MAXIMISING THE EFFICIENCY OF A HUGH PIGGOTT STYLE WIND TURBINE

advertisement

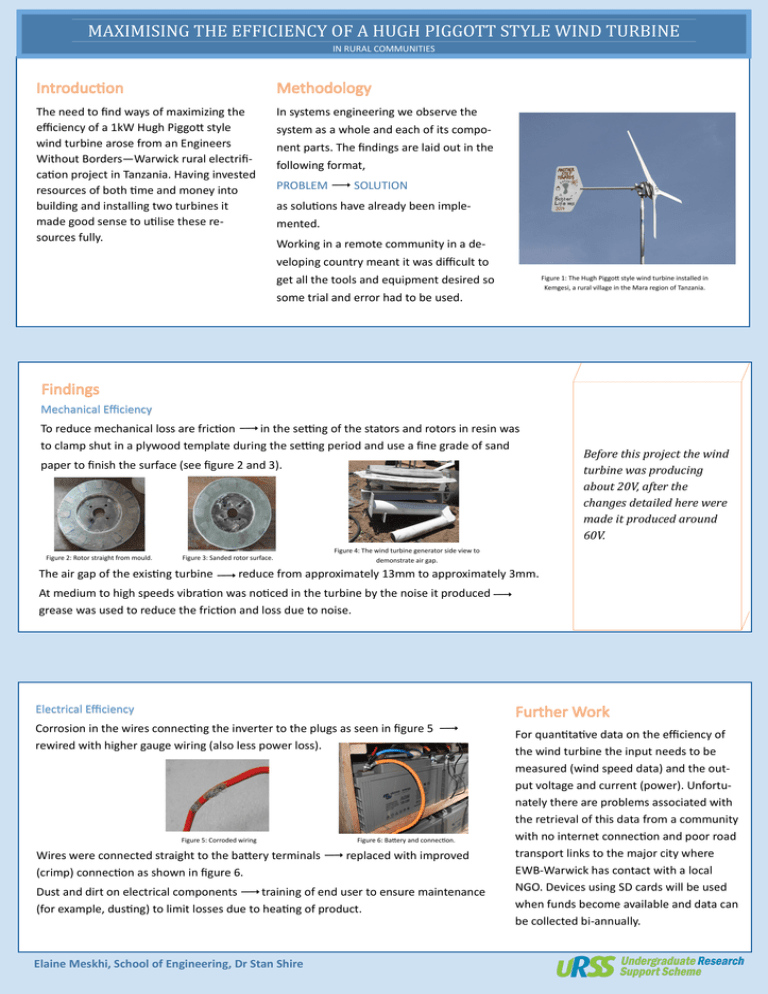

MAXIMISING THE EFFICIENCY OF A HUGH PIGGOTT STYLE WIND TURBINE IN RURAL COMMUNITIES The need to find ways of maximizing the efficiency of a 1kW Hugh Piggott style wind turbine arose from an Engineers Without Borders—Warwick rural electrification project in Tanzania. Having invested resources of both time and money into building and installing two turbines it made good sense to utilise these resources fully. In systems engineering we observe the system as a whole and each of its component parts. The findings are laid out in the following format, PROBLEM SOLUTION as solutions have already been implemented. Working in a remote community in a developing country meant it was difficult to get all the tools and equipment desired so Figure 1: The Hugh Piggott style wind turbine installed in Kemgesi, a rural village in the Mara region of Tanzania. some trial and error had to be used. Mechanical Efficiency To reduce mechanical loss are friction in the setting of the stators and rotors in resin was to clamp shut in a plywood template during the setting period and use a fine grade of sand paper to finish the surface (see figure 2 and 3). Figure 2: Rotor straight from mould. Figure 3: Sanded rotor surface. The air gap of the existing turbine Before this project the wind turbine was producing about 20V, after the changes detailed here were made it produced around 60V. Figure 4: The wind turbine generator side view to demonstrate air gap. reduce from approximately 13mm to approximately 3mm. At medium to high speeds vibration was noticed in the turbine by the noise it produced grease was used to reduce the friction and loss due to noise. Electrical Efficiency Corrosion in the wires connecting the inverter to the plugs as seen in figure 5 rewired with higher gauge wiring (also less power loss). Figure 5: Corroded wiring Wires were connected straight to the battery terminals (crimp) connection as shown in figure 6. Figure 6: Battery and connection. replaced with improved Dust and dirt on electrical components training of end user to ensure maintenance (for example, dusting) to limit losses due to heating of product. Elaine Meskhi, School of Engineering, Dr Stan Shire For quantitative data on the efficiency of the wind turbine the input needs to be measured (wind speed data) and the output voltage and current (power). Unfortunately there are problems associated with the retrieval of this data from a community with no internet connection and poor road transport links to the major city where EWB-Warwick has contact with a local NGO. Devices using SD cards will be used when funds become available and data can be collected bi-annually.