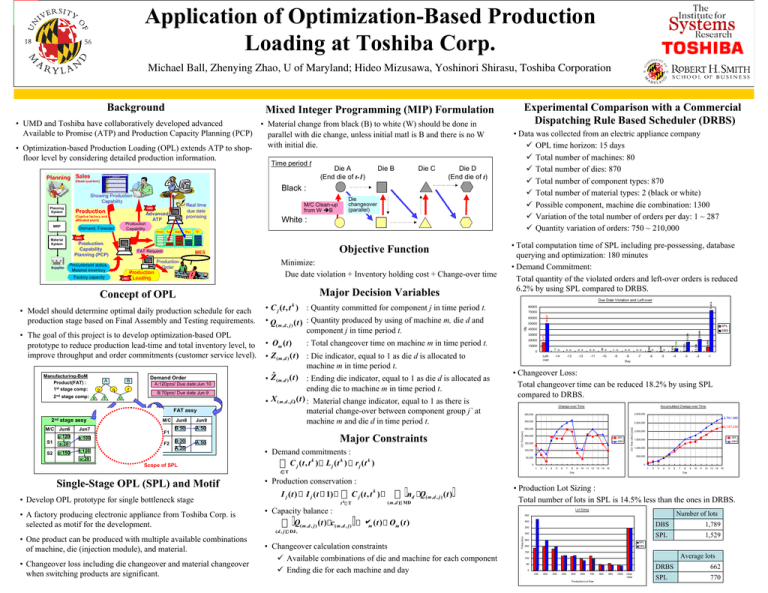

Application of Optimization-Based Production Loading at Toshiba Corp.

advertisement

Application of Optimization-Based Production Loading at Toshiba Corp. Michael Ball, Zhenying Zhao, U of Maryland; Hideo Mizusawa, Yoshinori Shirasu, Toshiba Corporation Background • UMD and Toshiba have collaboratively developed advanced • Material change from black (B) to white (W) should be done in Available to Promise (ATP) and Production Capacity Planning (PCP) parallel with die change, unless initial matl is B and there is no W with initial die. • Optimization-based Production Loading (OPL) extends ATP to shopfloor level by considering detailed production information. Time period t Planning Sales (Head quarters) Die A (End die of t-1) Die B Die C Die D (End die of t) Black : Showing Production Capability Planning Planning System System Production Advanced ATP Production Capability Demand, Forecast mon tue wed thu Die changeover (parallel) M/C Clean-up from W ÎB White : fri • Data was collected from an electric appliance company 9 OPL time horizon: 15 days 9 Total number of machines: 80 9 Total number of dies: 870 9 Total number of component types: 870 9 Total number of material types: 2 (black or white) 9 Possible component, machine die combination: 1300 9 Variation of the total number of orders per day: 1 ~ 287 9 Quantity variation of orders: 750 ~ 210,000 UMD Minimize: Due date violation + Inventory holding cost + Change-over time Production UMD Loading Major Decision Variables Concept of OPL 2nd stage comp: s Demand Order B A p r q t A:120pcs/ Due date:Jun.10 B:70pcs/ Due date Jun.9 u • Q( m ,d , j ) ( t ) : Quantity produced by using of machine m, die d and component j in time period t. 60000 M/C S1 S2 1st stage assy M/C Jun7 Jun6 Jun7 u:120 s:100 U1 p:40 t:120 U2 r:70 q:100 s:20 u:150 M/C Jun8 p:80 F1 F2 q:100 Jun8 Jun9 B:50 A:50 B:20 q:90 u:20 Scope of SPL Major Constraints • Develop OPL prototype for single bottleneck stage • A factory producing electronic appliance from Toshiba Corp. is selected as motif for the development. • Changeover loss including die changeover and material changeover when switching products are significant. -11 -10 -9 -7 -6 -5 -4 C j (t , t k ) t k 3,000,000 300,000 2,500,000 T • Capacity balance : Q( m ,d , j ) ( t ) c( m ,d , j ) 200,000 SPL DBS 150,000 SPL 1,500,000 DBS 1,000,000 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Day • Production Lot Sizing : Total number of lots in SPL is 14.5% less than the ones in DRBS. Lot Sizing Number of lots 450 am ( t ) Om ( t ) 400 350 300 Frequency • Changeover calculation constraints 9 Available combinations of die and machine for each component 9 Ending die for each machine and day 22,446 2,147,220 2,000,000 500,000 0 ( m ,d ) MD -1 2,761,980 50,000 nd Q( m ,d , j ) ( t ) -2 Accumulated Change-over Time Change-over Time 350,000 Day I j ( t 1) -3 Day 100,000 • Production conservation : 8,094 17,379 879 6,100 -12 1,353 439 0 -13 1,129 293 0 -14 DBS • Changeover Loss: Total changeover time can be reduced 18.2% by using SPL compared to DRBS. ( d , j ) DJ , • One product can be produced with multiple available combinations of machine, die (injection module), and material. 8 0 Leftover 7 0 0 • Demand commitments : C j (t , t k ) L j (t k ) rj (t k ) I j (t ) -8 10000 t T Single-Stage OPL (SPL) and Motif 0 0 Qty 20000 250,000 A:50 A:20 SPL 40000 30000 material change-over between component group j` at machine m and die d in time period t. FAT assy 2nd stage assy 50000 85 0 • Om (t ) : Total changeover time on machine m in time period t. • Z ( m ,d ) ( t ) : Die indicator, equal to 1 as die d is allocated to machine m in time period t. • Zˆ ( m ,d ) ( t ) : Ending die indicator, equal to 1 as die d is allocated as ending die to machine m in time period t. X ( t ) • ( m ,d , j ) : Material change indicator, equal to 1 as there is 70000 CO Time (ACC) [sec] Manufacturing-BoM Product(FAT) : 1st stage comp: 80000 0 0 • The goal of this project is to develop optimization-based OPL prototype to reduce production lead-time and total inventory level, to improve throughput and order commitments (customer service level). • C j ( t , t ) : Quantity committed for component j in time period t. CO Time [sec] • Model should determine optimal daily production schedule for each production stage based on Final Assembly and Testing requirements. 73,614 Due Date Violation and Left-over k 0 0 Factory capacity • Total computation time of SPL including pre-possessing, database querying and optimization: 180 minutes • Demand Commitment: Total quantity of the violated orders and left-over orders is reduced 6.2% by using SPL compared to DRBS. 0 0 Procurement status, Material inventory Objective Function MES Production Order 50,921 FAT Request 16,710 Production Capability Planning (PCP) 17 0 Material Material System System Supplier Real time due date promising UMD (Captive factory and affiliated plant) MRP MRP Experimental Comparison with a Commercial Dispatching Rule Based Scheduler (DRBS) Mixed Integer Programming (MIP) Formulation 250 DBS 1,789 SPL 1,529 SPL DBS 200 150 Average lots 100 50 0 100 200 300 400 500 600 700 Production Lot Size 800 900 1000 Over 1000 DRBS 662 SPL 770