Abstract structure that has been retrofitted to make them to

advertisement

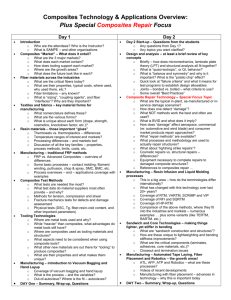

International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Natural Fiber Jute and Egg Shell Powder as Filler Material B.J.Praveenkumar1 K.Pradeepkumar 2. PG Scholar, Mechanical Engineering, Nandha Engineering College, Erode, India 1 Assistant Professor, Mechanical Engineering, Nandha Engineering College, Erode, India 2 Abstract— The interest of using natural fibers as reinforcement in polymers has increased dramatically. Natural fibers are not only cheap but also contain less weight. In this research work an investigation was carried out to use jute fiber and egg shell powder in different weight percentages to determine its properties. Epoxy resin is used as a matrix material. Hand lay up is carried out and then it was tested for its physical and mechanical properties. The result shows that the strength of the composite material is increasing because of the addition of eggshell powder in the fiber in higher percentage. In the addition of eggshell powder in higher percentage it gradually increases the mechanical properties. The percentage of elongation decreases and it gradually increases because of its properties. The studies show that the separation of powder in various places is achieved. The tensile strength and flexural strength are 64 MPa and 48 MPa. The impact strength gradually decreases in a proper ratio due to the addition of eggshell powder. Index Terms— Egg shell powder; Jute; Epoxy resin; Void content; Mechanical Properties. 1. INTRODUCTION The materials made from two or more materials which can carry different physical or chemical properties when combine and produce material different from individual components. It will affect the environment. Now in the recent trends interior and exterior parts of the car are made up of natural fiber, because natural fiber carries less weight and cost wise it is low. Composites are now extensively used for strengthening of pre-existing ISSN: 2231-5381 structure that has been retrofitted to make them to repair damage caused by seismic activity. Rapid increase in demand of fiber reinforced polymer (FRP) composites in last few decades. The composites of FRP provides high strength and stiffness and great versatility. The fiber reinforced base composites made up of boron glass, carbon. To keep our environment green and safe, it is essential to reduce the glass fiber usage. Research in the area of polymer and composites increased day by day to increase the strength and to decrease its cost. Natural fiber ,such as jute, sisal, kenaf, coconut and pineapple fiber are used and accepted as less weight, high strength and not affect our environment. The jute fiber is used in our investigation is not only environmentally good but also it is highly available in India and Bangladesh. The composite material is mostly used in automobile industry to reduce its weight and increases its efficiency [5]. If the bonding of fiber and flexible epoxy resin is weak then they resulted in indifferent impact strength improvement [8]. The lack of fiber and poor resistance will reduce the potential of natural fiber. Thermoplastic matrix composite has been always better the thermo set. In this fiber simple extraction and injection moulding process is carried out. The warp direction strengths and modulus is higher than weft direction in the composites [16]. The weaving of fiber gives an interlocking that increases the strength higher than fiber matrix binding strength. Some composites provides interfaces when surface dissimilar constituents interact with each other. The fabrication method depends on its matrix properties and the effect of matrix http://www.ijettjournal.org Page 7 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 properties of reinforcements. A number of investigations have been conducted on several types of natural fibers such as kenaf, hemp, flax, bamboo, and jute are used to study the effect of these fibers on the mechanical properties of composite materials. Most PMC materials in use today have thermosetting matrices; consequently, after they have been cured, they have no apparent scrap value. Although attempts have been made to grind them up and use them as fillers, this has not proven to be economically practical. Incineration is the toxic smoke so it is avoided. The major purpose of this study is to investigate the utilization of egg shell powder with epoxy resin in jute fiber. The usage of jute fiber with epoxy resin with an egg shell powder is not yet used in the natural composite fiber. The addition of egg shell powder in natural composite carries scope to research further. 2. EXPERIMENTAL DETAILS Jute fiber has been obtained from the local sources. Epoxy resin and the corresponding hardener which is supplied from Coimbatore. Egg shell is taken and then dried for 36 hours and then powdered by ball machining process. The polymers composites are fabricated by hand layup technique. Composite specimens with different percentage of egg shell powder (0, 2, 4, 6, 8,10wt %) is added. Fig no. 1 Epoxy +egg shell powder+ jute Fig no 2 plate after cut by using saw Tensile Test After the unreinforced epoxy resin and natural fiber jute is dried. For testing the material it is cut in a standard size by using saw cutter. The material is cut according to the ASME D638 standard. The gauge length and the dimension of each part are based on the ASTM standard. The test is conducted by using instron universal testing machine. It carries two cross sections in which one is adjustable for modifying length and other one is fixed. The piece is placed in the instron universal tester with a grip in 10mm gauge length. In this process, elongation is recorded. All the tests are taken on the average of two tests. The Gauge section carries smaller cross section, so that deform and failure occur in that area. Fig no 3 American society std materials1 Flexural Test The flexural test specimen dimension was 15mm ×100mm×5mm and three point bend method was used for flexural test, according to BS EN ISO 14125:1998 ISSN: 2231-5381 http://www.ijettjournal.org Page 8 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 Impact Test The impact test is performed by izod impact test machine. The dimension of specimen is 10 x 10 mm x mm. The V shape notch was prepared. 3. RESULTS AND DISCUSSION TENSILE TEST: The void content in the composite may affect the mechanical properties. The air entrapment occurs during the preparation of resin system which leads to formation of void content in polymer composites. The void content in more level shows that the resin has not surrounded properly to all places of fibers and that results indicates low in strength and carries a chance to crack initiation and the growth of void content. The composite material is cut in to required dimension using saw cutter and the edges finished by using emery paper for tensile testing. It is understand that the pure epoxy carries low content of void than addition of jute and egg shell powder in the composite. IMPACT STRENGTH: The specimen is loaded in testing machine and allowed the pendulum until it breaks. During impact test good adhesion between matrix and fiber is responsible for good resistance to crack propagation. Fig no 5 Test sample piece Contact area between the fiber and matrix increased by increasing the fiber content. Impact transfer is more efficient at higher level of fiber loading. The graph of strength shows that gradual decrease in impact strength. The jute and epoxy alone carries 0.65 and addition of egg shell shows decreases as 0.54, 0.5, 0.45, 0.45, and 0.42. FLEXURAL TEST: The load vs length is used to determine the flexural strength in which the parameter peak loads and it elongates in cross head section. The strength of fiber increases by increasing the addition of egg shell powder in jute and resin. Fig no 4 ASTM Standard piece The tensile strength variation by the addition of epoxy and egg shell powder is shown in Fig . It shows clearly that increase in egg shell powder content with epoxy and jute fiber increases its strength gradually. The fiber plate of composite which can withstand higher load before its failure compared to neat epoxy and jute fiber. The variation level of tensile strength is 40 MPa to 64 MPa. The results varied depending upon the percentage level addition of egg shell powder in jute fiber. The 10% addition of egg shell powder ISSN: 2231-5381 shows high strength compared to 6 and 8%. The addition of 2% carries very less strength. Fig no 6 Flexural Test Sample piece http://www.ijettjournal.org Page 9 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 The jute and epoxy resin simply carries 30MPa. Now the addition of egg shell powder in 10% shows higher strength. In this addition of epoxy and egg shell powder in jute at 2 and 4 % indicates decrease in percentage and addition of egg shell powder increases its properties. The flexural strength varies from 20MPa to 48MPa. The inclusion of jute fiber improves the load bearing capacity and also improves the capability to with stand the load. property of flexible epoxy treated natural fiber reinforced PLA composites‖. Energy procedia. Pp. 839- 847. 2013. 4. M. Jawaid , H.P.S. Abdul Khalil, A. Abu Bakar, P. NoorunnisaKhanam, Chemical resistance, void content and tensile properties of oil palm/jute fiber reinforced polymer hybrid composites, Materilas and Design;2011;12: 1014-1019. 5. M. Jawaid, H.P.S. Abdul Khalil, Azman Hassan, Rudi 4. CONCLUSION: The conclusions of jute epoxy and egg shell powder is shown below: 1. The fabrication of jute fiber and the addition of egg shell powder and epoxy resin in the fiber can be done by using hand layup technique. 2. Addition of egg shell powder in jute epoxy increases its tensile and flexural properties but gradually decrease the impact strength. 3. The loading of fiber increases and their strength also increases the tensile and flexural properties. 4. By adding egg shell powder up to 10% it increases gradually, 10% increases shows higher strength. 5. The addition of egg shell powder more than 10% it tends to brittle and reduces the strength of material. 6. Impact strength decreases by the addition of powder due to its void content. Dungani, A. Hadiyane, Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites, Composites:Part B;2012. 6. B.J.Praveenkumar K.Pradeepkumar, ―Naturalfiber composite using Epoxy reinforcement : A review.‖ International Journal of Applied Engineering Research 2014. 7. Hossain, Dewan,Hosur, ―Physical, mechanical and degradability properties of chemically treated jute fiber reinforced bio degradable nano composites‖.2011. 8. Zandiatashbar, Koratkar,Picu, ―Mechanical behavior of epoxy- graphene platelets nano composites‖.Journal of Engineering Materials and Technology. Vol 134. 2012. 9. Joshi, Drzal, Mohanty, Arora, ―Are natural fiber composites environmentally superior to glass fiber reinforced composites?‖ Applied science and manufacturing. Pp. 371- 376. 2004. 10. Nabi 5. REFERENCES: and sahib, ―Natural fiber polymer composites‖.1999. 11. Potts, J. R., Dreyer, D. R., Bielawski, C. W., and 1. Vivek Sharma and SandhyaraniBiswas, ―Physical and mechanical properties of bi- directional jute fiber epoxy composites‖.Procedia engineering. Pp.561566. 2013. Ruoff, R. S., 2011, ―Graphene-Based Polymer Nanocomposites,‖ Polymer, 52(1), pp. 5–25. 12. Li, B., and Zhong, W.-H., 2011, ―Review on Polymer/Graphite NanoplateletNanocomposites,‖ J. 2. Goulart S.A.S., Oliveira T.A., Teixeira A., Mileo P.C., Mulinari D.R., Mechanical behaviour of Mater. Sci., 46(17), pp. 5595–5614. 13. Ash, B. J., Siegel, R. W., and Schadler, L. S., 2004, polypropylene reinforced palm fibers composites, ―Mechanical Behavior of Alumina/Poly (Methyl Procedia Engineering;2011;10:2034-2039. Methacrylate) Nanocomposites,‖ Macromolecules, 3. WiphaweeNuthong, PutinunUawongsuwan, 37(4), pp. 1358–1369. WerapornPivsa-Art, Hiroyuki Hamada, ―Impact ISSN: 2231-5381 http://www.ijettjournal.org Page 10 International Journal of Engineering Trends and Technology (IJETT) – Volume23 Number 1- May 2015 14. TijanaRadoman, Katarina Jeremic, BranimirGrgur, ―Improvement of epoxy resin properties by incorporation of titanium oxide nano particles surface modified with Gallic acid esters‖.Materials and design.Pp. 158- 167. 2014. 15. YanjunXie, Callum A.S. Hill, Zefang Xiao, HolgerMilitz, Carsten Mai, ―Silane coupling agents used for natural fiber/polymer composites: A review‖. Composites.Pp. 806- 819. 2010. 16. ByungChul Kim, Sang Wook Park, Dai Gil Lee,‖ Fracture toughness of the nano-particle reinforced epoxy composite‖ composite structures. pp. 69- 77 .2008. 17. SongboXuAydarAkchurin, Weston Wood, ―Wear and Friction of Carbon Nano fiber-Reinforced HDPE Composite‖.2012. 18. Sagarray,KabirMitra, Chintal Desai. ―Detonation Nano diamonds Reinforcements and in Carbon Epoxy Nanotubes Composites as -a Comparative Study‖Journal of Nanotechnology in Engineering and Medicine. Vol 4 .2013. 19. Paul and Robeson, ―Polymer nanotechnology: Nano composites‖. Polymer.Pp. 3187- 3204. 2008. 20. Arifuzzaman Khan, M. Terano , M.A. Gafur , M. ShamsulAlam. ―Studies on the mechanical properties of woven jute fabric reinforced poly (L-lactic acid) composites‖. Production and hosting. 2013. 21. . K. G. Satyanarayana, K. Sukumaran, P. S. Mukherjee, C. Pavithran and S. G. K. Pillai. ―Natural Fiber–Polymer Composites‖, J and Concrete Composites, Cement 12(2)(1990), pp. 117–136. ISSN: 2231-5381 http://www.ijettjournal.org Page 11