A novel chemical additive for in-situ recovery of heavy oil... flooding process water Omid Mohammadzadeh

advertisement

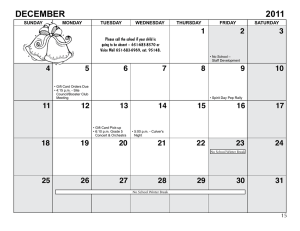

Journal of Petroleum Science and Engineering 135 (2015) 484–497 Contents lists available at ScienceDirect Journal of Petroleum Science and Engineering journal homepage: www.elsevier.com/locate/petrol A novel chemical additive for in-situ recovery of heavy oil using waterflooding process Omid Mohammadzadeh a,n, Ioannis Chatzis b,1, John P. Giesy c,d,e,f a DBR Technology Center – Schlumberger, Edmonton, AB, Canada Department of Chemical Engineering – University of Waterloo, Waterloo, ON, Canada c Department of Veterinary Biomedical Sciences and Toxicology Centre – University of Saskatchewan, Saskatoon, SK, Canada d Department of Zoology and Center for Integrative Toxicology – Michigan State University, East Lansing, MI, USA e School of Biological Sciences – University of Hong Kong, Hong Kong, China f State Key Laboratory of Pollution Control and Resources Reuse, School of the Environment, Nanjing University, Nanjing 210046, PR China b art ic l e i nf o a b s t r a c t Article history: Received 10 June 2015 Received in revised form 29 September 2015 Accepted 8 October 2015 Chemical-assisted waterflooding is injection of specialty chemical(s) along with water to enhance the productivity through a series of mechanisms. There are several mechanisms responsible for increased ultimate recovery of such a process compared to the traditional waterflooding process including in-situ emulsification of oil, conformance control and treatment of adverse mobility ratio, reduction of Interfacial Tension (IFT) between the in-situ oil and the injecting phase, and wettability modification to facilitate recovery of oil by enhanced relative permeability values. Although chemical-assisted waterflooding has been applied since the early 20th century, it has not been until recently that applicability of this process has been tested for recovery of heavy oil using preliminary macro-scale as well as pore-scale studies. A new chemical technology (i.e. IPC Technology as referred in this paper) has been developed. A proprietary mixture of surfactants is used in several techniques associated with surface extraction as well as in-situ recovery of heavy oil and bitumen. This formulation of solvents and surfactants is reusable, low foaming, non-flammable, not acutely toxic and non-carcinogenic. A systematic study, based on a series of coreflood tests, was designed and conducted to assess efficacy of IPC in the ultimate recovery of different types of oils by use of IPC-assisted waterflooding. Effects of IPC on IFT between oil and IPC solutions at different brine salinities/hardnesses and IPC concentrations were determined. Compatibility of IPC with different brine hardnesses and salinities was determined. IPC technology was particularly effective in recovering heavy oil. The performance of IPC as an additive during waterflood at elevated temperature for recovery of heavy oil was also investigated. For this particular purpose, thermal stability tests were conducted to determine the threshold temperature below which the formulation is thermally stable. When production performance of IPC-assisted waterflood was compared with alkali flooding and a commercial surfactant, IPC gave superior ultimate recovery. & 2015 Elsevier B.V. All rights reserved. Keywords: Chemical-assisted waterflooding Coreflood Interfacial tension Salinity Thermal stability 1. Introduction A recent estimate of recoverable oil and bitumen, using primary and commercially-proven Enhanced Oil Recovery (EOR) technologies in Canada, is about 178 billion barrels, with oilsands production contributing about 85% to the total (NEB, 2006). Although these are significantly large reserves, they are considered to be only a fraction of the total available resources, which is estimated to be more than 1.5 trillion barrels (NEB, 2004). The n Corresponding author. E-mail address: omohamma@uwaterloo.ca (O. Mohammadzadeh). 1 Present address: Kuwait University, Kuwait. http://dx.doi.org/10.1016/j.petrol.2015.10.009 0920-4105/& 2015 Elsevier B.V. All rights reserved. largest deposits are located in the Western Canada Sedimentary Basin (WCSB). The significant difference between recoverable reserves and available in-situ resource estimates is the amount of oil and bitumen for which there is no proven, commercially viable EOR technology for extraction. Chemical flooding is an EOR technique that involves injecting slugs of dilute chemicals into a formation to increase microscopic (i.e. pore-level) and macroscopic (i.e. sweep) efficiencies of the displacement process. Three main classes of chemicals are typically used: (1) alkalis; (2) surfactants and (3) polymers. Several other types of chemicals, such as scale inhibitors and co-solvents, can also be added to the formulation if necessary. Each class of chemical has a different primary purpose when added to the O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 formulation of the chemical “slug” injected. The main purpose of adding alkali to the injected water is to generate surfactants in situ upon contact with the reservoir oil through saponification of the natural acids that exist in the oil phase. Surfactants, added at the surface or generated in situ, reduce IFT between oil and water, hence mobilizing the oil phase which is trapped in porous media by capillary forces. The concentration of active surfactants in the injected water is usually between 0.05 and 2 wt%, depending on the type of chemical, its cost and design parameters of the EOR process. It is typically necessary to reduce IFT by three to four orders of magnitude, attaining 10 2–10 3 mN/m, to achieve significant reduction in residual oil saturation. At least two other mechanisms, not directly related to reduction of IFT, can also contribute to increasing recovery of oil by use of flooding with surfactants. Wettability modification and in-situ emulsification of oil as a result of the presence of chemical provide flow conformance and favorable mobility ratios especially when more viscous oils comprise the displaced phase. Sandstone reservoirs are typically naturally water-wet. However, sandstone formations containing heavy oil are often found to have neutral or mixed wettability. Some chemicals have the ability to change the wettability of formation rock through chemical reactions, ion exchange or adsorption mechanisms. Changes in wettability lead to changes in the pore-scale fluid distribution patterns and relative permeability to oil and water, and often results in re-mobilizing previously trapped oil. In-situ emulsification of oil can also reduce the residual oil saturation, hence facilitates increased oil flow towards the production wells (Chatzis et al., 1983; Somasundaran and Hanna, 1979; Johnson, 1976; Mayer et al., 1983; Shah et al., 2010). Initial wettability of the porous structure and any further changes due to the presence of surface active agents in the chemical flood significantly affect performance of EOR processes (Morrow , 1990). Vijapurapu and Rao (2003) performed an experimental study on the effect of chemical flood and brine on spreading and adhesion behavior of the crude oil on dolomite surfaces. Anionic surfactants change the wettability of the calcite surface to intermediate/water-wet condition compared to that of the cationic surfactants (Seethepalli et al., 2004). Mechanisms responsible for changes in wettability have been described following a chemical EOR process in carbonates (Wu et al., 2006). Effect of pore wettability on pore-scale mechanisms of oil recovery as well as on the topology of the trapped wetting and non-wetting phases through dilute surfactant flooding of porous structures have been described with different wettability conditions (Jamaloei and Kharrat, 2010a and 2010b). One limitation of surfactant-based EOR processes is sensitivity to salinity of the reservoir fluids as well as that of the injected flood. Several studies have been performed to study effects of salinity on performance of surfactant flooding. There have also been studies of effects of divalent ions on IFT values (Bansal and Shah, 1978a; Kumar et al., 1984). Effects of optimum salinity and divalent ions on IFT and surfactant phase retention have also been investigated (Bansal and Shah, 1978b; Glover et al., 1979; Gupta and Trushenski, 1979). IFT values were found to be proportional to concentrations of divalent ions in connate water and it has also been demonstrated that optimum salinity is not constant in brines containing divalent ions. Because of interactions between divalent ions and petroleum sulfonates, precipitation followed by re-dissolution of the precipitates at higher concentrations of the surfactant occurred (Celik et al., 1982). Evolution of precipitates, due to contact of petroleum sulfonate with divalent-ions in connate water, might also result in greater recovery factor of the surfactant flooding (Agharazi-Dormani et al., 1990). The objective of this study was to evaluate enhancement of recovery of different types of oil by use of a proprietary chemical 485 additive during waterflooding process. Although different mechanisms contribute to enhanced productivity of chemical-assisted waterflooding, the focus in this paper is on the ability of the IPC formulation to reduce IFT between in-situ oil and the displacing phase. Incremental oil recovery associated with this chemical was also compared against those of two commercial chemical additives through a series of coreflood tests. 2. Materials and methods The IPC formulation (Patent US 2013/0157920 A1) is a proprietary, liquid cleaning, degreasing, and disinfecting concentrate composition, comprised of: (1) caustic soda in a range of about 0.181% to about 5.45% by volume; (2) a de-emulsifier in a range of about 0.028% to about 9.09% by volume; (3) an alkyl glucoside surfactant of about 0.090% to about 7.27% by volume; (4) a phosphated alkyl ethoxylate surfactant of about 0.028% to about 1.81% by volume; (5) a tridecyl alcohol surfactant in a range of about 0.363% to about 9.09% by volume; (6) a non-polar bonding agent of about 0.028% to about 1.81% by volume; and, (7) water forming the remainder percentage by volume. The IPC formulation used as an additive during waterflooding, was characterized to describe its bulk physical properties and partitioning behavior in aqueous and oleic phases, and thermal stability. These tests were complemented with a set of tests to evaluate recovery of different types of oils by IPC-assisted waterflooding. Compatibility of IPC with brines of various salinities and hardnesses was investigated. Interfacial tension between oils and solutions of IPC in brine was measured. Once these parameters had been optimized, a series of 1D coreflood tests were conducted to determine overall effectiveness of IPC in producing the original oil in place (OOIP). 2.1. Physical properties of IPC Density and viscosity of IPC were determined at ambient pressure and three temperatures. To understand how the IPC mixture partitions between aqueous and oleic phases, bench-top volumetric tests at ambient temperature were conducted. For volumetric partitioning tests, measured volumes of heavy oil, deionized water, toluene, and IPC were added to a 100 mL centrifuge test tube and mixed by vigorous shaking until a homogeneous phase was formed, then centrifuged for 30 min. Volumes were measured and photographs were taken. However, the volumetric partitioning tests were inconclusive. 2.2. Thermal stability of IPC The maximum use temperature of a chemical is an approximate threshold temperature value at which it begins to decompose. A series of tests including Thermal Gravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC), Simulated Distillation (SD) and Carbon Number Distribution (CND) determination were used to characterize IPC. The TGA and DSC tests can determine the onset and degree of thermal degradation and the SD test determine the volatility of the chemical. The CND test can determine the range and relative amounts of each carbon unit from C1 to C30 þ (or possibly C60 þ ) in IPC. Since these thermal stability tests cannot determine if the effectiveness of IPC is diminished at elevated temperatures, other tests were used to assess several EOR processes at elevated temperatures. For the purpose of chemical-assisted waterflooding, effectiveness as a function of temperature was assessed based on optimizing parameters such as IFT and coreflood tests. One SD test using a Gas Chromatographic (GC) technique and a CND calculation was attempted in this study. In addition, two TGA 486 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 and two DSC tests were conducted on IPC. For the latter two tests, baseline tests with empty pans and with local carrier water used to manufacture the chemical were also conducted and then used to correct the thermal stability threshold values. Samples were heated from ambient room temperature at a nominal rate of 5 °C/ min. One of the TGA tests and one of the DSC tests were conducted under a Nitrogen atmosphere so that thermal decomposition into volatile constituents by pyrolysis could be detected. The other two tests were conducted under air, and indicated the temperatures at which portions of the sample are oxidized. 2.3. Evaluation of IPC as an additive in waterflooding process using coreflood tests Efficacy of IPC as an additive during waterflooding process was determined using 1D coreflood tests. For this purpose, compatibility of IPC with several mixtures of brine with different ionic concentration/salinity/hardness was studied. Solutions were inspected visually for incompatibility. Samples were stored in an oven at constant temperature and were observed periodically for at least one month. Studies were focused on reduction in IFT between displacing and displaced phases. Therefore, relevant tests were designed and conducted to quantify the effectiveness of IPC in reducing IFT between brine and oil. Three different oils, light oil (A), medium oil (B) and heavy oil (C), were used in this study (Table 1). The reason for testing three types of oil is that IPC, due to its PH, has the potential to interact with components of mediumand high-viscosity oils to further reduce IFT in-situ and this effect can be specific to the type of oil studied. To evaluate stability and integrity of reduction of IFT, these tests were repeated after several durations of ageing. During the oil preparation stage, the dead oil samples were cleaned by centrifugation. The cleaned dead oils were then characterized in terms of density and viscosity at typical reservoir temperature as well as total acid number. For each oil sample, two similar fresh brine solutions, one for IFT test and another for assessing repeatability after ageing, were prepared, followed by making IPC in brine solutions. Three concentrations of IPC (2, 10, and 30 wt%) prepared in a 1 wt% NaCl brine were tested. The IFT values between individual oils and IPC solution in brine were measured by use of the Spinning Drop method. In addition, a baseline measurement of IFT between brine and oil in the absence of IPC was conducted for each oil type using the Pendant Drop technique. All measurements were repeated using the other batch of IPC in brine solution which was aged at constant temperature and the results were compared with the original data obtained using fresh solutions. To evaluate the effect of salinity of brine on reduction of IFT, three additional tests were performed with light oil A by use of a Table 1 Properties of oils used in IFT measurement tests. Density, kg/m3 Viscosity, mPa s Acid number (mg KOH/g) a Measured at 25 °C. Temperature (°C) Light Oil A Medium Oil B Heavy Oil C 15 °C 20 °C 40 °C 806.4 802.7 794.7 948.5 942.1a 932.1 986.9 983.7 971.5 15 °C 20 °C 40 °C 2.37 2.15 1.83 928 737a 150 22,800 12,500 1620 0.07 1.20 1.13 2 wt% IPC in brines with 0.5, 2, and 4 wt% NaCl concentration. Some other additional tests, one with medium oil B and one with heavy oil C, each with 2 wt% IPC solution in 4 wt% brine, were also conducted. Stability of IPC solution in maintaining reduced IFT values and the effect of ageing on reduction of IFT were evaluated by repeating these measurements for medium-viscosity oil B as well as heavy oil C with IPC solutions that had been aged for a period of six weeks. All these measurements were conducted at 20 °C. One dimensional coreflood tests were conducted to assess the effectiveness of the IPC formulation in increasing ultimate recovery of oil through displacement during waterflooding. Five coreflood tests were conducted with a variety of oil types at ambient temperature and one coreflood with heavy oil at an elevated temperature. In the first coreflood test, heavy oil C with the greatest viscosity was used in an IPC-assisted waterflood at 21 °C. In the second coreflood, a commercial alkaline material was used to recover heavy oil C at room temperature (21 °C). In the third coreflood, recovery of heavy oil C with the aid of a commercial surfactant flood was determined at room temperature. Coreflood tests 2 and 3 were conducted for comparison with the results of coreflood test 1 in which IPC was used as the chemical additive. In coreflood tests 4 and 5, IPC-assisted waterflooding was used to recover light oil A and medium-viscosity oil B at temperatures between 20–30 °C. In the last coreflood test, IPC was used as the chemical additive to recover heavy oil C at an elevated temperature of 200 °C. A complete coreflood test was composed of initial waterflood stage, followed by chemical flood stage and an extended waterflood. A shut-in period for soaking was also considered after the chemical flood. A mixture of synthetic silica sand and a reservoir sand from a heavy oil field, mixed in equal proportions, was used to simulate the porous media. The sand was packed in confinement lead core sleeves measuring 30.5 cm (i.e. one foot) long by 3.81 cm (i.e. 1.5 in.) diameter, and then was placed in the overburden vessel (i.e. core holder) and was confined under differential overburden pressure. The dry core was then saturated with CO2, evacuated and was subsequently checked for possible leaks. The core was then saturated with 4 wt% NaCl brine solution to measure initial pore volume and porosity. During the brine flow tests, the absolute single-phase permeability to brine was measured. Each core was then saturated with dead oil and was aged for a period of at least three weeks at room temperature to allow for chemical equilibration between brine, oil and rock. The core prepared for the elevated temperature test (i.e. test # 6) was aged at 200 °C. Conditions were then adjusted to an operating pressure of 2,500 kPa, overburden pressure of 5,000 kPa and a pre-determined operating temperature. Finally, different flood stages including initial waterflood using 4 wt% NaCl brine, followed by subsequent chemical flood and a prolonged waterflood were conducted during which data were collected including oil and water production as a function of fluid injected, injection and production pressures as well as pressure drop across the core. The 4 wt% NaCl brine concentration was selected based on the results of compatibility tests and IFT measurement tests. 3. Results and discussion 3.1. Physical properties of IPC formulation The density of IPC is similar to those of many oil reservoir brines at the temperatures studied (Table 2). Kinematic viscosity of IPC at the same temperatures is also presented (Table 2). The dynamic viscosity of IPC is approximately 3 cP at standard conditions of one atmosphere pressure and 15 °C, which is approximately O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 487 Table 2 IPC density and viscosity at different temperatures. Temperature (°C) Density (Kg/m3) Viscosity (cSt) 15 25 40 1067.4 1065.3 1058.1 2.79 2.56 2.24 3 times that of water under similar conditions. It was assumed that IPC exhibits Newtonian behavior although it was not tested for non-Newtonian behavior. This seems a valid assumption considering the fact that most dilute solutions, especially when mixed with water, exhibit Newtonian behavior. Amounts of IPC partitioned into the oil phase as a function of chemical ratios were measured in bench-top volumetric partitioning tests. In conclusion, although IPC partitioned into the oleic phase for some of the mixing ratios, the tendency of IPC to partition correlated neither with the water/chemical volume ratio, nor with the oilþ toluene per chemical volume ratio used in these partitioning tests. Fig. 2. Derivative TGA signals of samples of IPC under Nitrogen and air. 3.2. Thermal stability of IPC Thermograms of the two TGA tests are shown (Fig. 1). The majority of the sample vaporized just below 100 °C as a volatile solvent or solvent mixture. The remaining material appeared to be stable at temperatures greater than 200 °C, above which the sample began to lose weight at a rate that gradually increased with temperature until the rate peaked around 310 °C. This event can be seen more clearly in Fig. 2 which shows the time derivative of the signals shown in Fig. 1. The derivative of the TGA signal taken under air was similar, except that it showed weight loss peaking at a lower temperature of about 265 °C, which is consistent with the oxidation of paraffinic hydrocarbons. There was essentially no weight change above 360 °C, but only about 1.5 wt% of the sample was remained at this temperature condition. The sample amount that was left behind appeared to be a white, crystalline mineral. The peaks that appear in Fig. 2 just above 100 °C and at 150 °C are thought to be due to the irregular vaporization, because they were not reproduced on the trace under air, and are therefore not significant. DSC response to IPC was determined under both Nitrogen and air atmospheres (Fig. 3). Except at temperatures near 300 °C under air, the responses were endothermic, either because of heat absorption through evaporation, or as an indication of the normal heat capacity of a material being heated. The exothermic peak around 305 °C corresponds to the oxidation peak seen by TGA (Fig. 1). An attempt was made to isolate the effects produced by the non-aqueous components, by subtracting the thermal analysis signals that were observed for the carrier water samples from those taken for the chemical samples. The results, which are presented in Figs. 4 and 5, revealed that a substantial amount of IPC that boiled off below 100 °C was not water. The overall Fig. 1. TGA traces of samples of IPC under Nitrogen and air. Fig. 4. Difference in TGA traces of water and IPC under Nitrogen. Fig. 3. DSC traces of samples of IPC under Nitrogen and air. 488 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Table 4 Results of IPC compatibility tests with different brines. Brine # 5 vol% IPC @ 22 °C 50 vol% IPC @ 5 vol% IPC @ 22 °C 75 °C 50 vol% IPC @ 75 °C 1 Cloudy (bottom 2.5 mL) Cloudy (bottom 2 mL) Cloudy (bottom 32 mL) Clear cloudy (bottom 26 mL) Cloudy (bottom 2.5 mL) Cloudy (bottom 2 mL) Cloudy (Crystalline, 90% vol.) Clear Cloudy (2 phase) 2 3 4 5 Fig. 5. Difference in DSC traces of water and IPC under Nitrogen. conclusion of these tests is that any surface active agent in IPC formulation will begin to degrade at temperatures greater than 220 °C. If the EOR processes involve any form of steam injection, then at best IPC could be used only in the shallower oilfields in which pressures are less and the saturated steam temperature is near or below 200 °C; otherwise, these surface active agents will not survive long enough to be effective in the heated region of the oil reservoir. 3.3. IPC – brine compatibility and stability The purpose of these tests was to determine chemical compatibility and stability of IPC in common oilfield brines solutions. Two concentrations of IPC, 5% and 50%, were tested with five brines of various mineral contents (Table 3). Each test was conducted at two different temperatures: room temperature (22 °C) and 75 °C. Test vials were observed for a period of 1.5 months. Results for compatibility and stability tests are provided (Table 4). Four of the five brines showed signs of incompatibility. Brines with the greatest salinity and hardness levels (brine #3 and #5) had the most severe precipitation (Figs. 6 and 7). Precipitates formed immediately upon contact of IPC with these two brines and did not significantly change with time. The mixture of IPC with brine #3 emitted a strong ammonia smell. Increasing the concentration of IPC increased the amount of solid precipitate in the highly saline brines #3 and #5, and slightly decreased the amount of solid precipitate in the brines of lower salinity (#1 and #2). This is likely because the amount of precipitate-forming ions is limited in the less saline brines. The amount of precipitate at room temperature was similar to that of the elevated temperature at similar levels of Table 3 Brine analysis. Parameters Unit Brine #1 Brine #2 Brine #3 Brine #4 Brine #5 Bicarbonate Chloride PH TDS Calcium Magnesium Potassium Sodium Barium Iron Manganese Sulfate mg/L mg/L PH units mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L mg/L – 11143 18288 65 80 – 7000 – – – – 1130 8900 7.93 16300 57 85 50 6000 0.09 0.05 0.02 760 – 106000 5.78 295000 7080 1020 3700 90200 1.7 48 2.7 540 – 3047 5020 14 0 0 1959 – – – – 794 48500 7.07 82600 1800 930 670 27300 35.8 1.1 1.1 2 Cloudy (bottom 4 mL) Cloudy (bottom 4 mL) Cloudy (bottom 10 mL) Clear cloudy (bottom 10 mL) Cloudy (bottom 4 mL) Cloudy (bottom 4 mL) Cloudy (bottom 6 mL) Clear cloudy (bottom 10 mL) brine concentration; however, the nature of the precipitate was different. The precipitate in the 50 vol% solution of IPC with brine #3 had a crystalline structure after a period of 1.5 months at 75 °C. The solid precipitate in the 50 vol% solution of IPC with brine #5 formed two phases after a week at 75 °C. Brine #4 appeared to be compatible with IPC, likely due to its low content of divalent ions (Ca2 þ and Mg2 þ ). In order to check which ions in brine solutions are responsible for severe solid precipitation in the presence of IPC, four solutions of 5 vol% IPC in various single-salt brines – sodium bicarbonate, magnesium chloride, calcium chloride and sodium chloride – were prepared (Table 5). Precipitation occurred in solutions that contained divalent ions (Fig. 8). Therefore, it can be concluded that IPC is incompatible with brines of medium and high hardness when divalent ion concentrations are greater than 150 ppm. It is possible, however, that slightly acidic or alkaline conditions could improve the tolerance of IPC to the divalent ions. 3.4. IFT Measurements for IPC solutions in Brine and Oil The purpose of these tests was to evaluate IPC for its ability to lower IFT values between brine and oil (Tables 6–8 and Figs. 9–18). For all types of oil used in this study, a typical trend in IFT vs. IPC concentration is observed: addition of IPC to the binary of water– oil system decreased the IFT value from its original value (i.e. in the absence of chemical). However, the observed trend was not monotonic, and an optimum value of chemical concentration was found in which IFT reached a minimum. This trend was expected because IPC is a formulation containing surface active agent(s) so that addition of IPC to the solution will decrease IFT between chemical solution and oil. Reduction in IFT as a result of the presence of IPC was more significant with greater viscosity crude compared to the lighter oils. An increase in salinity of brine up to 4 wt% NaCl also led to greater reduction in IFT values, which means that optimal salinity of brine with the employed oil types is greater than 1 wt%. For both medium-viscosity and heavy oils, there was an apparent optimal concentration of IPC between 0 and 10 wt% at which IFT reached a local minimum. It is possible that this optimal concentration of IPC chemical is even lower than 2 wt%. The typical concentration range for surfactants in field chemical EOR projects is from 0.05 to 2 wt%, with most of applications utilizing between 0.1 and 0.3 wt% of active surfactant. In the case of light oil at a constant level of brine salinity, the greater the chemical concentration, the smaller the IFT. Technically, it is better to use the maximum chemical concentration, but this might not be economical. Considering the typical values of IFT needed for a successful chemical-assisted waterflood test (i.e. 0.01–0.001 mN/m or even less), even the IFT value at the maximum concentration of IPC (i.e. 0.41 mN/m) is not sufficient to achieve desired values. It is important to consider that just one of the mechanisms responsible for the effectiveness of chemical- O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 489 Fig. 6. Compatibility tests of IPC with brine #3 (after 1.5 months). assisted waterflooding, i.e. reduction in IFT value as a result of addition of chemical, is discussed in this paper. Considering these results, IPC was not successful in achieving the desired IFT even at the maximum concentration used when light oil A was used in the measurements. The employed brine concentration of 1 wt% NaCl was not the optimum salinity for lowering IFT. Reducing IFT beyond that of brine–oil mixture by use of IPC was totally different when intermediate-viscosity oil B and heavy oil C were used. When these oils were tested against IPC in brine solutions with different chemical concentrations, an optimum amount of IPC in brine was obtained that caused the largest decrease in IFT. Considering the intermediate-viscosity oil B, it was determined that an IPC solution of 2 wt% in brine was optimal Table 5 Compatibility of IPC with single-salt brines. Brine 2 wt% NaHCO3 1 wt% MgCl2 1 wt% CaCl2 2 wt% NaCl 5 vol% IPC @ 20 °C Clear Cloudy (bottom 12 mL) Cloudy (bottom 30 mL) Clear with a minimum IFT of 0.38 dynes/cm. However, IFT was still greater than the target value for a chemical-assisted waterflood of 0.01–0.001 mN/m or less. In this particular test, salinity of brine (i.e. 1 wt% NaCl) was not optimal. When another test was conducted with a brine composed of 4 wt% NaCl, it was determined Fig. 7. Compatibility tests of IPC with brine #5 (after 1.5 months). 490 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Table 8 IFT values for heavy oil C with fresh and aged brine solutions. NaCl concentration in brine (wt%) 1.0 1.0 1.0 1.0 4.0 IPC concentration in brine solution (wt%) 0 2 10 30 2 IFT (mN/m) Fresh brine solution Fresh brine solution (repeated tests) Brine solution aged for 6 weeks 58.25 0.14 0.61 0.40 0.07 – 0.20 0.55 0.48 0.03 – 0.41 0.58 0.74 0.11 Fig. 8. Compatibility tests of IPC with single salt brines at 22 °C. Fig. 9. Effect of IPC concentration on dynamic IFT data for light oil A with 1 wt% NaCl brine at 20 °C. Table 6 IFT values for light oil A with fresh IPC in brine solutions. NaCl concentration in brine, wt% IPC concentration in brine solution, wt% IFT, mN/m 1.0 1.0 1.0 1.0 0.5 2.0 4.0 0 2 10 30 2 2 2 15.74 1.11 0.77 0.41 0.96 0.96 0.83 Table 7 IFT values for medium-viscosity oil B with fresh and aged IPC in brine solutions. NaCl concentration in brine (wt%) 1.0 1.0 1.0 1.0 4.0 IPC concentration in brine solution (wt%) 0 2 10 30 2 IFT (mN/m) Fresh brine solution Brine solution aged for 6 weeks 16.72 0.38 0.65 0.52 0.34 – 0.45 0.65 0.45 0.32 that IPC performed slightly better at greater brine salinity compared to the lesser salinity. For the heavy oil C which has viscosity in the range of crude in Lloydminster heavy oil reservoirs, IPC worked efficiently and the drop observed in IFT compared to the other two previous cases was greatest. The IFT obtained between heavy oil C and 2 wt% IPC solution in 1 wt% NaCl brine was the smallest value obtained (i.e. 0.14 dynes/cm). Similar to the cases of light and intermediate-viscosity oil, the brine salinity was not optimum as far as the effectiveness of IPC in lowering IFT is concerned. When similar concentrations of IPC were tested in the Fig. 10. Effect of brine salinity on dynamic IFT data for light oil A with brine solutions at constant IPC concentration of 2 wt% at 20 °C. Fig. 11. Equilibrium IFT vs. IPC concentration for light oil A. O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Fig. 12. Equilibrium IFT vs. brine salinity for light oil A. Fig. 13. Effect of brine salinity and IPC concentrations on dynamic IFT data for medium-viscosity oil B (fresh IPC in brine solutions). 491 Fig. 15. Effect of brine salinity and IPC concentration on dynamic IFT data for heavy oil C (fresh IPC in brine solutions). Fig. 16. Effect of brine salinity and IPC concentration on dynamic IFT data for heavy oil C (aged IPC in brine solutions). Fig. 14. Effect of brine salinity and IPC concentration on dynamic IFT data for medium-viscosity oil B (aged IPC in brine solutions). presence of greater salinity (i.e. 4 wt% NaCl), the IFT was reduced by 50%. Repeatability of IFT results was checked. Measurements of IFT were repeated after 6 weeks of ageing. It was expected to see similar or slightly lower values after this ageing period. Except for two single measurements, i.e. heavy oil C with chemical concentrations of 2 and 30 wt% which showed an unusually large increase in IFT after aging, the expected trend was observed and the difference in IFT values before and after ageing was within 5– 7% of the original values. The “rule of thumb” for chemical EOR is that a two-fold decrease in IFT results in approximately a 10% increase in ultimate recovery of oil. It is typically desired to have IFT Fig. 17. Equilibrium IFT values versus IPC concentration for medium-viscosity oil B. 492 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Table 10 IFT values for solutions of several commercial surfactants with heavy oil C. Chemical name IFT, mN/m Ethomen 18–25 Rhodacal DSB N-85 Bio-Terge PAS-8 S Arquad T-50 1.86 2.40 0.96 2.84 0.22a a Fig. 18. Equilibrium IFT values versus IPC concentration for heavy oil C. values in the range of 10 2–10 3 mN/m or less. According to this estimate and results of IFT reduction only, IPC could be considered for chemical EOR in a field containing heavy oil “C”, depending on the salinity of in-situ brine. IFT reduction with oil types “A” and “B” was not sufficient to the extent of providing significant benefits through the reduction of capillary forces. However, it is possible that improvement in oil recovery could still be achieved through oil emulsification and/or alteration of formation wettability by the use of IPC as an additive. 3.5. Coreflood experiments Six core displacement experiments were conducted. Some details about properties of rock and fluid are listed (Table 9). Three oils were used: light oil A, medium-viscosity oil B and heavy oil C (Table 1). Five coreflood tests were conducted at ambient temperature and one experiment was conducted at 200 °C. To compare performance of IPC to other commercial products that are currently being used in EOR processes, two baseline coreflood experiments were conducted: one with a mixture of two alkali materials (sodium carbonate and sodium hydroxide) and the other one with a commercial surfactant, Arquad T-50, that was selected from among five different commercial surfactants based on their after 70 min, IFT increased to 0.68 mN/m. ability to reduce IFT between brine and oil (Table 10). One additional surfactant was also tested and found to be effective in reducing IFT. However, it was not used in the coreflood experiments because it had not been used in the EOR processes in the past. Results of the core displacement experiments are provided (Tables 11 and 12, Figures 19–28). The greatest incremental recovery over the initial waterflood was 16.4% of OOIP for heavy oil C in the ambient temperature coreflood when IPC was used (RUN #3, Table 11, Figs. 19 and 20). This oil also had the least IFT with IPC solution in brine. About 4.5% OOIP of additional oil was also recovered in the coreflood with medium-viscosity oil B in RUN # 2 when IPC was added to the injection mainstream (Table 11, Figs. 19 and 20). Practically, no additional oil was recovered in the corefloods with light oil A (RUN #1 with a minor enhancement of only 0.68% of OOIP in incremental oil recovery) and the one at elevated temperature of 200 °C with heavy oil C (RUN #6 with a minor enhancement of 1.48% OOIP in incremental oil recovery) in the presence of IPC as an additive (Table 11, Figs. 19 and 20). Failure in recovering more oil in these two corefloods was likely due to the fact that the initial waterflood recovery associated with these two tests was very great. In the former test, the great initial waterflood recovery is due to very small value of in-situ oil viscosity whereas in the latter case, it was due to reduced viscosity of heavy oil as a result of heating. Therefore, the remaining oil saturations, and consequently relative permeability to oil, at the beginning of the chemical flooding stage were significantly less compared to the other coreflood tests. The greatest ultimate recovery factor was observed in RUN #6 (i.e. 56.96% of OOIP) in which in-situ viscosity of heavy oil was significantly reduced with the aid of thermal heating and the fact that microscopic sweep efficiency was also enhanced with the presence of IPC in the injection mainstream due to reducing the IFT value (Table 11 and Fig. 19). The coreflood test with heavy oil C at ambient conditions was affected more by addition of IPC to the injecting phase during the chemical flooding stage of the process, with an incremental oil recovery of 16.4% of OOIP, followed by corefloods using medium-viscosity oil B, heavy oil C at elevated temperature, and light oil A with incremental oil recovery values of 4.5%, 1.48%, and 0.68% of their associated OOIP values, respectively (Fig. 20). Table 9 Rock and fluid properties for the coreflood experiments. Test No. Oil 1 Light oil A 2 Medium oil B 3 Heavy oil C 4 Heavy Oil C 5 Heavy Oil C 6 Heavy Oil C Brine Chemical Temperature, °C Core length, cm Core diameter, cm Initial permeability, mD Porosity, % 4 wt% NaCl 2 wt% IPC 22 30.8 3.81 7.2 38.76 2 wt% IPC 22 31.3 3.81 7.8 40.5 2 wt% IPC 22 30.9 3.81 7.4 36.2 1 wt% Na2CO3 þ 1 wt% NaOH 22 31.3 3.81 6.3 36.43 1 wt% Arquad T50 22 30.9 3.81 5.4 35.78 2 wt% IPC 200 30.7 3.81 5.1 41.1 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 493 Table 11 Recovery efficiency of coreflood tests with IPC as an additive. Process stage during coreflood Initial oil saturation stage Initial waterflood stage Chemical flood stage Extended waterflood stage Light oil A Medium oil B Heavy oil C So % OOIP recovered So % OOIP So % OOIP recovered So % OOIP recovered 0.622 0.320 0.319 0.316 0.0 48.48 48.76 49.16 0.847 0.629 0.615 0.591 0.0 25.7 27.4 30.2 0.940 0.833 0.685 0.678 0.0 11.4 27.1 27.8 0.690 0.294 0.287 0.284 0.00 55.48 56.55 56.96 Table 12 Performance comparison of IPC to commercial surfactant Arquad T-50 and alkaline additives using 1D coreflood experiments with heavy oil C. Process stage during coreflood IPC So Initial oil saturation stage Initial waterflood stage Chemical flood stage Extended waterflood stage % OOIP recovered Heavy oil C at 200 °C Alkaline Arquad T-50 So So % OOIP recovered % OOIP recovered 0.940 0.0 0.910 0.0 0.937 0.00 0.833 11.4 0.817 10.3 0.826 11.79 0.685 27.1 0.695 23.7 0.729 22.13 0.678 27.8 0.693 23.8 0.722 22.97 Two coreflood experiments, both with heavy oil C, were conducted with typical chemical additives that have been used in chemical EOR processes: (1) RUN #4 with alkali (2 wt% solution of the 1:1 mixture of sodium carbonate and sodium hydroxide) as an additive, and (2) RUN # 5 with a commercial surfactant “Arquad T-50” as an additive which was selected from among five different surfactant chemicals based on the achieved reduction in IFT value (Table 10). Production performance results of these two corefloods are listed in Table 12 and plotted in Figs. 21 and 22. Both of these two additives resulted in significant incremental oil recovery (i.e. 11.18% of OOIP for Arquad T-50 assisted waterflood in RUN #5 and 13.5% OOIP for alkali flooding in RUN #4). However, the coreflood test with IPC as an additive (i.e. RUN #3 with an incremental oil recovery of 16.4% of OOIP) exhibited superior performance compared to these two chemical additives at similar operating conditions and rock and fluid properties (Table 12 and Figs. 21 and 22). For each particular coreflood test, results of instantaneous recovery factor, in terms of produced percentage of OOIP as a function of PV injected, are plotted along with pressure drop across the core for different production stages including initial waterflood, chemical flood, and prolonged waterflood stages associated with each core displacement test (Figs. 23–28). The incremental recovery plots, during the chemical flooding stages associated with all these tests, correlate very well in dimensionless time, in terms of pore volume injected, with an increase in pressure drop across the cores. This behavior indicates that additional volumes of oil were being mobilized and transported through the core towards the producing end as soon as chemical was injected into the mainstream, i.e. commencement of chemical flooding stage, in each particular coreflood test. In general, the pressure drop plots across the core for all six coreflood tests are in good agreement with the incremental recovery plots, i.e. the greater the incremental recovery value is, the greater is the moving average value of the pressure drop plot at that particular process time (i.e. pore volume injected). 4. Conclusion A number of tests including thermal stability, physical properties determination, compatibility of IPC with brine, IFT measurement and coreflood displacement experiments were conducted to determine the effectiveness of IPC for chemical-assisted waterflooding process. The following conclusions are obtained: 1. About 80 wt% of the chemical was lost by 85 °C in an open system of TGA testing unit. However, the weight-loss trend of the chemical was almost stable at higher temperature range up Fig. 19. Effect of oil type on recovery efficiency of IPC-assisted waterflood during full life of the coreflood. 494 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Fig. 20. Effect of oil type on recovery performance of IPC-assisted waterflood during chemical flood stage of the coreflood experiments. Fig. 21. Effect of chemical additive on recovery performance of chemical-assisted waterflood using heavy oil C during the full life of the coreflood tests. Fig. 22. Effect of chemical additive type on recovery efficiency of chemical-assisted waterflood to recover heavy oil C during chemical flood stage of the coreflood experiments. O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Fig. 23. Oil recovery and pressure drop along the core during full life of coreflood #1 to recover light oil A using IPC-assisted waterflood. Fig. 24. Oil recovery and pressure drop along the core during full life of coreflood #2 to recover medium-viscosity oil B using IPC-assisted waterflood. Fig. 25. Oil recovery and pressure drop along the core during full life of coreflood #3 to recover heavy oil C using IPC-assisted waterflood. 495 496 O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 Fig. 26. Oil recovery and pressure drop along the core during full life of coreflood #4 to recover heavy oil C using alkaline assisted waterflood. Fig. 27. Oil recovery and pressure drop along the core during full life of coreflood # 5 to recover heavy oil C using Arquad T50 surfactant assisted waterflood. Fig. 28. Oil recovery and pressure drop along the core during full life of coreflood # 6 to recover heavy oil C using IPC-assisted waterflood at elevated temperature of 200 °C. O. Mohammadzadeh et al. / Journal of Petroleum Science and Engineering 135 (2015) 484–497 2. 3. 4. 5. 6. until 220 °C. It is concluded that any surface-active agents in IPC will begin to degrade at temperatures greater than a threshold temperature of 220 °C. IPC formulation, in its original form, has densities similar to oil reservoir brines and viscosities about three times greater than water at the same temperature and pressure conditions. IPC can be used as an agent to avoid the adverse mobility ratio during waterflooding of heavy oil reservoirs by making the injecting displacing phase more viscous, and at the same time, it can be used as a surfactant to reduce the interfacial tension. All these characteristics have the potential to improve oil recovery with the aid of IPC-assisted waterflooding. From the IFT measurement tests, it was found that IPC was equally or more effective in reducing IFT values at concentration of 2 wt% than at greater concentrations, suggesting that the optimal concentration of IPC may be lower than 2 wt%. Lesser IFT were achieved in tests in which 4 wt% NaCl concentration was present in brine samples, and therefore optimal salinity for IPC chemical was above 1 wt% Total Dissolved Solid (TDS) for the brine and oil samples tested. This is a positive result, since most of the heavy oil reservoirs (for which the IPC appears to be effective) have brines with salinities in the range of 40,000– 100,000 ppm. Coreflood displacement experiments and IFT measurements indicated that IPC can be very effective in improving heavy oil displacement efficiency in ambient temperature (22 °C) conditions in which the greatest incremental oil recovery was achieved (i.e. 16.4% of OOIP). However, the application of IPC at elevated temperature of 200 °C with the same oil did not show a significant improvement on oil recovery after injection of over one pore volume of chemical solution due to the fact that the initial waterflood stage recovered most of the oil and the remaining oil saturation in the core was low at the time when the chemical flood was started. IPC was moderately effective in recovering additional oil in the coreflood experiment with medium-viscosity oil B. In total, 4.5% of incremental OOIP was recovered after the expiry of the chemical flood as well as that of the extended waterflood stages. This number can be significant if applied to the field; however, results of 1D coreflood experiments cannot be directly upscaled to the field conditions. Additional work, such as larger scale experiments, a larger variety of oils and numerical simulation will need to be tested before any practical trend can be observed with certainty. The amount of oil recovery using IPC was compared with those obtained by alkali and a commercial surfactant flooding when heavy oil C was used. These results, along with the typically achieved incremental recovery values associated with surfactant-type chemical additives lead to the conclusion that IPC does have a potential in chemical EOR applications for in situ recovery of heavy oil. 497 Acknowledgment The research was supported by a Grant from Western Economic Diversification Canada (Project # 411342) and Enterprise Saskatchewan (Project # 411347). The authors wish to acknowledge the support of an Instrumentation Grant from the Canada Foundation for Infrastructure. JP Giesy was supported by the Canada Research Chair program and the Einstein Professor Program of the Chinese Academy of Sciences. References Agharazi-Dormani, N., Hornof, V., Neale, G.H., 1990. Effects of divalent ions in surfactant flooding. J. Petrol. Sci. Eng. 4 (3), 189–196, July. Bansal, V.K., Shah, D.O., 1978a. The effect of divalent cations (ca, mg) on the optimal salinity and salt tolerance of petroleum sulphonates and ethoxylated sulphonates mixtures in relation to improved oil recovery. J. Am. Oil Chem. 55 (3), 367–370. Bansal, V.K., Shah, D.O., 1978b. The effect of addition of ethoxylated sulfonates on salt tolerance, optimal salinity, and impedance characteristics of petroleum sulphonates solutions. J. Colloid Interface Sci. 65 (3), 451–459. Chatzis, I., Morrow, N., Lim, H.T., 1983. Magnitude and detailed structure of residual oil saturation. SPE J. 23, 2. Celik, M.S., Manev, E.D., Somasundaran, P., 1982. Sulfonate precipitation – redissolution – reprecipitation in inorganic electrolytes. AIChE Symp. Ser. 78, 86–96. Glover, C.J., Puerto, M.C., Maerker, J.M., Sandvik, E.L., 1979. Surfactant phase behavior and retention in porous media. SPE J. 19 (3), 183–193, SPE Paper 7053PA. Gupta, S.P., Trushenski, S.P., 1979. Micellar Flooding-Compositional Effects on Oil Displacement, SPE Paper 7063-PA. SPE J. 19 (2), 116–128. Johnson Jr., C.E., 1976. Status of caustic and emulsion methods. J. Petrol. Technol. 1, 85–91. Kumar, A., Neale, G., Hornof, V., 1984. Effects Of Connate Water Composition On Interfacial Tension Behavior Of Surfactant Solutions, PETSOC. J. Can. Petrol. Technol. 23 (1), 37–41. Mayer, E.H., Berg, R.L., Carmichael, J.D., Weinbrandt, R.M., 1983. Alkaline injection for enhanced oil recovery—a status report. J. Petrol. Technol. 35 (1), 209–221. Morrow, N.R., 1990. Wettability and its effect on oil recovery. J. Petrol. Technol. 42 (12), 1476–1484. National Energy Board (NEB), 2006. Canada's oil sands: Opportunities and challenges to 2015: An Energy Market Assessment, Calgary, June 2006. National Energy Board (NEB), Canada's oil sands: Opportunities and challenges to 2015: An Energy Market Assessment, Calgary, May 2004. Somasundaran, P., Hanna, H.S., 1979. Adsorption of sulfonates on reservoir rocks. SPE J. 19, 221–232. Shah, A., Fishwick, R., Wood, J., Leeke, G., Rigby, S., Greaves, M., 2010. A review of novel techniques for heavy oil and bitumen extraction and upgrading. Energy Environ. Sci. 3, 700–714. Seethepalli, A., Adibhatla, B., Mohanty K.K., 2004. Wettability Alteration During Surfactant Flooding of Carbonate Reservoirs, SPE Paper 89423-MS, Presented at the SPE/DOE Symposium on Improved Oil Recovery, 17–21 April, Tulsa, Oklahoma. Vijapurapu, C.S., Rao D.N., 2003. Effect of brine dilution and surfactant concentration on spreading and wettability, SPE Paper 80273-MS, Presented at the SPE International Symposium on Oilfield Chemistry, Houston, TX. Wu, Y., Shuler, P.J., Blanco, M., Tang, Y., Goddard, W.A., (2006). A Study of Wetting Behavior and Surfactant EOR in Carbonates With Model Compounds, SPE Paper 99612-MS, Presented at the SPE/DOE Symposium on Improved Oil Recovery, 22–26 April, Tulsa, Oklahoma. Jamaloei, B. Yadali, Kharrat, R., 2010a. Analysis of microscopic displacement mechanisms of dilute surfactant flooding in oil-wet and water-wet porous media. Transp. Porous Media 81 (1), 1–19. Jamaloei, B. Yadali, Kharrat, R., 2010b. Analysis of pore-level phenomena of dilute surfactant flooding in the presence and absence of connate water saturation. J. Porous Media 13 (8), 671–690.