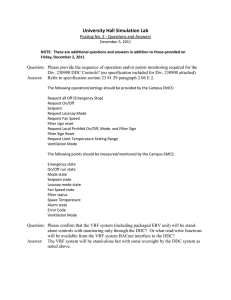

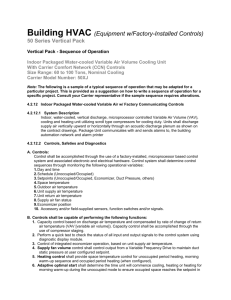

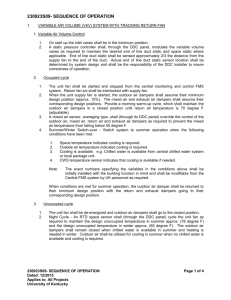

************************************************************************** USACE / NAVFAC / AFCEC / NASA ...

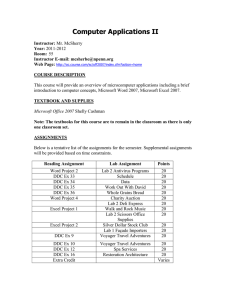

advertisement