Mansour Al.Haddabi

advertisement

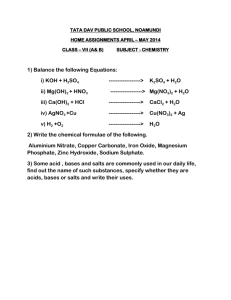

Mansour Al.Haddabi Water Sources Produced Water: A new Source Ceramic membrane Possibilities Conclusion Red/Orange –Scarcity Tan –Stress Blue –Sufficient Water The water that is trapped in underground formation and brought to the surface along with the oil and gas production PDO currently produces 7.5 barrels of water for a barrel of oil H2O H2O OIL H2O H2O H2O H2O H2O H2O H2O Dissolved and dispersed oil components Dissolved minerals Production chemicals Production solids Dissolved gases Minimize the volumes of water produced by adopting proper reservoir and well management Inject the water to oil producing formations or reservoirs Discharging it to the environment after it complies with the discharge regulations. Consume in Beneficial use: treat to meet quality required for beneficial uses like irrigation, land restoration, cattle and animal consumptions and industrial application Along with oil PDO produces about 5 million barrels of water per day Salinity ranging from 5000-200000 mg/l Oil content range from 100-1000 mg/l The produced water is utilized for reservoir's pressure maintenance by injection into shallow and deep sub-surface formations The disposing of the produced water is expensive Environmental regulations are becoming more stringent Reuse potential of produced water needs investigations De-oiling: removing dispersed oil and grease Soluble organics removal Disinfection: removing microorganisms Removal of SS Removal of dissolved gases Desalination or demineralization Softening (removal of excess hardness) Miscellaneous: removing NORM Physical processes: Such as cyclones, API, CPI, sand filters, Electrodialysis and DAP Chemical Processes: chemical oxidation, electrochemical processes, photocatalytic and ozone Biological Processes: the use of aerobic and anaerobic microorganisms High cost of treatment The use of toxic chemicals Space for installation Secondary pollution New class of materials made from clays of nitrides, carbides and oxides of metals. It can operate in both cross-flow filtration and dead-end filtration modes Lifespan > 10 years The ability to accomplish the current regulatory treatment objectives without chemical pre-treatment Thermal stability Ease of scale up, low running investment and small area requirements Resistance to solvents, chemicals and thermal stress allows good recovery of membrane performance Mechanical strength and long life-time Membrane cleaning with harsh chemicals (if necessary) does not reduce membrane performance stability It has higher fluxes and higher oil rejection due to their high porosity and more hydrophilic surface, compared to polymer membranes . They are operational in pH-range from 1-14. Therefore, cleaning is not an issue. High oil removal efficiency Low energy requirements Effect of TMP on Permeate Flux (CFV: 1.68 mS-1) TMP (MPa) Flux (Lm-2h-1) TOC removal efficiency (%) 0.05 30 97.3 0.1 70 97 0.15 110 95.2 0.2 170 93 (Edible oil mixed with water and surfactant) Effect Of CFV on permeate Flux (TMP: 0.2 MPa) CFV (mS-1) Flux (Lm-2h-1) TOC removal efficiency (%) 0.17 0.42 0.8 1.7 122 135 140 165 97.5 97.4 97.5 97.4 Parameter Unit Feed Treated wastewater by using tubular ceramic MF (α-Al2O3) Total Suspended Solids (TSS) mg/l 92 Trace Oil and grease content mg/l 26 4 Total Organic Carbon (TOC) mg/l 141 7 Turbidity mg/l 21 0.3 (TMP: 1.25 bar, CFV: 2.25 mS-1and T: 32.5 oC). API effluent of refinery. Agricultural Use Solar Ponds Aquaculture, Brine Shrimps Mineral Recovery High value salts, Fertilizers Magnesium metals and Alloys Fire retardants Building Products Sealant and Flocculating agents Greening the desert Agroforestry Forage production Biofuel Oil recovery Other benefits: Carbon credit Energy savings Livestock drinking water ( possible up to 7000 ppm) Irrigation: salinity, SAR, Boron Salt tolerant plants and trees are available and have been tested under Omani conditions Poor land restoration Possibilities exists for using water as a resource Field research is urgently needed Firm government decisions on its use such as forge production, growing trees, subsidies, ownership, aquifer storage Further research on low cost membrane treatment Water Management decisions have a very significant impact on project economics How clean should be the water? Controls the design of the treatment facility Injection rates and pressure Produced water can be a potential source to solve the water scarcity (if treated well!!)