“How Enterprise- Academic Collaboration can drive Design Innovation in China” 1 INTRODUCTION

advertisement

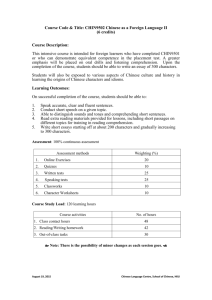

1 “How Enterprise- Academic Collaboration can drive Design Innovation in China” 1 INTRODUCTION Thank you for your kind welcome. This is a wonderful time to be in China, with the Shanghai expo and the Automotive Expo showcasing Chinese innovation at a crucial moment in the global economy’s return to growth. I’d like to thank the Ministry of Science and Technology, PTC and the British Embassy for their kind invitation. Whenever I discuss China with business and government leaders, there is a moment when the sheer scale of China comes home to them. From the growth of the Pearl River delta or the rapid expansion of the Chinese Automotive industry in what is now the largest vehicle market in the world; Chinese growth leaves leaders sharply aware that the world is changing. They’re right. It is. So the challenge for them, and for all of us, is how to harness that changing world. I believe there is only one sure path to commercial success – a sustained focus on the value of applied research, and on using that research to meeting the needs of the community via constantly innovative product and process design. 1 2 In other words, the opportunities China offers can only be grasped by developing what President Obama calls “an Ecology of Innovation” amongst businesses, universities, students and workers. To do this well requires partnership and collaboration between equals. 2. What WMG does The creation of strong links between business and academic research is the mission of my professional life. I founded Warwick Manufacturing Group thirty years ago. We had a staff of two and a single shared office. We now have more than 220 academic staff and academic bases in China, Singapore, Africa and around the world. We have trained more than 24,000 students and awarded 6,000 research degrees. We exist to show business that investing in academic research, design innovation and product development will help them develop the quality products and processes that their customers demand. Our vision is to use academic rigour to solve complex real world problems in industry. That vision has guided us as we have grown. 2 3 We now carry out world class research in engineering in fields as varied as automotive, housing, healthcare and cryptography. We work with commercial partners to broaden the skill base of their employees, and our students work is focused on the importance of applying research and the scientific method to the world around them. We offer modular degrees so as many workers as possible can gain these insights. Whether undergraduate or graduate, our courses are project-oriented right from the beginning, and are developed in partnership with employers, so a company has a real commercial incentive to support employee learning. This market focus helps us understand the needs of our global partners. We have a huge range of these, from private sector global leaders like PTC, Jaguar LandRover, Tata and China Aerospace to leading public sector innovators. It is this practical focus that has made us successful. This year, we were awarded the Queen’s Award for excellence in Higher Education, an honour reserved for the highest level of achievement in Education. 3. FOCUS ON DESIGN AND SKILLS So our focus is on partnership with employers making real world experience central to our work. 3 4 The UK is a fantastic place to do this work. The UK has a world leading Science base, with genuine quality in research and openness to students and businesses from all over the world. In addition the UK has outstanding sectoral strengths, from Pharmaceutical, to aerospace to automotive, all set in an open trading economy. Companies like Rolls Royce, GSK and GKN, who are presenting here today, are leader in their fields and leaders in applied research. WMG is at the heart of a cluster of advanced manufacturers and innovative companies, a position that means we have been able to build long term relationships with world class companies, which in turn has attracted those who wish to share that expertise. We know our partners need a future workforce with ever greater skills and understanding of engineering principles. So we start early. Our work begins in the secondary school classroom, where we provide training for teachers, curriculum development and work based courses for students. This has the major benefit of introducing students to the software and techniques that they will use at university and at work, and inspiring them with the incredible things a scientific, design based approach to the world can deliver. It has real benefits for employers too. 82% of British schools now use 3D solid modeling software based on that used in universities 4 5 and workplaces, smoothing the transition between school, university and work. 4. WMG & CHINA So our credentials in industrial design, research and development are strong, but as everyone knows, China is unique. It rewards hard work and understanding. I’ve long known how much we have to learn from Chinese science and research. My first visit to China was back in 1981, when I was invited to view the Long March Rocket programme, with the great Dr Liang. That was a stunning insight into Chinese capability. I was blown away by the brilliance of the engineering and ever since I have been focused on building strong links between WMG and China. In 1998, the Group established a direct relationship with the Chinese Government body responsible for all overseas training, the State Administration of Foreign Experts Affairs. Today we train 250 Chinese Students each year and have strong research partnerships with Chinese Universities, such as Harbin and Wuhan and businesses like China Aerospace. We deliver annual training courses tailored to the needs of selected managers from most of the major industries and 5 6 institutions in China, including oil and gas, automotive, transport, and defence industries, We’ve educated more than a dozen Chinese billionaires at WMG. Business leaders like Henry Tseng learnt how to lead with us. We’ve established relationships with more than 170 Chinese companies. Our courses are specifically developed for each cohort of participants with an intensive two-month period of teaching and project work, with modules selected to meet the needs of the individuals. The 2007 cohort, for example, was mainly from high volume manufacturing industries and covered such subjects as logistics, production and material control and financial analysis and control systems. Some 600 senior managers have attended these courses. 5. CHINA’S CHANGING STRENGTH So from our perspective as a long term partner, what do we see in China? Well, outstanding growth, obviously, but what’s significant is the change within that growth. Most of China’s growth last year is attributable to the strong stimulus package put in place by the government. The scale of that investment astonishes outsiders. 6 7 If we take only Transport, China plans 30 urban transit projects – more mass rail and tram schemes than any other nation. There will be10 High Speed rail links – more than anywhere else in the world. In Green technologies, China’s investment is world leading, with a $220 billion dollar investment planned. Chinese research too has been strengthening fast over the last decade, with an impressive increase in citations in Scientific and Technical journals, as you can see here. Leading Universities, such Tsinghai, are increasingly focused on developing global partnerships to increase the impact of their research. 6. CHINESE INNOVATION The result of this stimulus is that Chinese R&D spend will match that of Japan this year. Another way of looking at this is that China’s research spending will be double that of Germany, regarded by many as the world’s leading high tech manufacturer. Much of the explanation for this lies in the unique understanding of the importance of engineering amongst China’s leadership. I’m constantly saying to western leaders that 18 of the top posts in the Central Committee are held by engineering graduates. As a result, China has a leadership uniquely committed to scientific innovation. 7 8 The Chinese challenge is to seize this unique opportunity of a growing market, expanding research funding and determined leadership to become stronger innovators. 7. CHINA’S SKILLS NEEDS So how is China’s education system meeting the challenge of expansion? The first point is to salute the rapid expansion of China’s University sector. 6.1 million students will graduate China’s Universities this year, a staggering number. Yet despite a labour market that is hungry for high skilled workers, there is a gap between graduate capability and Industrial need. 44% of Chinese executives rate recruited skilled staff as their biggest issue – and it is an issue that runs from the university sector right down to Secondary school. A March 12 article in People’s Daily about college graduates summed up the situation. “New workers at Huachen Brilliance Auto Factory in Shenyang, Liaoning province need experience in welding, distribution or logistics, car maintenance, or electronics – knowledge that most college graduates and migrant workers do not have. “As a result of an influx of new technology and management ideas, the type of workers we recruit has changed completely,” said Li Xuelian, a spokesperson for Brilliance. “The quality of people we recruit is much higher now.” 8 9 The pressure of Global competition requires a global standard of Labour. It is vital that Universities and Businesses work together to develop such a qualified workforce. Whatever happens, China will grow, but it will be far better if that growth is made in China. 8. THREE OPPORTUNITIES I can see three major opportunities to be taken in China. Each of them requires a focus on product and process design. The first is expanding China’s share of both existing and expanding large markets. Some of this can be achieved via acquisition, as Geely have shown with the purchase of Volvo, but acquisitions won’t deliver long term growth without constantly improved products. Last year’s Volvo won’t be competitive in world markets for long. Next, satisfying the product needs of the fast growing domestic market will create a whole galaxy of new products, and that will mean design decisions that make the most of limited consumer budgets. Only designers who intimately understand the Chinese consumer will win in this market. Here it will be vital to get greatest impact from China’s R&D investment and ensuring knowledge transfer so cross-over applications find their way to market. Finally, there is the need to maximize both workforce skills and capital investment to improve productivity. The challenge of improving productivity is a constant, no matter how much Labour 9 10 is available. Wage pressure will be constant, as will ever greater regulatory burden, in this environment, both greater mechanisation and lower cost production processes will be key to competitiveness. These too will require innovation. 9. Only design innovation can grasp opportunities It is my view that seizing those three opportunities requires one consistent element- an emphasis on design innovation. To achieve sustained growth requires invention that creates outstanding products and processes. What does this mean? Invention is self explanatory. It is an innovative solution to a need, whether that need is known or unknown. But that alone is not enough. When researchers discovered how to communicate wirelessly over pairs of frequencies more than 60 years ago, it was hard to see how this would come to dominate telecommunications. It was the designers of mobile products that translated research insight into commercial application. So design can be thought of as “invention plus”. It is invention plus the skills needed to translate and commercialise a product or process successfully. 10 11 10. Innovation comes from R&D This pattern hold true through any number of technological breakthroughs from research. Whether we are talking about the development of the LCD screen, or the development of ARPAnet, we can see how the first source of innovation is Research and Development. But the process cannot stop there if it is to change lives. It needs to translate into products. This is where applied research and Design innovation is central. 11. Profit from Design What’s more, it is the best designs that build profits. Those who have profited most from the establishment of the Laptop market are not GRID, who developed the first laptop, but companies like Lenovo who have met consumer needs best. In the same way, the first models of bicycles were rapidly replaced by superior, ergonomic designs that have stood the test of decade. The firms who led the way in that process still exist today. Even in a field as complex as aerospace, it is the iterative process of superior design solutions to difficult problems that have taken us from bi-planes to dream liners. 11 12 12. Design is key to innovation Why is design such a powerful tool for growth? For a manufacturer, without design, all you are doing is assembly. Value lies not merely in building a product, but in being able to build it better. The attempt to develop an improved product teaches you the weaknesses and strengths of your product. The act of asking what can be done better provides insight into how and where a product can improve. Embracing the pressure to find a better design also forces you to ask tough questions. After all, If you don’t you will discover that somebody else has.. 13. A growing need for quality design This gap shows the need for quality domestic design innovation built on a collaboration of equals. The government and business leaders clearly understand this need, and have made it a key part of the “Made with China” campaign. Only global partnerships can help deliver this innovation. From the adoption of the global standard CAD-CAM software to carrying out research with Universities, the future of design 12 13 innovation is one of partnership across nations, across sectors and across the Business-Academic boundary. As markets overseas get tougher, with low growth, there is increased need for China designed products which ensure a more revenue returns to manufacturers – and this research and design process will require partnership with institutions which can help Chinese industries meet consumer needs at home and abroad. This is why innovative manufacturers, like Geely, Chery, Changan. and Shanghai Automotive, are developing partnerships with leading research oriented and design companies, such as Lotus, Ricardo, GKN, and PTC. 14. JLR Talking theoretically is all very well, but I am an engineer. I want to share with you some of the ways research partnerships have made business breakthroughs at WMG. We are leaders in Experiential Engineering – engineering the process in which consumers experience a product. Think of the sensation a driver gets from accelerating- what is it that gives a sense of quality, or power, or thrill? One answer to this is the sound experience the driver has. So we have been researching consumer reactions to sound in the premium automotive sector. We have developed ways to convert the driver’s subjective reaction to sounds into objective measures for suppliers and vehicle designers to aim for –whether the growl of engine acceleration or the solid “clunk” of a door closing safely. 13 14 15. Research Breakthroughs Nor is the impact of design innovation limited to traditional manufacturing. Take our work on healthcare at WMG. Because we have experience in materials science and in the automotive sector, we were able to develop a bioceramic synthetic bone product which is based on the manufacture of Catalytic converters. This product is easier for tissues to bond with because it shares the porosity of human bone. Research is also key to improving process, as a part of the continual search for product quality improvement. We can see this in our work on spot-welding aluminum. By developing the ability to resistance spot weld aluminum for a car manufacturer, we removed the need for complexity in production – as over 3000 rivets were no longer needed in each vehicle. We also reduced product weight and cost. The same principle is at work in our research to end the plastic paint shop in automotive manufacture. Painting plastic parts is time consuming, expensive, complex and leads to high CO2 emissions. So we have developed techniques to develop an in-mould solution to parts painting, so the painting 14 15 stage can be integrated with part moulding, providing lower cost, lower waste and higher quality fittings. 16. The Challenge: Integrated research & design innovation So how do we deliver these innovations for our industrial partners? One of the key elements of our approach is our Engineering Doctorate. WMG’s EngD programme was created in 1991 with a unique focus on a portfolio approach, enabling industrial managers to develop their career at the same time as studying on the programme; this was a major factor in attracting senior industrialists to participate. Our Doctorate is a research degree but participants are also required to develop competences required of an engineering manager, through studying Masters modules, a technique which has made the degree attractive to companies who need to strengthen the skills of their next generation of leaders. The EngD instills academically critical thinking applied to industrially relevant innovations. Far better for leaders to do practical research on real business issues than to spend years imbibing Business school mantras! The research done has driven practical benefits. For example – A WMG EngD student developed a system to detect surface and 15 16 internal defects in hot moving steel slabs resulting in a significant reduction in waste products and quality improvement; The Eng D is not restricted to traditional manufacturing. A leading UK homebuilder, Westbury, used EngD research to reengineer their house-building process to achieve mass customization and higher build quality. It led the firm to develop the first large-scale off-site homes construction facility for residential housing in the UK, supplying thousands of units a year. This business focus is reflected in their fast career rise of participants. Many are already Directors in companies such as Rolls-Royce, while others are owners of companies. 17. UK Motorsport We’re seeing this is process happening in the Motorsport industry. Advanced motorsport engineering has long been a British specialty, even as the rest of the UK automotive sector has struggled. It is a hotbed of innovation for parts, for design systems and for new design techniques. The leading firms in this field partner with academic researchers to solve complex problems in every area from aerodynamics to fuel efficiency to materials weights. As a result we now see companies from all over world subcontract Auto R&D to the UK. In turn, this means that the parts suppliers follow suit, as they seek to anticipate the new technologies that will impact their products. 16 17 This shows the importance of global partnerships, customer understanding, design culture and, most importantly, a continual awareness of the importance of innovation and applied research to your industry, where-ever you stand in the supply chain. 18. Major opportunities I see two major opportunities for Chinese companies, and to succeed in either area will require strong, ongoing partnership between companies and applied researchers. The first opportunity is to extend the share of high value design and research product development in Western Markets. To do this will require an in depth understanding of customer needs and concerns – which in turn requires the ability to judge how well your product fares against competitors, and research the ITERATIVE improvements needed to meet consumer and regulatory standards in these markets. The second opportunity is the challenge of retaining the current high share of fast growing domestic market via outstanding products. This second environment will be the most competitive in the global economy. After all, every Fortune 500 and FTSE Chief Executive says that the BRIC countries are their biggest opportunities for growth. Here the challenge is to utilize the research strength of innovators around the world alongside the insights of domestic experts to 17 18 employ industry leading design techniques so that your product development is globally competitive. The need is for world class product innovation to meet domestic market needs. 19. Challenges In other words, whichever path you see growth coming from in your industry, there is real benefit to be had by building a collaborative relationship with globally capable institutions. So what should you look for in a partner? I’d argue there are three crucial elements. Your partners should have a deep understanding of what it takes to make applied research and design innovation work. They should have a track record of success in your field – of delivering real results for companies, not just high flown statements. Finally, your partners should have an experience in China and deep respect for the talents and innovative capability of Chinese industry. I believe these principles for successful partnership apply across a number of fields, whether in academic research or design partners. 18 19 I would like to conclude by making one final point. The wonderful thing about innovative design is that it is an iterative process. It is marked by continual progress. It is something that moves step by step towards better products. There are no short cuts, or easy answers, no cookie cutter application of management consultant “rules”, simply the gradual development of better designs to meet customer needs. No product is perfect first time. No insight makes it to market unadjusted. There is always room for improvement. What applied research and a focus on design innovation can do is quicken those changes, and turbo charge your ability to improve products. In that light, the priority is developing long term research and design partnerships that can improve your innovation capability, whether by developing the skills of your staff, helping you understand differing consumer needs, or by taking the time to understand the specific, unique pressures your industry faces. Done well, this ensures that your internal capability to innovate and design grows alongside your product improvement. This double win – of research advance and increased innovative capability is the heart of what applied research can offer your company. In China, the fastest growing and most competitive market on earth, that could well mean the difference between being an industrial dynasty or a commercial footnote. 19 20 China is already a major global player. It will certainly be even more significant in the future. That significance will be even greater if the needs of the global economy are not only made in China, but designed in China too. “ 20