Volatile Organic Compounds ( VOC s )

advertisement

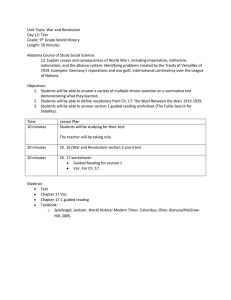

Volatile Organic Compounds (VOC s) Christophe Ponce, Automotive Product Manager (Seating) Warwick, 16/05/07 Brief summary of the presentation I intend to follow: Introduction to Huntsman Polyurethanes & the European automotive market Definitions: How do we describe emissions in an automotive context ? Description of key VOC test methods Huntsman investement Where do emissions come from in a PU context ? Comparison study : VOC Testing in Car Seats, based on Huntsman systems. Conclusions Corporate Introduction to Huntsman Polyurethanes and the European Automotive market Who is Huntsman? Differentiated business portfolio Polyurethanes MDI Materials and Effects Performance Products Design & Composites Engineering Performance Specialties Power & Electronics Performance Intermediates Pigments Polyols PO/MTBE TPU Coatings, Construction & Adhesives Textile Effects Titanium Dioxide Maleic Anhydride & Licensing Systems Corporate Growth rates of the WE & Emerging markets 2002 calculated CAGRs 2021 and CAGR 3.2% CAGR 0.75% CAGR 1.7% CAGR 0.1% CAGR -0.9% CAGR -0.5% CAGR 11.8% CAGR 3.1% CAGR 6.4% Western Markets Emerging Markets Data from JD Powers vehicle build Q4 2006 Corporate Impact of vehicle growth on total consumption of PU within the European automotive market Plastic Families PP and alloys PUR PA and alloys Other plastics PE ABS and alloys PVC PBT and PET PC and alloys UP POM TOTAL 2005 (kg/car) 65.9 19.9 17 13.2 10.7 8.1 4.2 3.3 3.5 2 2.2 150 Car production [mil/y] (kton) 1440 440 370 290 240 180 90 70 80 40 50 3290 18.9 2010 % (kg/car) 44 73.6 22.1 13 19.4 11 13.7 9 7 11.4 8.6 5 5.1 3 3.9 2 2 3.7 1 2.4 2.3 1 166 (kton) 1765 533 465 328 270 205 125 90 85 55 53 3973 % 44 13 12 8 7 5 3 2 2 1 1 MPV & SUV growth 21.1 Growth in PU: - More cars, greater share of SUV s & MPV s & more diesel engines - CAGR PU 2005 2010: - CAGR vehicle build 2005 2010: 3.9% 3.5% Diesel engine growth Corporate Definitions: How do we describe emissions in an automotive context ? Huntsman Polyurethanes CONFIDENTIAL Definitions: VOC Classification by the WHO Boiling point Term Examples < 50 ºC Very Volatile Organic Compounds (VVOC) Formaldehyde (- 21 ºC) Acetaldehyde (20 ºC) > 50 ºC < 260 ºC Volatile Organic Compounds (VOC) Benzene (80 ºC) Toluene (110 ºC) Styrene (145 ºC) Dabco (175 ºC) > 260 ºC < 400 ºC Semivolatile Organic Compounds (SVOC) BHT (265 ºC) Di-n-butyl phthalate (340 ºC) Di-n-ethylhexyl phthalate (390 ºC) > 400 ºC Particulate Organic Matter (POM) PCB Corporate Definitions: In car air quality terms mean ? what exactly do the VOC: Sum of VVOC and VOC which easily evaporate from sample at test-temperature 25 << 100 ºC/1barr and with in-car concentration at least > 2 times higher than outside FOG (Windscreen Fogging): Sum of VOC and SVOC which evaporate from sample at testtemperature > 90 ºC/1barr Odour compounds (OC s): Organic chemicals with very high vapour pressure and readily evaporating at normal pressures and temperatures and quite often not detected as VOC s Corporate Which VOC substances monitored ? 1 2 3 Formaldehyde Acetaldehyde Propionaldehyde ESIS: R-phrases 23 24 25 34 40 43 12 36 37 40 11 36 37 38 4 Benzene 23 24 25 36 38 45 46 48 65 5 6 7 8 9 10 11 12 13 14 Toluene Xylene Ethylbenzene Styrene Chlorobenzene Paradichlorobenzene Dichlorobenzene Bromobenzene Parabromochlorobenzene Bromochlorobenzene 11 10 11 10 10 36 20 20 20 20 20 40 38 48 63 65 67 21 38 36 38 51 53 50 53 ECB Carc. Cat 3 Carc. Cat 4 IARC Carc. Cat. 1 Mut. Cat 2 Repr. Cat 3 Carc. Cat 3 EC Nr 200-001-8 200-836-8 204-623-0 CAS Nr 50-00-0 75-07-0 123-38-6 200-753-7 71-43-2 Carc. Cat 2B Carc. Cat 2 Carc. Cat 2B Repr. Cat.3 22 23 24 25 34 48 68 Mut. Cat 3 53 22 34 Carc. Cat 3 25 40 52 53 59 28 45 61 36 61 Repr. Cat 2 Repr. Cat 2 & 3 62 Repr. Cat 2 203-625-9 215-535-7 202-849-4 202-851-5 203-628-5 203-400-5 246-837-7 203-623-8 203-392-3 249-303-1 108-88-3 1330-20-7 100-41-4 100-42-5 108-90-7 106-46-7 25321-22-6 108-86-1 106-39-8 28906-38-9 15 Nitrobenzene 23 24 25 40 48 51 53 62 202-716-0 98-95-3 16 17 18 19 20 21 22 23 20 20 12 23 26 20 50 60 203-632-7 246-698-2 204-697-4 200-262-8 Phenol Benzylchloride Dimethylamine Tetrachloormethane Nitrosodimethylamine Dimethylformamide Di-n-butyl-phtalate Di-n-ethyl- hexyl- phtalate 21 51 20 24 27 21 61 61 108-95-2 25168-05-2 124-40-3 56-23-5 200-679-5 68-12-2 201-557-4 84-74-2 204-211-0 117-81-7 Corporate Which VOC substances monitored? R-phrases 10 11 12 20 21 22 23 24 25 26 27 28 29 34 36 37 38 40 41 43 45 48 50 51 52 53 59 60 61 62 63 65 67 Flammable Highly flammable Extremely flammable Harmful by inhalation Harmful in contact with skin Harmful if swallowed Toxic by inhalation Toxic in contact with skin Toxic if swallowed Very toxic by inhalation Very toxic in contact with skin Very toxic if swallowed Contact with water liberates toxic gas Causes burns Irritating to the eyes Irritating to the respiratory system Irritating to skin Limited evidence of a carcinogenic effect Risk of serious damage to the eyes May cause sensitization by skin contact May cause cancer Danger of serious damage to health by prolonged exposure Very toxic to aquatic organisms Toxic to aquatic organisms Harmful to aquatic organisms May cause long-term adverse effects in the aquatic environment Dangerous to the ozon layer May impair fertility May cause harm to the unborn child Risk of impaired fertility Possible risk of harm to the unborn child Harmful: may cause lung damage if swallowed Vapours may cause drowsiness and dizziness Corporate Description of key VOC test methods Huntsman Polyurethanes CONFIDENTIAL Important criteria Selectivity Which VOC s can be identified and at which level => VOC list Test capability How accurate => correctness / sensitivity (ppm, ppb,,.) How precise => repeatability (one lab, same conditions) =>reproducability (different labs, same conditions) In house studies to study these parameters Corporate Test methods (1) 1. Daimler Chrysler VDA 278 VOC (90 ºC) - total (ppm) FOG (120 ºC) -total (ppm) Sample size ca 20 mg 2. Chamber (1 m³) test GS 97014-3 BMW (headspace µg/m³ ~ ppb) Based on VDA 276-1 VOC (µg/m³) by GC/MS Aldehydes after DNP derivatisation (special cartridge) by HPLC Conditions 7 days preconditioning (60 to 70 m³/hr purified air flow at 20-25 deg C, no humidity control) Chamber 65 deg / 5 % rel. humidity / air exchange rate/hr 0.4 , residence time: 5 hours (after sampling blank values) Target product load 0,4 m /m3 (depending on emission intensity) Corporate Test methods (2) 3. Huntsman HPLC carbonyl method Quantifies total (ppm) C1, C2, C3, C4, aldehydes - free and bounded (acetal) Principle: ACN extraction (ACN /water: 50/50 for formaldehyde) + DNP derivatisation on foam Sample size: ca 200 mg 4. VDA 277: (PV 3341) VW / Audi method Not used because poor reproducibility and no identification of VOC components (result in ppm Carbon ) 5. VDA 275: Formaldehyde by colourcomplex Not used because low reproducibility and influenced by higher carbonyls. Corporate Huntsman Investments Huntsman investments Dedicated resources in the organisation Full programme started Q1 2006 Structured approach Create awareness and coordinate action plans at the production locations Measure Analyse the results Action plans Corporate Huntsman investments Purchase new analytical equipment 1 m³ VOC chamber (including preconditioning chamber) Upgraded analytical equipment (GC/MS ) Corporate Everberg Test Chamber Air sampling point Inside the test chamber (1 m3) Sampling for GCMS analysis (air volume !) Corporate VOC test methods Small scale test methods Industrial standards (example VDA 278, VDA 277, 275, ) Qualitative and /or Quantitative Specific methods (Huntsman HPLC carbonyl for aldehydes) Usually quantification of total available VOC s (ppm, ppb,..) VDA 278 most commonly applied test in industry (ppm level) Bigger scale test methods = Chamber tests Differentiation by test parameters Furniture, Automotive different conditions Usually quantification by headspace concentration (µg/m³) = emitted VOC s (~ ppb level !) Examples VDA 276, GS 97014-3 BMW OEM s use their own test methods => need for standardisation Corporate GS 97014-3: BMW method Based on VDA 276-1 Positives; Can test production samples, eg. Car seats Evaporation technique: measures VOC s in the headspace : expressed (µg/m3 air) Results can be more directly related with full scale vehicle cabin tests and air quality Can analyse very low VOC contents because of large sample size and air collection More flexibility: control chamber conditions (temperature, humidity, air collection time, multiple air sample collections in parallel, Negatives; Large investment and running costs: test-chamber - test-room - sample conditioning Elaborate test : 7 days pre-conditioning / collecting air samples / residence time 5 hrs / analysis Corporate Test Chamber parameters and variables Clean air Test Chamber (x m³) Test exhaust specimen sampling analysis differentiation Temperature control Test specimen load m²/m³ Air exchange rate Humidity control Test specimen weight Corporate Which methods do we apply ? VOC measurements VDA 278 Daimler Chrysler (including FOG) at ppm level 1 m³ Chamber test (including aldehydes) at ppb level Aldehyde measurements Huntsman Carbonyl method on foam and polyol samples for total carbonyls at ppm level Corporate Conclusions test methods Chamber test most appropriate for VOC/Aldehyde measurements. similar precision (value X +/- ca 15 % max) for a better accuracy (~ppb vs ppm) => Bigger sample size => Example aldehyde study (doping experiments). For values close to detection limit lower precision figures. Better selectivity for VOC Becomes Industry standard. => good investment Negative is that measurements are highly time consuming (+ high investment costs). Corporate Aldehyde measurements capability (µg/m³) emissionchamber Formaldehyde Formaldehyde doping test Measurements by the chamber (µg/m³) 140 120 100 80 60 40 20 0 0 2 4 6 8 10 12 Theoretical value (ppm) 40 (µg/m³) emission Chamber Acetaldehyde Acetaldehyde doping test Measurements by the chamber (µg/m³) 30 20 10 0 0 1 2 3 4 5 6 7 8 9 10 The ore tical v alue (ppm) Corporate We have described what emissions are where do they come from in a PU context ? Huntsman Polyurethanes CONFIDENTIAL Foam sample selection most critical step for chamber VOC analysis. The nature of the VOC compound will have an effect on quantitative and qualitative VOC analysis, depending on the : Foam Shape => product load (mentioned in BMW GS 97014-3) Foam Weight (not linear!) Foam surface (skin/no skin) Open cells (crushing / no crushing ) => need for a strict standard test protocol in order to allow comparison Corporate Foam samples for Chamber measurements standard system (1) Bucket foam samples (volume ca 12 l, height ca 23 cm) Buckets heated at 70 - 80 deg C for 15 minutes to remove contaminants Controlled Chemicals One variable at the time to check for VOC contribution of that one variable standard test system Polyol water catalyst (s) silicone(s) stabilizer other additive Isocyanate (index ca 100) Corporate If we look at the processing of PU systems there are a number of potential sources of VOC materials quite complex !!. Primary VOC s 4. Contaminations 3. Substances intentionally added 2. Impurities unintentionally formed B) PU Chemistry & part processing 1. Impurities in raw materials A) Premature raw material degradation Secondary VOC s PU part C) PU degradation & absorption PU part : Total Emission Corporate Foam samples for Chamber measurements standard system (2) Foam preparation In clean environment to avoid cross contamination Mixing 10 s / 3000 rpm (clean mixer blade) Foams to meet stability/closed cell requirements Final foam weight 500 g +/- 10 g 2 hours after foam preparation standard test system Polyol water catalyst (s) silicone(s) stabilizer (criticality investigated) Foams are demoulded with (clean) gloves Foams are fully crushed other additive Isocyanate (index ca 100) (consistent manner!) Packed in PE lined aluminium foil and sealed off Corporate Comparison study : VOC Testing in Car Seats, based on Huntsman systems. Test methods considered 1. Daimler Chrysler VDA 278 2. Chamber (1 m³) test GS 97014-3 BMW 3. VDA 277: (PV 3341) VW / Audi method 4. VDA 275: Formaldehyde by colour-complex 5. Huntsman HPLC carbonyl method Corporate Key results summary GS 97014-3 BMW and VDA 278 Foam ID A B µg/m³ ~ ppb 14054 30527 4452 2638 10238 C1 µg/m³ ~ ppb 149 136 66 51 74 C2 µg/m³ ~ ppb 190 195 32 7 35 C3 C4 µg/m³ ~ ppb µg/m³ ~ ppb 60 31 142 20 10 0 18 3 25 6 Foam weight Chamber load VDA 278 VOC g m2/m3 1100 0.54 1080 0.47 440 0.35 440 0.35 292 0.13 ppm 174 744 62 54 866 FOG ppm 13 479 24 29 1030 GS 97014-3 TVOC C D Rubliflex Rubliflex HR+ HR+ Standard Standard E Aldehydes Corporate GS 97014-3 BMW: Key Results Summary Foam ID A B C D Rubliflex Rubliflex Standard HR+ HR+ 30527 4452 2638 E TVOC µg/m³ ~ ppb Standard 14054 Aldehydes C1 C2 C3 µg/m³ ~ ppb µg/m³ ~ ppb µg/m³ ~ ppb 149 190 60 136 195 142 66 32 10 51 7 18 74 35 25 Foam weight Chamber load g m2/m3 1100 0.54 1080 0.47 440 0.35 440 0.35 292 0.13 10238 TVOC: Low D / C < E < A << B High Aldehydes: all samples contain C1, C2 and C3 For C1, C 2 and C 3 : C/D/E << A/B (Rubiflex HR+ provisional formaldehyde spec = 28 µg/m3 Overall: Rubiflex HR+ systems superior to A,B and D system. Note: Foam weights are different and it is known that this influences the results but the correlation between foam weight and emission values has yet to be established (indications that it is not a linear relationship) Corporate GS 97014-3 BMW: TVOC details Rubiflex HR+ GS 97014-3 BMW: TVOC details (µg/m³) A B C D E 35000 Low C / D < A / E << B high 30000 Majority are amines 25000 Dabco (A/B very high) and A 99 B/D : high levels of B 16 20000 15000 10000 5000 0 A B C D E 2 -ethyl- hexanoic acid 98 340 11 9 35 Glycolether 363 3892 197 123 228 alkane and alkene 62 206 Siloxaan 2198 1941 Toluene 48 Amine 13 11272 48 21 39 3553 20344 N,N dimethylamine derivatives DMF and dimethylacetamide B significant nonanone levels 2138 A 99 Dabco 67 B high level of glycolether due to monol-PO components A high and C very high load of toluene A/B high siloxane levels E contains 44 87 4762 120 77 72 1790 2321 4978 Corporate GS 97014-3 BMW: Aldehyde details Rubiflex HR+ GS 97014-3 BMW: Aldehyde details (µg/m³) A B C D E 500 450 A / B strongly inferior to C/D/E 400 350 300 250 200 All samples contain C1, C2, C3 and C 4 150 100 50 0 A B C D E C4 31 20 0 2.5 6 C3 60 142 10 18 25 C2 190 195 32 7 35 C1 149 136 66 51 74 Corporate VDA 278 VOC : Details and key results summary Rubiflex HR+ A 174 VDA 278 VOC (ppm ) B 744 C 62 D 54 E 866 900 800 Low C/D < A << B/E High Majority VOC : amines Amine in B and E is B 16 (hexadecylamine) B and also A / E contain volatile siloxanes 700 600 500 400 300 200 100 0 A. Glycolether 2-ethyl hexanoic acid D E 11 14 47 10 7 38 9 6 12 13 32 3 3 11 500 Amine Dabco C 9 Alkane/Alkene siloxanes B 140 118 783 50 45 39 Corporate VDA 278 FOG: Details and key results summary VDA 278 FOG (ppm ) A 13 1200 B 479 C 24 D 29 E 1030 1000 low C/D < A << B << E high High fogging for E/B due to B 16 catalyst (hexadecylamine) E : fogging by siloxanes 800 600 400 200 0 A B C D E 3 A lkane/alkene 2 Siloxanes 51 A cridine + derivates 2 2 9 7 8 Glycolether 11 4 15 21 4 1.3 964 A mine 471 Corporate Conclusions from VDA 278 VDA 278 VOC : results confirm the GS 97014-3 BMW results, but are less selective in terms of qualification and quantification. Amine catalysts constitute the majority of the VOC s Siloxanes and glycolether VOC s follow usually the same trend VDA 278 FOG: results provide complemetary information to VDA 278-VOC and GS 97014-3 BMW test results Trace components or low concentration components in VOC are intensified in FOG Acridine levels are most likely formed out of MDI at 120 deg C. Small traces butylated DPA (Irganox 5057) is detected , probably as contaminant, Corporate Huntsman HPLC Carbonyl: Key Results Summary Rubiflex HR+ Foam ID C1 free C1 bonded (acetal) C1 total C2 free C2 bonded (acetal) C2 total C3 free C3 bonded (acetal) C3 total A B C D E ppm ppm ppm 1.3 0.9 2.2 1.2 0.9 2.1 1.7 0.8 2.5 1.5 0.9 2.4 1.7 0.9 2.6 ppm ppm 10.4 2.6 13 2.6 2.0 4.6 3.3 1.6 4.9 1.3 2.2 3.5 2.3 2.0 4.3 ppm ppm 312 46 358 178 67 245 304 45 349 242 45 287 257 35 292 Method not as selective as the GC 97014-3 BMW chamber test for C1 aldehyde. High C2 aldehyde content only confirmed for sample A , compared to GC 97014-3 BMW chamber test But indications that the test capability is limited. Real value of the results according the Huntsman HPLC Carbonyl test will be further investigated as soon as more data and comparisons with GS 97014-3 BMW become available. Corporate Conclusions Huntsman Polyurethanes CONFIDENTIAL Conclusions on Test methods (1) Based on the experience obtained so far, the GS 97014-3 BMW method produces the most reliable VOC data, because; More accurate and reproducible at µg/m³ thus ~ ppb level Highly selective in terms of qualification and quantification, ie Pictures best TVOC and individual VOC compounds at very low levels Best method for aldehydes Measures real VOC by headspace sampling Disadvantage of the GS 97014-3 BMW Chamber method are; High investment costs Time required per analysis. The Huntsman HPLC carbonyl method has much more limited capability; Specific to carbonyl compounds It quantifies bonded and free aldehydes/ketones, enabling insight in origin of aldehyde VOCs which can be a strong benefit Foam extraction conditions for formaldehyde are being optimized. It measures total available compounds which is expected to correlate less with VOCs, as such Seems less accurate at ppm level than GS 97014-3 BMW at ppb level Much less elaborate than GS 97014-3 BMW is a strong benefit The correlation between aldehydes by GS 97014-3 BMW and HPLC carbonyl method is being studied Corporate Conclusions on Test methods (2) VDA 278 (VOC and FOG) ; Quick and easy for TVOC and VOC-group fingerprints Not usable for aldehydes (nor for any very volatile VOC) Cannot measure very low VOC concentrations Measures total available compounds thus less representative as chamber VOC test method VDA 277: (PV 3341) VW / Audi method Not used because of poor reproducibility found No identification of VOC components (result in ppm carbon ) Little use in industry Will not be used as VOC test method in Everberg VDA 275: Formaldehyde by colour-complex Limited to formaldehyde Found low sensitivity even at 5 10 ppm levels Low repeatability and reproducibility and results influenced by other carbonyl compounds. Will not be used as VOC test method in Everberg Corporate Conclusions: Over the coming years there will be more focus on the total emission profile within our vehicles Measurement techniques have developed to such an extent that ppb levels of materials can be under discussion Little work has been be done to compare test methods to allow clear pictures of automotive specifications to be developed Work will be need to be done by all parties in the chain (raw material supplier / Tier 2 / Tier 1 / OEM) to optimise emission performance as the raw materials & processing impact the emission profile Based on our knowledge we have developped and we are constiously improving in all application and especially in the Automotive seating area (see Rubiflex HR+ recent development with low emission results and improved comfort and durability properties). Corporate A new PU seating system concept to provide simplicity in meeting a broad range of customer specifications often seen in an emerging market Text Fully formulated system Excellent flow and stability Wide range of index Effective in all mould types No polymer polyol EXCEPTIONALLY ROBUST Fully formulated system Excellent flow and stability Wide range of index Effective in all mould types Produces low emission foam No polymer polyol Enhanced COMFORT Enhanced DURABILITY THE KEY MESSAGE THE FORMULATED POLYOL SYSTEM FOR BOTH TECHNOLOGIES IS THE SAME Huntsman Polyurethanes CONFIDENTIAL Corporate How do the systems perform against standard OEM specifications ? Technology Technology LOW EMISSION is designed for mainly VW, RSA, PSA, Fiat and passes all specs at density from 45-55kg/m³. Huntsman Polyurethanes CONFIDENTIAL Corporate In summary: Better static comfort Good static comfort Improved dynamic comfort characteristics enabling thinner seats Good dynamic comfort used for significant % of FSC in Europe Better durability Good durability Good fatigue properties even with low emission catalyst packages Good standard properties even at low densities Good mechanical properties across a very wide range of densities Good mechanical properties across a very wide range of density. Positioning Designed to improve comfort at standard thickness or reduce density to achieve similar performance Allow to achieve low emission properties Positioning Designed as standard offer for PUR seating systems capable of meeting customer needs across a broad range of densities and hardness. Can be used to replace TDI for seat backs / cushions. Corporate Thank you for your attention: My contact details should you have other questions: Christophe Ponce Huntsman Polyurethanes Everberg Tel: +32 2 758 9353 / Fax : +32 2 758 7353 christophe_ponce@huntsman.com Information contained herein is based on our present knowledge and experience and does not release the converter from conducting his own comprehensive tests. tests. A legally binding guarantee, guarantee, also regarding possible rights of third parties, parties, is expressly denied. denied. Our products are sold according to our General Terms of Sales and Delivery. Corporate