HEWLETT-PACKARD JOURNAL •mà 1974 Ã5

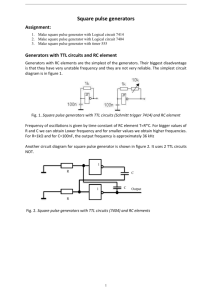

advertisement