PMA Regional Meeting - February 24, 2012

advertisement

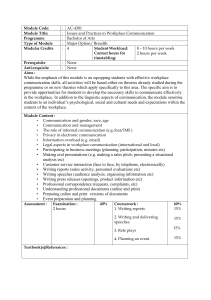

PMA Regional Meeting - February 24, 2012 HOUSEKEEPING ITEMS Cell Phones Washrooms/Breaks Fire Exits INTRODUCTIONS NAME MUNCIPALITY THE WORKPLACE HEALTH, SAFETY & COMPENSATION COMISSION GETTING TO KNOW US OUR VISION “Our vision of the Commission is of safe and healthy workplaces within a viable and sustainable system which reduces the impact of workplace injuries by providing the highest level of service to workers and employers” PREVENTION SERVICES Field Services Health & Safety Advisors Consulting Mentoring OH &S Program development & implementation support Auditing Liaise with Service NL (OH &S Division) PREVENTION SERVICES Other Prevention Services Injury trend analysis Training Standards & Certification OH & S Committee/WH &S Representative/Designate Young Workers Resource Development WHO WANTS TO SAVE A LIFE? NL MUNICIPALITIES Lost time claims 2004-2010 Claims by the 5 leading “Types of Accidents’ Type of accident % Total lost time claims Overexertion 15% Bodily reaction 12% Fall on same level 6% Struck by object 5% Exposure to noise 3% Fall to lower level 3% NL MUNICIPALITIES Lost time Claims - 2004-2010 Claims by the 5 leading “Nature of Injury’ Type of injury % Total lost time claims Traumatic injuries to muscles, tendons, ligaments, joints, etc 52% Other traumatic injuries and disorders 21% Traumatic injuries to bones, nerves, spinal cord 7% Surface wounds and bruises 7% Open Wounds 4% NL MUNICIPALITIES Lost time Claims - 2004-2010 Claims by the 5 leading “Body Part’ Body Part % Total lost time claims Back, including spine, spinal cord 30% Multiple body parts 15% Legs 10% Ankle(s) 7% Finger(s), fingernail(s) 7% NL MUNICIPALITIES Lost time Claims - 2004-2010 Claims by the 5 leading “Occupations’ Type of Occupations % Total lost time claims Public works & maintenance labourers 35% Heavy equipment operators (except crane) 16% Construction trades helpers, labourers 6% Auto Service technicians/truck mechanics/rep 4% Firefighters 4% OBJECTIVES Training & Certification Standards Legislative Requirements OH & S Management System PRIME OH & S CERTIFICATION TRAINING STANDARDS Traffic Control Person (TCP) January 1, 2011 Fall Protection – January 1, 2012 Confined Space Entry – January 1, 2013 WHERE TO START? Internal Responsibility System (IRS) Everyone is Responsible! IRS Based on : Commitment, involvement and accountability of all workplace parties. Belief that employers have a legal and moral duty to provide a safe and healthy workplace. Belief in open communication by workplace parties. DUE DILIGENCE Taking all reasonable care to protect the well-being of employees or co-workers. Guilty until proven innocent. LEGISLATITVE REQUIREMENTS PROVINCIAL OH &S Act and Regulations CSA Standards EMPLOYER Employer’s General Duty – OH &S Act, Section 4 An employer shall ensure, where it is reasonably practicable, the health and safety and welfare of his or hers workers EMPLOYER Specific Duties of Employers (OH &S Act Section 5) Maintain a healthy & safe workplace, systems, equipment, tools; Provide information, instruction, training and supervision, including requirements by the OH &S Act and Regulations & other associated legislation; Provide operating instruction for the use of devices/equipment; Identify workplace hazards and ensure supervisors/workers are aware of hazards; Establish an OH & S Committee/WHSR/WHSD Respond in writing to recommendations within 30 days from the OH &S Committee/WHSR/WHSD EMPLOYER Conduct Workplace Inspections; Co-operate with OH &S Inspectors; Provide & ensure that PPE is used; Ensure SWP are followed; Report serious injuries. SUPERVISORS General duty: OH & S Act Section 5.1 A supervisor shall ensure, where it is reasonably practicable, the health, safety and welfare of all workers under his or hers supervision SUPERVISORS Specific Duties (OH & S Act , Section 5.2) Advise workers any identified hazards; Provide workers with proper instructions regarding precautions; Ensure workers use PPE or any other devices or apparel required under the OH &S Act. WORKERS General Duty (OH& S Act Section 6) A worker, while at work, shall take reasonable care to protect his or her own health and safety and that of workers and other persons at or near the workplace. WORKERS Specific Duties - OH &S Act, Section 7 Protect his/her health & safety and that of co-workers at or near the workplace; Co-operate with employer, co-workers, OH & S Committee/WHSR/WHSD, and OH &S Inspectors; Follow instructions & training; Report hazardous conditions; Properly use all safety equipment/devices/clothing. RIGHTS OF WORKERS Right to Know Right to Participate Right to Refuse ALL EMPLOYERS MUST PROVIDE A SAFE AND HEALTHY WORKPLACE FOR EMPLOYEES POLICY OR PROGRAM OH &S POLICY OH& S Act – Section 36.2 Where less than 10 workers are employed at a workplace, the employer shall establish an OH & S Policy In consultation with the WH & S Representative/ Designate OH &S PROGAM OH & S Act Section 36.1 Where 10 or more workers are employed at a workplace, the employer shall establish and maintain an occupational health and safety program In consultation with OH & S Committee In writing 10 elements OH &SCOMMITTEE ? WORKER HEALTH & SAFETY REPRESENTATIVE ? WORKER HEALTH & SAFETY DESIGNATE ? OH &S COMMITTEE OH & S Act, Section 37 Where 10 or more workers are employed at a workplace, the employer shall establish an Occupational Health and Safety Committee to monitor the health and safety and welfare of the workers employed at the workplace. WORKER REPRESENTATIVE OH & S Act, Section 41 Where less than 10 workers are employed at a workplace, the employer shall ensure that a worker not connected with the management of the workplace is designated as the worker health and safety representative to monitor the health, safety and welfare of workers employed at the workplace WORKPLACE DESIGNATE OH & S Act , Section 42.1 Where less than 6 persons are engaged at a workplace and the designation of a worker health and safety representative is impracticable, the employer may designate a workplace health and safety designate to monitor the health, safety and welfare of workers employed at the workplace. OH &S COMMITTEE/WHSR/WHSD Duties Seek & identify workplace hazards; Participate in workplace inspections; May make recommendations to workplace parties, contractors or government representatives; Receive OH &S complaints from workers; Establish and promote OH &S education; Maintain records; Co-operate with OH &S Inspectors. OH &S MANAGEMENT SYSTEM OH &S MANAGEMENT Leadership & Administration Hazard Recognition, Evaluation & Control Workplace Inspections Accident/Incident Investigations Education & Training Emergency Preparedness/Response OH &S MANAGEMENT SYSTEM Violence Prevention Working Alone Communicating Health and Safety LEADERSHIP & ADMINISTRATION Employer participation is critical to OH&S system success Developing, implementing & monitoring effective programs Incorporation of safety into daily activities Setting positive examples Policies: OH &S, RTW, HAZARD RECOGNITION The process of identifying, evaluating and recommending controls to correct concerns/hazards WHAT IS A HAZARD? A hazard: …is a condition, substance, behavior or practice with the potential to cause loss due to injury, illness or property damage Two major categories of hazards: – Health hazards – Safety hazards HEALTH HAZARDS Four categories: Chemical Physical Biological Ergonomic SAFETY Machine Energy Confined space Materials handling Falls Group Activity #1 List Health & Safety Hazards HAZARD REPORTING OH&S Legislation require workers to report workplace hazards to their supervisor. Therefore, employers should implement a hazard reporting process to ensure: hazards are reported and documented corrective action is taken corrective action taken is communicated to reporting person and others involved follow up on corrective action to ensure it is effective HAZARD REPORTING All hazards must be evaluated Controls must be implemented WORKPLACE INSPECTION WORKPLACE INSPECTION Regular examinations of the workplace conducted to ensure a healthy and safe work environment Workplace inspections should be conducted routinely in all work areas to identify health or safety hazards Personnel at all levels should be involved in some way in the inspection process A written report should be completed after each inspection WORKPLACE INSPECTION Two types: Informal – practiced awareness which identifies potential hazards of daily processes, conditions and activities in the workplace Formal – regularly scheduled examinations of the workplace and are conducted with the aid of a checklist and inspection report Activity #2 Formal vs Informal Inspections Let’s look at some examples: Cindy is walking through the kitchen to get to the staff lunch room and notices that a cord on one of the vending machines has been connected to a receptacle which causes the cord to be in a walkway. She mentions it to a supervisor in the area. Is this a formal or informal inspection? Informal Mark is getting his crew ready to repair a roof. As part of their safety tool box talk they discuss the importance of inspecting their harnesses which will be used for fall protection . Each worker is required to inspect their harness before usage. Is this a formal or informal inspection? Informal – since it is a visual inspection that will be conducted each time prior to use. Although formal inspections will occur annually. Matthew is the first aider in the grocery department and a member of the OH&S committee. Each month he inspects the first aid kits in the store using the First Aid Regulations as a guide to ensure the kits are adequately stocked. He replenishes them when required and also reviews the first aid logs and brings the information back to the OH&S committee meetings. Is this a formal or informal inspection? Formal – he would use a checklist and sign off when completed. Susan is a licensed practical nurse who has been asked to assist a nurse moving a patient from a bed. The nurse manager walks by the mechanical lift in the hall and notices the two workers moving the patient using the hook lift. She informs the workers of the requirement to use the mechanical lift as per their written safe work practices and procedures. Is this a formal or informal inspection? Informal – as the corrective action may not be recorded. Colin is the lead hand at the local tire manufacturing plant. Monday mornings he performs a check of the conveyor belt before the workers begin their shift. This report is then filed with the shift supervisor and the maintenance supervisor. Is this formal or informal? Formal- documentation will be available for review ACCIDENT/INCIDENT INVESTIGATIONS A/I INVESTIGATIONS Accident - an undesired event that results in a personal injury, illness or damage to or loss of property, process or environment Incident - an undesired event that under slightly different conditions, could have resulted in an injury or loss A/I REPORTING Employees are required to report all accidents/ incidents to the immediate supervisor as soon as possible after the occurrence Complete an accident/incident report form for all injuries and near misses Employers/supervisors are responsible for investigating, reporting and implementing corrective action A/I INVESTGATIONS Will determine how and why accidents occur Examine and implement possible corrective action Prevent further accidents/incidents Investigation is not intended to place blame EDUCATION & TRAINING EDUCATION & TRAINING Ensures: Workers are knowledgeable about their jobs Workers can do their jobs in the safest and healthiest way More competent, knowledgeable workforce EDUCATION & TRAINING Employee training: Orientation – new employee, rehires, those returning after long absence Job specific, task specific First aid Other training? EMERGENCY PREPRENESS/ RESPONSE PLAN EMERGENCY PREPARENESS/ RESPONSE PLAN An emergency plan specifies procedures for handling sudden unexpected situations The emergency plan should include: all possible emergencies, consequences, required actions, written procedures, and the resources available detailed lists of personnel including their home telephone numbers, their duties and responsibilities floor plans large scale maps showing evacuation routes Workers, Managers & Supervisors Must: Take reasonable care in protecting the health and safety of themselves and others Participate in emergency response training exercises and education sessions Immediately report all hazards and substandard conditions having the potential to cause emergency situations WORKPLACE VIOLENCE WHAT IS WORKPLACE VIOLENCE? An attempted or actual exercise by a person, other than a worker, of physical force to cause injury to a worker, and includes threatening statements or behavior which gives a worker a reason to believe that he or she is at a risk of injury When is Workplace Violence Likely to Occur? When working alone Late at night Early in the morning Specific times of the day/week/month Geographic locations that are isolated or in high crime areas How can you identify hazards in your workplace associated with violence? IDENTIFYING THE HAZARDS Get input from workers Review the history of workplace incident reports Examine the history of workplace violence in similar workplaces Conduct a workplace inspection WORKING ALONE WORKING ALONE To work alone or in isolation means to work in circumstances where assistance would not be readily available to the worker In case of an emergency; or In case the worker is injured or in ill health Determining Availability of Assistance Presence of others Are other people in the vicinity? Awareness Will people capable of providing assistance be aware of the worker’s need? Willingness Is it reasonable to expect those people to provide assistance? Timeliness Will assistance be provided within a reasonable period of time? Examples of Working Alone Retail employees Taxi drivers Truck and delivery drivers Home care and social services employees Security guards Warehouse workers COMMUNICATING HEALTH & SAFETY COMMUNICATION The exchange of information throughout the organization Several ways of communicating information to employees Bulletin boards Safety talks Posters Newsletters PRIME STATISTICS 2010 284 Prime Eligible employers 47% pass validation rate Total PRIME $ on the table = $505,924 (experience and practice) Prime refunds awarded = $336,757 (67%) A two-part program Practice incentive of 5% based on workplace practices Experience incentive based on claims cost experience Meeting the requirements of the PRIME program does not ensure compliance with Occupational Health and Safety (OH&S) legislation Practice incentive Reward for complying with health and safety and returnto-work practices Experience incentive Early in the year, employers will be given a range against which their claims costs will be compared Claims costs below the range - Refund Claims costs above the range - Charge Claims costs in the range - No impact Small PRIME employer – less than 10 workers per workplace (<$48 000 in average assessment) Requirements: OH&S policy statement RTW policy statement Separate or one combine statement Certification Training – WH&S representative/designate Injury reporting system- outlining steps to be taken following an injury Medium PRIME employer – greater than 10 workers per workplace (<$48 000 in average assessment) Requirements: OH&S policy statement RTW policy statement Separate or one combine statement OH &S Committee – trained and functioning Injury reporting system- outlining steps to be taken following an injury Orientations Workplace Inspections A/I Investigations Hazard Recognition, Evaluation & Control Emergency Preparedness/Response SWP/P Training procedures Communication Large PRIME employer – greater than 10 workers per workplace (>$48 000 in average assessment) Requirements: OH&S policy statement RTW policy statement Separate or one combine statement Certification Training – OH &S Committee Injury reporting system- outlining steps to be taken following an injury Orientation Inspections A/I investigations Hazard Recognition, Evaluation & Control Emergency Response SWP/P (Plan to train) Communication ESRTW Program SUMMARY Training Certification Legislative Requirements Managing Health & Safety PRIME requirements Please visit WHSCC website at www.whscc.nl.ca Our website contains information on: Prevention Services PRIME Ergonomics CEO Leadership Charter CONNECT You can also access from our website: Publications Forms Posters Training Providers See the resource tab in your booklet for an overview of additional information provided on our website Thank You!!! For more information, please call WHSCC office nearest you: St. John's (709) 778-1000 1-800-563-9000 Grand Falls (709) 489-1600 1-800-563-3448 Corner Brook (709) 637-2700 1-800-563-2772