to output logic high on PM0, then a logic low, and enclose those in an infinite loop. There is one additional thing you have to do at the beginning of your program, and that is to designate PM0 as an output pin instead of an input pin (the default is input). To do this, we write a “1” to the corresponding bit in the “data direction register” for port M. Just insert the following lines at the beginning of your program (before the loop) to configure PM0 for output: ldaa staa #$01 DDRM ; Write a 1 to bit 0 of DDRM to configure ; .. PM0 for output Note: Make sure the power is off when you implement the following hardware changes. Connect an LED from PM0, through a current limiting resistor, to ground. You can use a discrete resistor, or the resistor DIP part provided in the kit (see the lab webpage for the datasheet). At this point (and for the rest of the semester) it may be convenient to use the protoboard on the SSMI board (the large white breadboard) for connections. The protoboard doesn’t have any connections to the rest of the SSMI board, so you have to make the connections yourself. You will find it convenient to connect a black wire from the row on the protoboard labeled “-” to the ground pin on H1. Just leave that wire in place for the remainder of the semester, so that the protoboard always has a ground connection. Sketch a schematic of the LED design. Include the predicted current through the LED • Sign-Off 1: Have the instructor check your schematic and implementation before turning on the power. Instructor sign-off needed. Compile, download, and step through the program. Verify that the LED turns on and off. • In your lab report, include a schematic diagram of your circuit, a listing of the program, and an explanation of the circuit and the program. 3 EENG 383 • • Microcomputer Architecture and Interfacing Fall 2015 Sign-Off 2: While the LED is on, measure the current through the LED with the multimeter. Instructor sign-off needed. Try running the program run at full speed (instead of stepping through it one instruction at a time). Explain what you see on the LED. Now connect a second LED from pin PM1, through another current limiting resistor, to ground. Note – for this step and in the future, always disconnect the power when making hardware changes, and double check all connections before turning power back on. Change the program to implement a 2-bit binary counter, where the least significant bit of the counter is shown on the LED attached to PM0, and the most significant bit is shown on the LED attached to PM1. You can use the inca or adda instruction to increment the accumulator. • Sign-Off 3: Demonstrate the 2-bit binary counter to the instructor by stepping through the program. 5 Clock Frequency You can slow down the rate at which the LEDs blink by inserting some delay in the program. Insert a bunch of “nop” instructions in your loop. Run the 2-bit binary counter program at full speed. • Sign-Off 4: Look at PM0 and PM1 on the oscilloscope simultaneously and measure the period of each waveform. In your report, include a screen capture of the scope trace, with the cursors showing the period or frequency. • Determine the number of clock cycles in your loop, by looking up each instruction in the instruction set table, and adding them all up. It would be helpful to indicate the clock cycle count for each instruction in the comments of the program. • From your measured loop period, and the number of clock cycles in the loop, estimate the period of one CPU clock cycle, and the clock frequency. Include your calculations and the program listing in your report. 4 EENG 383 Microcomputer Architecture and Interfacing Fall 2015 Lab 1: Driving LEDs Name: ________________________________Name: ________________________________ Task Description Initials Sign-Off 1 LED schematic and implementation Sign-Off 2 LED current measurement Sign-Off 3 2-bit Counter Sign-Off 4 Oscilloscope: Waveform period measurement 6 Rubric Deliverables 20 pts Pre-Lab Driving the LED /7 Clock Frequency / 8 Demonstrations Scope trace(s) /5 Composition Questions 5 pts Total 5 pts /5 20 pts Sign-Off 1: Implementation /2 Sign-Off 2: LED Current Measurement /5 Sign-Off 3: 2-bit Adder /8 Sign-Off 4: Waveform Period Measurement /5 / 50 pts 5