Document 12056633

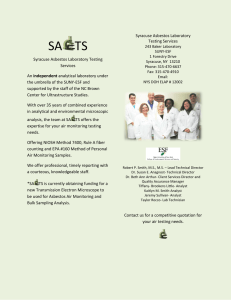

advertisement