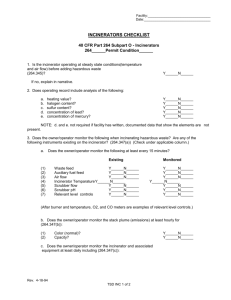

************************************************************************** USACE / NAVFAC / AFCEC / NASA ...

advertisement