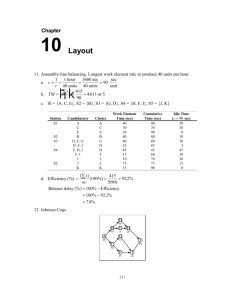

Solution

advertisement

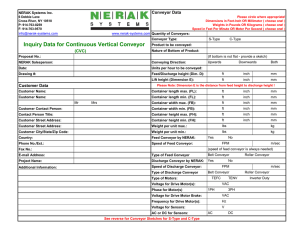

Student’s Name: ………………………………….. Student’s No.: ………………………………… ISE 313 AUTOMATION AND COMPUTER INTEGRATED MANUFACTURING FINAL EXAM 1. 14.01.2010 Provide a definition of material handling. Answer: Material handling is defined as “the movement, storage, protection and control of materials throughout the manufacturing and distribution process including their consumption and disposal.” 2. The CNC grinding section has a large number of machines devoted to grinding shafts for the automotive industry. The grinding machine cycle takes 3.6 min. At the end of this cycle an operator must be present to unload and load parts, which takes 40 sec. (a) Determine how many grinding machines the worker can service if it takes 20 sec to walk between the machines and no machine idle time is allowed. (b) How many seconds during the work cycle is the worker idle? © What is the hourly production rate of this machine cluster? Solution: (a) n = 3.6( 60) 40 = 256/60 = 4.27 40 20 Use n1 = 4 grinding machines because no machine idle time is allowed. (b) Worker idle time IT = 256 – 4(60) = 256 – 240 = 16 sec © Tc = 256 sec = 4.267 min Rc = 4 60 = 56.25 pc/hr 4.267 3. A certain type of machine will be used to produce three products: A, B, and C. Sales forecasts for these products are: 52,000, 65,000, and 70,000 units per year, respectively. Production rates for the three products are, respectively, 12, 15, and 10 units/hr; and scrap rates are, respectively, 5%, 7%, and 9%. The plant will operate 50 weeks per year, 10 shifts per week, and 8 hr per shift. It is anticipated that production machines of this type will be down for repairs on average 10 percent of the time. How many machines will be required to meet demand? 4. Solution: AT = 50(10)(8)(1 – 0.10) = 3600 hr/yr per machine WL = 52,000 65,000 70,000 12(1 0.05) 15(1 0.07) 10(1 0.09) n = 16,913.2/3600 = 4.67 4. = 4561.4 + 4659.5 + 7692.3 = 16,913.2 hr/yr use 5 machines An overhead trolley conveyor is configured as a continuous closed loop. The delivery loop has a length of 120 m and the return loop of 80 m. All parts loaded at the load station are unloaded at the unload station. Each hook on the conveyor can hold one part and the hooks are separated by 4 m. Conveyor speed is vc = 1.25 m/s. Determine (a) maximum number of parts in the conveyor system, (b) parts flow rate; and (c) maximum loading and unloading times that are compatible with the operation of the conveyor system? Solution: (a) Number of parts on the conveyor = (b) Rf = n p vc sc (c) TL = Tu = = (1part / carrier )(1.25m / s) ( 4m / carrier ) 1 Rf = 1/0.3125 = 3.2 sec 120m 4m / part = 30 parts = 0.3125 parts/s = 1125 parts/hr