1-2 PLASTIC DEFORMATION

advertisement

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

1-2 PLASTIC DEFORMATION

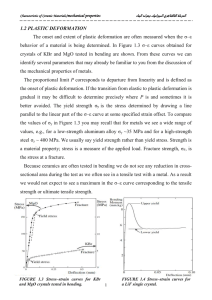

The onset and extent of plastic deformation are often measured when the σ–

εbehavior of a material is being determined. In Figure 1.3 σ–ε curves obtained for

crystals of KBr and MgO tested in bending are shown. From these curves we can

identify several parameters that may already be familiar to you from the discussion of

the mechanical properties of metals.

The proportional limit P corresponds to departure from linearity and is defined as

the onset of plastic deformation. If the transition from elastic to plastic deformation is

gradual it may be difficult to determine precisely where P is and sometimes it is

better avoided. The yield strength σy is the stress determined by drawing a line

parallel to the linear part of the σ–ε curve at some specified strain offset. To compare

the values of σy in Figure 1.3 you may recall that for metals we see a wide range of

values, e.g., for a low-strength aluminum alloy σy ~35 MPa and for a high-strength

steel σy ~ 400 MPa. We usually say yield strength rather than yield stress. Strength is

a material property; stress is a measure of the applied load.

Fracture strength, σF, is the stress at a fracture. Because ceramics are often tested in

bending we do not see any reduction in cross-sectional area during the test as we

often see in a tensile test with a metal. As a result we would not expect to see a

maximum in the σ–ε curve corresponding to the tensile strength or ultimate tensile

strength. Figure 1.4 shows a σ- ε curve for LiF that illustrates an abrupt elastic–

plastic transition. Plastic deformation begins at the upper yield point and there is a

decrease in stress. At the lower yield point deformation continues at lower stress

levels. This type of behavior is similar to that of some low-carbon steels as well as

aluminum oxide and magnesium oxide at high temperatures.

1

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

FIGURE 1.3 Stress–strain curves for KBr

and MgO crystals tested in bending.

FIGURE 1.4 Stress–strain curves for

a LiF single crystal.

1-2.1 Dislocations

Dislocations are line defects, but like all crystal defects, they are actually

volume defects; i.e., we should think of them as tubes, or pipes, whose properties

change across the tube radius and that generally do not have cylindrical symmetry.

Two vectors define the fundamental properties of any dislocation:

- The line direction

- The Burgers vector

The glide plane of the dislocation is the plane that contains both vectors. To

summarize:

●Geometry Burgers vector and line direction define the glide plane.

●Displacement When a dislocation is present, atoms are displaced from their

positions in the perfect crystal; the material is strained so there must be a stress.

●Movement Dislocations move and interact (they even intersect).

●Reacting We generate dislocations; they multiply and combine (by intersecting).

What is special about dislocations in ceramics?

●Complex and large unit cells are the norm rather than the exception.

●Charge-if you insert an extra half plane to make an edge dislocation, you must

consider the charge.

●Directional bonds-if you break a bond, does it reform?

2

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

In contrast to point defects, dislocations never exist in thermodynamic equilibrium

because they have formation energies of ~1 eV (or more) per atom along the line and

there is no significant balancing entropy contribution as there is for point defects.

They are almost always present in crystals because of how the crystal grew or

because it was deformed. Therefore dislocations usually form due to non equilibrium

conditions, such as thermal and mechanical processing, or for thin films and single

crystals, during growth. There are two special types of dislocation.

- Edge dislocations

- Screw dislocations

All other dislocations are referred to as “mixed.”

*Defining the Burgers Vector and the Glide Plane

The Burgers vector is defined by constructing a closed circuit around the

dislocation line. We first draw a circuit around the dislocation in a clockwise (righthanded screw) direction from the start (S) to the finish (F) as shown in Figure 1.5a.

We then transfer this circuit to a perfect crystal as shown in Figure 1.5b. If there is a

dislocation, this second loop will not close on itself. We then define the vector FS,

which is required to close the loop in the perfect crystal, as the Burgers vector. This

method of defining the Burgers vector, b, is known as the FS/RH perfect-crystal

convention. The Burgers vector is then defined with respect to the perfect crystal; you

would not want to define it in the imperfect crystal! It is important that you are

consistent in using this convention. Some other texts, and even some of the classic

papers, use a convention that produces the opposite sign for the Burgers vector. For

example, they might use an anticlockwise circuit, set b = SF, or draw the circuit in

the perfect crystal first. You must use a convention consistently.

- Edge dislocation: An extra half-plane of atoms is inserted above the glide plane as

illustrated in Figure 1.5a. The Burgers vector is perpendicular to the dislocation line,

u. The Burgers vector will be opposite if the extra half plane is below the glide plane.

- Screw dislocation: Successive atomic planes are connected to form the surface of a

helix (or screw) around the dislocation line where the dislocation is perpendicular to

3

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

the planes: like the core of a spiral, parking ramp. The Burgers vector is parallel to

the dislocation line and can point up or down for a left- or right-handed screw.

- Glide plane: This is the plane containing both the dislocation line and the Burgers

vector.

FIGURE 1.5 the Burgers circuit in the imperfect and perfect lattices for an edge dislocation in a

simple-cubic crystal.

1-2.2 Summary of Dislocation Properties:

We have not reviewed all the properties of dislocations, but have concentrated

on those you should know when considering dislocations in ceramics.

- Dislocations cannot end inside the crystal lattice.

- We almost always assume that strains are so small that linear elasticity is a good

approximation; so, Hooke’s law holds.

- The displacement field for any dislocation falls off as r

−1

as we move away from

the dislocation.

- The strain energy (or self energy) of a dislocation actually depends on the character

of the dislocation, but setting E =αGb2 is a good estimate, where α is ~0.5.

- Parallel dislocations repel one another if the angle between their Burgers vector is

less than 90°.

-A dislocation can always lower its strain energy by spreading its core or

dissociating. Whether this will lower the total energy depends on the energy required

4

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

to form the distorted region between the “partial dislocations.” If dissociation occurs

(forming identifiable partial dislocations) then this region is called a stacking fault.

- Dislocations glide by the movement of kinks and climb by the movement of jogs.

Since climb requires changing the number of point defects.

1-2.3 Dislocation in Ceramics:

In discussing dislocations in ceramic materials, the principle is always the

same. We deduce the possible Burgers vectors first, then the glide planes. We will

begin by asking if there is anything special about dislocations in ceramics; we can

preempt the answer by saying yes, as usual, the bonding and charge can add their

own effects. The second best-known special feature of dislocations in ceramics is

actually that the unit cell of such materials is usually larger than for the simple

metals. The structure of the dislocation core in ceramics depends on three factors

1. Charge of the ions

2. Size of ions

3. Presence of directional bonds.

Perhaps the more important question is: why learn about dislocations in ceramics

when ceramics do not deform plastically as easily as metals?

* Structure of the Core:

Not much is really known about the core of dislocations in ceramics. For

understand that chosen one Burgers vector (usually the most important one), one line

direction, and thus one glide plane. Furthermore, we usually draw the edge

dislocation because it is easiest to draw, not because it is the most important. In this

section, we will assume that the dislocation core is compact. The examples are

chosen to illustrate particular features.

- NaCl: it is relatively simple and illustrates the effect of charge.

- Si: it illustrates the effect of directional (covalent) bonding.

- Al2O3 and olivine: they are non cubic materials.

5

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

Although NaCl and MgO structures are both based on the cubic-F lattice, like Cu,

there is no evidence for any dislocation dissociation. A schematic diagram of such a

dislocation viewed along the [001] direction is shown in Figure 1.6. All the ions seen

here lie in the same (001) plane. If we remove this plane of atoms the structure looks

the same, but all the ions are reversed in sign. So charge is balanced as long as there

are no jogs or kinks on the dislocation.

The glide plane for dislocations in NaCl and MgO is {110} rather than the {111}

you might expect for fcc. You may read that the glide plane is {110} because this

plane is electrically neutral and motion on this plane avoids charged layers gliding

over one another. PbS, a semiconductor with this structure, shows glide occurring on

{001} planes and in TiC dislocations glide occurs on {111} planes. The real reason

the suspicion is that the core actually does spread on different planes. The simplest

covalently bonded ceramics are Si and Ge. The covalent bond formed by two atoms

sharing electrons is a localized and directional bond. Cubic ZnS has the same

structure, but the Si–Si basis is replaced by Zn–S, although the bond still has a large

covalent component. This feature is important in determining the characteristics of

dislocations in covalent materials. Dislocations in these materials tend to be immobile

at low temperatures.

Extensive slip occurs only at elevated temperatures of the many covalent crystals,

the diamond-cubic and c-ZnS structures are among the simplest and most widely

studied. Since the crystal lattice is fcc, perfect dislocations have the fcc Burgers

vector 1/2 <110>. Like dislocations in fcc metals, dislocations in Si, Ge, and c- ZnS

glide on {111} planes. These two dislocations are fundamentally different because

the zinc blende structure does not have a center of symmetry. Similar considerations

will hold for materials such as AIN and GaN, which also lack a center of symmetry

but have the wurtzite structure crystal structure. The stacking fault in the diamondcubic structure is described: the pair of planes behaves just as if it were one fcc plane

in this case.

6

ﻓﺮﻉ ﺍﻟﺴﻴﺮﺍﻣﻴﻚ ﻭﻣﻮﺍﺩ ﺍﻟﺒﻨﺎﺀ/ﺍﻟﻤﺮﺣﻠﺔ ﺍﻟﺜﺎﻟﺜﺔ

Properties of Ceramic Materials

Many ceramic materials are neither cubic nor hcp. Olivine and sapphire both have

oxygen sublattices that can be thought of as distorted hexagonal close packed (hcp),

but the distribution of cations makes them very different.

Olivine: In the olivine group of minerals (important orthorhombic silicates), the

energies of the [100], [010], and [001] dislocations are all different. The added

complication is that olivine is not an isotropic material.

Sapphire: Al2O3 is also very anisotropic although the perfect dislocations do have the

shortest Burgers vector 1/3

but other perfect dislocations have been reported

including [0001].Even when they have the shortest b, they may glide on other planes

such as.

FIGURE 12.10 the core of a dislocation in NaCl.

7