Advance Journal of Food Science and Technology 10(4): 262-269, 2016

advertisement

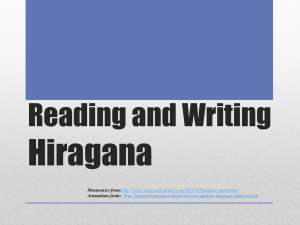

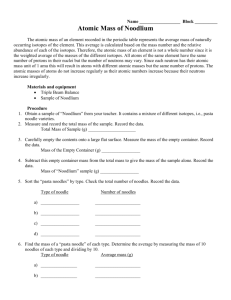

Advance Journal of Food Science and Technology 10(4): 262-269, 2016 DOI: 10.19026/ajfst.10.2066 ISSN: 2042-4868; e-ISSN: 2042-4876 © 2016 Maxwell Scientific Publication Corp. Submitted: April 14, 2015 Accepted: May 10, 2015 Published: February 05, 2016 Research Article Sensory Quality and Physico-chemical Properties of Three Types of Commercial Dried Chinese Noodles Rui Liu, Yi-Min Wei, Ya-Nan Xing, Jie Wang, Ying-Quan Zhang and Bo Zhang Institute of Agro-products Processing Science and Technology, Chinese Academy of Agriculture Sciences/Key Laboratory of Agro-products Processing, Ministry of Agriculture, Beijing, 100193, P.R. China Abstract: Sensory quality and physico-chemical properties of 60 samples of white salted noodles, 23 egg noodles and 16 buckwheat noodles, collected from large-scale noodle manufacturers, were measured. The differences in quality among the three types of commercial dried Chinese noodles and relationships between the various quality parameters were investigated. Color and flavor were the main aspects of quality that varied among the commercial dried noodles. In texture profile analysis of the noodles after cooking, buckwheat noodles showed significantly lower measurements of hardness, cohesiveness, chewiness and resilience and these differences were confirmed by sensory tests. The color score of white salted noodles was positively associated with L* and negatively with a* (p<0.01); but for buckwheat noodles, the associations were reversed. Hardness, chewiness of TPA and all sensory parameters for the 3 noodle types were negatively correlated with cooking loss. The association between water uptake, chewiness and noodle firmness score was described by means of a quadratic regression model. Compared with the winter wheat region in south China, dried white salted noodles originating from the winter wheat region in north China showed lower moisture, higher color b* and higher scores in stickiness, flavor and total scores. Keywords: Buckwheat noodles, cooking properties, egg noodles, sensory evaluation, texture profiles, white salted noodles chemical qualities of the noodles showed large variability (Liu et al., 2012). Two main types of DCN are produced in China, according to the Chinese Industrial Standard SB/T 10068-92 and SB/T 10069-92, released by the Ministry of Commerce-these are classified as “ordinary DCN” and “varied DCN”. The ordinary DCN are made only of wheat flour, water and salt, while the varied DCN have other ingredients such as eggs, beans, corn, buckwheat, vegetables and other nutritional and flavoring additives. Traditionally, many people make the fresh noodles with eggs at home to make them more delicious and nutritious and dried egg noodles are one of the most popular commercial noodle types manufactured in China (Liu et al., 2013). Buckwheat noodles are a traditional Chinese food which are made of wheat flour mixed with buckwheat flour. According to preliminary surveys on the dried noodle market in China, White Salted Noodles (WSN) are the most important ordinary DCN type, while egg noodles and buckwheat noodles are the 2 main varied DCN types. All three types of noodles were studied in this study. A classification of wheat quality regions in China was released in 2002, based on factors including INTRODUCTION Noodles are a traditional staple food that enjoy great popularity in China and some Asian countries and are consumed worldwide. The importance of noodles in the Asian diet is significant. Currently, an average of 20-50% of total wheat flour consumption in many countries occurs in the form of noodles (Hou, 2010). Dried Chinese Noodles (DCN, named Guamian in Chinese), manufactured on a mechanized processing line, have a much higher total commercial value than other noodle types (Liu et al., 2013). As at 2012, DCN output in China was recorded at 6.5-7.0 million tons and about 9.0-10.0 million tons of wheat was used for its production (Chinese Institute of Food Science and Technology, 2013). With the rapid development of the DCN industry, the bright market prospects of dried noodles attracted many companies to invest in this industry, including some multinational corporations, such as Wilmar International Limited, Nissan Jinmailang Foods Co., Ltd. and Uni-President Enterprise Corporations (Liu et al., 2013). Recent surveys indicated that there are many brands and types of noodles in the China market and the physico- Corresponding Author: Yi-Min Wei, Institute of Agro-products Processing Science and Technology, Chinese Academy of Agriculture Sciences/Key Laboratory of Agro-products Processing, Ministry of Agriculture, Beijing, 100193, P.R. China, Tel.: 8610-62815956 This work is licensed under a Creative Commons Attribution 4.0 International License (URL: http://creativecommons.org/licenses/by/4.0/). 262 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 output of more than 50000 tons and were located in 16 provinces, including Henan, Hebei, Shandong, Anhui and Hunan. Color was measured using a Chromameter (CR400, Konica Minolta Camera, Japan) with the CIE L*, a*, b* color space equipped with a C illuminant. Color of dried noodles was measured at infinite optical thickness by placing a large amount of dried noodles into a 20×10 cm rectangular pallet, which eliminates interference from the background. Each sample was placed 3 times and 5 different points were selected for determination each time and the color was expressed as the average value of fifteen determination results. The optimal cooking time for each sample was determined using AACCI Method 66-50 (AACC International, 1999). It was evaluated by observing the time of disappearance of the core of the noodle strands during cooking, by squeezing the noodle strands between two transparent glass plates. The water uptake and cooking loss were determined according to Chinese Standard Method SB/T 10068-92, with some modification. A 10 g sample of dried noodles was placed into 500 mL of boiling distilled water until optimal cooking time. The cooked noodles were taken out and weighed after standing for 5 min. Water uptake during cooking was calculated as a function of the increase in cooked noodle weight relative to the raw noodle weight and expressed on a g/g basis. The noodle soup was evaporated in a stainless steel pot on an induction cooker until nearly dry and heated to complete dryness in an air drying oven. Cooking loss was reported as a percentage of the starting material (calculated on a dry basis). Texture properties of the cooked noodles were measured by compressive Texture Profile Analysis (TPA) using a TA-XT2i Texture Analyzer (Stable Micro Systems, London, England) under optimal test conditions. A set of five strands of cooked noodles were placed in parallel on a flat metal plate. Instrument settings were compression mode, A/LKB-F probe, trigger type, auto-10 g; pretest and posttest speed, 2.0 mm/sec; test speed, 0.8 mm/sec; strain, 70%; interval between two compressions, 10 sec. The eating quality of noodles was subjectively evaluated by six trained panelists according to Chinese Standard SB/T 10137-93 with some modification (Ministry of Commerce of the People’s Republic of China, 1993). The maximum score of 10 is given for a bright white uniform color and a 10 for visual surface smoothness, 20 for medium firmness, 20 for elasticity, 20 for no stickiness, 10 for smoothness in the mouth and 10 for a fragrant wheat smell. The control sample used in the present study was a representative sample of cultivar Xiaoyan 6, which had shown a relatively good noodle quality score in a preliminary sensory test. The control noodles were given scores, for each of the characters assessed, except Fig. 1: Chinese wheat production zones I: Red semi-hard and hard spring wheat region in north China; II: White hard and semi-hard winter wheat region in north China; III: Red semi-hard and soft winter wheat region in south China rainfall, temperature and sunshine, soil type, fertility, farming system, genetic potential for quality performance and wheat kernel quality data collected for the last 15 years (He et al., 2002). In general, three regions are recognized, i.e., red semi-hard and hard spring wheat region in north China (Zone I), white hard and semi-hard winter wheat region in north China (Zone II) and red semi-hard and soft winter wheat region in south China (Zone III) (Fig. 1). As a subregion of Zone II, the Yellow and Huai River Valleys Winter Wheat Zone occupies about 60% of the national wheat area and contributes about 70% of the total production in China. It is grown across the Central and Southern Hebei Province, Henan Province, Shanxi Province, Shandong Province, Northern Jiangsu Province and Northern Anhui Province. In order to study the quality of commercial dried Chinese noodles in China, 99 noodle samples including 60 white salted noodles, 23 egg noodles and 16 buckwheat noodles were collected from 39 typical large-scale dried noodles enterprises, including 25 manufacturers from Zone II and 14 manufacturers from other 11 wheat-producing provinces. Sensory quality, texture profiles and cooking properties of DCN samples were measured, with aims to compare: • • The main types of noodles (i.e., WSN, vs. Egg, vs. Buckwheat) The quality of WSN between Zones I, II and III and to investigate relationships among the noodle quality parameters MATERIALS AND METHODS Ninety nine (99) commercial noodle samples (of which the width were all 2-3 mm) including 60 white salted noodles, 23 egg noodles and 16 buckwheat noodles were collected from 39 Chinese noodle manufacturing companies in the period October to December 2012. These included 12 domestic largescale Chinese noodle manufacturers with an annual 263 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 Table 1: Cooking properties of three types of commercial dried Chinese noodles Noodles types Parameters Optimal cooking time/min White salted noodles Mean 5.60±1.30a Range 3.50~8.50 (n = 60) CV/% 23.21 Egg noodles Mean 6.10±1.08a (n = 23) Range 4.00~8.00 CV/% 17.70 Buckwheat noodles Mean 5.70±0.80a Range 4.50~7.50 (n = 16) CV/% 14.04 Different letters within columns are significantly different at p<0.05 level Water uptake/g/g 1.84±0.16a 1.52~2.15 8.70 1.77±0.16a 1.51~2.03 9.04 1.81±0.18a 1.53~2.18 9.94 Cooking loss/% 6.60±0.89b 4.90~9.00 13.49 6.70±0.77b 5.30~8.30 11.55 7.60±1.06a 6.00~9.50 14.02 Fig. 2: The color L*and a* values of white salted noodles (n = 60), egg noodles (n = 23) and buckwheat noodles (n = 16) The boundary of the box indicates the 25th and 75th (top and bottom) percentiles; The line within the box marks the median; The whiskers above and below the box indicate the minimum and maximum values; Bars labeled with the same letter are not significantly different at p<0.05 level Choy et al. (2013), where instant noodles made by incorporating buckwheat flour, produced lower L* values corresponding to a brownish color of the noodles. firmness, that were 80% of the full score. Xiaoyan 6, with medium firmness, was given 100% of the full score. The data were expressed as means of at least three replicated determinations. One-way analysis of variance was used to analyze the data and significant differences among means were compared by the LSD test using SPSS version 16.0 for Windows. Cooking properties: Cooking properties of different types of commercial dried noodles were shown in Table 1. The results showed that, there was no significant difference in optimal cooking time among white noodles, egg noodles and buckwheat noodles. Similarly, no significant difference was observed in water uptake during cooking among the three types of noodles, however the cooking loss of buckwheat noodles was significantly higher than that of the other two types of noodles. Chinese Industrial standards SB/T 10068-1992 and SB/T 10069-1992, issued by the Ministry of Commerce of the People’s Republic of China (1992), specifies that the cooking loss of ordinary DCN (first grade) shall not exceed 10.0%, while that of varied DCN shall not exceed 15.0%. With respect to the collected DCN for this study, the cooking loss of ordinary DCN (white salted noodles) and varied DCN (egg noodles and buckwheat noodles) were 4.9~9.0% and 5.3~9.5% respectively, complying with the standard requirements. RESULTS Color: Color is one of the important quality traits of dried noodles and often the first and main sensory impression of consumers to dried noodle products. The ranges of color L* and a* values of white salted noodles, egg noodles and buckwheat noodles were 75.50~88.37 and -1.18~1.70, 78.13~87.55 and -1.04~1.39 and 55.75~84.92 and -1.64~4.22, respectively. Buckwheat noodles showed a relatively wider variation in color than white noodles and egg noodles (Fig. 2). Analysis of variance showed that there was no significant difference in color between white noodles and egg noodles and buckwheat noodles showed significantly lower L* and higher a* than the other two noodles (Fig. 2). Similar findings were reported by 264 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 Table 2: TPA parameters of three types of commercial dried Chinese noodles Noodles types Parameters Hardness/g White salted noodles Mean 322±88.86a (n = 60) Range 167~548 CV/% 27.60 Egg noodles Mean 321±81.80a (n = 23) Range 187~446 CV/% 25.48 Buckwheat noodles Mean 258±59.69b (n = 16) Range 181~408 CV/% 23.14 Different letters within columns are significantly different at p<0.05 level Cohesiveness 0.61±0.02a 0.54~0.66 3.28 0.61±0.02a 0.57~0.63 3.28 0.58±0.03b 0.49~0.62 5.17 Table 3: Sensory quality of three types of commercial dried Chinese noodles Noodles types Parameters Color Appearance Firmness Elasticity White salted Mean 7.30±2.05a 8.10±0.70a 18.30±1.53a 14.90±1.62a noodles Range 3.00~10.00 4.80~9.20 13.60~20.00 11.00~18.70 CV/% 28.08 8.64 8.36 10.87 (n = 60) Egg noodles Mean 6.80±1.94a 8.00±0.59a 18.50±1.22a 15.30±1.47a (n = 23) Range 2.40~9.50 6.40~8.80 16.00~20.00 12.80~18.40 CV/% 28.53 7.38 6.59 9.61 Buckwheat Mean 6.20±2.88a 7.10±0.93b 16.90±2.48b 12.10±3.28b noodles Range 2.00~10.00 5.00~8.00 12.00~20.00 6.00-16.00 CV/% 46.45 13.10 14.67 27.11 (n = 14) Different letters within columns are significantly different at p<0.05 level Texture parameters: As shown in Table 2, white salted noodles, egg noodles and buckwheat noodles exhibited relatively greater variation in TPA parameters hardness and chewiness than with cohesiveness and resilience, with all coefficients of variation exceeding 20%. No significant differences were observed in TPA parameters between white noodles and egg noodles; while the hardness, cohesiveness, chewiness and resilience of buckwheat noodles were significantly lower than that of the other two types of noodles. It was interesting to note that no significant difference was observed in eating quality between white noodles and egg noodles, while buckwheat noodles had lower hardness, cohesiveness, chewiness and resilience. Stickiness 18.30±1.42a 14.00~20.00 7.76 18.20±0.93a 16.00~20.00 5.11 15.20±1.83b 12.00~17.60 12.04 Chewiness 201±62.02a 107~455 30.86 194±46.23a 117~262 23.83 148±32.93b 107~240 22.25 Smoothness 8.00±0.78a 5.50~10.40 9.75 7.70±0.41a 6.80~8.40 5.32 6.30±0.70b 5.00~7.20 11.11 Resilience 0.45±0.04a 0.35~0.54 8.89 0.45±0.04a 0.38~0.52 8.89 0.42±0.05b 0.30~0.48 11.90 Taste 7.00±1.20a 2.00~8.40 17.14 6.80±1.16a 3.60~8.40 17.06 7.00±2.44a 2.00~10.00 34.86 Total score 81.90±5.28a 64.40~90.80 6.45 81.40±3.85a 75.60~90.00 4.73 70.80±8.16b 55.50~83.20 11.53 noodle made only of wheat flour, water and salt, is the most popular type of dried noodle in China and its quality was mainly affected by the wheat quality. The variance analysis results showed that there were significant differences in moisture, color and optimal cooking time of dried noodles and stickiness, flavor and total score of cooked noodles among dried white salted noodles from three wheat-producing regions (p<0.05). Dried WSN that originated from the spring wheat region in north China (Zone I) had higher L*, lower b*, longer cooking time and higher taste and flavor score of cooked noodles than from Zone II and III (Table 4). That is because these noodle samples originated from Hetao Plain covering Ningxia and parts of Inner Mongolia, where local main planted cultivars of wheat, especially Ningchun 4, are recognized for their high yield potential, low PPO activity, bright white color of flour and medium-strong gluten (He et al., 2010; Kang et al., 2010). Compared with the winter wheat region in south China (Zone III), noodles originating from the winter wheat region in northern China (Zone II) showed lower moisture, higher color b* and higher scores in stickiness, flavor and total scores. Different climatic characteristics lead to different noodle moisture contents. Dried noodles can easily absorb moisture during storage and transportation in Southern China's humid climate. Yellowness b* of dried white salted noodles is basically determined by the yellow pigment content of wheat grain (Zhang et al., 2006). Yang et al. (2008) reported that wheat cultivars from Northern Winter Wheat Region and Yellow and Huai Winter Wheat Region, two sub-regions of Zone II, showed higher yellow pigment content than those from middle and lower reaches of the Yangtze River Winter Wheat Region and Southwestern Winter Wheat Region, two sub-regions of Zone III. This result was consistent with our finding. Past studies have indicated that leading Sensory evaluation: As shown in Table 3, no significant difference was observed in sensory quality between white salted noodles and egg noodles, while buckwheat noodles showed lower scores in appearance, firmness, elasticity, stickiness, smoothness and total score than the other two types of noodles. Also, coefficients of variation and standard deviation of all sensory parameters of buckwheat noodles were higher than those of the other two types of noodles. The results indicated that the sensory quality of buckwheat noodles was poorer and presented wider variation. For each type of noodle, the coefficients of variation in color, taste and flavor were obviously larger than the other five sensory parameters, indicating that the variation in color and taste and flavor were the main aspects of quality variation of commercial DCN. The noodles with total score of not less than 80 included 43 white salted noodles (71.7%), 8 egg noodles (65.2%) and 1 buckwheat noodles (6.2%). Comparison among white salted noodles from various wheat-producing regions: White salted 265 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 Table 4: Quality traits of dried white salted noodles originated from various wheat-producing regions in China Quality traits Zone I (n = 5) Zone II (n = 38) Zone III (n = 17) Physic-chemical properties Moisture/% 10.75±0.92ab 10.61±0.67b 11.17±0.54a Color L* 85.49±1.71a 82.27±3.11b 82.89±2.61ab Color a* -0.21±0.61a 0.03±0.71a 0.41±0.68a * b a 16.11±1.30 18.47±1.88 16.20±1.82b Color b 5.40±1.21b 5.80±1.20ab Optimal cooking time/min 6.80±1.72a 184.10±16.58a 182.10±14.73a Water uptake/% 185.20±11.99a 6.71±0.95a 6.44±0.87a Cooking loss/% 6.45±0.34a 7.40±1.99a 6.70±2.27a Sensory quality Color 8.40±1.62a Appearance 7.60±1.60a 8.20±0.52a 8.00±0.50a 18.30±1.34a 18.20±2.07a Firmness 18.90±0.72a 14.90±1.57a 14.70±1.94a Elasticity 15.40±0.88a Stickiness 17.80±1.73ab 18.60±1.16a 17.70±1.73b 8.10±0.59a 7.70±0.92a Smoothness 8.10±1.45a a a 7.10±1.11 6.50±1.42b Taste and flavor 7.40±0.67 82.70±4.64a 79.60±6.03b Total score 83.20±6.49ab Zone: I: Red semi-hard and hard spring wheat region in north China; Zone II: White hard and semi-hard winter wheat region in north China; Zone III: Red semi-hard and soft winter wheat region in south China Fig. 3: Correlation between color score and L* and a* value of white salted noodles Fig. 4: Correlation between color score and L* and a* value of buckwheat noodles wheat cultivars growing in Zone III generally gave lower protein content and weaker gluten than those growing in Zone II (He et al., 2002; Hu et al., 2009; Qi et al., 2012). Also, wheat kernels can easily sprout in the humid climate of Zone III, which could lead to quality deterioration and poor noodle sensory quality. negatively correlated with color a* values, with correlation coefficients of -0.356, -0.494 and -0.539, respectively (p<0.05). The relationship between cooking properties and noodle texture attributes from both instrumental and sensory methods were analyzed based on the overall quality data of 99 noodle samples, as shown in Table 5. Optimal cooking time was significantly and positively correlated to elasticity score and cohesiveness. Cooking loss showed a significant negative relationship with all sensory traits including firmness, elasticity, stickiness and smoothness and most TPA parameters including hardness, cohesiveness and chewiness. Water uptake during cooking also showed significant negative associations with hardness and chewiness. Relationship between physico-chemical traits and noodles sensory quality: As shown in Fig. 3, the color score of white salted noodles was significantly and positively correlated with color L* value and negatively correlated with color a* (p<0.01). However, the opposite effects were noted for buckwheat noodles as shown in Fig. 4 (p<0.01). The appearance scores of white noodles, egg noodles and buckwheat noodles were significantly and 266 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 Table 5: Correlation coefficients between cooking properties and cooked noodle texture attributes Cooking properties Firmness Stickiness Elasticity Smoothness Hardness Cooking time 0.019 -0.169 0.283** -0.031 0.071 Cooking loss -0.275** -0.268** -0.288** -0.300** -0.278** Water uptake 0.122 0.181 -0.091 0.050 -0.384** n = 99; * and **: Significance at the 5 and 1% probability levels, respectively Table 6: Correlation coefficients between noodle sensory quality and TPA parameters TPA parameters Appearance Firmness Stickiness Hardness 0.215* 0.036 0.085 Cohesiveness 0.254* 0.295** 0.226* Chewiness 0.289** 0.105 0.155 Resilience 0.166 0.182 0.185 n = 99; * and **: Significance at the 5 and 1% probability levels, respectively Elasticity 0.392** 0.392** 0.437** 0.247* Cohesiveness 0.261* -0.220* 0.059 Chewiness 0.045 -0.289** -0.368** Smoothness 0.171 0.352** 0.236** 0.322** Resilience 0.170 -0.115 0.182 Total score 0.173 0.329** 0.245* 0.248* for more than 20% variation of each noodle sensory characteristic, with all correlation coefficients less than 0.45. DISCUSSION Noodle samples were collected from 39 mediumand large-scale DCN enterprises, including 12 manufacturers having an annual output of more than 50000 tons. The manufacturers were located in 16 provinces and the noodle samples were widely sourced to ensure good representation. Sixty of the ninety nine samples were from Henan, Hebei and Shandong, indicating that these provinces were favored regions in China for wheat milling and the processing of flour products, including noodles. Relatively large variation in physicochemical properties, cooking characteristics and sensory quality of each type of noodle were observed and variation in color and taste and flavor were the main aspects of quality variation of commercial DCN. As reported previously, protein content, protein quality and starch pasting properties have a strong impact on noodle quality (Moss, 1980; Crosbie, 1991; Hatcher et al., 2002; Park and Baik, 2004; Zhang et al., 2011). Both genotype and environment contribute to the diversity of wheat quality (Souza et al., 2004; Gazza et al., 2008; Vázquez et al., 2012). The Chinese wheat genotypes are quite diverse in quality traits and the wide geographic area of wheat production in China also leads to large differences in quality (Zhang et al., 2004, 2005). Therefore, wheat flour quality is a leading factor affecting commercial noodle quality in China, for manufacturers located in different wheat-producing areas. The results of this study showed that there were no significant differences in quality between white salted noodles and egg noodles. This may be due to a relatively small amount of added egg powder, causing no significant effect on noodle quality, or some manufacturers may have substituted colorants for eggs. Buckwheat noodles had a significantly weaker texture and lower eating quality score as well as larger cooking loss compared with the other two noodle types. This agrees with results reported by Choy et al. (2013), in which instant noodles made using Australian Soft Fig. 5: Association between water uptake, chewiness and firmness score Correlation coefficients between noodles sensory quality and TPA parameters are presented in Table 6. Hardness of TPA was positively correlated with appearance and elasticity scores. Cohesiveness was significantly and positively correlated with all sensory parameters and total score. Chewiness and resilience showed significant positive relationships with elasticity, smoothness and total score. Further analysis indicated a significant quadratic relationship between water uptake during cooking, chewiness of TPA and noodle firmness score (p<0.05) (Fig. 5). This suggests that, to certain extent (1.82 g/g and 214.62, for water uptake and chewiness, respectively), the firmness improves as these traits increase. However, at very high levels of water uptake and chewiness, firmness score is reduced. As a whole, cooking property and TPA parameters were closely related with noodles sensory quality, especially with elasticity score. However, none of the traits accounted 267 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 Chinese Institute of Food Science and Technology, 2013. 2012 China Dried Noodles Industry Development Report. Global Food Industry-China Pasta, 5: 14-22. (In Chinese) Choy, A.L., P.D. Morrison, J.G. Hughes, P.J. Marriott and D.M. Small. 2013. Quality and antioxidant properties of instant noodles enhanced with common buckwheat flour. J. Cereal Sci., 57: 281-287. Christa, K. and M. Soral-Śmietana, 2008. Buckwheat grains and buckwheat products-nutritional and prophylactic value of their components-a review. Czech J. Food Sci., 26: 153-162. Crosbie, G.B., 1991. The Relationship between starch swelling properties, paste viscosity and boiled noodle quality in wheat flours. J. Cereal Sci., 13: 145-150. Gazza, L., F. Taddei, M. Corbellini, P. Cacciatori and N.E. Pogna, 2008. Genetic and environmental factors affecting grain texture in common wheat. J. Cereal Sci., 47: 52-58. Hatcher, D.W., M.J. Anderson, R.G. Desjardins, N.M. Edwards and J.E. Dexter, 2002. Effects of flour particle size and starch damage on processing and quality of white salted noodles. Cereal Chem., 79: 64-71. He, Z.H., Z.J. Lin, L.J. Wang, Z.M. Xiao, F.S. Wan and Q.S. Zhuang, 2002. Classification on Chinese wheat regions based on quality. Sci. Agric. Sinica, 35: 359-364. (In Chinese) He, Z.H., X.C. Xia and Y. Zhang, 2010. Breeding Noodle Wheat in China. In: Hou, G. (Ed.), Asian Noodles: Science, Technology, and Processing. John Wiley & Sons, Hoboken, New Jersey, USA, pp: 1-24. Hou, G.G., 2010. Asian Noodles: Science, Technology and Processing. Wiley, Hoboken, New Jersey. Hu, X.X., G.Y. Zhou, L.N. Wu, W. Lu, L. Wu, J.M. Li, S. Wang, J.K. Song, X.L. Yang and B.J. Wang, 2009. Variation of wheat quality in main wheatproducing regions in China. Acta Agron. Sinica, 35: 1167-1172. (In Chinese) Kang, L., H.M. Yuan, D.S. Chen, X.L. Wang, W.J. Zhang, C.K. Lai and G.Z. Zhao, 2010. Research on the agronomic, quality traits and the corresponding background genes distribution of wheat germplasm Ningchun 4 and its parents. Agr. Sci. Tech., 11: 188-192. Liu, R., Y.M. Wei and B. Zhang, 2012. The quality investigation and analysis of dried white Chinese noodle in Beijing markets. In: Chinese Cereals and Oils Association (Ed.), 14th ICC Cereal and Bread Congress and Forum on Fats and Oils. Chinese Cereals and Oils Association, Beijing, China, Aug. 6-9, pp: 490-492. Liu, R., Y.M. Wei, B. Zhang and Y.Q. Zhang, 2013. The consumption behavior and consumer perception toward dried Chinese noodle in Beijing. Asian J. Agric. Food Sci., 1: 73-78. Wheat flour produced softer texture and a significant increase of cooking loss was observed when buckwheat flour was incorporated. It may be because the buckwheat proteins primarily contain water-soluble and salt-soluble albumins and globulins which are not suitable as contributors to the wheat gluten network (Wijngaard and Arendt, 2006; Christa and SoralŚmietana, 2008). In addition, it is also possible that the presence of fiber particles in buckwheat flour disrupted the continuity of the protein-starch network resulting in noodles with weaker texture (Choy et al., 2013). Two types of buckwheat are used in the manufacture of buckwheat noodles: common buckwheat with a dark brown flour color and tartary buckwheat with a yellowgreen flour color. Therefore, buckwheat noodles, made from a mixture of buckwheat flour and wheat flour had lower brightness, brownish color and poorer color uniformity than the other two noodle types. In addition, a large variation in eating quality of buckwheat noodles was observed as a consequence of a wide variation in the amount and quality of buckwheat flour added. Compared with the winter wheat region in south China, dried WSN originating from the winter wheat region in northern China showed lower moisture, higher color b* and higher scores in stickiness, flavor and total scores. That is due to large differences in climatic characteristics and quality of leading wheat cultivars. Relationships between the results from instrumental measures and sensory analysis were reported for cooked wheat noodles in the study by Tang et al. (1999). In that study, both TPA-derived hardness and cohesiveness were significantly and positively correlated with mouth feel firmness, stickiness and elasticity. Similar findings were observed in the present study, except the associations between TPA-derived hardness and sensory score of firmness and stickiness were not significant. ACKNOWLEDGMENT This study had been funded by the China Agriculture Research System (CARS-03), Special Fund for Agro-scientific Research in the Public Interest (Grant No. 201303070). The authors would like to thank the National Centre for research on wheat industry technology, China and the Jinshahe Flour Manufacturing Co. Ltd., China for their support. The authors are grateful to Prof. Dr. G.B. Crosbie for critically reviewing this manuscript. REFERENCES AACC International, 1999. Approved Methods of Analysis. 11th Edn., Method 66-50.01. Pasta and Noodle Cooking Quality-Firmness. AACC International, St. Paul, MN, USA. 268 Adv. J. Food Sci. Technol., 10(4): 262-269, 2016 2012. Influence of cultivar and environment on quality of Latin American wheats. J. Cereal Sci., 56: 196-203. Wijngaard, H.H. and E.K. Arendt, 2006. Buckwheat. Cereal Chem., 83: 391-401. Yang, F.P., X.Y. He, Z.H. He, X.W. Shang, W.X. Yang and X.C. Xia, 2008. Molecular detection and distribution of allelic variations of a gene for yellow pigment content in Chinese winter wheat cultivars. Sci. Agric. Sinica, 41: 2923-2930. (In Chinese) Zhang, L.P., J. Yan, X.C. Xia, Z.H. He and M.W. Sutherland, 2006. QTL mapping for kernel yellow pigment content in common wheat. Acta Agron. Sinica, 32: 41-45. (In Chinese) Zhang, S.B., Q.Y. Lu, H.S. Yang and D.D. Meng, 2011. Effects of protein content, glutenin-to-gliadin ratio, amylose content and starch damage on textural properties of Chinese fresh white noodles. Cereal Chem., 88: 296-301. Zhang, Y., Y. Zhang, Z.H. He and G.Y. Ye, 2005. Milling quality and protein properties of autumnsown Chinese winter wheats evaluated through multi-location trials. Euphytica, 143: 209-222. Zhang, Y., Z.H. He, G.Y. Ye, A.M. Zhang and M.V. Ginkel, 2004. Effect of environment and genotype on bread-making quality of spring-sown spring wheat cultivars in China. Euphytica, 139: 75-83. Ministry of Commerce of the People’s Republic of China, 1992. SB/T 10068-92. Dried Chinese Noodle. SB/T 10069-92. Varied Dried Chinese Noodle. Ministry of Commerce, Govt. of China, Beijing, China. Ministry of Commerce of the People’s Republic of China, 1993. SB/T 10137-93. Noodle Wheat Flour. Ministry of Commerce, Govt. of China, Beijing, China. Moss, H.J., 1980. The pasting properties of some wheat starches free of sprout damage. Cereal Res. Commun., 8: 297-302. Park, C.S. and B.K. Baik, 2004. Cooking time of white salted noodles and its relationship with protein and amylose contents of wheat. Cereal Chem., 81: 165-171. Qi, L.J., X.X. Hu, G.Y. Zhou, S. Wang, J.M. Li, W. Lu, L.N. Wu, M.B. Lu, L.J. Sun, X.L. Yang, J.K. Song and B.J. Wang, 2012. Analysis of wheat protein quality in main wheat producing areas of China from 2004 to 2011. Sci. Agric. Sinica, 45: 4242-4251. (In Chinese) Souza, E.J., J.M. Martin, M.J. Guttieri, K.M. O'Brien, D.K. Habernicht, S.P. Lanning, R. Mclean, G.R. Carlson and L.E. Talbert. 2004. Influence of genotype, environment and nitrogen management on spring wheat quality. Crop. Sci., 44: 425-432. Tang, C., F. Hsieh, H. Heymann and H.E. Huff, 1999. Analyzing and correlating instrumental and sensory data: A multivariate study of physical properties of cooked wheat noodles. J. Food Quality, 22: 193-211. Vázquez, D., A.G. Berger, M. Cuniberti, C. Bainotti, M.Z. de Miranda, P.L. Scheeren, C. Jobet, J. Zúñiga, G. Cabrera, R. Verges and R.J. Peña, 269