( AL -2Cu – 2Mg )

advertisement

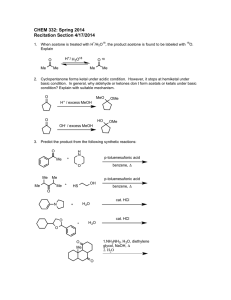

Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 ( AL -2Cu – 2Mg ) (3%HCl)) (Al-2Cu-2Mg) (30,40,50,60,70,80C°) ( (600X) ) ( (170°C) (45min.) (500C°) (3hr.) (500C°) (12) (80) (30) (24) (80) (30) (180) 443 ( AL -2Cu – 2Mg ) The Effect of Temperature On The Corrosion Behavior of (Al-2Cu-2Mg) Alloy In The Acidic Solution . Zuheir Talib Khulief Al-Tai Babylon University/College of Eng. Mat. Eng. Dep. Abstract: This study deals with the effect of temperature on the corrosion behavior of Al2Cu-2Mg) alloy by using simple immersion in acidic solution((3% HCl) by volume) at (30,40,50,60,70,80C°). The weight change method and microscopic examination are used in this study. Alloy without treatment, Solution heat treated at (500C°), Artificial aged at (150C°) are used to complete this study. The result of effects of temperature on the corrosion behavior of alloy in acidic solution showed a continuous increasing in corrosion rate with increase the temperature of solution. The result showed that the solution-treated alloy have the lowest weight losing compared with the untreated and artificial aged alloys where the last one show a mid stat between the other states. In the other hand the results of Arrhenius equation and the Arrhenius plots showed the rate of corrosion of the solution heat treated alloy increase ( 12 ) time when increase the temperature from (30C°) to (80C°) , the rate of corrosion of the artificial alloy increase ( 24 ) time when increase temperature in the same range above , and the untreated alloy appears high increase in corrosion rate ; the rate of corrosion increase ( 180 ) time when increase the temperature from (30C°) to (80C°) . The solution heat treated alloy submit to the Arrhenius equation while the untreated alloy and the artificial alloy not submit to the Arrhenius equation. (Corrosion theory and Corrosion Protection ,EM1110 – 2-3400, Apr – 1995) ( Pierre R. Roberge,2000) 444 Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 ( Vanhile P. and Tosto S.,1992 ) (Eiji Akiyama , K . Asami ,2000) ( Al – Cr ) ( Al – Ti ) ( Al – Cr ) ( Al – Ti ) ( Ni,Mo ) (Al-Ti) ( Al-Ti-Ni ,Al-Cr- ( Mg) (1M HCl ) (0.075M Na2B4O7+0.3M H3BO3+0.5M Ti ,and Al-Cr-Mo ) (Al-Ti-Mg ) NaCl ) (D. A. Little and J. R. Scully ,2001) ( C416 - C415 ) (Al-Cu-Mg-Ag) (SCC) (99.99) (0.006 – 0.06 M) (NaCl) (C416) (C415) (99.99) ( D.Bengtsson Blucher, J. E. Svensson and L.G. Johansson ( NaCl ) , 2002 ) ( AA1070 ) ( 4, 10 ,22 ,38 ,50, 60 C° ) 445 ( AL -2Cu – 2Mg ) ( 14-70 mg/cm2 NaCl ) ( 4 C° ) ( 10,22,38 C° ) ( 5-20 ) ( 38 C° ) ( 350 ppm ) ( 60 C° ) (H. N. Mcmurray, G.- Williams ( and S. O. Driscoll ,2002 ) ( AA2024T3 ) SrCrO4 ) ( 0.5 mol dm-3) ( ( HCl ) ( 93%RH ) ( 20 C° ) HCl ) ( 9.24h,12h,23.30h,30.41h,37.4h,46.17h,54.22h ) (0%,1vol%,5vol% ) ( HCl ) ( Passivation ) (Ingrid Rink and D. Martin Knotter,2003 ) ( 0.4% Cu ) (DS,XDS ) (8.4%H2SO4,3.8%H2O ) (8.4% (DSPH) (DSP) ( 8.4%,5% H2SO4 ) H2SO4,0.5%H3PO4 ) ( 75 C° ) ( 30 C° ,35 C° , 45 C° ) ( 30,45 C° ) ( XDS ) ( 35,45 C° ) 446 (DSPH) Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 ( 35,45 C° ) ( 45 C° ) ( Al , 0.4% Cu ) ( DSPH,XDS,DS ) ( 35 C° ) ( DSP ) Al-2Cu-2Mg ( 30,40,50,60,70,80C° ) ( Arrhenius Plots ) (Al-2Cu-2Mg ) 1 2000 2004 2002 Heater RT-1000ºC -1 -2 4-5 447 ( AL -2Cu – 2Mg ) -3 300-400ºC 15mm (Sola Basic S.B Lindberg 500ºC 200-1200ºC 2 ( ( 30 , 40 ,50 , 60 ,70 ,80 C° ) Jacob White ,Jw- England ) ( Arrhenius ) HERGON-mp200V Al–2Cu–2Mg 448 Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 500ºC 45min ( 3 hr. ) MLW 170 ºC (3% HCl ) ( Jacob White ,Jw- England ) (30,40,50,60,70,80C°) 0.0001 Sartorius ( 30 ,40 ,50 ,60 ,70 ,80 C° ) ( Arrhenius Plots ) ( union ME-3154 ) (600 X) 449 ( AL -2Cu – 2Mg ) (1) (3%HCl) (30,40,50,60,70,80C°) (50C°) (30,40C°) S,θ HCl (0.036 α (R.G.Buchheit, R.K.Boger, M.W.Donohue ,2001 ) (2) (0.0002 g/cm2.hr.) (180) (80) g/cm2.hr) (30) (3) (4) (4) (80C°) (5) (45min.) (500C°) (30,40,50,60,70,80) (30,40,50C°) θ (Al2Cu) ,S(Al2Cu Mg) 450 Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 (αss) (R.G.Buchheit,R.K.Boger,M.W.Donohue,2001,R.G.Buchheit, (6) R.K.Boger,2002) (12) (0.0024) (0.0002) (500Cº) (7) (8) ( 45 min.) (80C°) (8) (9) (3hr.) (170C°) (30,40,50,60,70,80C°) (60) (60) S" , S' (80) 3hrs. S(Al2CuMg) S",S' (10) (0.0002) 451 ( AL -2Cu – 2Mg ) (24) (3hr.) (0.0048) (170C°) (11) (12) (12) (13) (30,40C°) (14) 452 ( 80C° ) Zuheir Talib The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 (180) (12) (80C°) (30C°) (24) Corrosion theory and Corrosion Protection ,EM1110 – 2-3400, Apr – 1995 , http : // www.tankspan.com / safety – miscellaneous.htm1. D.A.Little and J. R. Scully, “An Electro Chemical Framework to Explain the Intergranular Stress Corrosion Path of two Al–Cu–Mg–Ag Alloys , C415 and C416” , PDF, 2001. D.Bengtsson Blucher, J.E.Svensson and L. G. Johansson," The NaCl – Induced Atmospheric Corrosion of Aluminum; the Influence of Carbon Dioxide and Temperature", PDF ,2002 . Eiji Akiyama, K. Asami and other, “Enhancement of Corrosion Resistance of Amorphous Aluminum alloys by Alloying Additions”, pdf, 2001 H.N .Mcmurray, G. Williams and S. O. Driscoll , "Chromate Inhibition of Filiform Corrosion on Organic Coated AA2024T3 Aluminum Alloy Investigated using a Scanning Kelvin Probe" , PDF .2002 . Ingrid Rink and D. Martin Knotter, "Passivation of Aluminum and Aluminum – Copper Alloys in Aqueous Acids", PDF, 2003. N.Barrngton & M.Black, “Aerospace materials and manufacturing processes at the millennium” On the web: http:// bookmark physics.iop.org/full books/0750307420/ cantorch 01.pdf. 453 ( AL -2Cu – 2Mg ) R.G.Buchheit, R.K.Boger, M.W.Donohue, "Copper Dissolution Phenomena in Al-Cu and Al-Cu-Mg Alloys", 2001. On the web:http//www.mse.ohiostst.edu/%7Ebruedigm/RGB02.pdf R.G.Buchheit, R.K.Boger, "Cu Redistribution and Surface Enrichment Due to Dissolution of Al-Cu Alloys", 2002. On the web:http//www.mse.ohiostst.edu/%7Ebruedigm/RGB03.pdf Pierre R. Roberge , " Hand book of Corrosion Engineering ", 1stEd., 2000. Vanhile P. and Tosto S. ," Surface and Coatings Technology ", N (80),PP(295303),1992. (1). ALLOY Al -2Cu – 2Mg Al 96 % wt Cu 2 % wt Mg 2 % wt 2 3% HCl 1 mm 2 mm 15 mm 3% HCl 1 mm 1.5 mm 15 mm 3% HCl 1 mm 1.5 mm -1.0 15 mm 0.1000 ) Weight loss ( g.cm Log C.R ( g /cm .hr ) -1.5 -2.0 -2.5 -3.0 0.0100 0.0010 0.0001 -3.5 -4.0 0.0000 0.010 0.015 0.020 0.025 0.030 0.035 1/T ( 1/C ) ( انعالقت بيه نوغاريتم معدل انتآكم2) انشكم ( نعينت3%HCl) ودرجت حرارة انوسط انتاكهي .غير معامهت حراريا454 20 30 40 50 60 70 80 90 Tempreature ( C ) ( انعالقت بيه انوزن انمفقود نوحدة1) انشكم (3%HCl) انمساحت ودرجت حرارة انوسط انتاكهي .نعينت غير معامهت حراريا The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 انشكم ) (3طبوغرافيت سطح عينت غير معامهت حراريا بقوة تكبير )(600X Zuheir Talib انشكم ) (4طبوغرافيت سطح عينت غير معامهت حراريا معرضت نوسط انتاكهي ) (3%HClفي درجت حرارة )(80C° بقوة تكبير )(600X 0.0100 -2.50 -2.75 ) Weight loss ( g/cm 0.0001 -3.25 -3.50 -3.75 0.0000 90 80 70 60 50 40 30 20 -4.00 0.03 0.04 ) Tempreature ( C انشكم ) (5انعالقت بيه انوزن انمفقود نوحدة انمساحت ودرجت حرارة انوسط انتاكهي ) (3%HClنعينت معامهت محهونيا بدرجت )(500C° 0.03 0.02 0.02 0.01 ) 1/T ( C انشكم ) (6انعالقت بيه نوغاريتم معدل انتآكم ودرجت حرارة انوسط انتاكهي ) (3%HClنعينت معامهت محهونيا بدرجت ).(500C° 455 ) Log C.R ( mg/cm .hr 0.0010 -3.00 ) ( AL -2Cu – 2Mg انشكم ) (8طبوغرافيت سطح عينت معامهت محهونيا بدرجت ) (500C°معرضت نوسط تآكهي )(3%HCl في درجت حرارة) (80C°بقوة تكبير )(600X انشكم ) (7طبوغرافيت سطح عينت معامهت محهونيا بدرجت ) (500C°بقوة تكبير )(600X 0.010 ) Weight loss ( g/cm 0.000 -2.50 -3.00 -3.50 -4.00 0.000 90 80 70 60 50 40 30 20 0.04 ) Tempreature ( C انشكم ) (9انعالقت بيه انوزن انمفقود نوحدة انمساحت ودرجت حرارة انوسط انتاكهي ) (3%HClنعينت معتقت اصطناعيا بدرجت )(170C° 0.03 0.03 0.02 0.02 0.01 ) 1/T ( 1/C انشكم ) (10انعالقت بيه نوغاريتم معدل انتآكم ودرجت حرارة انوسط انتاكهي ) (3%HClنعينت معتقت اصطناعيا بدرجت ).(170C° 456 ) Log C.R ( mg/cm .hr 0.001 -2.00 The Iraqi Journal For Mechanical And Material Engineering, Vol. 9,No. 3, 2009 Zuheir Talib انشكم ) (12طبوغرافيت سطح عينت معتقت اصطناعيا بدرجت ) (170C°معرضت نوسط تآكهي ) (3%HClفي درجت حرارة) (80C°بقوة تكبير )(600X انشكم ) (11طبوغرافيت سطح عينت معتقت اصطناعيا بدرجت ) (170C°بقوة تكبير )(600X -1 ( 3% Hcl ) Solution 0.01 Untreated 0.00 3% Hcl solution ) Weight Loss ( g/cm 0.00 -2 ) Artificial Aged at ( 170 C -3 Untreated ) Solution Heat Treated at ( 500 C ) Artificial Aged at ( 170 C -4 0.00 80 90 70 60 50 40 30 0.040 20 0.020 0.030 0.010 ) 1/T ( C ) Tempreature ( C انشكم ) (13انعالقت بيه انوزن انمفقود نوحدة انمساحت ودرجت حرارة انوسط انتاكهي )(3%HCl انشكم ) (14انعالقت بيه نوغاريتم معدل انتآكم ودرجت حرارة انوسط انتاكهي ). (3%HCl . 457 ) Log C.R ( g/cm .hr ) Solution Heat Treated at ( 500 C ( AL -2Cu – 2Mg ) 458