MECKLENBURG COUNTY FIRE MARSHAL'S OFFICE FIRE MAIN INSPECTION

advertisement

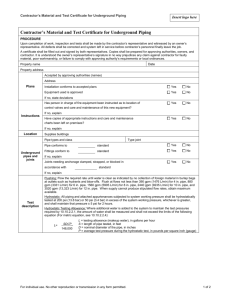

MECKLENBURG COUNTY FIRE MARSHAL'S OFFICE FIRE MAIN INSPECTION Per NFPA 24 the authority having jurisdiction shall always be consulted before the installation or remodeling of private fire service mains. Requirements: • Working plans shall be submitted for approval to the authority having jurisdiction before any equipment is installed or remodeled. • Pipe smaller than 6 inches in diameter shall not be installed as private service main supplying hydrants. • For mains that do not supply hydrants, sizes smaller than 6 inches shall be permitted to be used to the following restrictions: o The main shall supply only the following types of systems: Automatic sprinkler systems Open sprinkler systems Water spray fixed systems Foam systems Class II standpipe systems o Hydraulic calculations shall show that the main is able to supply the total demand at the appropriate pressure. • The Fire Department Connection (FDC) shall be properly supported. • 4 inch piping is the minimum size permitted for a Fire Department Connection (FDC). • Fire Department Connections (FDC) shall be located not less than 18 inches nor more than 48 inches above the level of adjoining ground, sidewalk, or grade surface. • Underground piping must rise 12 inches above ground to enter building. • Hydrants shall be provided and spaced in accordance with the requirements of the authority having jurisdiction. o Hydrants shall be located not less than 40 feet from the building to be protected. o Hydrants shall be of an approved type and have not less than a 6 inch diameter connection with the mains. o Hydrants shall have a 5 inch storz connection. • Joint restraint – All tees, plugs, caps, bends, reducers, valves, and hydrant branches shall be restrained against movement by using thrust blocks or restrained joint systems. o Thrust blocks shall be of a concrete mix not leaver than one part cement, two and one-half parts sand, and fire parts stone. o Thrust blocks shall be placed between undisturbed earth and the fitting t be restrained and shall be capable of resisting the calculated thrust forces. • Approval of underground piping – The installing contractor shall be responsible for the following: o Notifying the authority having jurisdiction and the owner’s representative of the time and date testing is to be performed. o Performing all required acceptance tests. o Completing and signing the contractor’s material and test certificate(s). • Hydrostatic Test – All piping and attached appurtenances subjected to system working pressure shall be hydrostatically tested at 200 psi or 50 psi in excess of the system working pressure, whichever is greater, and shall maintain that pressure at ±5 psi for 2 hours. PEOPLE • PRIDE • PROGRESS • PARTNERSHIPS 2145 Suttle Avenue • Charlotte, North Carolina 28208-5237 • (980) 314-3070 North Carolina Recommended Depth of Cover Above Top of Underground Yard Mains Pipe Thrust Block Examples 18 inch minimum 36 inch maximum Typical Hydrant Connection with a Minimum and Maximum Height Requirement Contactor’s Material and Test Certificate for Underground Piping PROCEDURE Upon completion of work, inspection and tests shall be made by the contractor’s representative and witnessed by the authority having jurisdiction. All defects shall be corrected and system left in service before contractor’s personnel finally leave the job. A certificate shall be filled out and signed by both representatives. Copies shall be prepared for approving authorities, owners, and contractor. It is understood the owner’s representative’s signature in no way prejudices any claim against contractor for faulty material, poor workmanship, or failure to comply with approving authority’s requirements or local ordinances. Property Name: Date: Property Address: Accepted by approving authorities (names) Address Plans Installation conforms with plans Yes No Equipment used is approved Yes No Yes No Yes No If no, state deviations Instructions Location Has person in charge of fire equipment been instructed as to location of control valve and care and maintenance of this new equipment? If no, explain Have copies of appropriate instructions and care and maintenance charts been left on premises? If no, explain Supplies Building Pipe types and class Underground Pipes and Joints Type Joint Pipe conforms to standard Yes No Fittings conforms to standard Yes No Yes No If no, explain Joints needed anchorage clamped, strapped, or blocked in accordance with standard In no, explain Test Description Flushing: Flow the required rate until water is clear as indicated by no collection of foreign material in burlap bags at outlets such as hydrants and blow offs. Flush at flows not less than 390 gpm (1476 L/min) for 4 in. pipe, 880 gpm (3331 L/min) for 6 in. pipe, 1560 gpm (5905 L/min) for 8 in. pipe, 2440 gpm (9235 L/min) for 10 in. pipe, and 3520 gpm (13,323 L/min) for 12 in. pipe. When supply cannot produce stipulated flow rates, obtain maximum available. Hydrostatic: All piping and attached appurtenances subjected to system working pressure shall be hydrostatically tested at 200 psi (13.8 bar) or 50 psi (3.5 bar) in excess of the system working pressure, whichever is greater, and shall maintain that pressure ± 5 psi (0.35 bar) for 2 hours. Hydrostatic Testing Allowances: Where additional water is added to the system to maintain the test pressure required by 10.10.2.2.1, the amount of water shall be measured and shall not exceed the limits of the following equation (For metric equation, see 10.10.2.2.6) L = Testing allowance (makeup water), in gallons per hour S = Length of pipe tested, in feet 𝑆𝑆𝑆𝑆√𝑃𝑃 𝐿𝐿 = D = Nominal diameter of the pipe, in inches 148,000 P = Average test pressure during the hydrostatic test, in pounds per square inch (gauge) Yes New underground piping flushed according to No standard by (company): If no, explain Through what type opening How flushing flow was obtained Public Water Flushing Tests Tank or Reservoir Fire Pump Hydrant Butt Open Pipe Yes Lead-ins flushed according to No Standard by (company): If no, explain Through what type of opening How flushing was obtained Public Water Tank or Reservoir Fire Pump Y Connection to flange and Spigot Open Pipe NFPA 24 (p. 1 of 2) Hydrostatic Test Joints Covered All new underground piping hydrostatically tested at psi for Yes hours No Total amount of leakage measured Leakage Test gallons hours Allowable leakage gallons Hydrants Number installed hours All operate satisfactorily Type and make Water control valves left wide open Control Valves Yes No Yes No Yes No If no, state reason Hose threads of fire department connections and hydrants interchangeable with those of fire department answering alarm Date left in service Remarks Name of installing contractor Tests Witnessed By: Signatures For property owner (signed) Title Date For installing contractor (signed) Title Date Additional explanation and notes NFPA 24 (p. 2 of 2)