Shear band formation

advertisement

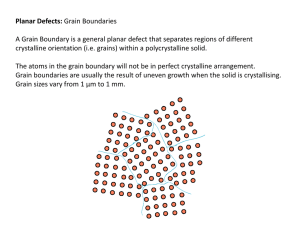

Shear band formation Limited non-homogeneous deformation Very large localized strain ε~1 or 100% Occurs especially under high strain rates Mechanism of deformation still unclear 1 Plastic deformation ⇔movement of dislocations Strengthening methods 2 Cold working Deformation at temperatures below 0.4 Tm Dislocation density increases from 106/cm2 to 1010-12/cm2 High dislocation density results in a large number of dislocation interactions which results in high strength and hardness 3 Solid solution strengthening Interaction between stress fields of alloy atoms and dislocations This is the purpose of alloying 4 Grain size refinement Small grains result in higher strength Small grains is equivalent to a large number of grain boundaries in the same volume Grain boundaries act as barriers to dislocation motion 5 Mechanism Strength is inversely proportional to grain size σ = σ0 + kyd-1/2 Hall-Petch equation Smaller grains have more boundary area and hence more barriers to dislocation motion 6 Precipitation hardening Precipitates are second-phase particles Hard precipitates act as barriers to dislocation motion Applicable only to some alloy systems 7