Semiconductor doping

advertisement

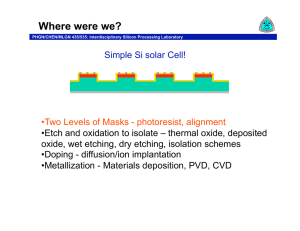

Semiconductor doping PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Si solar Cell • Two Levels of Masks - photoresist, alignment • Etch and oxidation to isolate – thermal oxide, deposited oxide, wet etching, dry etching, isolation schemes • Doping - diffusion/ion implantation • Metallization - Materials deposition, PVD, CVD What’s a metal, a semiconductor? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory IV How do we “dope” a semiconductor Electrons and holes PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Conduction Band Ec ED EA Ev Valence Band Sheet Resistance, what is it? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory What is the Resistance of this bar of material with resistivity ρ? t W L R = ρ L/Wt We can rearrange to get a film dependent quantity called the Sheet Resistance Rs = ρ/t =R / (L/W) Notice L/W is unit less, but gives us the number of “squares” in the length of the bar. The units of Rs are ohms, but they are often given as Ω / . Sheet Resistance - Four Point Probe PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory If Probe spacing is: • Larger than film thickness • Smaller than distance to edge of film • Probe points are “small” Using a four point approach is a standard technique for eliminating the effects of contact resistance Rs=4.53 V/I and ρ=Rst where t is thickness How do we get the doping? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Rs and t give us ρ, which gives us doping (but we must know t) Another way to get doping - from C-V of a diode PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Formation of a p-n junction Formation of a Schottky junction 1/C2 vs V PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory C-2 Slope gives carrier Concentration x-intercept give Vbiv Assumes an abrupt junction Schottky, p+n or n+p What if the line isn’t straight? How about the thickness of our Oxide? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Again, C = εA/W, so we should have another way to measure W. In practice, we must be careful about what C we use. Corresponds to oxide thickness What about trapped charge? Inversion in an MOS structure PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory accumulation (negative bias) no bias inversion (positive bias) What about I-V Characteristics? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Forward biased pn junction: Probability that carriers are over the barrier is like a Boltzmann factor But, there is also an electric field pushing carriers back so at V = 0 there should be no current. We can write this in a simpler form as: What about when light is shining on the device? Note, there is a sign difference with respect to the capacitance analysis How can we tell the carrier type PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Thermovoltage ee e Hall Effect • carrier type • mobility • sheet concentration Hot Probe V e e e ee Other methods of getting at the carriers PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory • • • • • SIMS RBS – Rutherford Backscattering Polaron profiler Spreading Resistance ... Doping - reminder PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Goal of Doping: Substitution of atoms with excess or deficiency of valence electrons e.g. B or P substituting for Si Diffusion doping (in fact most doping) is typically done in two steps: (Almost all doping is now ion implantation) Predeposition - Use a source to create the desired dose Drive in - Source at surface removed, additional diffusion to get desired distribution (in ion implantation the anneal also removes damage and activates the dopant). Generic Predeposition Process PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Deliver Dopants to Partially Masked Substrates • Diffusion (Hot) • Ion Implantation (Cold) Structure: Dopants Mask: Oxide, Nitride, Photoresist Silicon Dopant delivery Options for Diffusion PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory CB Gas Source: • Nasty Gases: AsH3, PH3, B2H6 • Very similar to Deal –Grove Oxidation Liquid Source: δ Cs xj Co Ci • SOG: Spin-On Glass • Doped SiO2 dissolved in solvents • Apply exactly like Photoresist Solid Source: • Glass Discs (B2O3, P2O5) • Close-space Sublimation • Vapors sublime/diffuse/react Which is Best? Drive-in - estimating the profile PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Fick’s law - You need the PDE, but you also need the boundary conditions! C(z,0) = 0, Z ≠ 0 dC(0,t)/dz = 0 C(∞,t) = 0 ∞ ∫ C(z,t)dz = Q T = constant 0 Solution: € QT C(z, t) = e πDt ⎛ -z 2 ⎞ ⎜ ⎟ ⎜ 4 Dt ⎟ ⎝ ⎠ We can model the drive in step from our homework, here after a P predep with p8545 we had a sheet resistance of 12Ω/ and depth of 1.1µm. This gave a carrier concentration of 5x1019/ cm3 and a surface concentration of 5.5x1015/cm2 Characteristic Length Scale Diffusion Length What about the diffusion Coefficient? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Use first three terms in Fair’s vacancy model. 2 n − ⎡ n ⎤ 2− I told you to assume n~ni ~1019/cm3 o D = D + D + ⎢ ⎥ D Is this reasonable? ni ⎣ ni ⎦ From Campbell table 3.2 (1100C=1373K) Do = 3.9cm2/s e-(3.66/k1373) = 1.43 x 10-13cm2/s D- = 4.4cm2/s e-(4.0/k1373) = 9.13 x 10-15cm2/s D2- = 44cm2/s e-(4.37/k1373) = 4.00 x 10-15cm2/s D = 1.56 x 10-13cm2/s Simulations PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Suprem-IV is a process simulation tool developed at Stanford University nanoHub TCAD tools PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory https://nanohub.org/tools Suprem simulation of boron predep and drive-in PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Boron Diffusion Log10(Boron) 20 Boron Predep 1100C 30 min. 15 Boron drivein 1100C 30 min. 10 Boron predep in gas at 5 x 1020/cm3 concentration followed by drive-ins. Boron drivein 1100C 60 min. 5 0 0 2 4 Depth in microns Boron drivein 1100C 60 min 200 angstrom oxide cap Effect of oxide cap on profile near the surface Boron Diffusion 21.0 20.5 Log10(Boron) Why 5x1020/cm3? 1) Damage threshold 2) Solubility limit 3) B partial pressure 1) Dimensional argument 20.0 19.5 19.0 18.5 18.0 0 0.5 1 1.5 Depth in microns 2 2.5 Solid Solubility, what is it? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory 1100C 5x1020/cm3 Oxide is an effective anti-diffusion barrier for Si VLSI? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory 1) 2) 3) 4) For boron but not for phosphorus For phosphorus but not for boron It works well for both It depends Final Topic on Diffusion: Oxide PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory How fast do dopants diffuse through oxide? Diffusivity important, Solubility important Consider Do of Boron Si prefactor 0.37cm2/s SiO2 prefactor 0.0003cm2/s Activation Energy Activation Energy 3.46eV 3.53eV Now Do of Phosphorous Si prefactor 3.9 cm2/s SiO2 prefactor 0.19 cm2/s Activation Energy Activation Energy 3.66eV 4.03eV • Oxide is often used as a diffusion mask- how thick does it need to be? • Oxide is used for isolation - does it isolate? What is the thermal load? • Oxide is also a gate dielectric with heavily B doped polysilicon gates diffusion through gate is an issue M Metal Doped polysilicon O Oxide S Silicon Suprem-IV Wet Oxide then Diffusion PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Oxide antidiffusion barrier Log10(Boron) 20 15 60 min wet O2 at 1000C, 30 min boron predep at 1100C 30 minute boron predep at 1100C 10 5 0 0 Effect of oxide cap on 1 2 3 profile near the surface 4 Depth in microns Substrate is P doped at 1 x 1014/cm3, Wet oxide growth at atmospheric pressure for 60 minutes at 1000C, Boron predep from 30 minutes at 1100C in gas with a concentration of 5 x 1020/cc. Simulation of predep and drive-in to find junction depth PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory 1000°C P predep in p-type wafer doped at 1x1017/cm3. 1100°C drive in. How long to get a 4.0µm deep junction?