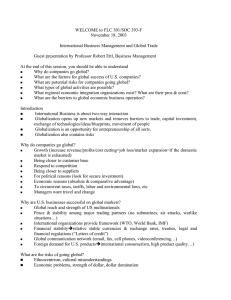

Low-wage Import Competition, Product Switching and Performance of

advertisement