Recycled Unbound Materials

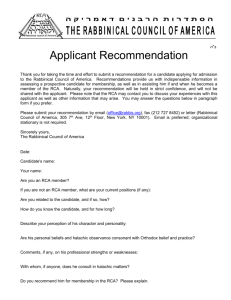

advertisement