Loss Density Distribution and Power Module Failure Modes of IGBT

advertisement

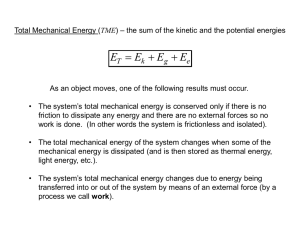

International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 1- Feb 2014 Loss Density Distribution and Power Module Failure Modes of IGBT Amit Thakur#1, Y S Thakur#2, Dr. D.K. Sakravdia#3 1 Ujjain Engineering College Ujjain, India Ujjain Engineering College Ujjain, India 3 Ujjain Engineering College Ujjain, India 2 Abstract- The major cause of IGBT devices failure is heat. There is a need of higher power densities and decreased packaging solutions in the industries commercial applications. In order to meet the through-life reliability targets for power modules, it is critical to understand the response of typical wearout mechanisms, for example wire-bond lifting and solder degradation So the concentration is on the tools that need to take into account detailed device structures and different physical phenomena / parameters that take place inside the semiconductor structure during operation and also to present the effect of power cycling frequency, load current and mean temperature on temperature variations within the power module structure and its impact on the life consumption for two common wear-out mechanisms (the bond wire and the substrate-solder). It is shown that bond wire degradation is the dominant failure mechanism for all power cycling conditions whereas substrate solder failure dominates for externally applied (ambient or passive) thermal cycling. Keywords: IGBT, Lumped parameter, Power cycling, Thermal Modeling, Thermal stress. I. Introduction IGBT devices are now being operated much nearer to their overload limits to decrease product costs and improve the efficiency, because of which the risk of adverse thermal conditions increases. Lumped parameter thermal models and numerical techniques such as finite difference and finite element, utilizing the results from this analysis have been developed. So for understanding of the loss mechanism, loss distribution, and thermal coefficients/ characteristics variation with temperature in power electronic ISSN: 2231-5381 devices is, therefore, a requisite for the development of the design tools which enable accurate prediction of temperature rise and better smart chip design for self-protection. Power module failures are frequently triggered by the thermo-mechanical driven wear-out processes affecting the device packaging, for example, bond wire lift-off or solder cracking. Thermal stress is generated at various locations within the power module by thermal deformation because of the difference of the coefficients of thermal expansion (CTE) of power modules' component materials. Failures may occur at different rates for different module designs and applications [1, 2] where the thermal cycling can be as a result of changing environmental or operational (load) conditions. II. Determination of loss density distribution The main aim of thermal modeling is to predict the temperature rise rather than the loss distribution. This method can be extended to the investigation of the distribution of losses within a device using the temperature distribution as the main indicator of losses. Since temperature distribution measurements are impossible to take place inside an IGBT device due to its small dimensions, a previously developed electrical model based on Hefner's model [2], [3] is used to estimate the power losses inside the structure. The power losses can then be taken from the electrical model and be distributed across the areas where these losses occur, Figure 1. Thermal modeling is used to predict the temperature rise in the IGBT device. However, the accurate prediction of these temperatures depends strongly on the accurate loss distribution and accurate determination of thermal coefficient variation with temperature. The distribution of losses can be used to calculate the temperature rise within the device. A portion of the energy delivered to the IGBT terminals is dissipated as heat and the remainder is stored in the http://www.ijettjournal.org Page 29 International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 1- Feb 2014 internal capacitances. Using the internal current and voltage components it is possible to calculate the instantaneous power that is dissipated as heat within the IGBT. In the same way the holes flowing through the basecollector depletion layer generate heat by the dissipated power given by Pbc = Vbc (IT-IMOS) (2) Where IT is the total current Figure 1: Loss density distribution for thermal analysis The losses in this model can be calculated analytically, and these are related to the schematic representation of the IGBT equations shown in Figure 2. The dashed-circled components represent the elements of current contributing to the power loss in the device. Figure 3 shows turn-on anode current, anode voltage, internal dissipated power and terminal power waveforms for a clamped inductive load [4]. A comparison between the carrier dissipated power and the terminal power is shown in with the dissipated power being larger than the terminal power at turn on. During turn-off or power-up of anode voltage, energy is stored in the drain-source and gate- drain capacitances that discharge through the MOSFET and that energy is dissipated as heat within the device [5]. After turn-on the dissipated power becomes less than the terminal power as the diffusion capacitance is charged. This dissipated power will be used in the calculation of temperatures in different regions in the IGBT. The corresponding dissipated power is given by PMOS = Vbc. IMOS, (1) Where Vbc is the base collector voltage and IMOS is the current passing through the channel. ISSN: 2231-5381 Figure 2: Analogue representation of IGBT model equations The equivalent power dissipated in the base resistance and in the emitter-base depletion layer (due to carrier crystal structure collisions) is given by PP = Veb. IT + Rb.IT2 (3) Where Veb is the emitter-base diffusion depletion voltage and Rb is the conductivity-modulated base resistance. The evaluation of the dissipated power by the electrical model is sufficient to predict the temperature in the different regions inside the IGBT [6]. So, in the following study, thermal and electrical models are coupled to give an adequate model of the IGBT allowing an accurate description of the electrothermal behavior. http://www.ijettjournal.org Page 30 International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 1- Feb 2014 III. Effects of power cycling frequency on power module failure mechanism In power cycling applications, thermal cycling for both the bond wire and the substrate-solder is affected differently by the converter modulation frequency. To show the effect of the modulation frequency on temperature variations, real time temperature estimates for the junction and substratesolder layers of a typical half bridge model were obtained for a converter modulated with a range of power cycling sinusoidal frequencies between 1mHz and 100Hz with a constant current amplitude of 300A. The PWM switching frequency was fixed at 5 kHz and the ambient (coolant) temperature was 40ºC. Comparison between the junction and the substratesolder temperature estimates is shown in Fig. 3. At frequencies below 0.01 Hz the temperature variations are independent of frequency and reflect the thermal resistance of the heat transfer path. For higher frequencies, the effect of heat capacity attenuates the variations with the substrate solder seeing a proportionally smaller variation compared to the bond wires. Figure 4: Comparison between bond wire and substrate-solder life time model mechanisms over a range of power cycling frequency IV. Effect of high temperature on power module failure mechanisms The study the effect of high temperature on life consumption of power modules is to be implemented over a range of mean temperatures. In order to achieve a variable set of mean temperature for each test, the ambient temperature in the real time model was changed. As a result, the life time of the corresponding component could be studied over a range of mean temperature values. The lifetime consumption of the substrate-solder layer is known to be very dependent on the layer's mean temperature. Fig. 5 shows the results of the life expectancy of the substrate-solder layer when the test was repeated over a range of mean temperatures. Figure 3: Comparison between the junction and the substrate-solder temperature estimates over a range of modulation frequencies The number of cycles to fail for both the bond wire and the substrate-solder were determined for the power cycling conditions described above. Fig. 4 illustrates a comparison (in number of cycles) as a function of the applied sinusoidal modulation frequency. The test results in this figure clearly show that the substrate-solder layer always fails first. Figure 5: Comparison of Life consumption for substrate-solder layer over a range of mean Temperatures ISSN: 2231-5381 http://www.ijettjournal.org Page 31 International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 1- Feb 2014 These tests show that although the thermal cycling has a big effect in causing failure in substrate-solders, it is clear that at high temperatures the substratesolder failure is faster. As a result, high mean temperatures can significantly reduce the substratesolder life. Fig. 6 illustrates the experimentally observed effects of both mean temperature and thermal cycling range on wire-bond wear out, illustrating that exposure to high temperature can reduce the degradation rate. Fig. 7 compares the life consumption of both the bond wire and the substratesolder as a function of power cycling frequency when the layer's mean temperature was fixed at 80°C. It is clear from these results that high mean temperature [7] has its direct impact on increasing the life consumption rate in solders meanwhile wire bond failure is not affected by the layer's temperature. On the contrary with high temperatures the bond wire failure is slower. V. Load current effect on failure mechanisms Life time tests were taken over different values of load current for both the bond wire and the substratesolder. For each load current the tests covered a range of power cycling frequencies allowing to compare the effect of load current over a variant range of thermal cycling on both the bond wire and solder-substrate life consumption [8]. Typical results are shown in Fig. (8) and (9) respectively. Comparing the results in Fig. 8 shows that with higher load current the bond wire wears out faster. At the same time, the load current has the same impact on the substrate-solder layer failure as illustrated in Fig. 9. Figure 8: Effect of load current on bond wire life time consumption Figure 6: Bond wire wear-out rate for different ranges of thermal cycling Figure 9: Effect of load current on substrate-solder life time consumption VI. Conclusion Figure 7: Comparison of Life consumption for bond wire and substrate-solder layer at high temperatures ISSN: 2231-5381 The equations derived the loss distribution inside the IGBT structure is sufficient to predict the temperature in the different regions inside the module. In addition the model can be used for device modeling. The effect of power cycling frequency on temperature variations and its impact on the life consumption for http://www.ijettjournal.org Page 32 International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 1- Feb 2014 the two common power module wear-out mechanisms (the bond wire and the substrate-solder) under a range of prospective in-service conditions was presented. The results showed the effect of power cycling frequency, load current and the layer's temperature on both failure mechanisms. It was shown that the solder failure is very dependent on the layer's mean temperature while the bond wire degradation is more sensitive to temperature variations (∆T). Under the majority of power cycling conditions the bond-wire is identified as the dominant failure mechanism because it is subject to the greatest temperature variation. Conversely, under passive or ambient thermal cycling the substrate solder can be expected to fail first since in this case both bond-wire and solder see similar temperature variations. References [1] P A Agyakwa, W S Loh, M R Corfield, E Liotti, S C Hogg, C M Johnson, “Anomalous Reliability Behaviour of 99.99% and 99.999% Pure Aluminium Wire Bonds under Thermal Cycling”, IMAPS 41st International Symposium on Microelectronics, November 2008,Providence, Rhode Island USA Stafford, UK, pp. 426-430, 9-11th September 2002. [4] Trigkidis, G, Bousbaine, A, Dynamic Characterisation of the IGBT Using MATLAB, 37th International Universities Power Engineering Conference, Stafford, UK, pp. 426430, 9-11th September 2002 [5] Ammous, A, Ammous, K, Morel, H, Allard, B, Bergnone, D, Sellami, F, Chante, J.P, Electrothermal Modelling of IGBT's: Application to Short Circuit Conditions, IEEE Transactions On Power Electronics, Vol. 15, No 4, pp. 778-789, 2000 . [6] Sheng, K, Willliams, B.W, Finney, S.J, A new analytical IGBT Model with Improved Electrical Characteristics, IEEE Transactions On Power Electronics, Vol. 14, No 1, pp. 98-106, January 1999 [7] Hefner, R, An Analytical Model For The Steady State And Transient Characteristics Of The Power Insulated Gate Bipolar Transistor, IEEE Solid State Electron, Vol. 31, No 10, pp 15131532, 1988. [2] N Patil, D Das, K Goebel, and M Pecht, 2008. Identification of Failure Precursor Parameters for Insulated Gate Bipolar Transistors (IGBT’s), 2008 IEEE International Conference on Prognostics and Health Management [8] H Ye, M Lin, C Basaran, 2002, Failure Modes and FEM Analysis of Power Electronics Packaging, Journal of Finite Elements in Analysis and Design, Vol 38, p 601–612. [3] Bousbaine, A, An investigation into the thermal modelling of induction motors, Thesis, University of Sheffield, June 1993. Conference, . ISSN: 2231-5381 http://www.ijettjournal.org Page 33