Stephen M. Hall, PE January 21, 2016

Stephen M.

Hall, PE

January 21, 2016

Plan

• Operations

• Flows/Conditions

• Systems

Requirements

• Soils

• Acceptance

Criteria

• Costs

Inventory

• Tanks

• Equipment

• Piping

Level branch connections in horizontal pipeline

Flow direction into a TEE

Reynolds number –

It’s

not

that

easy!

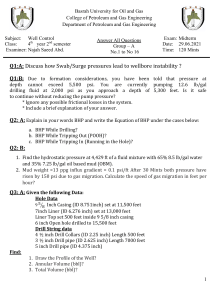

Type of Solid Flow Velocity, ft/s

Fine 3 to 5

Sand 5 to 7

Pipe Size Flow for 5 ft/s Re

(water @25 C)

1 inch

1 ½ inch

9.3

23.0

gpm 38,200

60,200

2 inch

3 inch

42.8

100.8

82,200

126,100

P1

NPSHa =

H

VP

Δ P

P1 = Tank Pressure, psia

H = Liquid Height, ft

Δ P = Pressure Loss to Friction, psi

VP = Vapor Pressure, psia

P1 x 2.31

+ H

‐ Δ P x 2.31

‐ VP x 2.31

PSI x 2.31

= feet H

2

O

Pity

the

poor

operator

Equipment setup

Manual cleaning steps

Monitoring

Documentation

Plan

Regulatory

Flow

Rates/Paths

Hydraulics

Utilities/

Infrastructure

Operations

Validation

Take inventory – know what needs to be cleaned

Establish acceptance criteria – write a URS

Clean in a Reproducible and Effective manner

Find a path to every pipe, component and equipment

Calculate pressure drops

Remember NPSH requirements for pumps

Purified water and WFI consumption rates establish size(s) for CIP tank(s)

Valves vs.

flow panels / swing elbows

Equipment setup / COP

Acceptance criteria from URS