MODULE DESCRIPTOR Code: Alt Codes: Title:

advertisement

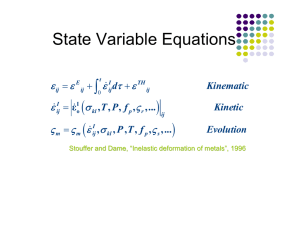

MODULE DESCRIPTOR MECH105P - Fundamentals of Materials Code: MECH105P Alt Codes: None Title: Fundamentals of Materials Level: 1 UCL Credits/ECTS: 0.5/7.5 Start: January End: April Taught by: Dr Adam Wojcik Prerequisites: None. Course Aims: To present students with the major theoretical concepts associated with materials science, such as bonding, atomic and molecular structure, phase equilibria, crystallography, and dislocation theory, so that a strong understanding of the relationship between structure and properties in materials can be developed. To define and understand the levels of structure inherent in materials, ranging from atomic and crystalline, through to micro and macro-structure. To qualify and quantify the principal parameters (such as strength and toughness) used to characterise the mechanical behaviour of materials and to present and develop some of the principal methods and analyses associated with the measurement of mechanical behaviour of engineering materials when under load, both in the elastic and plastic regimes. To develop an understanding of how properties can be optimised and changed (particularly strength) and how engineers can best work at the microstructural level to do this, particularly via manufacturing processes. The survey and introduce principal manufacturing processes used for engineering materials within a context of the structure-property-processing triad that is central to materials science and engineering. Method of Instruction: Traditional lectures for the majority of the theoretical content covering materials basics. Structured laboratory sessions (3 off) which combine tutorial/lecture content with hands-on observation and property characterization with brief write ups. A range of coursework submissions which aim to promote self-study and bookwork associated with the lab-sessions, only one of which is a conventional lab report. As part of the MECH102P Mechanical Engineering Practical Skills I all first year students will have had a hands-on workshop practice sessions to cover major manufacturing processes used for principal engineering materials categories. This module will build on this experience as well as that gained in the scenarios from Design and Professional Skills ENGS102P. Materials & Manufacturing case study based project (group based) to aimed at understanding link between materials, manufacturing and design. Significant report expected. On-line e-resource to support manufacturing project outlining techniques in use for common engineering materials. In third term, exam timetable permitting, 2 hours revision lectures. Assessment: Exam (70%) Case study (15%) Lab report (15%) (3 x 5) Lab coursework Lab sheet To pass this course, students must: Obtain an overall pass mark of 40% Content: General: Basic definitions and fundamental properties important to the mechanical engineer. Bonding. Solids. Alloys: including phase diagrams, analysis of the Pb-Sn, relationship between mechanical properties and the phase diagram. Steel. An introduction to Polymers including glass. A basic introduction to crystallography. Deformation: The concepts of slip, critical resolved shear stress and dislocation. Increasing strength: Mechanisms of strengthening of materials and the role of dislocation movement. Review and summary of major manufacturing processes. General Learning Outcomes: Knowledge and Understanding A basic understanding of the level of structure within materials right down to the atomic level. A sound knowledge and understanding of the structure-property relationships present in materials. An understanding of the categories and importance of mechanical properties. A basic knowledge of manufacturing methods and their use in modern systems and components and which methods are appropriate to which materials.