Department of Materials Science and Engineering Massachusetts Institute of Technology

advertisement

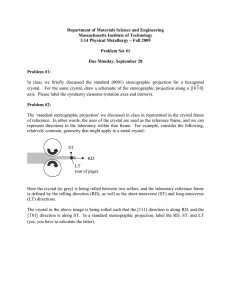

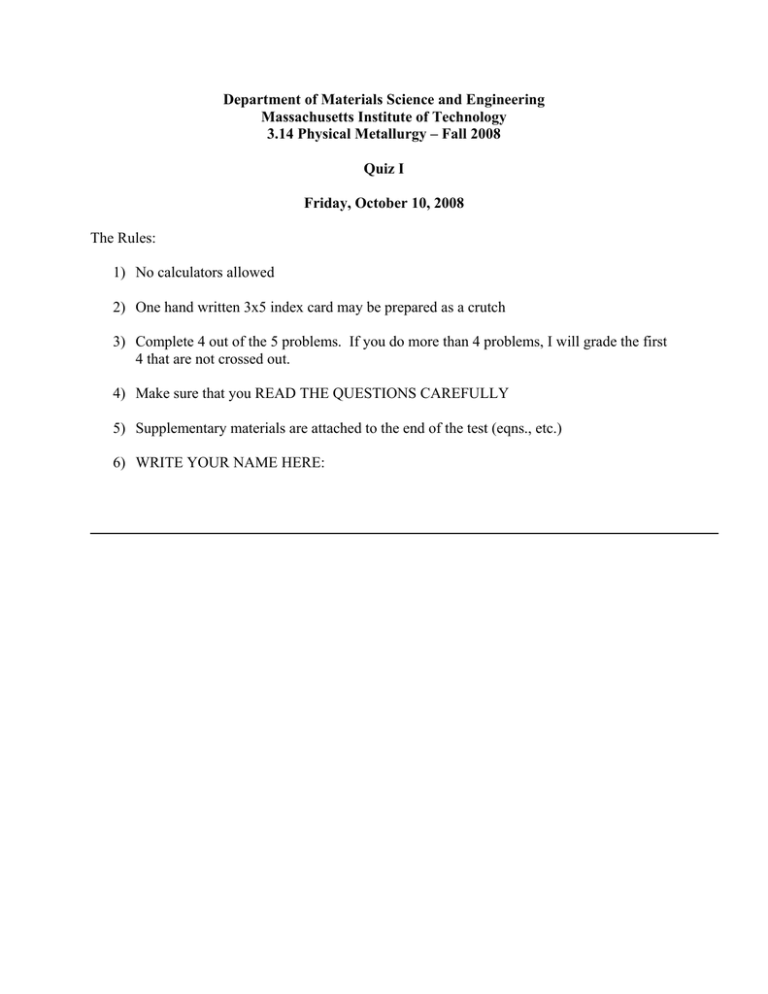

Department of Materials Science and Engineering Massachusetts Institute of Technology 3.14 Physical Metallurgy – Fall 2008 Quiz I Friday, October 10, 2008 The Rules: 1) No calculators allowed 2) One hand written 3x5 index card may be prepared as a crutch 3) Complete 4 out of the 5 problems. If you do more than 4 problems, I will grade the first 4 that are not crossed out. 4) Make sure that you READ THE QUESTIONS CAREFULLY 5) Supplementary materials are attached to the end of the test (eqns., etc.) 6) WRITE YOUR NAME HERE: Problem #1: Superdislocations! In pure metals there is only one kind of atom, and the Burger’s vector is therefore always one atomic spacing. What about in a chemically ordered, two-component solid (for example, NaCl, SiC, CuAu)? Here is a 2-D picture of an ordered solid. Part A: Draw a 2-D picture of a full edge dislocation in such an ordered solid. (Reminder- a full edge dislocation leaves the crystal undisturbed far away from the core) Part B: Draw a Burger’s circuit around your full edge dislocation and label the Burger’s vector. Part C: Do you think that this full dislocation would like to dissociate? Describe the forces/energetics involved in the choice of whether dissociation occurs or not. If yes, explain why and draw a picture of it. If no, explain why not. Problem #2: FCC or BCC? Three different crystals, all of which are cubic (either FCC or BCC) are strained, and the orientation of the crystal is tracked. Each of them is strained in compression. In the stereographic projections below, the results of these tests are shown. Identify whether you think the crystal is FCC or BCC, and explain briefly why in each case. Problem #3: Unphysics Each of these scenarios is unphysical. Explain what is wrong in each case, and correct it to make it physically correct. In each drawing, the arrow denotes the Burger’s vector. A) The small crystal at the left is stressed as shown. One dislocation moves to the right, intersecting another dislocation and leaving the structure shown at the right. B) A single crystal is loaded in tension, and slip happens on two planes as shown. Dislocations run into each other and form a Lomer lock on the red line. C) In the microscope, a dislocation loop is observed. The Burger’s vector is not known. Over time, the loop expands spontaneously with no external load applied to the sample, due to the repulsive forces exerted by different parts of the loop on one another. D) A small crystal contains a bunch of parallel dislocations, and is strained in tension. The dislocations move in the directions shown by the red arrows. The Burger’s vectors are shown by the black arrows ┴ ┴ ┴ S~ Problem 4: Wherein the Student Demonstrates Knowledge of Both the Stereographic Projection and Inter-Dislocation Forces Here are two dislocations in a crystal. The coordinate system is defined to lie on one of them, as shown. They lie in different planes. y Now, notice that for the right dislocation, the Burger’s vector is defined—it is a screw dislocation. For the dislocation on the left, the Burger’s vector is undefined. It can lie in any direction. In fact, it could lie anywhere on the stereographic projection. y z x x z Part A: Allow the Burger’s vector of the left dislocation to vary over the stereographic projection at the left. On the projection, indicate how the interactive forces between the dislocations change with position in the projection. More specifically, draw in regions where the dislocations would be attracted to each other, repulsed from one another, or non-interacting. Part B: y z x Now add some more details to the projection: for regions where the dislocations are attracted or repelled, please mark regions of the diagram in which they will actually move in response to the interaction, and regions in which they will not move despite the forces they feel. A second copy of the diagram is provided if you need extra/clean space to work. Problem 5: Frank-Read Redux A dislocation segment is pinned at two pinning points, and is experiencing external stress that encourages bowing. Its Burger’s vector is shown. This is the situation we covered in class that led to the Frank-Read Source. partials Full Burger’s vector Projection view Top down view Consider what happens if this is not a full dislocation, but rather is split into partials. For the full dislocation, the bowing goes until a local annihilation event occurs. How does this annihilation look for the dissociated dislocation? Draw some pictures and briefly walk though the sequence of events. Helpful (?) Bonus Information Stress field around an edge dislocation: σ xx = − σ yy = σ xy = μb y(3x 2 + y 2 ) 2π (1−ν ) (x 2 + y 2 ) 2 μb y(x 2 − y 2 ) 2π (1 −ν ) ( x 2 + y 2 ) 2 μb x(x 2 − y 2 ) 2π (1−ν ) (x 2 + y 2 ) 2 σ zz = ν (σ xx + σ yy ) all other σ components are = 0. Stress field around a screw dislocation: σ rz = μb 2πr all other σ components are = 0, and note that r2 = x2+y2 Forces between dislocations: Parallel edge: μb 2 y(3x 2 + y 2 ) Fy = 2π (1 − ν ) (x 2 + y 2 ) 2 μb 2 x(x 2 − y 2 ) 2π (1 − ν ) (x 2 + y 2 ) 2 Parallel screw: μb 2 Fr = 2πr Fx = Inspirational Quote: “The dislocation plays a commanding role in those grandest of all deformations on Earth: the upheavals that have produced the mountain ranges and the continents themselves” Johannes and Julia Weertman, pioneers in dislocation theory, 1964 9/21/2009 023 012 113 011 001 014 013 104 103 114 113 123 014 013 012 023 114 113 123 011 102 213 112 032 133 203 122 132 101 313 021 212 021 132 212 111 111 121 031 031 121 312 313 302 312 131 131 201 221 211 041 041 211 231 221 141 141 231 311 301 311 401 331 321 321 331 110 120 140 140 120 110 210 410 100 410 210 010 010 310 320 230 130 130 230 320 310 311 321 331 331 301 231 231 311 141 211 321 141 221 041 201 221 041 211 131 131 312 302 312 031 121 031 121 111 313 101 212 111 132 132 021 212 313 021 122 122 213 203 133 032 032 213 112 112 133 102 113 113 123 103 123 011 011 114 104 114 023 023 012 012 013 013 014 014 001 133 122 032 112 213 Figure by MIT OpenCourseWare. 112 123 213 011 023 132 331 221 121 113 114 012 013 104 014 123 203 103 101 102 001 114 113 313 213 312 212 211 112 311 113 114 104 014 411 103 114 013 141 111 123 111 213 231 321 012 212 102 113 221 023 221 122 313 203 112 331 133 331 312 123 213 011 132 101 321 313 121 211 133 032 231 212 302 122 201 312 110 111 132 021 110 311 131 320 031 301 121 411 401 211 221 131 041 141 230 310 311 141 410 120 140 411 321 331 231 210 130 310 320 110 120 140 100 010 410 141 411 231 321 230 130 210 131 411 141 041 411 321 331 401 231 311 311 131 031 301 121 211 221 211 121 021 201 131 112 312 302 101 312 212 313 213 111 114 132 221 113 112 032 132 331 011 123 Figure by MIT OpenCourseWare. 4 MIT OpenCourseWare http://ocw.mit.edu 3.40J / 22.71J / 3.14 Physical Metallurgy Fall 2009 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.