Tests of Wheat Tests of Milling

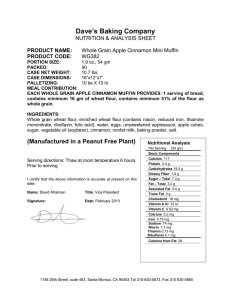

advertisement