… denipro Rolling conveyor technology in the process flow

advertisement

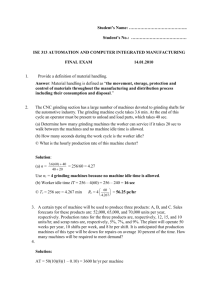

denipro… Rolling conveyor technology in the process flow Key Energy efficient 24/7 Dependable serviceability Easy maintenance Credits January 2015 Copyright © 2015 Denipro AG, 8570 Weinfelden / Switzerland 2 w ww.wrh-marketing.ch www.ferag.com www.walter-reist-holding.ch Discover the ease of conveying More and more, the market is recognizing the value of rolling ­conveyor technology. For good reason. Denipro AG in Weinfelden, Switzerland: here, conveyor systems are created that save energy and costs. Denipro AG is based in Weinfelden, Switzerland. The driving force behind the company is our approximately 100-strong team of young, young-at-heart and wide-awake talent. Open to the needs of our customers and possessing great creative energy, we are working on innovative and flexible solutions that satisfy the demands of the marketplace. We are the specialists in rolling conveyor technology. Our concepts are based on the principle of “rolling rather than sliding”, which has earned us recognition all around the world. Traditionally, our home territory has been the printing industry, where over the decades we have acquired and continually expanded our know-how. By developing and constructing innovative conveyor components, we play a large part in the success of Ferag AG, our associate company and the world leader in the supply of systems to newspaper and magazine printers. But companies from entirely different industries, too, have long been depending on our experience and expertise. At Denipro AG, they will find the made-to-measure, intelligent answer to the challenges they face in all aspects of intralogistics and the efficient flow of goods. Whether it’s well-known automobile and pharmaceuticals manufacturers, leading brands in the cosmetics industry, beverage and food chains, packaging manufacturers or established players in e-commerce, they all depend on solutions from Denipro AG. Because it’s thanks to our technology and our experience in process optimization that they can draw upon new and efficient solutions from a single supplier when squaring up to their intralogistic challenges. Denipro is part of WRH Walter Reist Holding AG. Since its foundation almost 60 years ago, this owner-operated family enterprise has maintained its independence – also from the financial point of view. A large percentage of its revenue is ploughed back into research and development. So the innovation pipeline is ­always full. The integration of Denipro into Walter Reist Holding AG creates a stable platform for the future prosperity of the company. Denipro customers not only invest in an exceptional and sustainable technology, but also in a long-term collaboration with a sound and progressive partner. www.denipro.com 3 Clean high performance for In the high-volume food process flow, versatile and secure logistics soluti Italy – Easychain for gourmets the world over: Parmesan cheese from Gennari. 4 Denipro technology conveys high volumes along sections up to several hundred metres in length, without transfer stations. Even large height differences are mastered by the system with ease. Continuity in the process flow is guaranteed, regardless of possi- ble malfunctions in an upstream or downstream process. With its logistics system, Denipro has opted for modularity, using a flexible layout to master all three dimensions to give the conveyor technology its unique ability to adapt to existing spaces. Rollers France – Deniway at Auchan: order picking Germany – Deniway at Delta Fleisch: transport from storage in the drive-in format. to shipping. the food industry ons from Denipro make all the difference. 24/7 High conveyor speed Food-grade materials For hygienically demanding production environments Simple technology, quick to install run smoothly on slender rails to keep friction coefficients low. This is a zero-maintenance system and, when it comes to energy consumption, it achieves the lowest values ever seen. In logistics, these qualities are unique. They bring maximum efficiency to a dependable process flow. The overall efficiency of the process is assured over all steps, right through to palletizing. It goes without saying: compliance with food processing standards and corrosion resistance are a hallmark of Denipro ­ logistics solutions. They can be used in hygienically demanding production environments and cleaning with water presents no problems. Easychain: one flow of goods connects all processes. www.denipro.com 5 Efficient returns management Intelligent system solutions from Denipro bring meaningful process autom Deniway at Zalando: workflow optimization, thanks to our used-carton conveyor. The online mail-order business is growing. And along with that growth comes a rise in the demand for returns management. The contents must be removed from the packaging, the goods returned to the stores, and the box transferred to disposal. That 6 Online shopping is a trend. calls for sensible, intelligent automation. Denipro conveyor technology provides an easy-to-follow link between the processes, saves resources and boosts efficiency. The modular Denipro system forms the basis of made-to-measure logistics solutions of all Resource optimization through automation. in e-commerce ation to the mail-order business. 24/7 Sensible and intelligent automation Conveyor sections are free of transfer stations Simple control Secure operation under constant loads sizes and for all user requirements. Behind Denipro logistics is a uniform, standardized technology that creates the ideal con­ ditions for uninterrupted conveyor sections, free of transfer stations, thus aiding the process flow, increasing process security, and simplifying control over the overall system. Height differ­ ences are bridged by spiral conveyors with uninterrupted transport, free of transfer stations, being maintained at all times. Denipro conveyor technology is distinguished by its rugged design and high dependability under prolonged load conditions. The low-friction system is guided by rollers to run in a channel. Which is why this technology also scores top marks for low maintenance and low energy consumption. Deniway: used-carton handling made easy. www.denipro.com 7 An efficient flow of goods for Denipro conveyor technology brings high performance with low operating Switzerland – Easychain at Mibelle: transporting empty bottles to the filling plant. In the industrial environment, logistics solutions from Denipro ­really shine. Innovative conveyor technology combines high transport speeds with an almost unrestricted choice of layout. The modular system is easy to integrate into existing production environments. Its flexibility is highlighted by the ease with which it 8 Easychain at Frike: efficient overhead transport of chemical products. copes with large height differences – even over several floors. Process steps are linked by an uninterrupted layout, with gentle, totally clean transport from A to B of bulk materials from the most varied sources. Which means that it’s possible to transport labelled, but still empty, containers to the filling plant. Denipro Easychain at Mibelle in Switzerland. industrial applications costs to industrial applications. 24/7 A free choice of layout Easy integration into existing production environments Uninterrupted conveyor routes over several floors Low energy requirement, easy maintenance conveyor technology rolls in almost complete silence and with no sliding friction on a rail system that’s both slender and stable. That brings the consumption of electrical energy down to un­ precedented levels while delivering outstanding results when it comes to ease of maintenance. And because Denipro transport technology operates completely without lubricants, the limits to its applications are set far apart. Its uses extend to applications that place above-average demands on hygiene. Belgium – Deniway at Sioen: simple product tracking thanks to virtual windows on a Deniway plate chain conveyor. www.denipro.com 9 Sorting and allocation really The operators of distribution centres have good reasons to opt for precision Belgium – end-of-line sorting of special clothing. When it all comes down to efficient sorting and precise allocation of several different items, then Denipro conveyor technology reveals its unique strengths. The system operates with adaptive transport containers. They adjust automatically to the size of each item. So the Denipro system conveys at maximum density and 10 Easychain at Gennari: simple integration of a checkweigher. guarantees the optimum utilization of transport capacity. Denipro conveyor and sorting technology enables items to be tracked ­using simple path-cycle tracking; no more need for tracking by means of complex measuring and sensor sections and software controls. As an option, every individual item can be marked can be this intelligent n sorting technology from Denipro. 24/7 Adaptive transport containers for maximum product density Simple item tracking An uninterrupted transport system without interfaces Energy saving and maintenance-free with an identity and will seek out its own route, reaching its prescribed destination securely and dependably. The efficiency of Denipro conveyor technology is also exceptional. And as far as electrical energy requirements are concerned, the transport system, guided in a channel by rollers, achieves values that are far lower than conventional solutions. In addition to outstanding operating efficiency, Denipro logistics solutions bring calm and simplicity to the sorting and transport process. The rollers run silently and maintenance-free in the ­centre channel guide. Deniway is the energy-saving way to create demanding layouts. www.denipro.com 11 The sound basis for quality Well-known automobile manufacturers work with the ultra-flat conveyor Denimove as a worker ride-on belt in the automobile industry. An ultra-flat worker ride-on belt brings safety, productivity and quality to modern automobile construction. The ultra-flat conveyor from Denipro moves factory staff without a slip-stick effect on a safe base at a speed that’s synchronized with the assembly line. 12 Denimove: flowline conveying as the “main artery” of the production line. Conveyor segments up to 40 metres in length without transfer stations allow the installation of needs-based transport segments. Robust edge shields provide top safety at work. Wipers reliably remove small parts and tools lying on the conveyor and automobile construction from Denipro because they care about safety and quality. 24/7 Slip- and stick-free safety, plus high-level ergonomics Segments up to 40 metres in length and no transfer stations Energy-saving transport with no sliding-friction losses Easy drive changes using clip connectors deposit them in a receptacle. The tough belt is supported by ­numerous small rollers and runs with no sliding friction. Even heavy loads can be moved by small, energy-efficient motors integrated into the drive shafts. Denipro has designed the ultra-flat conveyor as a modular system. The load distribution can be precision tuned to the specific requirements of the customer. Using simple clip and plug con­ nections, drives and individual components down to the smallest ­roller parts can be replaced quickly without the need for tools. Maximum availability with exceptionally easy maintenance is guaranteed. Denimove 110: a typical production cell in the automobile industry. www.denipro.com 13 Perfectly suited to many situations Deniway: the innovative plate chain conveyor with the robust C-channel and the flexible steel chain. Deniway is a robust conveyor system for almost all goods logistics applications. Solid plastic carrier plates are supported by rollers and guided in a stable steel channel. So even in difficult, dusty and contaminated environments, Deniway is dependable and requires little maintenance. The hard and durable plate mate- rial is distinguished by its mechanical and thermal resistance. And even though Deniway is as tough as they come, in the area of flexibility and efficiency, the conveyor system is exceptional. Deniway adapts to all spatial situations with ease. Section layouts can be adjusted to growing demands at any time. Deniway uses spirals to negotiate height differences. With its continuous, circulating chain, the system masters long transport sections, even when they pass Deniway: high tech in detail. 14 Deniway: individual layout. through several levels. That not only protects the transported goods, but simplifies assembly and control. Deniway’s exceptional strengths go hand in hand with its very low energy requirement. Three 1.5 kW motors are enough to drive a 400-metre conveyor section. select Three options for a wider range of applications Multi-functional flow of goods for all requirements. With the Deniway Select option, the Deniway conveyor system can be equipped with automatically triggered, rubber-coated rollers. At rest, the rollers are retracted below the transport surface. Specific rollers can be activated and brought into the standby position. Deniway Select carries out buffering, acceleration and holding functions. Buffering When individual transport units have to be brought into a holding position during the conveyor process, the rollers move upwards and decouple the unit by lifting it slightly from the conveyor system. ­Buffering can be applied to specific transport units. The normal transport flow with Deniway is maintained. Acceleration If the transport unit is required to accelerate, it will receive an impulse by increasing the rotational speed of the rollers in relation to the conveyor speed. The acceleration function comes into play when, for the sake of a higher conveyor performance, the narrow separation between the transport units has to be stretched to preserve the process flow. Holding Deniway Select’s holding function is ­activated on ascending and descending gradients. When not rotating with the conveyor, the rollers act as a braking force and prevent the transported goods from sliding forwards or backwards on the d ­escending or ascending conveyor section. Buffering, acceleration and holding thanks to Deniway Select. 24/7 www.denipro.com 15 Adaptable in all three dimensions Easychain: the multi-dimensional conveyor system. Easychain is pure rolling conveyor technology. Light-weight plastic plates glide on rollers along a slender, stainless-steel rail system. Easychain runs in almost complete silence with minimum rolling friction and a low energy requirement. The 16 Easychain in detail. two-component material requires no lubrication and is completely maintenance-free. The plastic is certified as food-grade material according to USA NSF-61. Easychain is a modular design. The plate chain elements are simply assembled to create transport systems of any length using plug-in connections. The drive concept allows the motors to be arranged at any position along the conveyor section, to support unrestricted conveyor layouts within existing spaces. Thanks to tight curves down to 600 mm radius, Easychain transport sections master all three dimensions in limited spaces. The conveyor system reveals its adaptability by negotiating ascending and descending gradients with curves down to 300 mm radius on short sections. Plastic plates are available up to 240 mm in width. An underside profile gives the material its high stiffness, enabling Easychain to transport loads up to 20 kilograms per metre at impressive speeds up to 1.5 metres per second. Easychain, the rolling conveyor system. 24/7 Plug-and-move at its most efficient The Denimove ultra-flat conveyor is based on a modular design principle. For Denimove, the smooth and gentle transport of heavy loads comes easy. The ultra-flat, variable length conveyor system is supported by countless small rollers. Denimove operates free of sliding friction and has a correspondingly low energy requirement. A small motor integrated into the drive shaft is enough to move heavy transport goods weighing several hundred kilograms at speeds up to 30 metres per minute without gliding friction. Denimove is quick to assemble. It’s also just as easy to move the conveyor system to another position, and extend and adapt it to changed operational requirements. This is plug-and-move at its most efficient, and promises investment security. This is guaranteed by Denimove’s modular design and robust construction with its built-in long service life. Denimove is based on a modular concept. The elements are up to 40 metres in length and can be assembled to form conveyor sections of almost any length. Using a simple, patented connection technology, the drives and individual conveyor ele- Denimove as a general product conveyor. ments dismantle and interchange in just a few minutes. So Denimove is also perfectly placed for quick maintenance and servicing work. Denimove with integrated Denirug elements (patented technology). 24/7 www.denipro.com 17 Smooth movement of heavy loads France – Denirug at Val d’Eurre: simple intermediate storage during the production process. With Denirug, almost no force is required even when moving heavyweight loads. The extremely smooth-running heavy-­ duty support is based on the simple prin- 18 Denirug im Detail. ciple of rolling conveyor technology. Acting like a carpet, numerous small, tough rollers carry the entire weight. With ­Denirug, there is no sliding friction and frictional values are reduced by more than 90 percent compared to conventional solutions. Even very heavy objects can be moved manually with remarkable ease. When it comes to energy requirements, it’s clear that the Denirug drive system with its minimum values is a winner. The Denirug heavy-duty support is based on standardized modules. They can be assembled into conveyor lines of almost any length and configuration, and integrated into an existing production flow. Directional changes are possible simply by using pneumatic deflectors. Denirug supports heavyweight loads directly, across the entire surface area. The system does away with the high-friction sliding rails and tables required by modular belts or belt conveyors. The material Denirug with next to no transfer stations. used with Denirug is distinguished by its high mechanical strength. Reliability is assured, with no maintenance, for years to come. 24/7 Globally active! www.denipro.com 19 DP_leaflet_4922EN_01.15 Denipro AG Denipro AG Tannenwiesenstrasse 5 Tannenwiesenstrasse 5 CH-8570 Weinfelden CH-8570 Weinfelden Telefon +41 71 626Phone 47 47 +41 71 626 47 47 Fax +41 71 626 48Fax 48 +41 71 626 48 48 info@denipro.cominfo@denipro.com www.denipro.comwww.denipro.com