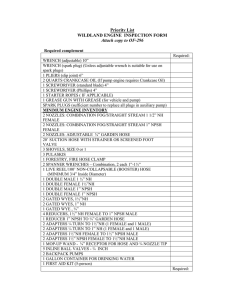

Water Handling Equipment Guide PMS 447-1

advertisement