Reasons For and Against Enterprise System Adoption Enterprise Architectures Conference David L. Olson

advertisement

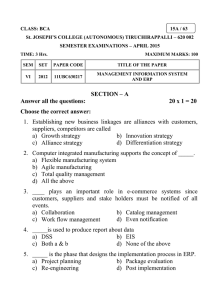

Reasons For and Against Enterprise System Adoption Enterprise Architectures Conference David L. Olson Stockholm, 28 October 2004 Enterprise Systems (ERP) • A tremendous success – Enable firms to more efficiently • Integrate data • More timely reports needed for decision making • Improved processes lead to more efficient operations – One of the most profitable software implementations And yet… • 65% of executives believe ERP can be harmful (Sarkis & Sundarraj, 2003) • IT investment is often wasted (Garry Lowenthal, CFO of Viper Motorcycle Co – Millman 2004) • Only a small minority, 10%, believe they are achieving a high return on technology investments (annual survey of financial executives, FEI & Computer Services Corporation – Millman 2004) • Only a select few companies have gotten value out of their ERP implementations, and those are world-class companies (David Hebert, The Hackett Group – Millman 2004) Millman (2004) • ERP is notoriously over-sold and under-delivered • ERP is the most expensive but least-value derived kinds of implementation (Scott Phares, VPbusiness services, Business Engine) • When a lot of ERP investments are made, there wasn’t a business case built (Brian Zrimsek, The Gartner Group) Notable ERP Failures • 1999 Hershey Foods Corporation had 19% drop in 3rdQuarter profits, 29% increase in inventories – problems in $112 million ERP (Motwani et al., 2002) • City of Oakland – paycheck problems from $21 million ERP project (Motwani et al., 2002) • Miller Industries - $3.5 million operating loss in 4thQuarter 1999 from ERP problems (Motwani et al., 2002) • WW Grainger Inc. - $11 million reduction in operating earnings after ERP implementation (Motwani et al., 2002) • FoxMeyer Drug bankruptcy through ERP (Ehrhart, 2001) Carton & Adam (2003) • Four Irish ERP implementations in manufacturing – Each had international operations – ERP for supply chain efficiencies • Pain of Learning – – – – Require unlearning old ways of working Changes often imposed rather than designed Integration of data led to centralizing ownership IT support often centralized to reduce cost • Responsibility for accurate data entry at subsidiary – Changes balance of power, usually centralizing Overview • Multinational ERP Issues – Business Process Reengineering – Federalism/Customization – Supply Chain Issues/Outsourcing – Lessons Learned – Conclusions • Social issues from – Network Society – Emergence of Systems – Future expectations Business Process Reengineering Millman (2004) • Brian Zrimsek, The Gartner Group – “The value isn’t in the system, but in what you change.” • Mitch Spitzer, VP GreenPoint Financial Corp. – “It wasn’t Oracle that got us the savings, but rather the reengineering of existing business processes, most through elimination of systems, reduction of headcount, streamlining processes.” BPR Problems Reported: 4 Cases Study BPR Problems Suggested Resolution Al-Mashari & Zaire (2000) Anxiety from job reduction Scope & focus creep Communication needs Technical mindset Communication Project milestones Newsletters, e-mail, Web Focus on business value Motwani et al. (2002) Projects out of control Sarkis & Sundarraj (2003) Initial productivity dip Planned for Yusuf et al. (2004) Match process to software Data cleanup Training Communication with users Bridge legacy systems Plan, focus on value BPR & Multinationals • The need to reflect different costs of doing things may change best practices by country • Different legacy practices exist across countries • Regulations impose different constraints • Cultural resistance to change may vary Federalism Davenport (1998) • Different elements of the organization have their own ERP versions – Linked together at a high level – Enable elements to cultivate unique competitive advantages – Regional units tailor operations to local requirements, local regulatory structure • Implemented by: – Monsanto – Hewlett-Packard – Nescafe Customization Millman (2004) • Ken Stoll (partner, Accenture) – “Taking a firm line on customization is one of the most effective ways to control ERP cost and maximize value.” • Plan $6 million, but $20 million customization • Paul Janicki (global finance director, Dow Chemical Co.) – “Dow one of first adopters of SAP, customized extensively, held off upgrading. SAP is discontinuing support, Dow faces difficult decision.” Tradeoff • Federalism vs. Customization • Federalism provides flexibility to meet local needs – Multinational subsidiaries have local requirements • CUSTOMIZE – Customization is very risky & expensive Supply Chain Factors – Multinational ERP • Multinational organizations inherently involve supply chains – Link suppliers, customers • A great deal of value in open systems – A major ERP trend since 1999 Supply Chain Successes • Texas Instruments (Sarkis & Sundaraj 2003) – Web ability key factor in enterprise system • Over 70% of external transactions electronic • Reduced customer order costs • Had access to global information in real time • Rolls Royce (Yusuf et al. 2004) – Integrated supply chain activities Supply Chain Benefits Goutsos & Karacapilidis (2004) Benefit Comments Improvement of buyersupplier relationship Web-based platform facilitates early supplier involvement Coordinate resources, synchronize work Reduction of production costs Inventory management Balance carrying costs and acquisition costs Open System Effectiveness Ash & Burn (2003) • B2B - business – Efficient sourcing of standard components – Efficient asset leverage in business network – Create new competencies through alliances • B2C - customer – Remove product/service delivery – Product/service customization • B2E - expertise – Maximize individual experience – Harness organizational expertise – Leverage community expertise Multinational ERP Supply Chain Conclusions • Multinational organizations naturally involve supply chain coordination – Web linkage can tie non-ERP systems together – Gain from EDI • Inherent security problem – Technology exists to cope Outsourcing • Supply chain participation brings in many smaller organizations – May not have had their own ERP – Forced to conform to core business ERP • “For smaller companies, the only way to reap fruits of globalization may be through outsourcing.” Paul Janicki, global finance director, Dow Chemical Co. (Millman, 2004) Outsourcing ERP • When a large organization implements ERP, they often hire consultant to operate it – Texas Instruments: transferred 250 IT personnel to Andersen Consulting – Rolls-Royce: transferred IT development to EDS • While not called outsourcing, in effect it is – Technical difference – ownership of platform and rental of software Beulen & Ribbers (2003) • Asian discrete manufacturing – Locally managed subsidiary of European country – 5year outsourcing contracts in 1998 – Operated assembly & testing in 3 countries to access lower wage costs – Lacked experience in client/server systems – Transferred 17 IT employees to services supplier • Kept 8 for IT strategy & functional specifications – Problem: • Lack of IT sophistication in low-wage work force • Still improved competitive position Huin (2004) • More small to medium-sized enterprises in Southeast Asia involved in supply chain operations • More outsourcing ERP – Heavy investment too risky – Forced to purchase from approved vendor lists – Forced to use customer document formats Multinational Outsourcing • Large multinationals likely to have own IT – Better to retain control – Still often use consultant to operate • Smaller participants in supply chains (or smaller firms operating independently) – Need to hire expertise – Application service provider risk • Reduces risk of vendor upgrade • Introduces risk of ASP stability, pricing Lessons Learned Lesson 4 firms Business case X Benchmark X Align w/strategy X Tex Inst Rolls- 2 Royce firms X X Data cleanup X Mid-course correction X Training X Metrics X X X X Business Cases • Mabert et al. (2001); Olhager & Selldin (2003) – Formal financial methods often not used – Cost data unreliable – Benefits unpredictable • Cases indicate business case lacking – Texas Instruments did, but included intangible • Web access for supply chain • Consolidation of independent IS programs • Improved inventory accuracy Survey of Manufacturers Mabert et al. (2000); Olhager & Selldin (2003) FORMAL METHOD ROI Use in US 53% Use in Sweden 30% Payback 35% 67% Expected NPV 15% 12% Other 11% 20% Critical Success Factors Reimers (2003) • Job security a significant factor – Resistance has sabotaged a number of cases • Top management involvement needed – Leadership rather than imposition • Teamwork required • Team member qualifications critical • Avoid customization Importance of Training • Training traditionally under-budgeted – Typically 6% of budget; 11% of actual – If do not customize, training even more important • Force employees to learn new methods • The cause of the “1st year dip” • Those who learn stay; those who don’t leave (the source of ERP savings) Multinational Training Factors • Multinational subsidiaries have labor forces with varying computer skill background – BPR: automation replaces labor – If labor skill high (or if cost lower), less reason to automate – The greater the regulatory variation (or cultural factors of doing business), the more need for local labor CONCLUSIONS • ERP systems very valuable – BPR provides improved methods – Open systems provide greater supply chain efficiency – Federalism can satisfy local requirements • Need to balance with cost of customization • ISSUES – Vendor manipulation – Application Service Providers FUTURE • We live in a Networked Society – Castells • Systems emerge – Maturana & Varela; Steven Johnson – Systems naturally emerge without plan • These emerging systems are beyond control – SAP, Microsoft, economies, politics – unknown future systems • At best, we can be flexible, prepared for change