Chemical Sensing and Advanced Process Control for AlGaN/GaN HEMT Manufacturing [Lab or

advertisement

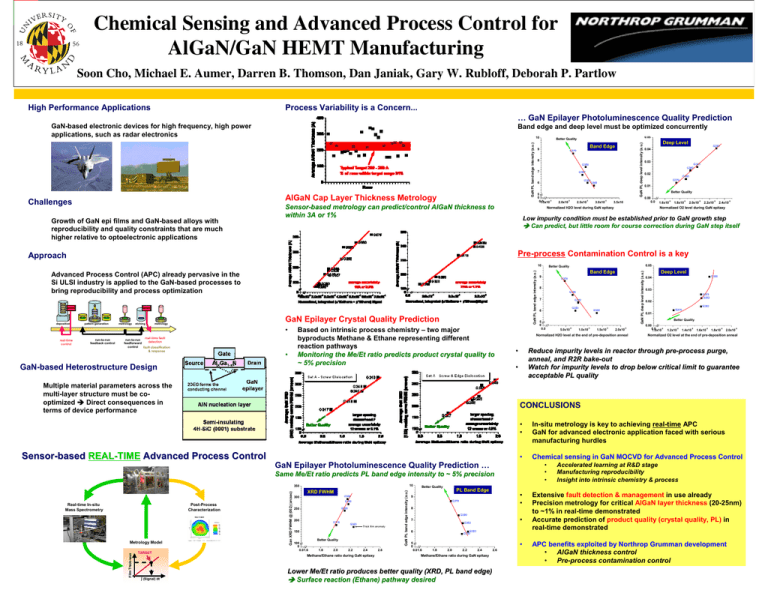

Chemical Sensing and Advanced Process Control for AlGaN/GaN HEMT Manufacturing [Lab or Research Group Logo] Soon Cho, Michael E. Aumer, Darren B. Thomson, Dan Janiak, Gary W. Rubloff, Deborah P. Partlow Process Variability is a Concern... High Performance Applications … GaN Epilayer Photoluminescence Quality Prediction GaN-based electronic devices for high frequency, high power applications, such as radar electronics Band edge and deep level must be optimized concurrently AlGaN Cap Layer Thickness Metrology Challenges Growth of GaN epi films and GaN-based alloys with reproducibility and quality constraints that are much higher relative to optoelectronic applications SensorSensor-based metrology can predict/control AlGaN thickness to within 3A or 1% Band Edge 9 G379 8 G386 7 G382 G383 6 G380 5 0 -3 0.0 1.5x10 -3 2.5x10 -3 3.0x10 - 3.5x10 G386 0.03 G383 G382 0.02 G380 G379 0.01 Better Quality 0.00 0.0 Normalized H2O level during GaN epitaxy -5 1.6x10 -5 1.8x10 -5 2.0x10 -5 2.2x10 -5 2.4x10 Normalized O2 level during GaN epitaxy Low impurity condition must be established prior to GaN growth step step Pre-process Contamination Control is a key sensor sensor pattern generation metrology etching GaN Epilayer Crystal Quality Prediction metrology • run-to-run feedback control real-time fault run-to-run detection feedforward control fault classification & response Based on intrinsic process chemistry – two major byproducts Methane & Ethane representing different reaction pathways Monitoring the Me/Et ratio predicts product crystal quality to ~ 5% precision • GaN-based Heterostructure Design Multiple material parameters across the multi-layer structure must be cooptimized Î Direct consequences in terms of device performance • 10 Film Thickness XRD FWHM G380 300 G382 G386 250 200 G379 G383 Thick film anomaly 150 Better Quality 100 0 0.01.6 1.8 2.0 2.2 2.4 Methane/Ethane ratio during GaN epitaxy 2.6 GaN PL band edge intensity (a.u.) Post-Process Characterization Gan XRD FWHM @ (002) (arcsec) 350 Better Quality PL Band Edge • G386 7 G382 G383 6 G380 5 0 0.0 -4 5.0x10 -3 1.0x10 -3 1.5x10 -3 2.0x10 G386 0.03 G383 G382 0.02 G380 G379 0.01 Better Quality 0.00 -5 0.0 1.0x10 1.2x10 -5 -5 1.4x10 -5 1.6x10 -5 1.8x10 -5 2.0x10 Normalized O2 level at the end of pre-deposition anneal • • In-situ metrology is key to achieving real-time APC GaN for advanced electronic application faced with serious manufacturing hurdles • Chemical sensing in GaN MOCVD for Advanced Process Control • • • • • 9 G379 8 G386 • 7 G382 G383 G380 6 5 0 0.01.6 • 1.8 2.0 2.2 2.4 Methane/Ethane ratio during GaN epitaxy Lower Me/Et ratio produces better quality (XRD, PL band edge) ∫ (Signal) dt 8 Deep Level 0.04 Reduce impurity levels in reactor through prepre-process purge, anneal, and R2R bakebake-out Watch for impurity levels to drop below critical limit to guarantee guarantee acceptable PL quality Same Me/Et ratio predicts PL band edge intensity to ~ 5% precision precision TARGET G379 Normalized H2O level at the end of pre-deposition anneal GaN Epilayer Photoluminescence Quality Prediction … GaN MOCVD Process Metrology Model Band Edge CONCLUSIONS SensorSensor-based REALREAL-TIME Advanced Process Control Real-time In-situ Mass Spectrometry 0.05 Better Quality 9 GaN PL deep level intensity (a.u.) GaN PL band edge intensity (a.u.) 10 Advanced Process Control (APC) already pervasive in the Si ULSI industry is applied to the GaN-based processes to bring reproducibility and process optimization real-time control -3 2.0x10 Deep Level 0.04 Î Can predict, but little room for course correction during GaN step step itself Approach deposition 0.05 Better Quality GaN PL deep level intensity (a.u.) GaN PL band edge intensity (a.u.) 10 Î Surface reaction (Ethane) pathway desired 2.6 Accelerated learning at R&D stage Manufacturing reproducibility Insight into intrinsic chemistry & process Extensive fault detection & management in use already Precision metrology for critical AlGaN layer thickness (20-25nm) to ~1% in real-time demonstrated Accurate prediction of product quality (crystal quality, PL) in real-time demonstrated APC benefits exploited by Northrop Grumman development • AlGaN thickness control • Pre-process contamination control

![Structural and electronic properties of GaN [001] nanowires by using](http://s3.studylib.net/store/data/007592263_2-097e6f635887ae5b303613d8f900ab21-300x300.png)