Applied Laboratory Manual Reporting Sheets Part B

advertisement

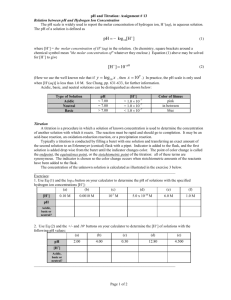

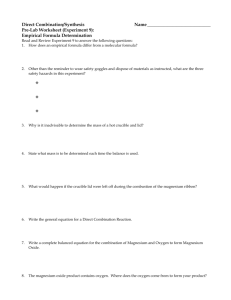

Applied Laboratory Manual Reporting Sheets Part B This record book belongs to: ……………………………………. Contents Workplace protocols ................................................................................................... 4 Report Writing ............................................................................................................ 5 Relative and Absolute Descriptions of Error ........................................................... 7 Other Distillation Methods .......................................................................................... 8 Practical Observation of Fractional Distillation ........................................................... 9 Practical Observation of Steam Distillation ............................................................... 12 Practical Observation of Vacuum Distillation ............................................................ 14 Measurement of density ........................................................................................... 16 Liquid density measurements ............................................................................... 16 Density 7.7 ............................................................................................................... 17 Gravimetric Analysis................................................................................................. 22 Moisture content by oven-drying 8.1 ..................................................................... 24 Ash Content 8.4 ....................................................................................................... 25 Analysis of a mercury chloride and determination of its empirical formula. .............. 26 Experimental Investigation of combustion of magnesium......................................... 30 Gravimetric determination of Ni by precipitation with dimethylglyoxime. .................. 33 Atomic Structure and Bonding .................................................................................. 36 Volumetric Analysis .................................................................................................. 38 Practice titration 9.1.................................................................................................. 39 Preparation and Standardisation of hydrochloric acid 9.2 ...................................... 41 Preparation and Standardisation of sodium hydroxide 9.3 ....................................... 43 Ethanoic acid content of Vinegar 9.4 ........................................................................ 45 Sodium Carbonate Content of Washing Soda 9.5 .................................................... 47 Acid content of Commercial Fruit Juice 9.6 ............................................................ 48 Open Ended Task: 3 White Powders .................................................................... 49 Crystallisation Methods ............................................................................................ 52 Purification of Benzoic acid by recrystallisation ........................................................ 54 Organic Synthesis .................................................................................................... 56 Preparation and analysis of aspirin .......................................................................... 58 Extraction Techniques .............................................................................................. 60 Automated Extraction : Fat in Snack Food ............................................................. 63 Nuclear Radiations ................................................................................................... 66 2 Half Life of Barium- 137* .......................................................................................... 68 Determination of Half Life of an Isotope of Barium ................................................... 69 3 Workplace protocols 1. Safety Procedures (a) (b) (c) (d) (e) (f) (g) Consult Safety Data sheets* and method of analysis for advice on hazards and precautions to be taken Wear appropriate PPE Use fume hood etc as necessary Maintain tidy workspace Exercise care not to endanger other people Observe emergency procedures Report spillages and all accidents 2. Recording and Reporting Register samples into laboratory system (b) Label samples (c) Record which tests the sample should undergo (d) Record sample description, compare with specification, record and report discrepancies (e) Record calibration results for instruments/equipment in tables and/or charts, following quality system (f) Keep records of calibration status and calibration schedule for instruments / equipment (g) Report faulty equipment (h) Keep records of solutions prepared, by expected use-by date, and by name of person who prepared them (i) Record results legibly, and chart when required to identify trends (j) Interpret trends (k) Identify and report atypical results promptly to appropriate personnel (l) Record approved results into workplace system (m) Comply with quality system (n) Report all accidents and potential hazards (o) Maintain confidentiality of workplace information 3. Sample Handling (a) (b) Maintain sample integrity Prepare sample and standards for test 4. Testing (a) Refer to workplace procedures manual for standard method Conduct tests according to workplace procedures Clean up spills promptly Record results according to workplace procedures, without alteration Calculate results, checking against expected values and correcting errors Trouble shoot basic problems with procedure or equipment which have led to atypical results (b) (c) (d) (a) (e) (f) 5. Equipment and Reagents (a) (b) (g) Set up equipment and reagents Check calibration status of equipment; calibrate if necessary Monitor shelf-life of working solutions Prepare solutions when necessary, label and log into laboratory register Clean and care for test equipment and work space Dispose of faulty equipment or quarantine it for repair Store unused reagents 6. Wastes (a) (b) Minimise generation of wastes Collect, sort and dispose of wastes in accordance with procedures (c) (d) (e) (f) * SDS‟s were up until January 1 2012 referred to as MSDS (Material Safety Data Sheets) 4 Report Writing Written laboratory reports can take may formats. The general format that is required in the CFFET section is as follows. Prework Some practicals require Prework which must be completed prior to the lesson. The Prework should be kept in your logbook book or on the appropriate worksheet. . This must be checked and initialled by the teacher. 1. Summary A conclusion at the start of the experiment, containing the following information in no more than 6 lines WHAT SAMPLE was analysed WHAT RESULTS were obtained WHAT METHOD was used An example for the determination of iron in wine would be: “A sample of wine was analysed for its iron content using UV-vis spectrophotometry. The iron content was found to be 15 mg/L.” 2. Results A results sheet for each experiment, which provides for the collection of data necessary for the experiment, is included in this manual. This must be included in the practical report. It is not necessary to rewrite the results. 3. Calculations Most experiments will have a detailed section of the calculations necessary for the report. It is not necessary for you to follow the instructions exactly, but you must show your method of calculation. If you cannot understand how to approach a calculation, see your teacher. The point of writing up reports is not just to get you through the subject, but to learn how to carry out chemical calculations. Calculations in the report should: be clear and tidy be shown in full (except in the case of duplicates, which need to only have the final answer shown) contain all units at all times (in SI, unless otherwise stated) show relative precision data, where possible. When working with solution concentrations, there are a number of different units that are commonly used eg molarity, grams/litre, grams/100 mL (the same as %w/w), ppm (the same as mg/L and ug/L) etc. The experiment will indicate which unit is required. 5 When graphing of results is necessary in the experiment, you will be encouraged to use computer-based facilities for the drawing of the graphs. It will be possible, however, to submit hand drawn graphs. 4. Discussion Should include explanations to points in the practical and the following: a statement of your final results comparison with standard results, where possible problems encountered and possible solutions your comments on the advantages and disadvantages of the technique for the task other analytical methods that would be suitable for the analysis Some experiments will indicate other aspects that must be included in the discussion. A suitable discussion would take up to one and a half pages. 5. Questions These will generally involve looking at references other than the practical results. Your overall mark will reflect the answers that you give. Useful References You are encouraged to read further, the recommended texts for background theory, Vogel’s Textbook of Quantitative Analysis for details of the practical chemical analysis and Chemistry in the Marketplace by Ben Selinger, which provides a chemical background to most consumer products. 6 Relative and Absolute Descriptions of Error The absolute error (or absolute accuracy) is the difference between the observed value and the true value. The relative error (or relative accuracy) is the absolute error expressed as a percentage of the accepted value. The sign of the error may be positive or negative, indicating that the result is high or low respectively. The absolute precision is half of the range of the measurements. The relative precision is the absolute precision expressed as a percentage of the mean of the measurements. These definitions are summarised in the Table below Definitions and formulae used to describe errors Symbol Interpretation Formula X A measured or observed value x1 , x2, x3, etc. for all your readings R The range from biggest to smallest of all replicates for this measurement R = x biggest – x smallest µ The average of all replicates for this measurement µ = [x1 + x2 + x3 + … ] number of replicates X true The true or correct value Eabs The absolute error or accuracy Erel The relative error or accuracy Eabs = X – Xtrue Eabs = µ – Xtrue Erel = Eabs or × 100 Xtrue R 2 Pabs The absolute precision Pabs = Prel The relative precision Prel = Pabs × 100 µ 7 Other Distillation Methods Separation of a mixture by fractional distillation Simple distillation is useful to separate liquids that have a boiling point difference of greater than 700C. It does not satisfactorily separate liquids that have close boiling points, for example a mixture of water and ethanol. Here the water has a BPt of 100 o while ethanol boils at 78oC ie simple distillation is not able to isolate each of the fractions. Fractional distillation is a useful technique for separation of soluble substances with boiling points that are close, for example water and ethanol. The method utilises a fractionating column which provides a large surface area for the separation to occur. When conducting your distillation take particular note of the temperature differences on the two thermometers. 8 Practical Observation of Fractional Distillation Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To observe a mixture being separated by fractional distillation, identify the main pieces of equipment and note safety issues. Procedure 1) Draw a diagram of the fractional distillation apparatus, identifying the glassware components. 2) Complete the table with your observations Identity of mixture Temperature of bottom thermometer Temperature of top thermometer Boiling point of first component How could you identify the component 9 Questions 1. The rate of heating must be controlled in order to keep the maximum possible temperature gradient in the column. Too low means … Too high means 2. Identify safety issues that can arise during a fractional distillation 3. Identify where this process is applicable in the real world. 10 Steam Distillation Steam distillation provides a way of separating and purifying organic compounds. The process consists of passing steam into the organic mixture and water. Many organic compounds are volatile and this property enables the compound to distil with the steam. Essentially the steam is acting as a: Heat source, improving vapour generation Carrier gas to sweep the vapours away from the stillpot and into the condenser. Steam distillation takes place normally below the boiling point of water and generally well below the boiling point of the compound. This low temperature distillation prevents the decomposition of any compound which could occur if it was distilled at atmospheric pressure. Applications of steam distillation Steam distillation is very useful in separating or isolating volatile organic compounds. a) From non-volatile tarry substances which are formed as by-products in many reactions b) From aqueous mixtures containing dissolved inorganic salts c) In those cases where other means of separation might lead to difficulties (eg formation of emulsions) d) From compounds which are not appreciable volatile in steam e) From certain by-products which are steam volatile The general process A stillpot contains the mixture to be steam distilled The stillpot is fitted with a splash-head (or similar) which acts to prevent the accidental carry-over by splashing of liquid from the stillpot into the condenser. The stillpot receives externally generated steam, but is also heated to prevent too much water build up The vapours pass into the condenser, are cooled and the organic compounds and water are collected in a receiver. The method of isolation of the organic compound from the distillate depends on its water solubility 11 Practical Observation of Steam Distillation Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ Procedure and Results 1) Draw a diagram of the steam distillation apparatus, identifying the main components. 2) Complete the table with your observations and notes Identity of mixture Compounds in collection flask Appearance of collection flask Suggestions for separation of collected material 12 Questions 1. What is the purpose of the safety tube attached to the steam generator? 2. What would be the effect of removing the Bunsen flask before you disconnected the receiving flask? 3. What are the major safety concerns with the operation of this type of distillation? 4. How could you determine which is the organic layer in a separatory funnel? 5. Explain how the splash head works 13 Vacuum Distillation Many substances cannot be safely distilled at atmospheric pressures because the temperatures needed are sufficient to cause bond breaking to occur and the material to decompose. Steam distillation may not be an alternative if compounds are water sensitive. Vacuum distillation works by lowering the pressure above the distillation mixture thereby lowering the boiling point of the material of interest. In practice the procedure requires a number of modifications to a simple distillation A vacuum pump to reduce the pressure A sealed distillation system to contain the sample at reduced pressure A replacement for boiling chips which fail under vacuum Good quality glassware to handle the implosive stresses A vacuum gauge to monitor pressure to ensure B.Pt is reported at a fixed pressure and that vacuum failure or build-up can be anticipated A rapid failsafe shut down procedure in the event of an emergency. Practical Observation of Vacuum Distillation Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ Procedure and Results 1) Draw a diagram of the vacuum distillation apparatus, identifying the main components. 14 2) Complete the table with your observations and notes Identity of the impure compound Literature value for boiling point Observed boiling point under vacuum Questions 1. What is the reason for the inclusion of the “flashback” bottle in the system? 2. Why is a thick walled capillary tube inserted into the distillation flask? 3. Why is it preferable for high-boiling organic liquids to be distilled at reduced pressure? 15 Measurement of density The density of any gas, liquid or solid is its mass per unit volume. mass Density = volume Mass is measured with a balance Volume is measured by direct reading of a volume scale on the container or from displacement measurements by immersion in a suitable liquid. The object is immersed in the liquid and the apparent rise in level equals the volume of the object. Problems arise when: the material is soluble the void spaces absorb fluid the material dissolves, swells, expands or shrinks Liquid density measurements Two basic methods are used 1. density bottles (pycnometers): highly precise volumetric vessels which are filled with the liquid in question and weighed. 2. hydrometers: specially weighted floats which are immersed in the liquid. Refractive index can be correlated with density. The producers and users of sugarbased materials make extensive use of density as measured by hydrometry and refractometry to analyse for sugar content. 16 Density 7.7 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the density of a variety of materials Results and Calculations 1. Density of an irregular solid Sample mass (g) Identity or code Density = . mass . True volume Sample Identity or code True Volume (mL) Initial Volume (mL) Final Volume (mL) True volume = final volume – initial volume Density (g/mL) Literature Density You need to reference the source of your literature value data here. 17 2. Bulk density of various granular solids Sample mass (g) Mass (g) I.D. Empty cylinder Sample Bulk volume (mL) Settled volume (mL) + Cylinder Volume Water Volume reading Added Sample (mL) + water Density = . mass . Appropriate volume Mass sample = (Mass sample + cylinder) - mass cylinder True volume sample = (Volume reading sample + water) – volume water added Sample Mass sample I.D. (g) True volume (mL) Bulk density Settled density True density 18 3. Density of liquids & 4. Density of liquids by hydrometry Sample I.D. Density = . Mass Empty cylinder (g) Mass Sample + cylinder (g) Volume sample (mL) Hydro-meter reading mass . Volume Mass sample = (Mass sample + cylinder) - mass cylinder Sample I.D. Sample mass (g) Volume sample (mL) Density (g/mL) Hydrometer Lit. Density 19 5. Density of lead by density bottle Follow the method outlined in your Manual and record your data in the table below Step code Mass (g) Calculated values W code 1. W1 2. W2 3. = W2 – W1 W3 4. 5. W4 = W4 – W2 W5 6. W6 7. W7 = W6 – W1 8. Your density of = W3 (W7 – W5) Lead shot is 9. lit value 6. Sugar content by hydrometry Sugar Concentration Hydrometer reading Refractive index unk 1 unk2 You must plot a calibration graph (manually or by excel) for your RI and hydrometer results and use it to calculate the sugar content of each of your unknowns 20 Questions 1. The density of the same material (e.g. brass or lead), was measured by two different procedures. Report on your precision (how close to each other your results were) and your accuracy (how close to the correct answer you were). Which method and result do you favour? 2. A number of liquids were tested by different procedures. Report on your precision and accuracy. Which method and result do you favour, why? 3. Sugar content was measured by two different procedures. Report on your precision and accuracy. Which method and result do you favour? 4. Summarise the potential occupational hazards in performing these procedures on a regular and continuous basis. You should offer suggestions on hazard reduction tactics. 21 Gravimetric Analysis Gravimetric analysis is the use of weighing to determine the amount of a component in your sample. Gravimetric analysis, or gravimetry is normally performed either as a : loss of volatiles procedure where the sample is heated to release volatiles such as moisture or organic vapours and the change in mass is used to calculate the volatile content, or precipitation or separation procedure where a component in the sample is isolated or recovered in some form and this is weighed to complete the analysis. Loss of volatiles gravimetric analysis All loss of volatiles analysis is performed by a similar set of simple steps: 1. weigh your fresh sample 2. heat to remove volatiles 3. reweigh to measure mass loss 4. calculate percentage loss of mass or percentage residual mass In practice, many problems can arise if you consider what might go wrong in each of the steps. You need to: weigh enough sample to keep accuracy high but not too much so as to hinder vapour loss heat but not for too long or too hot or too cold cool without additional losses or pick-up of volatiles reweigh without losses or gains be sure the container does not change weight during the procedure. Heating to constant weight is the chief method used to ensure the container is not altered during treatment. Empty containers are subjected to the same treatment as the sample before any analysis and if their masses remain constant, then you can be sure they have been heated to constant weight and their empty mass is correct. Precipitation or separation gravimetric analysis Precipitation or separation gravimetric analysis follows these simplified steps: 1. weigh your fresh sample 2. treat to isolate component of interest 3. measure mass of pure, recovered material 4. calculate percentage of component 22 The treatment required to isolate the component can cover a wide range of techniques and procedures including: digestion with powerful reagents such as enzymes, acids or oxidants buffering to ensure conditions are suitable for recovery of the analyte addition of chemicals designed to selectively and quantitatively capture the component of interest. use of prolonged heating or contact with solvents such as occurs with Soxhlet extraction or Dean and Stark moisture determination. Validation of Gravimetric Analysis A requirement with all laboratory testing is some evidence or assurance of the reliability of your answer. This evidence comes in four major ways: 1. replicate analysis 2. control or standard analysis 3. literature values 4. alternative testing procedure Common containers for gravimetry 23 Moisture content by oven-drying 8.1 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the moisture content of a supplied sample Results and Calculations: Sample Sample 1 Sample 2 Sample ID Mass empty dried container Mass dried container + food Mass food Mass after weighing 1 Mass after weighing 2 Mass after weighing 3 Mass of moisture lost % moisture = mass moisture lost x 100 sample mass Questions: 1. Why shouldn‟t containers be handled with the fingers during the analysis? 2. Why are the samples placed in a desiccator when removed from the drying oven? 24 Ash Content 8.4 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the ash content of a supplied sample Results and Calculations Sample I.D. code Mass of empty crucible + lid Repeat mass after heating Mass crucible + lid + food Mass after ignition Repeat mass after additional heating Mass of food which was ashed Mass of ash residue % Ash = mass of residue x 100 mass of food Questions: 1. Why must containers removed from a muffle furnace be air-cooled before placing in a desiccator? 2. What is the purpose of the pre-charring step in the ash determination? 25 Analysis of a mercury chloride and determination of its empirical formula. Date Completed: Purpose ___________________ Teacher check _____________ Analyst signature __________ Introduction In this practical you will be given a compound of mercury and chlorine and by decomposing the compound into its elements you will be able to calculate the percentage composition and the empirical formula of the original compound. Decomposition of the mercury chloride is achieved by heating the substance with a mixture of sodium hypophosphite and hydrochloric acid until the element mercury is produced. WARNING All compounds of mercury should be considered to be highly poisonousdon‟t breathe in the fumes from the solution and make sure that the mercury is covered by solution during heating. Wash your hands thoroughly at the completion of the exercise and make sure all spillages are cleaned up correctly! Procedure: 1. Obtain a sample tube containing a mercury chloride and record the number on the tube. 2. Weigh a clean, dry evaporating basin, labelled with your name. Also weigh the sample tube plus contents 3. Carefully add the mercury chloride to the evaporating basin. 4. Collect 20 mL of distilled water and use some to rinse the contents of the sample tube into the evaporating basin. Add the remainder of the water to the evaporating basin. Re-weigh the empty, dry sample tube. 5. Add 10 mL of sodium hypophosphite/hydrochloric acid solution from the dispenser bottle to the contents of the evaporating basin. 6. Place over a steam bath in a fume cupboard and stir to mix the reactants (Care liquid is corrosive) 7. Continue heating and stirring until mercury collects in large silvery globules. (Avoid inhaling vapour while heating) 8. When all the mercury globules have coalesced, remove the basin from the steam bath and decant the colourless liquid AS DEMONSTRATED BY THE TEACHER. 26 9. Wash the contents of the basin twice with water and once with small amounts of methylated spirits. Collect all washings in the waste container provided. 10.Dry the mercury by pulling pieces of filter paper through it as demonstrated. 11.Re-weigh the basin containing the dry mercury. 12.Return the mercury to the class collection bottle. Results Sample ID Mass evaporating basin Mass tube + contents Mass empty tube (after washing) Mass evaporating basin + mercury Calculations 1. Calculate by subtraction of appropriate measurements Mass of mercury chloride used Mass of mercury metal produced Mass of chlorine originally present 2. From these figures calculate a) the percentage composition of your compound b) the empirical formula of your compound c) suggest a suitable name for your compound 27 Discussion Comment on any errors in your analysis and how this may be overcome. 28 Gravimetric determination of sulfate in bore water 8.6 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the sulphate content of bore water using a precipitation method. Results Sample 1 Sample 2 Crucible ID Mass of empty crucible (g) Mass of empty crucible (g) after heating to constant weight Mass of crucible + residue (g) Mass of crucible + residue (g) at constant weight Mass of residue (g) Average mass of residue (g) Calculations The value reported is typically in the units of mg sulphate / L Sulfate = average mass of residue x 40 x 0.4113 x 1000 29 Experimental Investigation of combustion of magnesium An open-ended investigation is one in which the student is asked to investigate a particular problem, with no specific information being provided about the end result. The student is asked to consider the possibilities and make judgements on how to proceed. In this practical you are to investigate the combustion of magnesium. A method will be provided but before commencement you are being asked to decide what will happen to the magnesium, will it change in any way, will it look the same, how might it change, will it be the same after as it was before…… Write your answers to the above before commencement of the practical Combustion of magnesium When magnesium is burnt (combusted) in air, it reacts with the oxygen gas forming a white ash of magnesium oxide. This is a highly exothermic reaction producing a large amount of energy as heat and light. Equation Magnesium(s) + oxygen(s) Magnesium oxide(s) + energy This practical investigates the mass of magnesium compared to the mass of the magnesium oxide (ash) produced. In an enclosed vessel (crucible) the magnesium will quickly use up available oxygen as it burns and so we will need to open the lid several times to allow air to enter. If sufficient oxygen is not present the nitrogen (from the air) will often combine with the magnesium forming white magnesium nitride and so the ash contains both magnesium compounds. 30 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine how the mass of magnesium burnt compares with the mass of the ash formed Procedure 1. Weigh an empty clean crucible with its lid and record the mass 2. Place three 2 cm pieces of magnesium ribbon in the empty crucible and record the mass 3. Heat the crucible, with the lid slightly ajar, in a strong Bunsen flame 4. After several minutes check that the magnesium has been burnt. 5. Allow the crucible to cool to room temperature with the lid on. 6. Weigh the crucible with contents and lid and record the mass Results Mass of crucible + lid = Mass of crucible + lid + magnesium = Mass of magnesium = Mass of crucible + lid + ash = Mass of ash = Conclusions The law of conservation of mass (matter) states that in any chemical reaction the total mass of reactants is equal to the total mass of products since the reaction involves just the re-arranging of the atoms which are already present “Matter can neither be created nor destroyed, it can only be changed form one form into another” 31 Questions 1. Assuming that your magnesium totally reacted to produce magnesium oxide, what mass of oxygen must have been used from the air? 2. When a piece of wood burns the resulting ash produced weighs much less than the original wood. Where did all the other atoms go? 3. The main elements in wood are carbon, hydrogen and oxygen. What compounds do you think carbon and hydrogen would form when the wood is burnt in air? 4. Carbon would combine with oxygen to form ………………………………. Hydrogen would combine with oxygen to form ……………………………. 32 Gravimetric determination of Ni by precipitation with dimethylglyoxime. This method involves converting nickel ions which are soluble in water into a complex which has reduced solubility at an increased pH. The procedure involves the use of a complexing agent dimethylglyoxime and strict pH monitoring to form an insoluble solid. The complex formed is Nickel dimethylglyoxime. The analysis is gravimetric as the precipitate formed is collected and weighed to determine the mass of nickel. Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the nickel content of a water solution SAFETY The technique involves digesting the solution over a steam bath. Remember steam and skin do not go well together. 1. Ammonia has a strong odour and work with ammonia should be carried out in the fume hood. When smelling do not inhale deeply (Use the wafting technique as demonstrated by your teacher.) 2. Concentrated HCl and skin to not go well together. 3. The sintered glass crucibles will be hot when removed from the drying oven Procedure 1. Clean two sintered glass filter crucibles with dilute HCl and dry in a 110 oC oven. 2. Pipette out two 20 mL samples of the supplied unknown into two 600 mL beakers 3. Dilute to about 150 mL with purified water 4. Add approximately 3g of citric acid to each solution and stir to dissolve. Leave the glass stirring rod in the beaker 5. Slide a piece of red litmus paper down the side of the beaker until it is mostly immersed in the solution, but sticks to the side. 6. Add 5 M ammonia slowly until the litmus turns blue, and then add concentrated HCl slowly until the paper returns to red. Add 2 mL more of concentrated HCl. Remove the litmus paper. 7. Heat the beakers on a hotplate to about 80oC but do not allow to boil. 8. Remove the beakers from the hot plate and slowly add 50 mL 1% dimethylglyoxime (DMG) solution with stirring. If a red precipitate begins to form, add concentrated HCl dropwise until it redissolves, and then continue to add the DMG solution. 9. Add 5M ammonia slowly with stirring until a red precipitate forms and the solution smells strongly of ammonia. 33 10. Stir well and stand on a steam bath for 30 minutes. 11. Check that the solution still smells of ammonia, (add extra if necessary) 12. Add 2 mL extra DMG using a plastic pipette, and stir well. 13. Cool the beakers to room temperature and filter the solutions through the previously dried and tared sintered glass filter funnels. 14. Wash the precipitate in the crucible 3 to times with water 15. Finally wash the precipitate once with 20-30 mL of 30% aqueous ethanol, which dissolves any remaining DMG from the precipitate. 16. Place the crucibles in an oven at 110oC for at least 2 hours. 17. The crucibles should be cooled in a desiccator and then reweighed. Results Sample 1 Sample 2 Volume solution taken Mass of sintered glass crucible Mass crucible + Ni(DMG)2 Calculations 1. Ni2+(aq) + 2DMG Ni(DMG)2(s) 2. Moles Ni2+ in original solution = moles of Ni(DMG)2 formed = mass Ni(DMG)2 . 288.88 3. Mass nickel in original solution = moles of nickel x Formula mass nickel Sample 1 = Sample 2 = Ave = 4. %w/v of nickel in the sample = mass of nickel in sample x 100 vol of sample 34 QUESTIONS 1. Why was it important to limit the amount of nickel in the sample by only taking 20 mL? 2. Why was the precipitate washed in aqueous ethanol? 3. Why was a sintered glass crucible used rather than filtration through paper? 35 Atomic Structure and Bonding Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To demonstrate that when two miscible liquids are mixed the volume is less than the sum of the two separate volumes. Equipment Reagents Ethanol Distilled water Additional burette clamps and stands 10mL measuring cylinders 25mL pipettes 100mL beakers Plastic funnel -small Procedure 1. Using a measuring cylinder, measure out about 5 mL of water and about 5 mL of ethanol, place in a small conical flask and mix thoroughly. 2. Set up the burette and add the prepared water solution. Adjust the volume to read 50mL. 3. Pipette 25 mL of ethanol into a 100mL beaker followed by 25 mL of water and stir well with a glass rod. 4. Pour into the burette using a plastic funnel and record the reading on the burette. Reading: 5. Wash the burette with water. Add water and adjust to read exactly 50mL. Pipette two lots of 25 mL of water into a clean, dry beaker, stir and add to the burette. Record this volume Reading: 6. Determine the volume decrease by comparing results from steps 3 and 5 36 Questions 1. Why fill the dead space in the burette with the mixture before beginning the experiment? Why not add the two pipette fulls of water directly to the burette in step 5. 2. What would be the total volume if 25 mL of water was added to 25 mL of petrol? Give a reason for your answer. 3. Compile a list of the sources of experimental error in this experiment. 37 Volumetric Analysis The terms volumetric analysis, titrimetry and titration are used interchangeably to describe a procedure which analyses chemicals in solution by accurate volume measurement. Principles of titration Titration is used to determine the concentration of an analyte in solution (the unknown solution) and hence the components of any material which can be made up into solution may be analysed this way. The method operates by reacting the analyte in the unknown solution with another solution (the standard solution). The process is carried out so that reaction between the two can be stopped exactly at the point when the last trace of analyte has been used up. The volume of both standard and unknown are used to obtain the required quantitative information. To perform titrimetry, the following need to be available: standard solutions volumetric glassware a suitable method of detecting the end-point a minimum quantity of analyte a standard that reacts appropriately with your analyte The burette is filled with a known concentration of chemical R which destroys A An accurately measured amount of the material containing analyte (A) The amount of A is calculated from the amount of R which is put into a known volume of solution R is added until the very last of A is destroyed – but not one drop more of R is allowed An aliquot of the test solution is now measured for titrimetric analysis Only A This flask now contains a fixed number of particles of A A is being consumed was added. Both A and R no longer exist by R as it is added 38 Practice titration 9.1 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ Results: 1. Observation of endpoint colour Colour of solution using screened M.O. Colour of solution using phenolphthalein Colour of solution Using M.O. Acid HCI Base NaOH End point 2. Practice Titration Concentration of supplied acid Volume of alkali pipetted into titration flask Volume of acid needed for titration end point 1 2 3 4 Average volume acid used for end point 3. Calculation of concentration of supplied alkali Concentration alkali = [Concentration acid x Volume acid] / Volume base = 39 Questions: 1. What are the possible sources of error in the use of a burette? 2. Why should all readings be written down and checked before draining or refilling burettes? 3. Place each of the following pieces of glassware which may be used in a titration in the appropriate preparation column. Pipettes, burettes, volumetric flasks, titration conical flasks, beakers and bottles used to hold standard and other solutions. Used dry rinsed with solution to be placed in it rinsed with distilled water. 40 Preparation and Standardisation of hydrochloric acid 9.2 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To prepare a solution of hydrochloric acid and then standardise the solution Prework: 1. Using the following formula C1V1 = C2V2 calculate the volume of 11.6 M HCl required to prepare 1 Litre if 0.1M HCl. 2. Calculate the mass of sodium carbonate required to neutralise 25.0 mL 0.1M HCl given the reaction ratio of Na2CO3 to HCl is 1: 2. The formula required are: Moles HCl = Volume HCl (L) x Concentration HCl Moles Na2CO3 Mass Na2CO3 = ½ moles HCl = moles Na2CO3 x Formula mass Na2CO3 Results and Calculations Complete the titration equation Hydrochloric acid + sodium carbonate sodium chloride + carbon dioxide + water HCl + Na2CO3 Reaction Ratio: 41 1 a Mass Na2CO3 (g) b Moles of Na2CO3 2 3 4 (a 106) c End point Volume (mL) d Volume (L) (c 1000) e Moles of your acid (b x 2) Concentration of your acid (e d) Average value for molarity of your prepared HCl is Questions: 1. Explain what is meant by the term quantitative transfer. 2. Why is the sodium carbonate kept in a desiccator? 42 Preparation and Standardisation of sodium hydroxide 9.3 Date Completed: Purpose ___________________ Teacher check _____________ Analyst signature __________ To prepare 1 L of approximately 0.1 M NaOH and the standardise the solution to obtain the exact concentration. Prework 1. Use the following formulas to calculate the mass of NaOH required to prepare 1 Litre of approximately 0.1M NaOH no. of moles NaOH = volume (L) x molarity mass NaOH = FW (NaOH) x No. of moles 2. Determine the mass of potassium hydrogen phthalate (labelled KHP, FW = 204.22) required to neutralise 25 mL of 0.1M NaOH given the reaction ratio is 1:1. moles NaOH = Concentration NaOH x Volume (L) mass KHP = moles KHP x FW 43 Results: (a) Standardising your prepared sodium hydroxide using potassium hydrogen phthalate (KHP) primary standard 1 a Mass KHP (g) b Moles of KHP 2 3 4 (a 204) c End point Volume (mL) d Volume (L) (c 1000) e Moles of your alkali (b x 1) Concentration of your alkali (e d) Average value for the molarity of your NaOH is 44 Ethanoic acid content of Vinegar 9.4 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the ethanoic acid content of vinegar. Chemistry: Complete the equation to enable the mole ratio to be determined Sodium hydroxide + ethanoic acid sodium ethanoate + water NaOH(aq) + CH3COOH(aq) NaCH3COO(aq) + H2O(l) Results: Volume of original vinegar taken (mL) = Volume of diluted vinegar prepared (mL) = Vol. of diluted vinegar titrated (mL) = Concentration of NaOH used = Titration volumes Average titration value = Calculations: moles of NaOH used = Concentration NaOH x Average titration / 1000 = moles ethanoic acid = moles of NaOH (because the mole ratio = 1:1) = Conc diluted ethanoic acid = moles ethanoic acid / (volume of aliquot/1000) = Conc original ethanoic acid = Concn of diluted vinegar x 10 (original vinegar solution) = 45 Mass (g) ethanoic acid per L = Concn original ethanoic acid x 60 = % w/v ethanoic acid in vinegar = mass ethanoic acid per L / 10 = Questions: 1. How would you titrate if brown vinegar had been used in place of white vinegar? 2. How does your answer for the vinegar compared to food authority standards for legal vinegar? (The ethanoic acid content must be at least 4.0% w/v). 46 Sodium Carbonate Content of Washing Soda 9.5 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the sodium carbonate content of washing soda by titration Equation: Sodium carbonate + hydrochloric acid Results: Mass of washing soda: (approx 3.6 g) = Size of volumetric flask: = Aliquot volume (mL) = Aliquot volume (L) = Concentration of HCl = Titration volumes (mL) Average titration (mL) Calculations: moles of HCl = concn of HCl x average titration volume / 1000 = moles Na2CO3 = moles of HCl / 2 in aliquot = Concn Na2CO3 = moles Na2CO3(dil) aliquot volume(L) = Mass Na2CO3 in volumetric flask % sodium carbonate = Conc n Na2CO3 4 x 106 = = mass sodium carbonate in 250 mL X 100 Mass of initial washing soda = 47 Acid content of Commercial Fruit Juice 9.6 Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the malic acid content of commercial fruit juice Results: Concentration of NaOH: = Volume of juice taken = Titration volumes (mL) Average titration (mL) Calculations: Moles NaOH = Conc NaOH x titration / 1000 = Moles malic acid in aliquot = moles NaOH / 2 = Mass of acid in 25 mL = moles acid x 134 = % w / v malic acid = mass malic acid in 25 mL x 4 = 48 Open Ended Task: 3 White Powders Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To identify the materials in separate tubes. Background 3 different unknown compounds resembling white powders will be issued for positive identification. You will perform a range of physical tests to classify each compound based on its unique set of physical properties. You will then confirm the identity of each white substance based on a simple chemical diagnostic test. Glucose, sodium chloride and starch are the chemical substances you must positively identify. Perform all chemical / physical tests in boiling tubes. PART A –CHEMICAL DIAGNOSTIC TESTS Complete the following table using the observations of the diagnostic tests. Glucose Salt Starch Iodine (Observation) Silver Nitrate (Observation) Benedicts Reagent + Heat (observation) 49 PART B – PHYSICAL PROPERTIES Glucose Salt Starch Solubility (soluble / insoluble) Conductivity (solution) (yes/no) Melting point (high/ low) Char (yes/ no) Devise a flowchart that will allow you to determine the identity of each of the tubes using the diagnostic tests above. You could use the results table over to assist make your decision 50 ___________ __________ __________ Iodine (Observation) Silver Nitrate (Observation) Benedicts Reagent + Heat (observation) Solubility (soluble / insoluble) Conductivity (solution) (yes/no) Melting point (high/ low) Char (yes/ no) Identity 51 Crystallisation Methods There are various steps which must be followed: Dissolution in minimum volume of solvent plus 10% at boiling point Addition of charcoal with care Filtration at B.Pt without losses in the paper Addition of co-solvent if necessary until just cloudy or 50% of total Allow to cool slowly Filter, wash carefully and air dry Determine melting point Example of a procedure for recrysallisation of benzoic acid 1. Dissolve sample in a suitable solvent Water is a suitable solvent for benzoic acid Ideally a solvent should have a high solubility for the substance at its B. Pt and a low solubility at room temperature. The impurities should either be insoluble in the solvent at its B. Pt (so that they are filtered out when hot solution is filtered) or they should have high solubility in the cold solvent (so they are left in the mother liquor) Therefore Place the impure material in a conical flask Dissolve the impure benzoic acid in water, using as small a volume as possible. Add some boiling chips and heat to boiling If dissolution has not occurred add 10% more water and reheat to boiling 2. Add decolourising agent Activated carbon is a decolourising agent. It has a large surface area and is able to absorb lots of impurities. Avoid excesses as loses can be incurred due to adsorption of product. Once dissolution has occurred allow the solution to cool slightly before adding the activated carbon. Disaster if you don’t. 3. Filter the hot solution Use a heated, short stemmed funnel and a fluted paper. Ideally have a small portion of solvent in a conical flask and keep this heated. Sit the funnel on the top and filter the solution through as quickly as possible. Remember for benzoic acid solubility decreases dramatically as the solution cools. After filtration is complete use a small portion of hot solvent to wash the flask and filter paper. 4. Cool the filtered solution Cool in an ice water mix. If crystals fail to form there is probably too much solvent and this will need to be evaporated off (or all the sample has been lost in the filtration step). 5. Filter the crystal slurry Filter using a Buchner funnel. Pour the crystal mix onto the filter pad, use the filtrate to wash any remaining crystals onto pad if necessary. Wash the crystals with a small amount of ice cold solvent. 52 6. Dry the crystals Crystals can be oven dried (below the melting point) or just air dried. These practicals are designed to practice routine procedures used to grow crystals and purify solids. TECHNIQUES USED Dissolution in hot solvent Use of carbon adsorption for removal of impurities Co-solvent inducement of crystallisation Assessment of the quality of the end product SAFETY Burns from hot equipment and solutions Chemical hazards associated with unknown materials 53 Purification of Benzoic acid by recrystallisation Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To purify a sample of benzoic acid by recrystallisation and confirm the purity using melting point determination Procedure Sample impure benzoic acid Purification initially by dissolving in a minimum of hot water and then adding activated carbon to adsorb the coloured contaminant. Followed by recrystallisation using water as the solvent 1. Weigh accurately, approximately 5g of the supplied material into a labelled 250 mL conical flask. 2. Add an amount of hot water to just dissolve the solid followed by another 10% of this volume. 3. Carefully add activated carbon to your sample as shown by your teacher 4. Add boiling chips to the flask 5. Place a set of gravity filtration equipment, use a short stemmed funnel, in the drying oven 6. Gently heat your flask until the colour appears to have disappeared from the solution 7. Quickly but carefully, filter the hot solution through the hot filtration equipment 8. Wash the filter funnel with small amounts of hot water 9. Allow the crystals to grow in the filtrate ie cool the solution 10. Filter off the crystals on to a weighed filter paper 11. Leave to dry and then weigh and determine the melting point of your compound Results Mass of impure substance Mass of filter paper (step 10) Mass of recrystallised substance Melting point of substance Literature melting point for benzoic acid 54 Questions 1. Why as the water heated to dissolve the benzoic acid? 2. What was purpose of the activated carbon? 3. Identify where in the procedure you lost product 4. How pure was your final product? 55 Organic Synthesis Aspirin was first synthesised in 1899, however, its beginnings can be traced back many centuries to natural remedies such as „bark of the willow‟ for treatment for malaria and flowers of meadowsweet for the treatment of inflammation. The isolation of the active ingredient in these plants has lead to the mass production of a chemical commonly referred to as „aspirin‟. Aspirin is now widely used as an analgesic (pain reliever) and antipyretic (fever reducer). Repeated use however, may cause gastrointestinal bleeding. Your work with aspirin has many goals in mind. One of the goals is to make you appreciate (a little more) the scientific effort that manufacturers of pharmaceuticals have to put in to make a safe and cost effective product. You will: duplicate the manufacturing process by blending together a highly dangerous, viscous liquid and a white powder. carefully monitor and control a difficult set of reaction conditions follow a complicated series of step just to obtain a crude product. purify and test the quality of your product and judge whether it is suitable for „tablet‟ing and sale. O The general equation for reaction is: C O H + O CH3 O O C C O the CH3 H Ethanoic Anhydride Salicylic Acid O C O H O C CH3 O Aspirin Asprin is the active ingredient in such familiar products as: Aspro Dispirin Bex 56 Scientifically, it is named via an old systematic as Acetylsalicylic acid and is named via the latest IUPAC system as 2- acetoxybenzoic acid. The organic synthesis of aspirin involves the use of: concentrated acids – severe corrosion hazard – wash with copious amounts of water and inform the teacher lachrymatory material – severe irritation to eyes – must use fume cupboard – use eyewash station if any discomfort is felt and inform the teacher It is most important that you follow the teacher‟s instructions carefully. If you are unsure – stop immediately and ask. You will perform the following techniques: 1. 2. 3. high temperature reaction vacuum filtration recrystallisation 57 Preparation and analysis of aspirin Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To prepare aspirin and to check the purity of the compound formed. Procedure 1. Weigh out Salicylic Acid (10.00g) into a 250mL beaker. 2. Add Ethanoic Anhydride (15.00mL) from the dispenser, with great care! NOTE 1: any spillage on skin or furniture must be cleaned up immediately with copious quantities of water and the accident reported to the teacher. 3. Add Pyridine (approx a dropper-full) to the mixture in the beaker. 4. Stir vigorously with a glass rod until the mixture GELS. NOTE 2: Take care not to puncture the bottom of the beaker with the rod – keep the beaker flat on the bench at all times. NOTE 3: Do not remove the stirring rod from the beaker at any stage otherwise you may drip the corrosive brew on yourself or on the bench top as a hazard for someone else. 5. Warm on a steam bath for approximately 10 minutes or until the gel dissolves completely. 6. Add ice water (150mL) and continue to stir until the oily droplets have all dissolved and a white powdery solid builds up. 7. Cool in an ice bath until no more solid is formed. 8. Filter by suction and recrystallise the moist filter cake from ethanol then water co-solvent. 9. Filter and dry the crystals. They will be tested in a later session 10. Weigh the crystals when they are dry. 11. Determine the melting point using the Kohfler Hot Bench as instructed. 12. Compare your value to the theoretical value. 58 Results Mass of empty beaker Mass of acid (g) A beaker with salicylic B Mass of salicylic acid used (g) M =B – A Mass of filter paper C Mass of filter paper + aspirin D Practical mass of aspirin (g) P=D–C M. Pt synthesised material Lit. M.Pt. of pure aspirin 59 Extraction Techniques Purification is a general term used to describe the selective removal of components from a mixture. Typical examples would be: extraction of gold from its ore recovery of sugar from cane juices isolation of caffeine from tea/coffee Normally, extraction, is the name reserved for purification techniques which use a solvent to dissolve and recover a component of the original mixture. This can be achieved by using physical and / or chemical methods for the selection of the component of interest. Physical methods of extraction depend on: solubility differences between two immiscible solvents solubility differences between the original matrix and a solvent Typical physical methods use a specially selected solvent (or a blend of two immiscible solvents) chosen for their ability to dissolve only some components of the mixture. Hence a cup of tea is a good example of selective physical extraction since only the palatable fractions are dissolved and the nasties are supposedly left behind to be discarded with the tea leaves. An example of two immiscible solvents would be salad dressing, where different flavours are found in the different layers ie the oil and vinegar. Chemical methods of extraction depend on: selective modification of the chemical structure of the analyte subsequent change in physical properties to cause extraction to occur reversal of original chemical change to recover the desired component the most common chemical method involves change in pH Typical chemical methods utilise the solubilities at different pH of the components. Consider a mixture containing only organic chemicals which are insoluble in water eg crude oil. The two will not mix and so none of the components of the crude oil will migrate into the water. However some of the chemicals are weak acids and can be made to react with a base such as NaOH. This reaction will cause the weak acids to become ionised and hence water soluble. ie weak acid + Na+ + OH- Na+anion- + H2 O Salting out Adding an inorganic salt (such as sodium chloride or sodium sulfate) to an aqueous solution containing an organic solute often reduces the solubility of the organic compound in the water and thus assists its separation. This salting out technique is often used in extractions and liquid-liquid separations: to maximise the transfer of an organic solute from the aqueous layer to the organic layer to separate n organic liquid from its aqueous solution to break emulsions 60 Drying of organic solvents. Organic solutions obtained from the extraction processes will almost certainly contain a small amount of dissolved water. The presence of dissolved water is normally indicated by cloudiness of the organic liquid. The water can be removed by adding a solid drying agent, generally an anhydrous ionic salt such as magnesium or sodium sulfate or calcium chloride. These salts will absorb the water into their crystal lattice, removing it from the organic liquid. Once the cloudiness has been dispelled, the drying agent must be removed by filtration. EXTRACTION OF SOLIDS A separatory funnel is obviously unsatisfactory if the mixture is a solid, since the solid material will block up the tap at the bottom. Other than dissolution of the solid in a suitable solvent, the most common method of extraction of a solid is by the use of the Soxhlet continuous extraction apparatus shown below. The solid substance is placed in the porous thimble and the latter placed in the inner tube of the Soxhlet apparatus. This is fitted to a round-bottom flask, which contains the extraction solvent and boiling chips and attached to a reflux condenser. The solvent is gently boiled; the vapour passes up through the side tube to be cooled in the condenser. The solvent then falls back into the thimble and slowly fills the body of the Soxhlet. When the solvent reaches the top of the tube, it siphons back into the flask, and thus removes the portion of the substances it has extracted from the solid. The process is repeated automatically until complete extraction has been achieved. 61 62 Automated Extraction : Fat in Snack Food Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To determine the fat content of snackfoods. Fats form the major energy storage in animals, When fats are „burnt‟ in the body they produce energy. Extraction of fat from snack food can be done using an apparatus called a soxhlet extractor. Procedure 1. Set up the apparatus as demonstrated. 2. Obtain and weigh a Soxhlet thimble and two evaporating basins. 3. Add to the Soxhlet about 5g of the allocated snack food and reweigh the thimble. 4. Place the thimble in the Soxhlet apparatus 5. Half fill the round bottom flask with trichloromethane 6. Ensure the water is on to the condenser 7. Switch on the heating apparatus 8. Allow the system to „cycle‟ for at least 45 minutes. You are required to draw a schematic diagram to show the passage of solvent and fat through the system. 9. Turn off the heat and allow to cool 10. Transfer the solvent (containing the fat) to the large evaporating basin, place on a water bath in the fume hood and allow the solvent to evaporate to dryness 11. Dry the outside of the basin and reweigh 12. Place the thimble in a small evaporating basin and place in an oven at 70oC for 1 hour 13. Reweigh the thimble 63 Schematic diagram Results and Calculations Food analysed Mass of empty thimble Mass of large basin Mass of small basin Mass of thimble + food Mass of thimble and residue in small basin Mass of large basin + fat residue Original mass of food Mass of food residue Mass of fat residue % Fat = mass of fat left in basin x 100 original mass of food 64 Questions 1. From the SDS record the dangerous properties of trichloromethane 2. What is the purpose of the cotton wool in the top of the extraction thimble? 3. Why is trichloromethane a suitable solvent for this extraction? 4. Soxhlet extraction is described as a continuous extraction technique. Explain what this means. 65 Nuclear Radiations Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ Warning: The radioactive sources may be dangerous if they are not handled properly When handling the radioactive sources you must follow the instructions exactly 1. 2. 3. 4. 5. Do not touch a source by hand Pick up a source with tongs Do not point a source towards anyone Make sure you are at least half a metre away from the source Wash your hands thoroughly after performing an experiment Background radiation Record the background radiation (the radiation due to natural radioactive elements in the earth, cosmic rays from space and nuclear explosions) Time 1st minute 2nd minute 3rd minute Count Shielding Repeat the following for each of the isotopes using air, paper, aluminium and lead (10 cm and 30 cm distances) Take duplicate counts for 1 minute Results Alpha source 10 cm 10cm 30 cm 30 cm Air Paper Aluminium Lead 66 Beta Source 10 cm 10cm 30 cm 30 cm 10 cm 10cm 30 cm 30 cm Air Paper Aluminium Lead Gamma source Air Paper Aluminium Lead Which radiation has the most penetrative ability? ………………………………….. Which radiation is stopped the easiest? ……………………………………………. What would be a satisfactory method of storage of radioactive isotopes? ……………………………………………………………………………………. 67 Half Life of Barium- 137* The half life of a radioactive substance is the time taken for its rate of nuclear decay to reduce by half. Different radioactive nuclei have half lives ranging from 10 -14 seconds to 1011 years. The half life of a radioactive substance is one of its most important characteristics. The value helps to determine the uses which can be made of the substance and the dangers associated with its use. Also the half life is closely related to the nature of the radioactive decay undergone by the substance and provides important clues to its nuclear structure. In this experiment you can observe the decay of a particular radioisotope of barium, Ba-137*, where the * indicates that the isotope is in an excited nuclear state. The isotope is obtained in solution by extracting it chemically from an „isotope generator‟ in which it is being continually formed by the radioactive decay of another element, caesium The excited state of the isotope decays into a non-radioactive ground state, with the emission of gamma radiation which can be detected with a Geiger counter. Ba-137* Ba-137 + γ 68 Determination of Half Life of an Isotope of Barium Date Completed: ___________________ Teacher check _____________ Purpose Analyst signature __________ To prepare an isotope of Barium and determine the half-life Procedure 1. Make five 30 second background reading counts and record them on the result sheet. 2. Slide the radioactive solution under the detector, start the stopwatch and the counter 3. Allow the stopwatch to continue timing but stop the counter after 30 seconds and record the value. 4. Start the counter again when the stopwatch reads 45 seconds for a further 30 seconds 5. Continue the process until 10 minutes have elapsed from the start of timing 6. Graph the count per 30 seconds, corrected for background, against the midtimes of the counting intervals as recorded in your results table. 7. Use your graph to determine several estimates for the half-life of Ba-137*. Derive an experimental value and compare it with the accepted value from literature. Results and Calculations Background Counts (/30 s) Mean count (/30 s) 69 Stopwatch readings (s) Time (s) 0 – 30 15 45- 1:15 60 1:30 – 2:00 105 2:15-2:45 150 3:00 – 3:30 195 3:45- 4:15 240 4:30-5:00 285 5:15 – 5:45 330 6:00 – 6:30 375 6:45 – 7:15 420 7:30 – 8:00 465 8:15- 8:45 510 9:00-9:30 555 9:45 – 10:15 600 Count (/30 s) Corrected count (/30s) Using your graph Select at least 3 pairs of values to estimate half life, where count2 is half of count1 . Count 1 Time 1 Count 2 Time2 Time 2- Time 1 Experimental value for half-life Ba-137* is ………………………………………….. 70