for the DEGREE OF MASTER OF SCIENCE

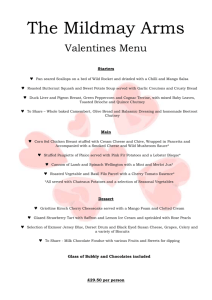

advertisement